Moving bed biofilm sewage treatment device

A sewage treatment device, moving bed biofilm technology, applied in biological water/sewage treatment, sustainable biological treatment, water/sewage multi-stage treatment, etc. Unbalanced moving state and other problems, to achieve the effect of sufficient repeated contact and scouring, reducing energy consumption of aeration and fluidization, and improving hydraulic flow characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

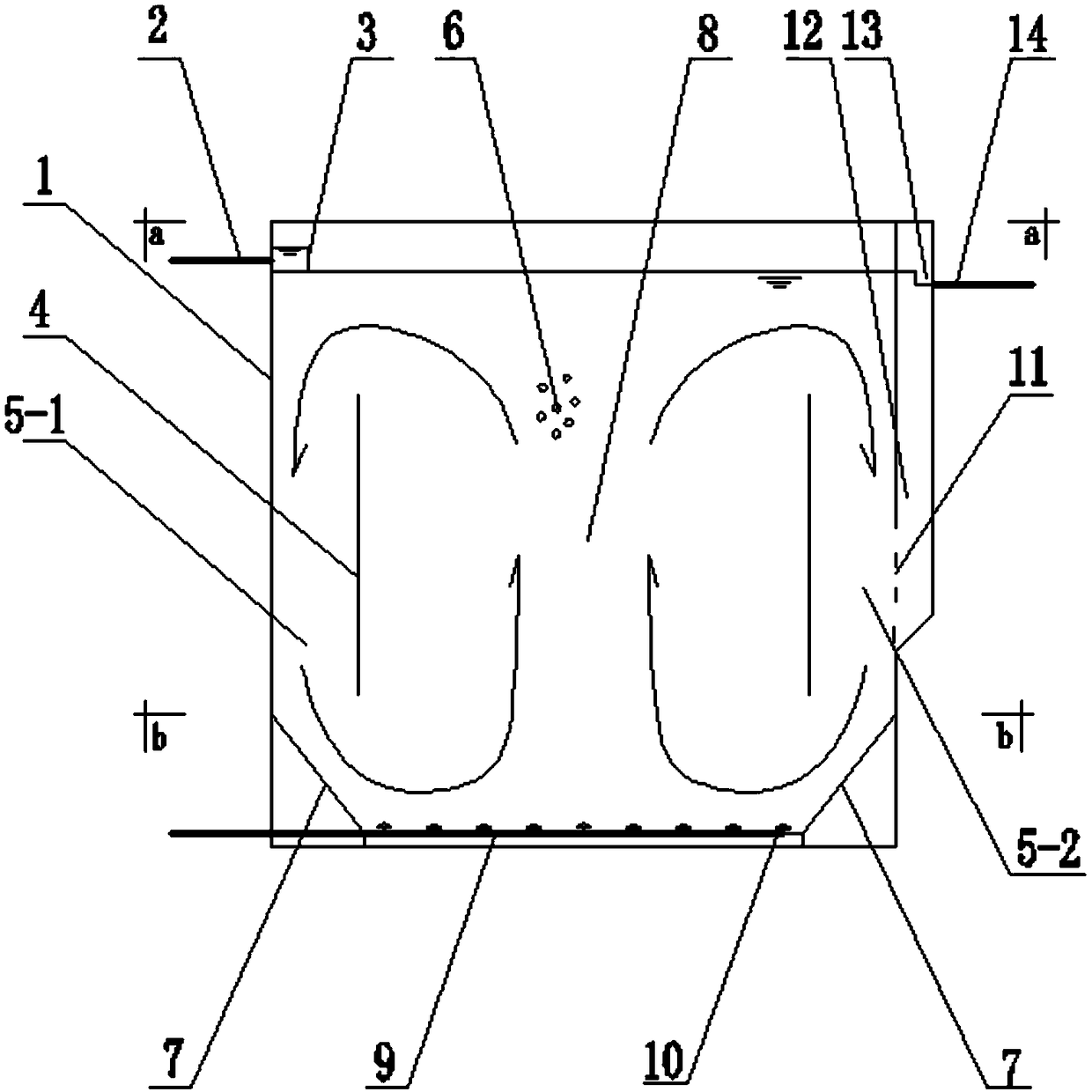

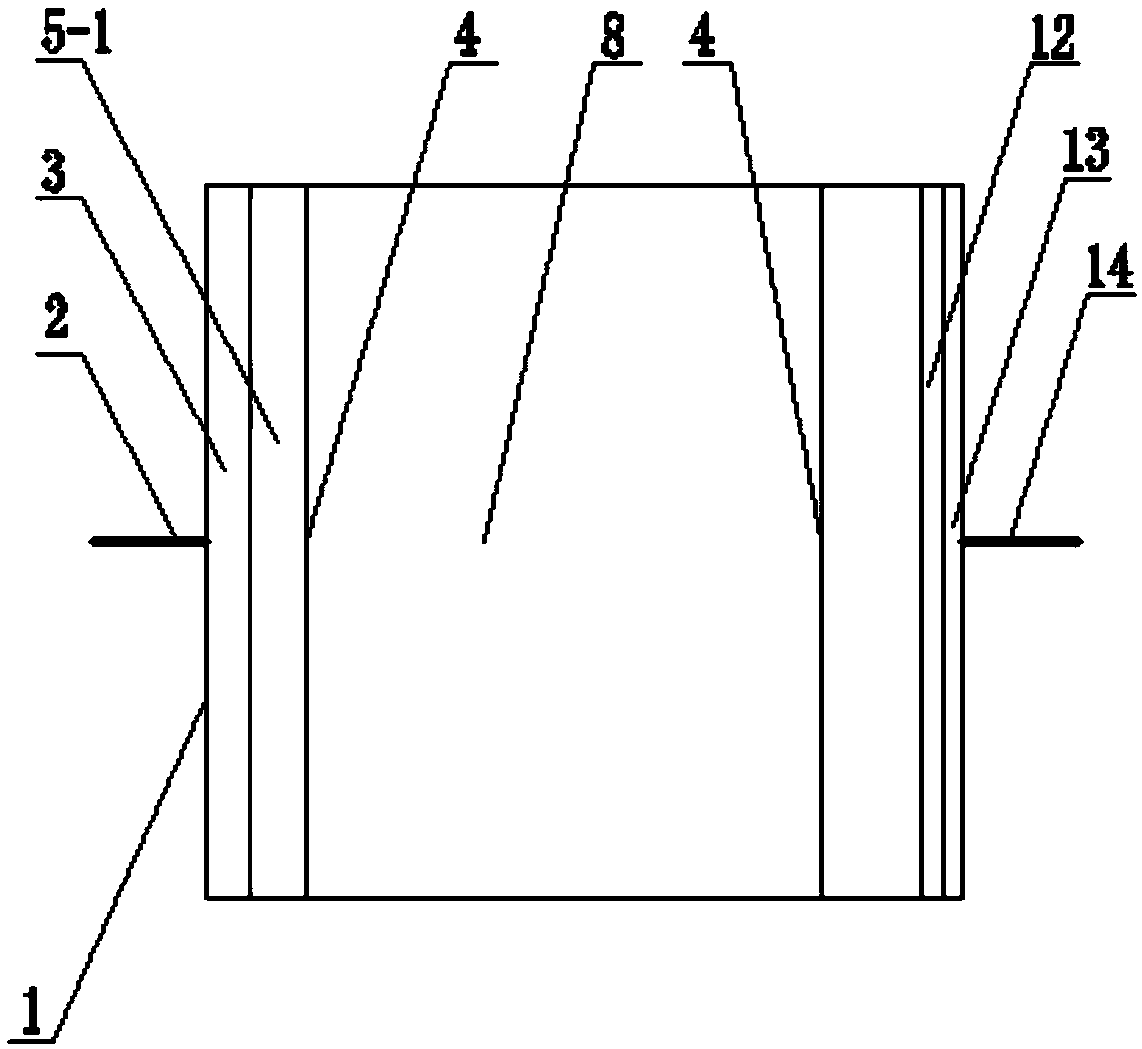

[0051] Such as Figures 1-1 to 1-5 As shown, in this embodiment, a water outlet groove 12 is provided on the outer wall of the peripheral partition wall of the pool body 1 on the other side corresponding to the water inlet hole, and the water outlet hole and the water outlet pipe 14 connected to the water outlet hole are arranged in the water outlet groove. The upper position of 12; the peripheral partition wall on the side where the outlet tank 12 is located is provided with a flow hole for installing the outlet screen 11; Water collection channel 13; the outlet screen 11 has strip or circular holes.

[0052] In this embodiment, the sewage to be treated is transported to the water inlet pipe 2 through the water inlet pump, enters the water distribution overflow weir groove 3 through the water inlet pipe 2, overflows evenly from the top of the water distribution weir into the water surface of the pool body 1, and is immediately aerated with the middle aeration zone 8 The wate...

Embodiment 2

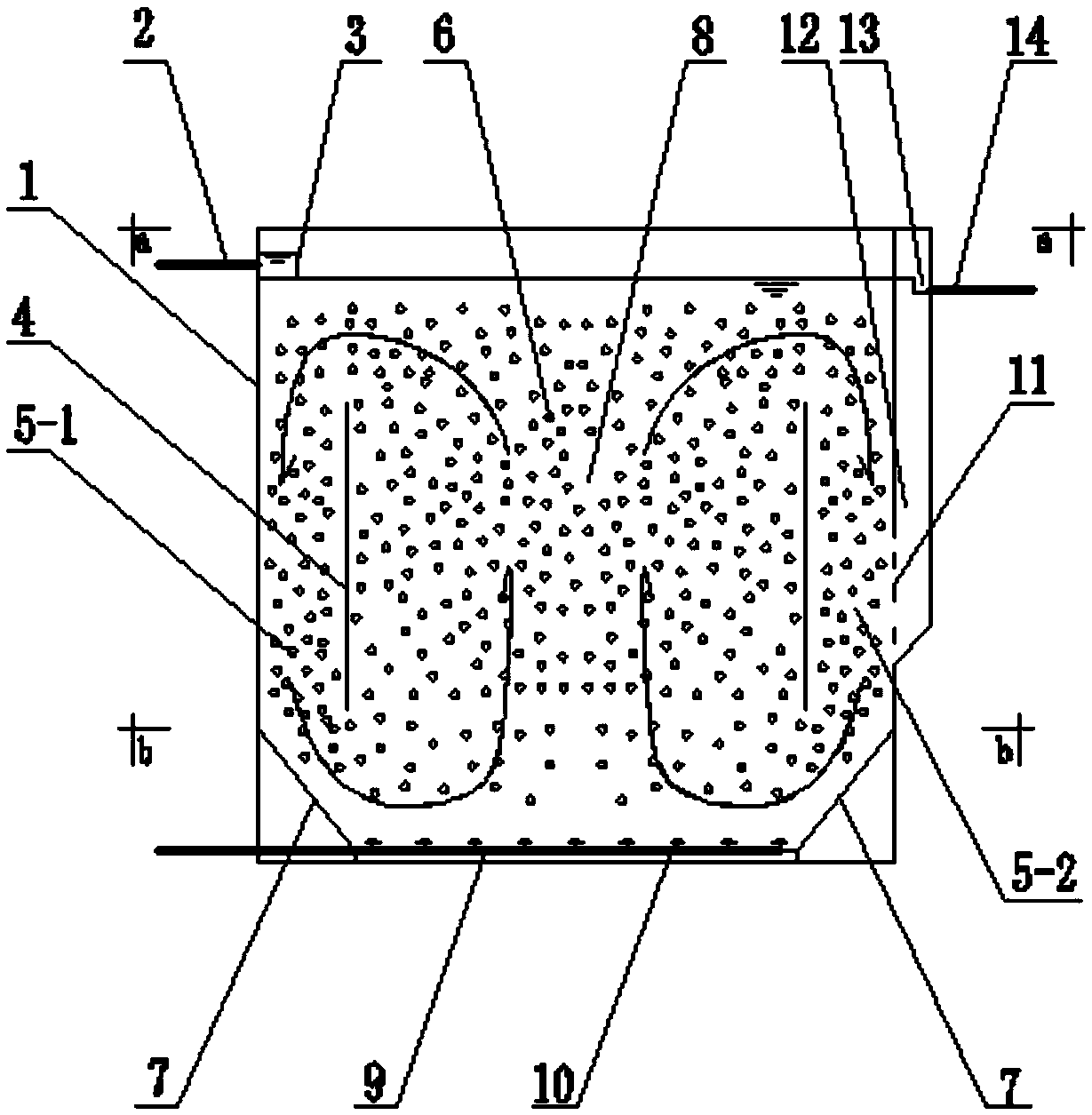

[0057] Such as Figures 2-1 to 2-6 As shown, the inner wall above the outer partition wall on the water outlet side of the pool body 1 is obliquely provided with a water outlet screen 11, and the water collection channel 13 is located between the water outlet screen 11 and the outer partition wall, and the water flow can flow through the outlet screen. 11 The overflow flows into the water collection channel 13; the outlet screen 11 is a bow-shaped bent plate grille, the two straight side plates of the bow-shaped bent plate are solid plates, and the middle hypotenuse plate has strip-shaped or circular holes.

[0058] In this embodiment, the sewage to be treated is transported to the water inlet pipe 2 through the water inlet pump, enters the water distribution overflow weir groove 3 through the water inlet pipe 2, overflows evenly from the top of the water distribution weir into the water surface of the pool body 1, and is immediately aerated with the middle aeration zone 8 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com