Wax removing and ash removing apparatus of plastic cracking oil production and cracking system thereof

The technology of cracking system and ash discharge pipe is applied in the field of wax removal and ash removal device, which can solve problems such as blockage of pipeline facilities, and achieve the effects of stable load, stable oil production quality, and stable wax removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

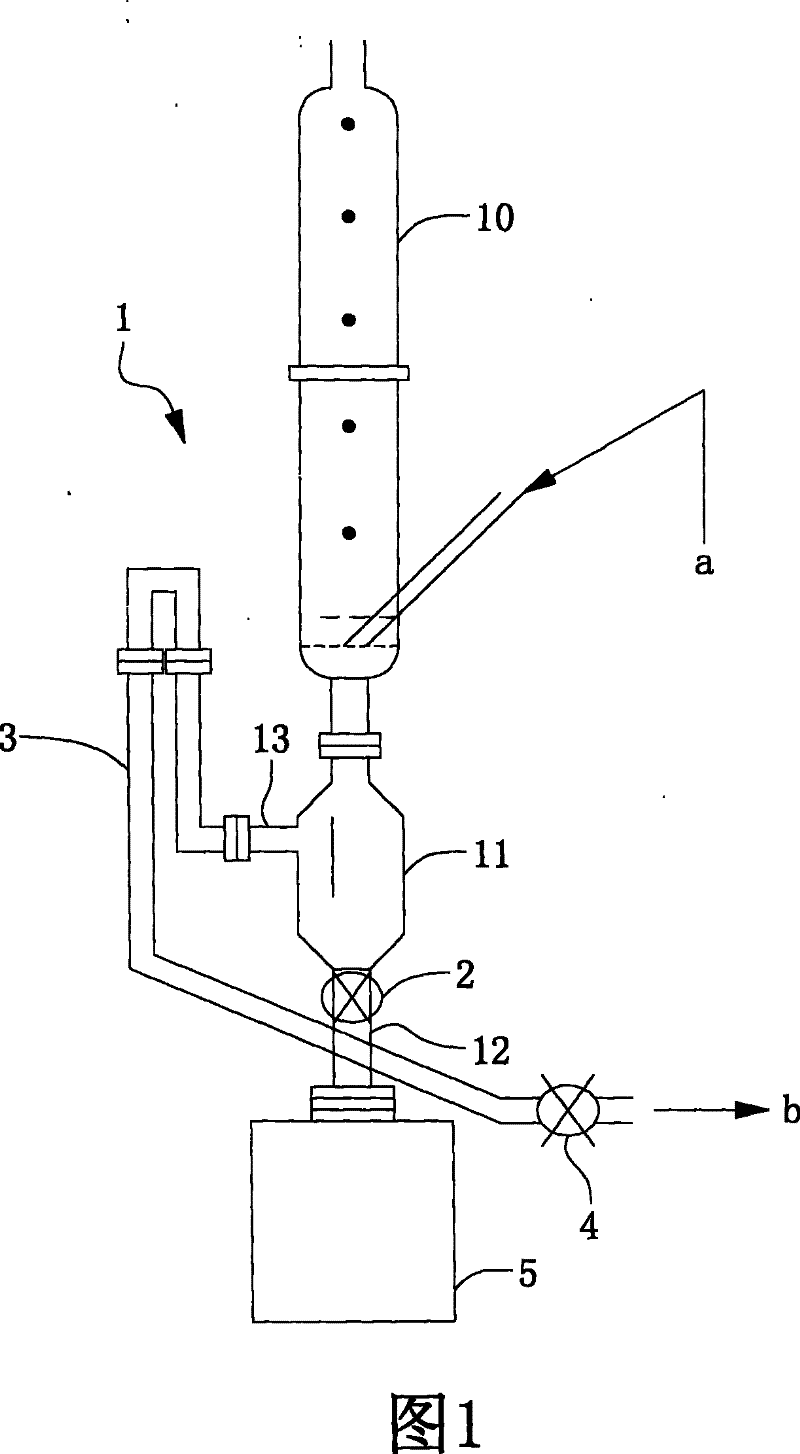

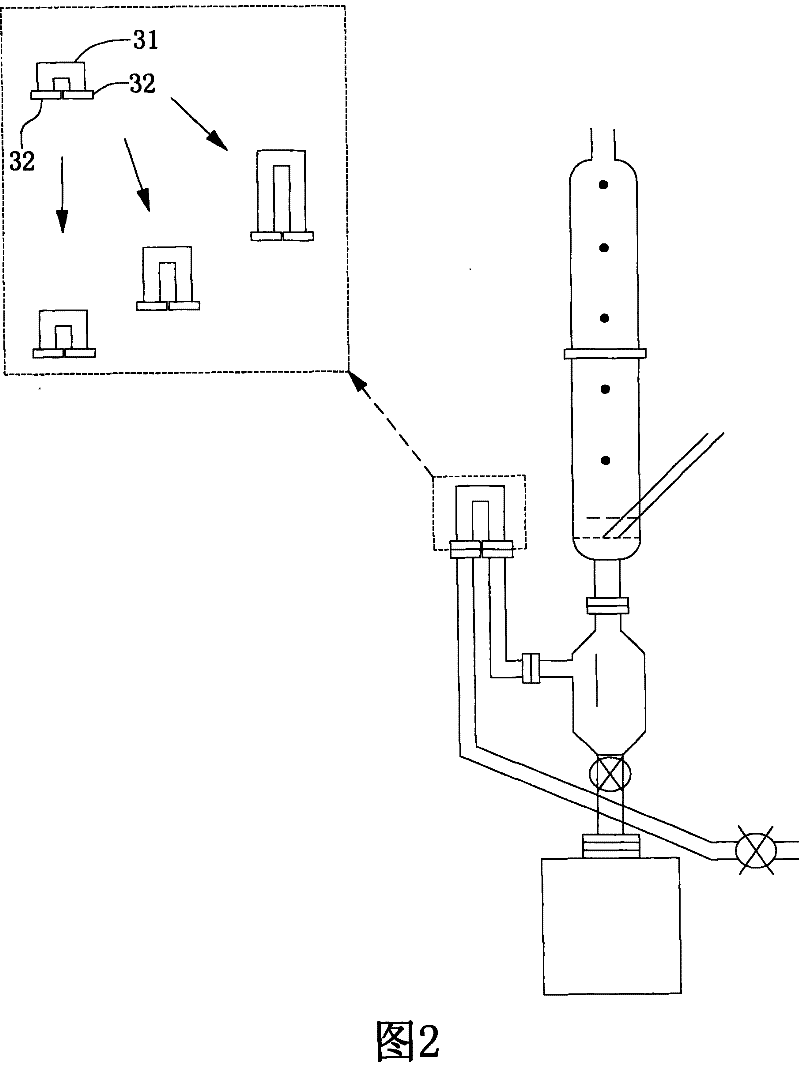

[0048] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the accompanying drawings, and the embodiments listed in the following drawings are only for auxiliary explanation, so as to facilitate the understanding of the examiners, but the technical means of this case are not Not limited to the figures listed.

[0049] see figure 1 Shown is a schematic diagram of the wax and ash removal device of the present invention. As shown in the figure, the wax removal and ash removal device includes a wax removal tower 10 , an ash sink 11 , an ash discharge valve 2 , a diversion pipe 3 , a wax discharge valve 4 and an ash collection tank 5 . Wherein, cracked gas is input from the direction of arrow a, and the top of this ash settling tank 11 communicates with the wax discharge port at the bottom of the dewaxing tower, and the bottom of the ash settling tank 10 has an ash discharge pipe 12, and the outlet of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com