Control ball valve for metering self-balancing type foam fire extinguishing system

A foam fire extinguishing and self-balancing technology, which is applied to valve details, valve devices, valve shell structures, etc., can solve the problems of inapplicable ball valve high-precision opening control requirements and low control accuracy, and achieve reliable sealing performance and equipment The effect of simple structure and wide range of flow adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

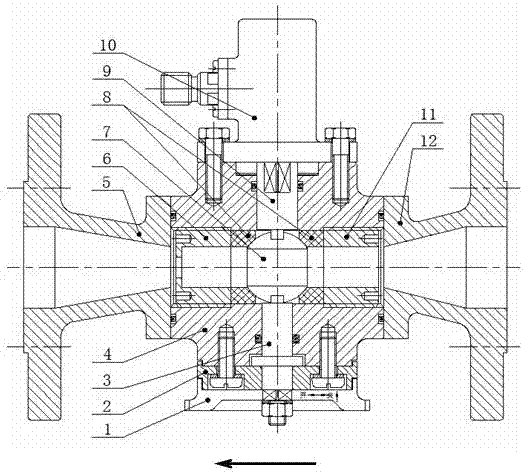

[0016] The control ball valve of the present invention has the structure as attached figure 1 As shown, it includes manual knob 1, opening indicator 2, lower valve stem 3, valve body 4, outlet flange 5, outlet threaded joint 6, ball 7, sealing ring 8, upper valve stem 9, drive motor 10, inlet Threaded joint 11, inlet flange 12 and other components.

[0017] The specific structure and connection relationship are as follows: the ball 7 is installed in the center of the valve body 4 by the left and right sealing rings 8, the inlet threaded joint 11, and the outlet threaded joint 6. The ball 7 is connected with the drive motor 10 through the upper valve stem 9, and the opening is indicated. The device 2 is fixed and installed on the lower part of the valve body 4 by 4 slotted pan head screws, the ball 7 is connected with the manual knob 1 through the upper valve stem 3, the inlet flange 12 and the outlet flange 5 are respectively fixed and installed on both sides of the valve body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com