A fully mixed internal circulation suspended packing biological denitrification reactor

A technology for suspended filler and biological denitrification, which is applied to the field of internal circulating suspended filler biological denitrification reactors, can solve the problems of ineffective treatment, affect the efficiency of wastewater treatment, adversely affect the effect of wastewater treatment, and improve the efficiency of wastewater treatment. , Strengthen the effect of wastewater treatment, shorten the effect of the film hanging time of the filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

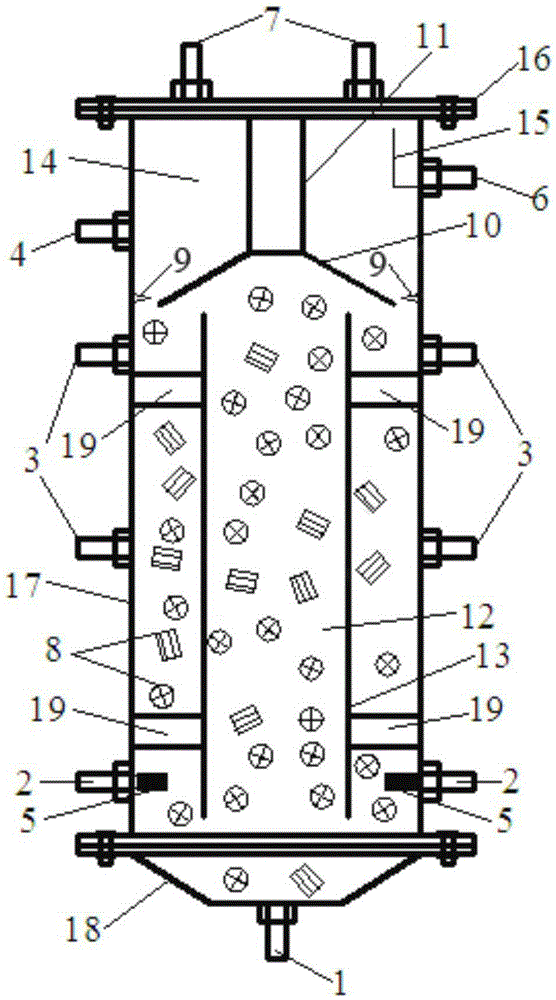

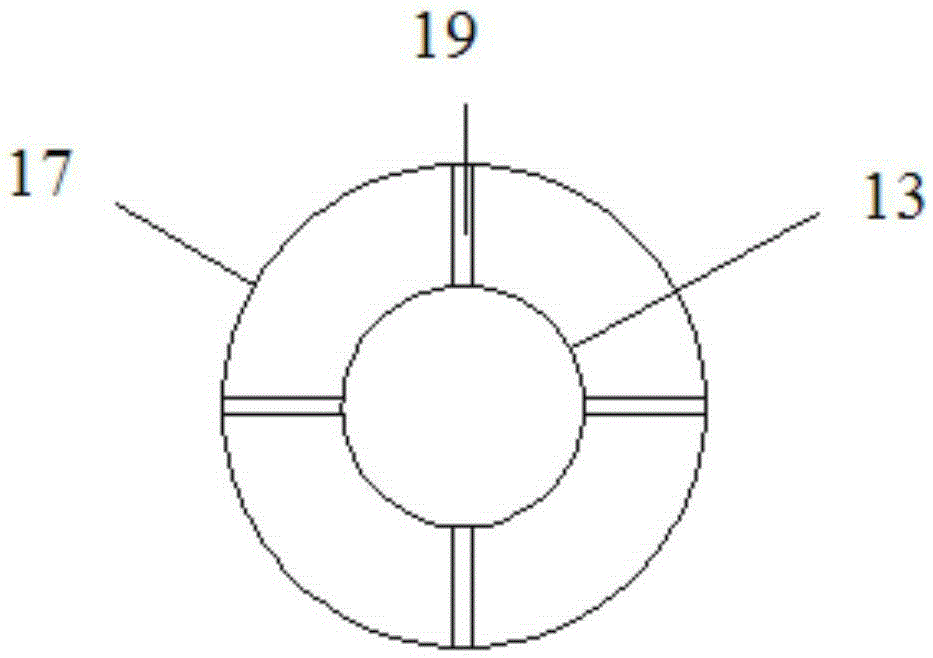

[0024] In this example, the structural schematic diagram of the biological denitrification reactor with fully mixed internal circulation suspended packing is shown in figure 1 , the reactor comprises a reactor main body, a suspension packing 8, a separation cover 10, a separation ring 9 and an inner sleeve 13; The lower cover 18 at the bottom of the cylindrical shell is composed of the height of the cylindrical shell 17 and the ratio of its inner diameter is 5:1; the separation cover 10 is a conical cover with a small top and a large bottom, and the opening is downward. The upper end of the separation cover 10 passes through the first A connecting rod 11 is connected with the upper cover 16, and the gap between the periphery of the lower end of the separation cover and the separation ring 9 arranged on the inner wall of the cylindrical shell is the water outlet seam, and the width of the water outlet seam is 15 mm. The chamber is divided into an upper settling area 14 and a lo...

Embodiment 2

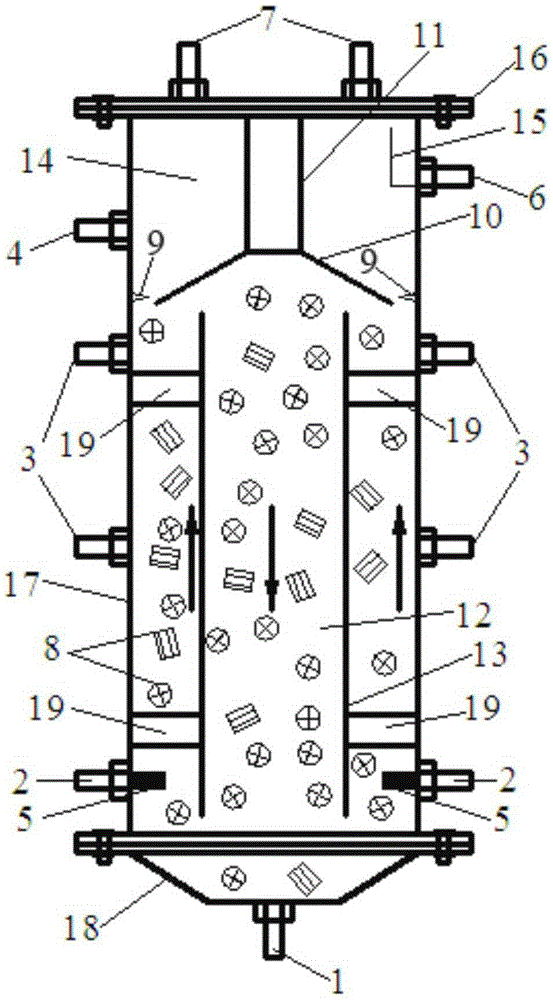

[0028] In this example, the structural schematic diagram of the biological denitrification reactor with fully mixed internal circulation suspended packing is shown in Figure 4, the reactor comprises a reactor main body, a suspension packing 8, a separation cover 10, a separation ring 9 and an inner sleeve 13; The lower cover 18 at the bottom of the cylindrical shell is composed of the height of the cylindrical shell 17 and the ratio of its inner diameter to 2:1; the separation cover 10 is a conical cover with a small top and a large bottom, and the opening is downward. The upper end of the separation cover 10 passes through the first A connecting rod 11 is connected with the upper cover 16, and the gap between the periphery of the lower end of the separation cover and the separation ring 9 arranged on the inner wall of the cylindrical shell is the water outlet seam, and the width of the water outlet seam is 20 mm. The chamber is divided into an upper settling area 14 and a lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com