Hot melting type shearer

A shearing and hot-melting technology, applied in the field of shears, can solve the problems of inconsistent length of nylon rope, difficult to control the length of nylon rope, and insufficient smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

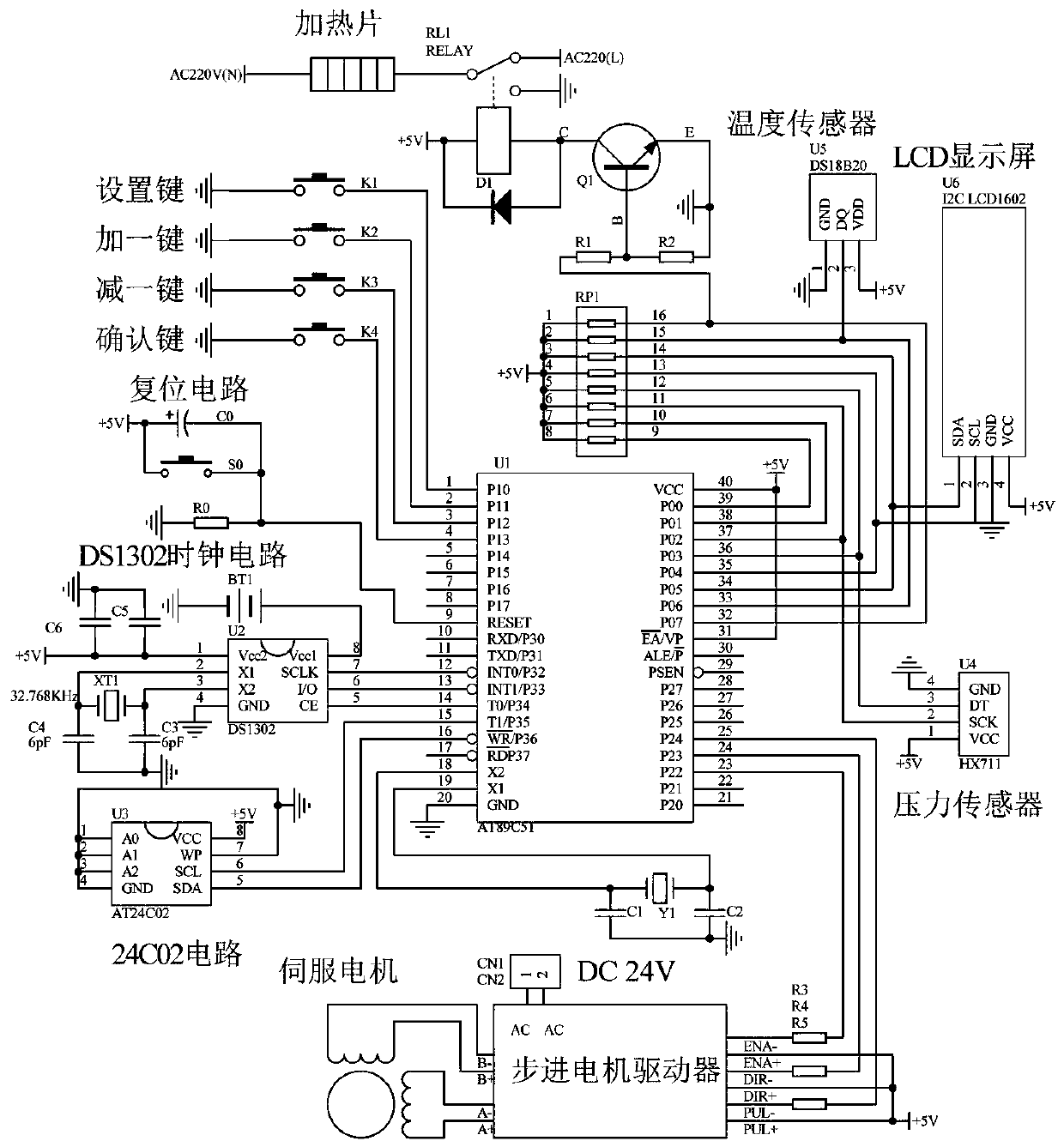

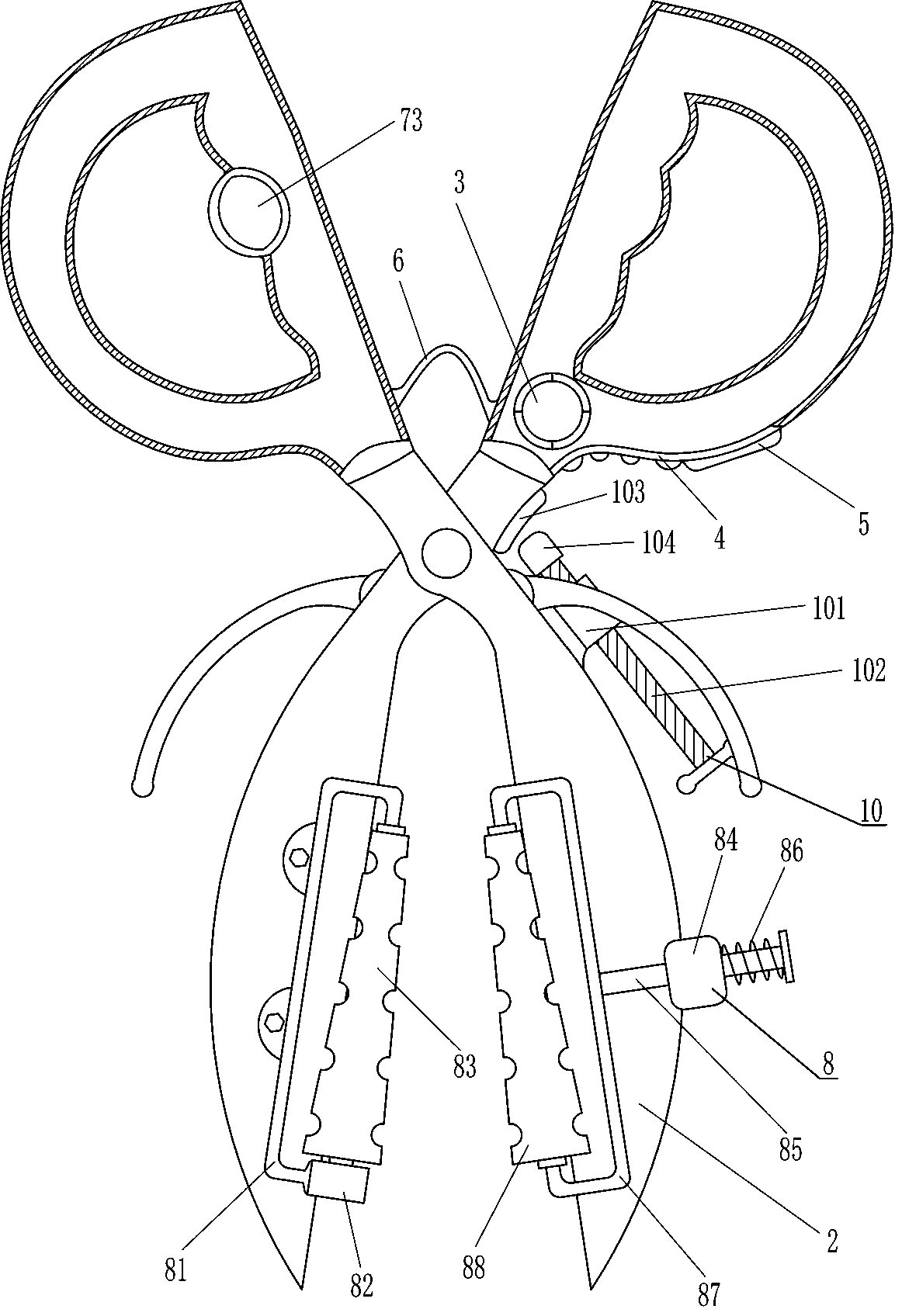

[0026] A hot-melt shear, such as Figure 1-2 As shown, it includes a heat-insulating handle 1, a blade 2, a first elastic piece 6, a heating plate 71, a temperature sensor 72, a pressure sensor 73 and a transmission mechanism 8. The bottom ends of the two heat-insulating handles 1 are connected with the blade 2, and the two The blades 2 are hingedly connected, and the first elastic piece 6 is connected between the two heat-insulating handles 1. A heating sheet 71 is provided on the rear side of the blade 2 on the left side, and a heating sheet 71 is also provided on the front side of the blade 2 on the right side. A temperature sensor 72 is installed on the upper part of the front side of the blade 2, a pressure sensor 73 is installed on the heat insulation handle 1 on the left side, and a transmission mechanism 8 is installed on the two blades 2.

[0027] Also include control module and LCD display 5, LCD display 5 is installed on the heat insulation handle 1 on the right sid...

Embodiment 2

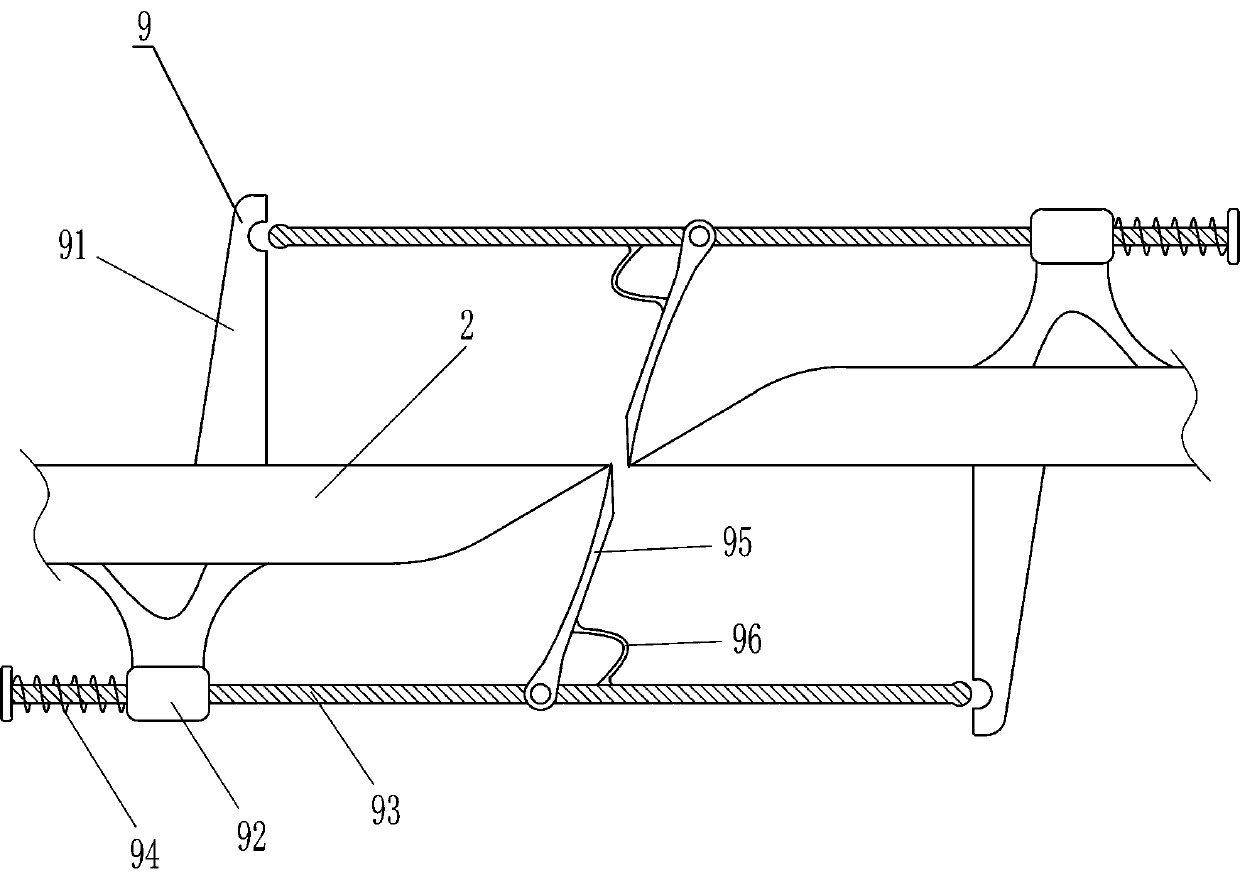

[0032] On the basis of Example 1, such as Figure 2-3 As shown, a cleaning mechanism 9 is also included, and the cleaning mechanism 9 includes a baffle plate 91, a sliding sleeve 92, a slide bar 93, a second spring 94, a scraper 95 and a second shrapnel 96, and the blade 2 rear side on the left side is connected with Baffle plate 91, the front side of blade 2 on the right side is also connected with baffle plate 91, the blade 2 front side of left side is equipped with sliding sleeve 92, the blade 2 rear side of right side is equipped with sliding sleeve 92, two sliding sleeves 92 The sliding type is provided with a slide bar 93, and the two baffle plates 91 are all provided with semicircular grooves, and the two slide bars 93 are respectively aligned with the two semicircular grooves. Both are wound with a second spring 94, one end of the second spring 94 is connected with the slide bar 93, the other end of the second spring 94 is connected with the sliding sleeve 92, the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com