Cherry tree planting equipment

A cherry tree and equipment technology, applied in the field of cherry tree planting equipment, can solve the problems of increasing labor costs, wasting labor, unfavorable seedling growth, etc., and achieve the effect of reducing work errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

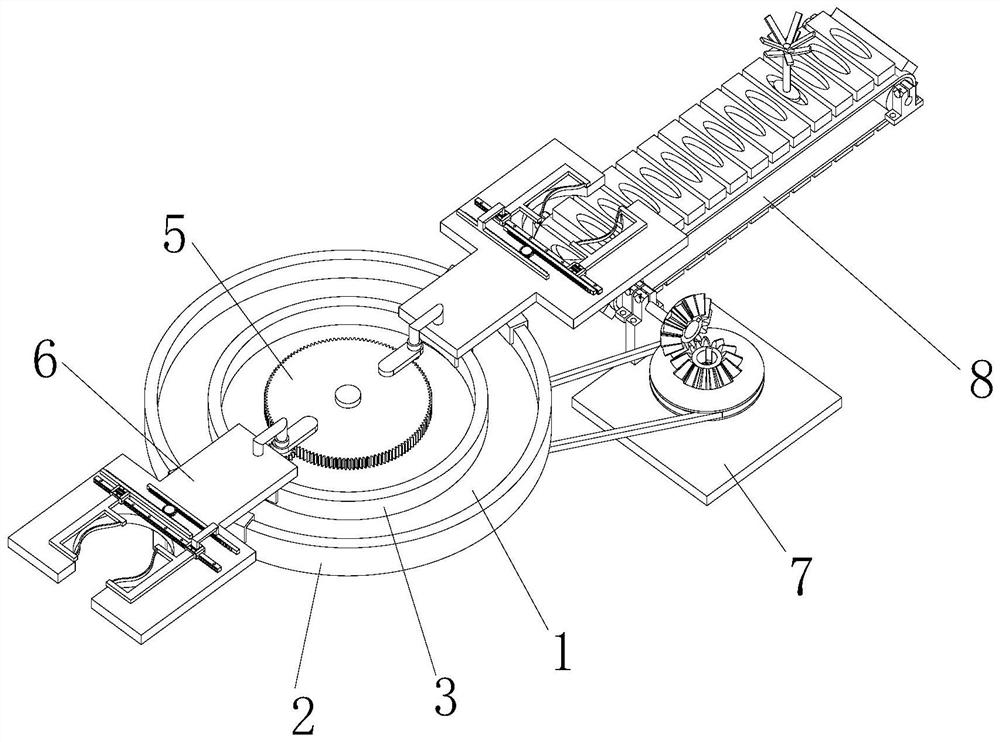

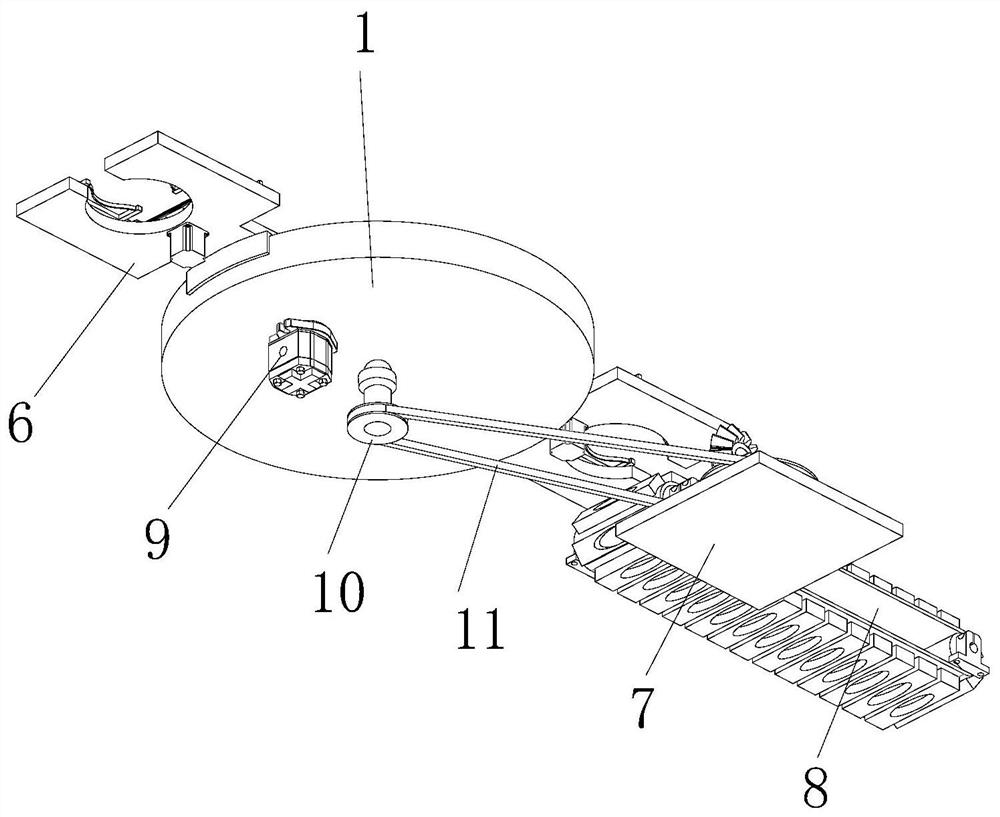

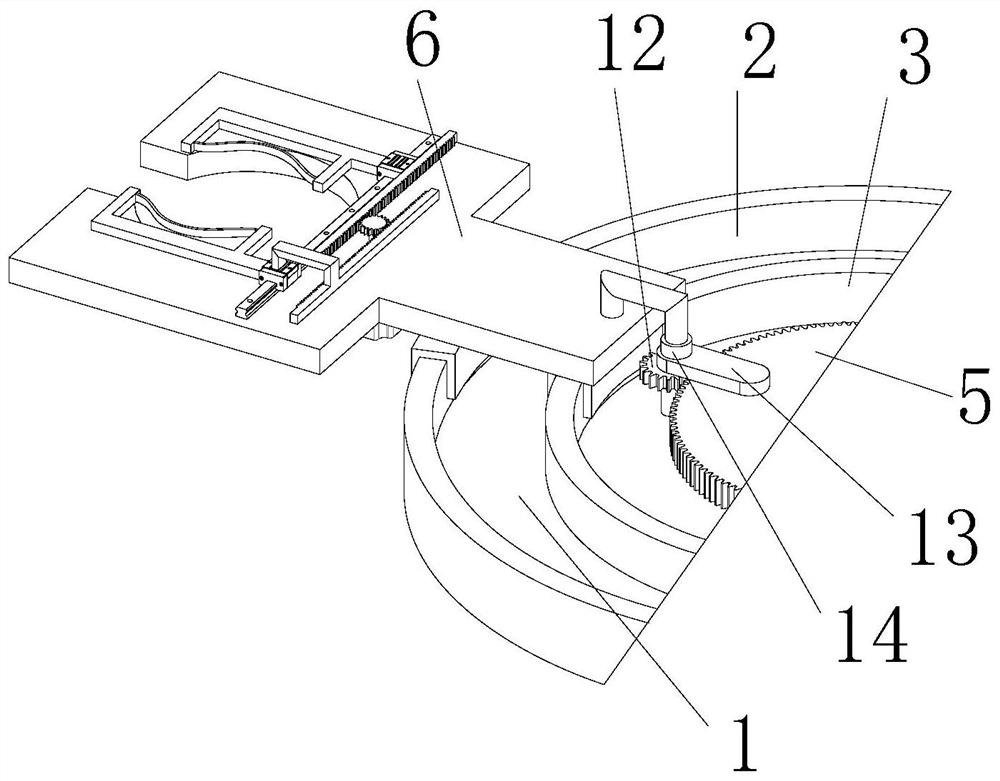

[0027] according to Figure 1 to Figure 8 As shown, the present invention proposes a cherry tree planting equipment, including a circular bottom plate 1, an outer ring 2 is installed on the top of the circular bottom plate 1, and an inner circle is installed on the circular bottom plate 1 inside the outer ring 2. ring 3, a gear plate 5 is installed in the middle of the inner ring 3, and a round rod 501 is provided at the bottom end of the gear plate 5, and a fixed bearing 4 is set on the round rod 501, and the outer ring of the fixed bearing 4 and The circular bottom plate 1 is fixedly connected, the middle of the circular bottom plate 1 is provided with an opening matching the round rod 501, the round rod 501 runs through the upper and lower sides of the circular bottom plate 1, and the two sides of the top of the gear plate 5 are provided with connection block 13, and one end of the connection block 13 is equipped with a circular sleeve 14, the second gear 12 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com