High-efficiency energy-saving single-stage high-speed centrifugal blower

A high-speed centrifugal, energy-saving technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of inability to meet flow requirements, difficulty in achieving energy-saving effects, and large energy loss, achieving improved efficiency and compact structure. , The effect of wide flow adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with accompanying drawing:

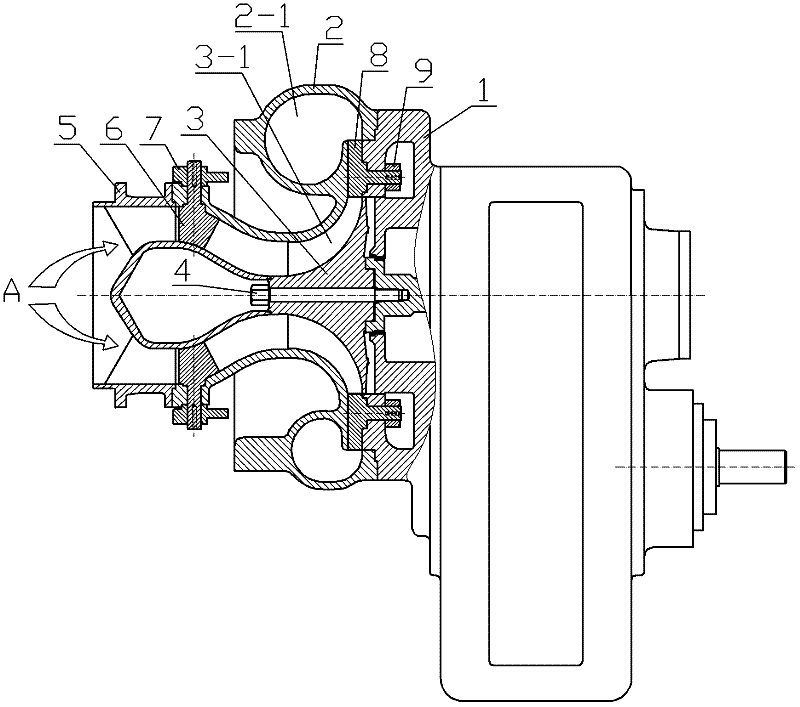

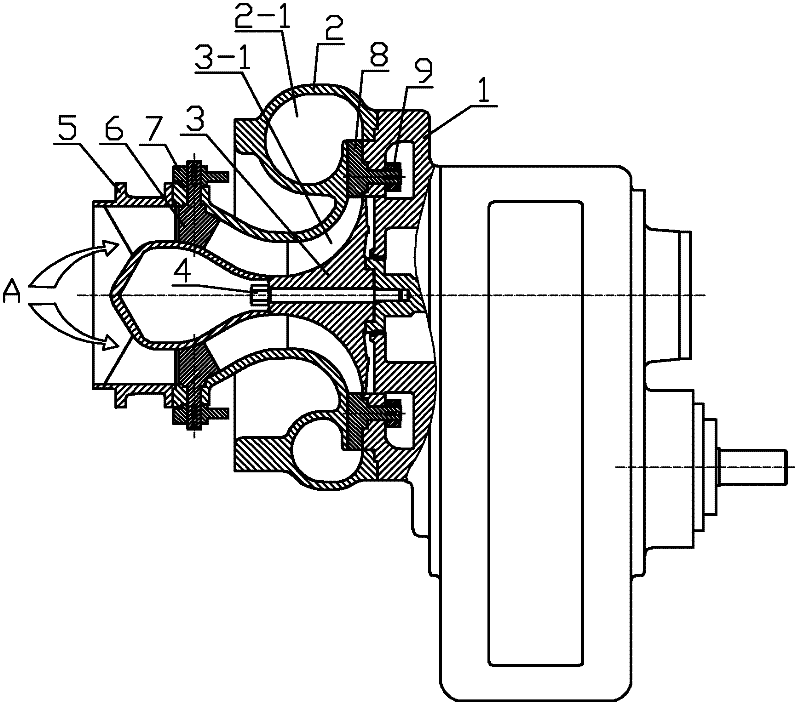

[0012] Such as figure 1 Shown: including high-speed gearbox 1, volute 2, impeller 3, bolt 4, air inlet body 5, inlet guide vane 6, inlet guide vane adjustment mechanism 7, outlet guide vane 8 and outlet guide vane adjustment mechanism 9, etc.

[0013] The volute 2 is installed on the flange of the high-speed shaft end of the high-speed gearbox 1, the impeller 3 is fixed on the high-speed shaft of the high-speed gearbox 1 by bolts 4, and the air inlet body 5 is installed on the inlet of the volute 2. At the air end, the several inlet guide vanes 6 (generally 11-19) are installed in the radial shaft hole of the air inlet end of the volute 2, and are uniformly distributed in the radial direction, and the inlet guide vane adjustment mechanism 7 is connected to On the shaft of the inlet guide vane 6; the several outlet guide vanes 8 (generally 9-19) are installed in the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com