Moving bed bio-membrane reactor

A moving bed biofilm and reactor technology, which is applied in the field of sewage treatment process equipment, can solve the problems of wear of suspended fillers, uneven distribution of intake air, and the volume of the pool cannot be too large, achieves sufficient repeated contact and scouring, and improves hydraulic flow. Characteristics, the effect of uniform distribution of intake air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

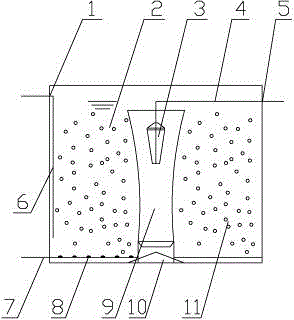

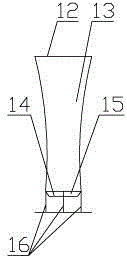

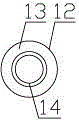

[0038] Such as figure 1 — Figure 7 , the present invention is a kind of moving bed biofilm reactor, has biochemical reaction tank 2, and is provided with water inlet hole 1 and water outlet hole 5 respectively on the upper part of any two side walls of described biochemical reaction tank, and water inlet hole and water outlet hole The water inlet pipe 6 and the water outlet pipe 4 are respectively connected, and the suspension filler 11 is placed in the biochemical reaction tank. The center of the bottom of the biochemical reaction tank is provided with a conical sliding table 10, and a diversion tube 9 is arranged directly above the conical sliding table. A water outlet screen 3 is arranged on the upper part, the upper end of the water outlet screen is connected with the water outlet hole through the outlet pipe, the bottom of the diversion cylinder is connected with a water outlet grid bracket 16, and the bottom of the biochemical reaction tank is located around the di...

Embodiment 2

[0052] Such as Figure 8 As shown, on the basis of embodiment 1, embodiment 2 is composed of 2 or more biochemical reaction tanks connected in series, which can handle moving bed biofilm reaction tank groups containing high-concentration pollutant sewage, or for higher A moving bed biofilm reaction tank group for advanced treatment of sewage with high concentration of pollutants.

Embodiment 3

[0054] Such as Figure 9 As shown, on the basis of embodiment 1 or 2, embodiment 3 is composed of two or more biochemical reaction tanks 1 connected in parallel, which can handle a large amount of water and contain high-concentration pollutant sewage moving bed biofilm reaction tank group to form a large-scale sewage treatment plant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com