Sample cutting workbench for packaging design

A workbench and component technology, applied in manufacturing tools, metal processing, positioning devices, etc., can solve the problems of inconvenience of diversification and modification, inability to batch cutting samples, and inconvenient to provide sufficient and relatively uniform and complete cutting samples, etc. To achieve the effect of increasing the cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

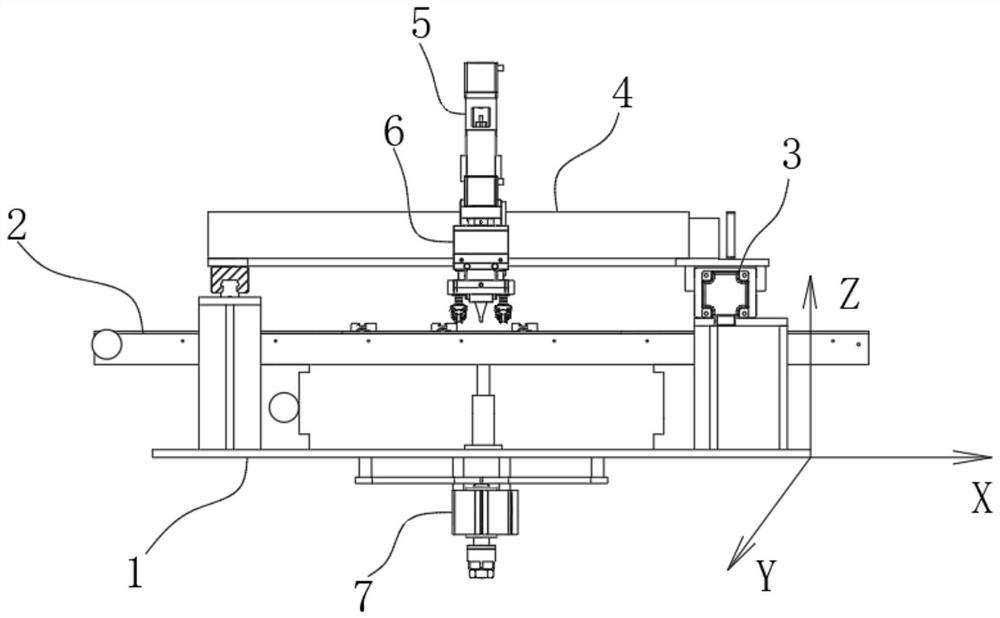

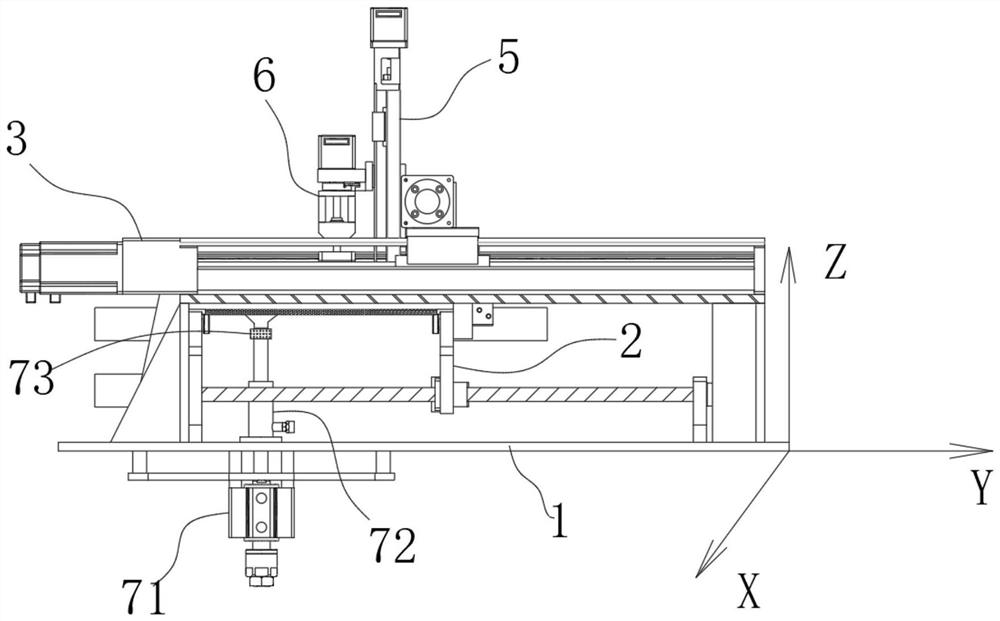

[0048] see Figures 1 to 6 , the present invention provides a sample cutting workbench for packaging design, including:

[0049] base 1;

[0050] The feeding and clamping assemblies 2 extending and distributed along the X direction, the feeding clamping assemblies 2 can clamp and fix the feeding plate 8 during the process of conveying the feeding plate 8;

[0051] A three-axis drive assembly having a drive end capable of three-axis movement; and

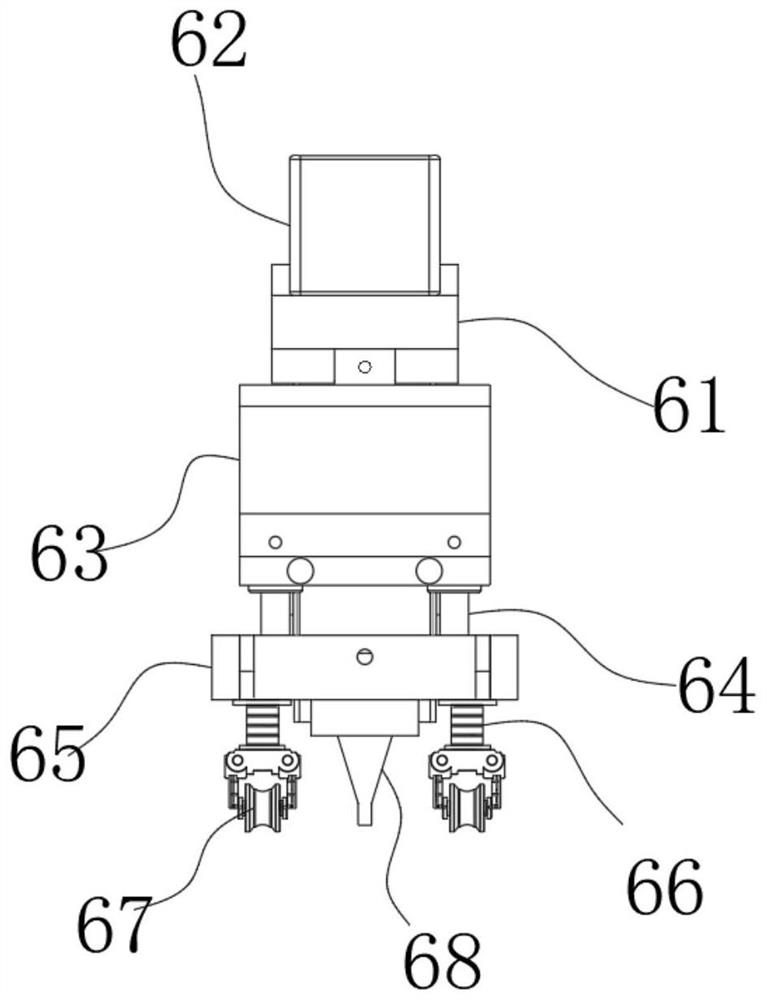

[0052] The cutting sample assembly 6, which is fixed on the driving end of the three-axis drive assembly;

[0053] And when the sample cutting assembly 6 is used for sample cutting, the three-axis drive assembly can drive the sample cutting assembly 6 to perform shallow sample cutting.

[0054] Among them, the three-axis drive components include:

[0055] The first horizontal displacement driver 3, which has a driving end that moves along the Y direction;

[0056] The second horizontal displacement driver 4 is fixed to the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com