Gripper and weft thread insertion device for a rapier weaving machine

A technology of shuttle loom and weft thread, which is applied in the field of weft thread insertion device, can solve problems such as wear and tear, and achieve the effect of allowing adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

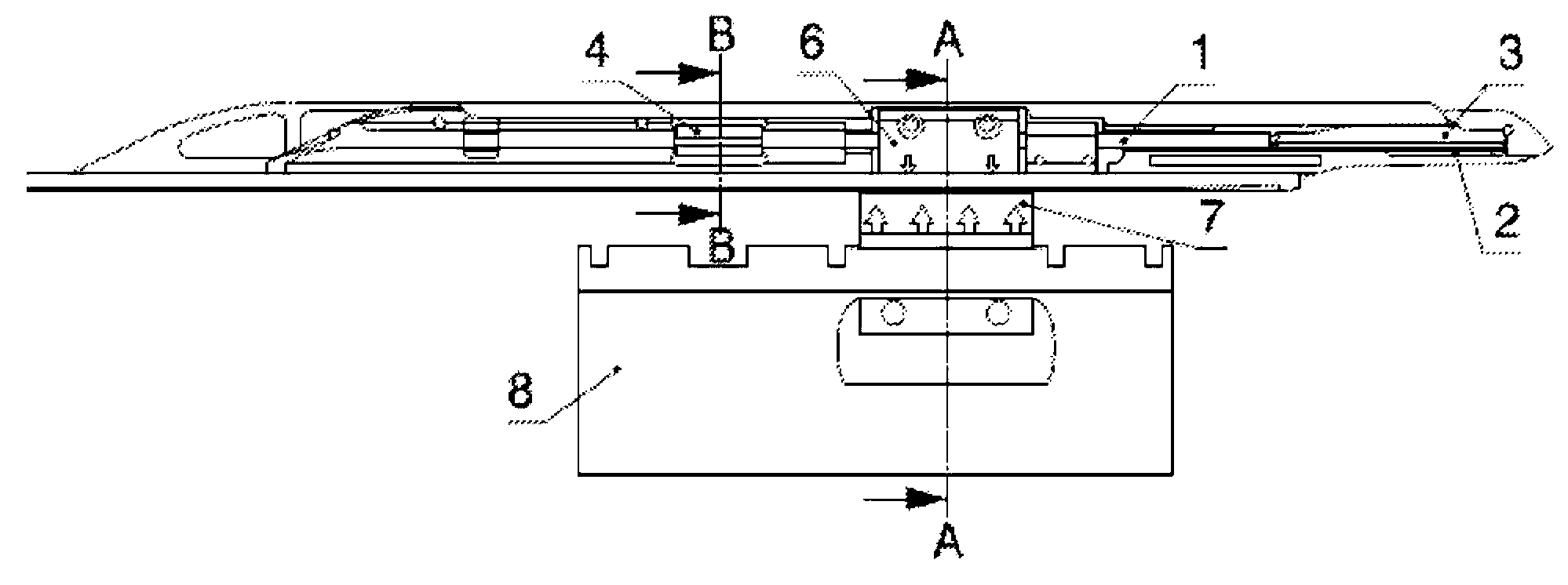

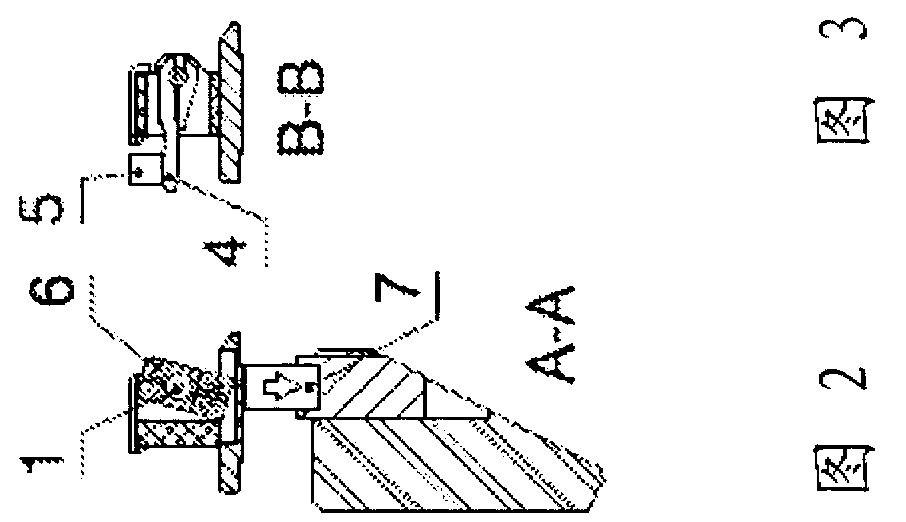

[0020] For a first example of the invention, see Figures 1 to 3 , which show the grippers of this example. The gripper is arranged on a gripper belt or gripper rack 18, guided along a shedway 13, comprising a housing, a gripping part with a gripping tongue 3 and an actuation for manually or mechanically actuating the gripping tongue 3 with 4. The gripper housing is made of plastic. The clamping part is made of metal and is connected with the housing.

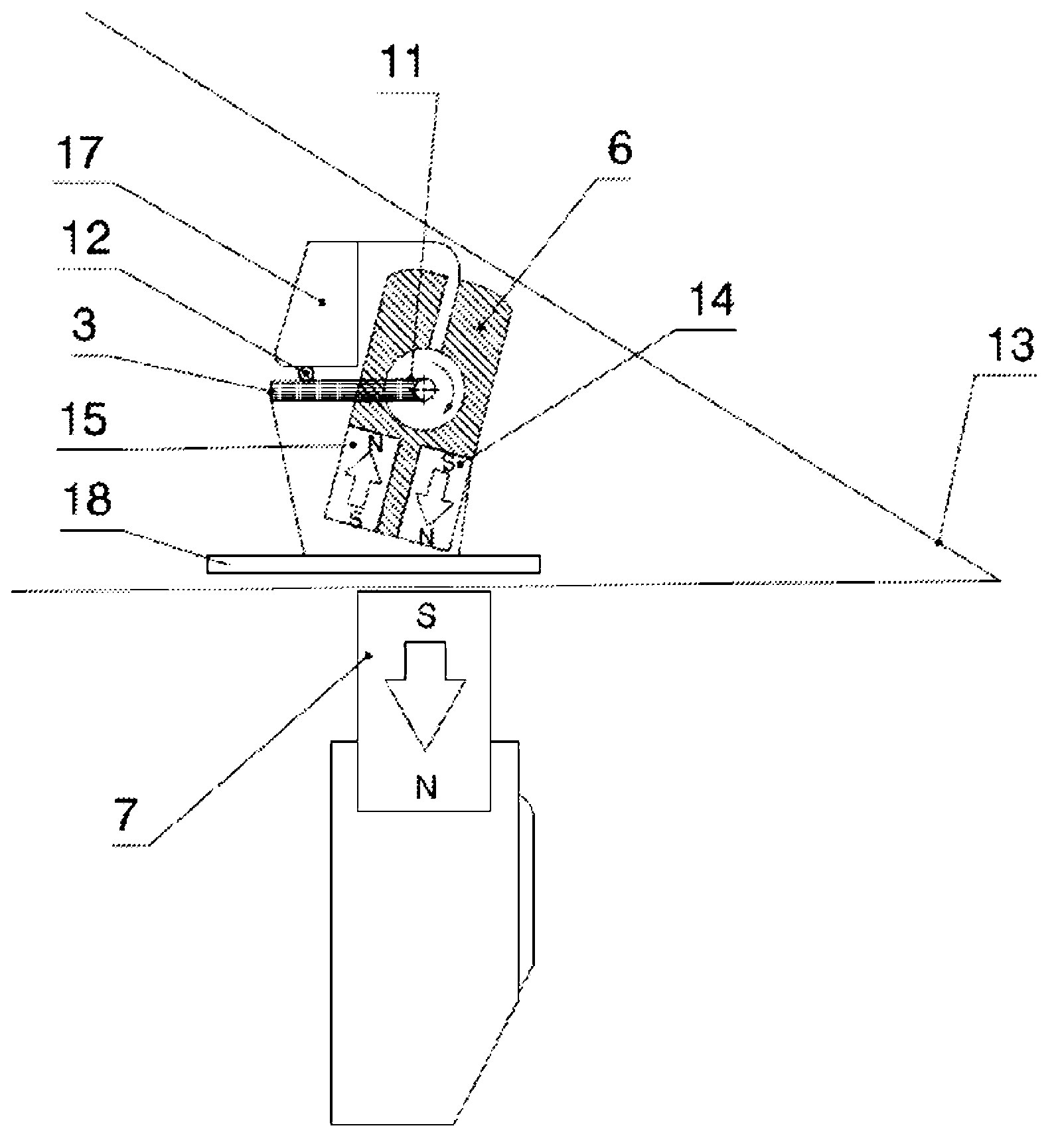

[0021] The action of the gripper is based on the Figure 4 The schematic diagram is easy to understand. The torsion shaft 1 is cooperatively connected on one side thereof with an actuation band 4 in a conventional manner. The actuation band 4 abuts against the adapter 5 . The torsion shaft 1 is cooperatively connected on its other side with a pair of permanent magnets 14 and 15 of opposite polarity. In the example, these permanent magnets 14 and 15 are arranged as an extension of a magnet unit 16 configured as an electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com