Patents

Literature

317 results about "Bio film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

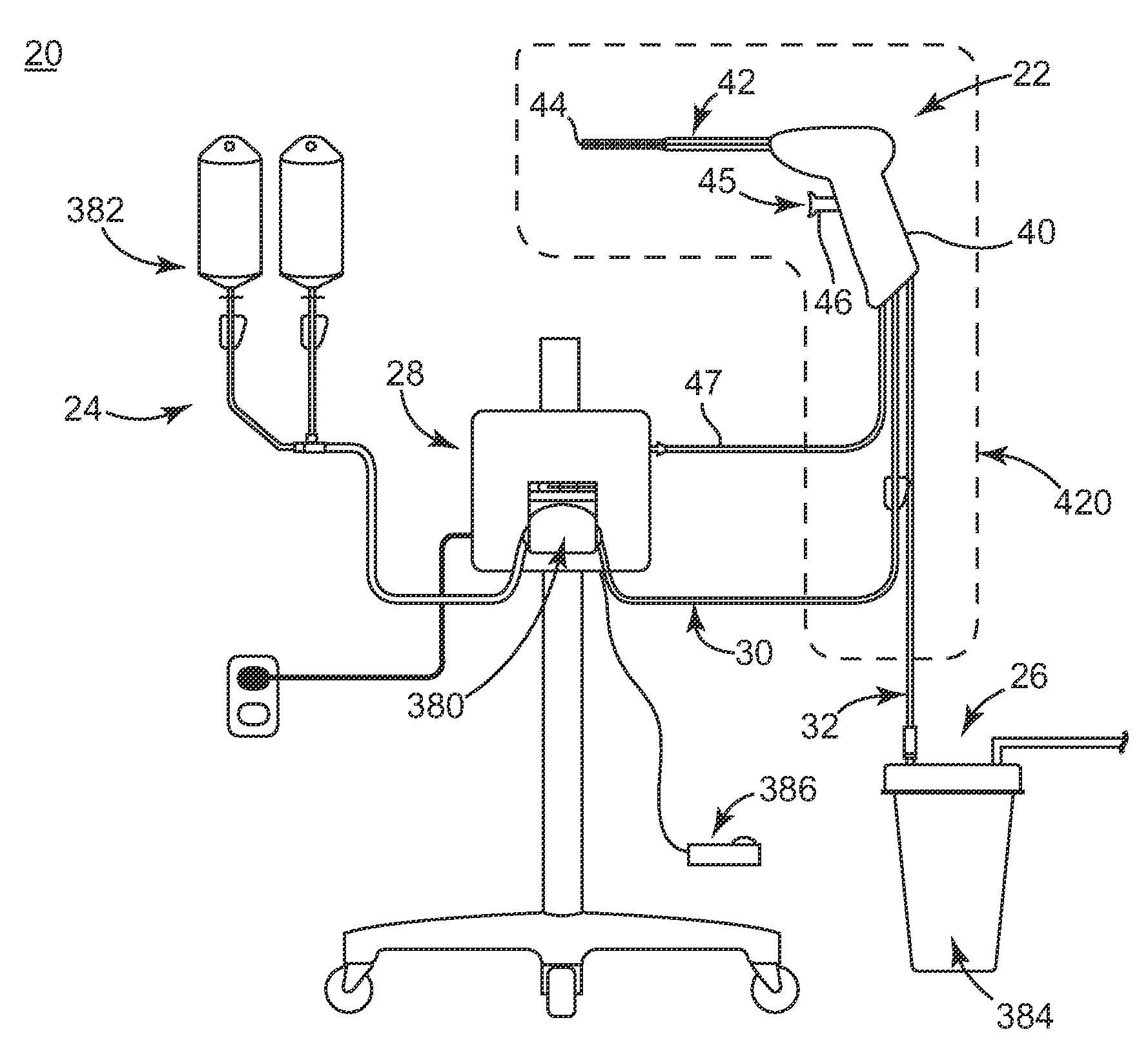

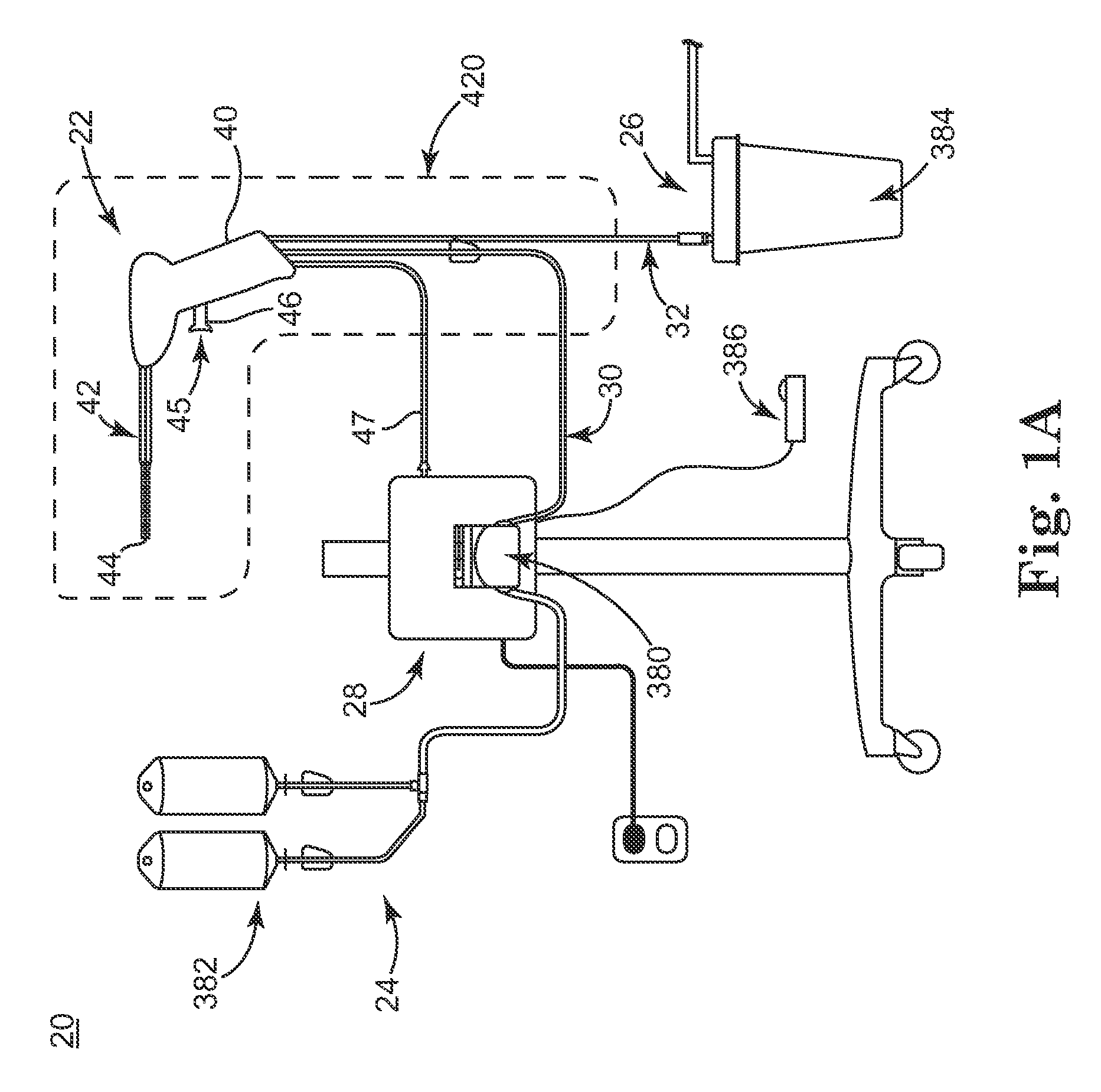

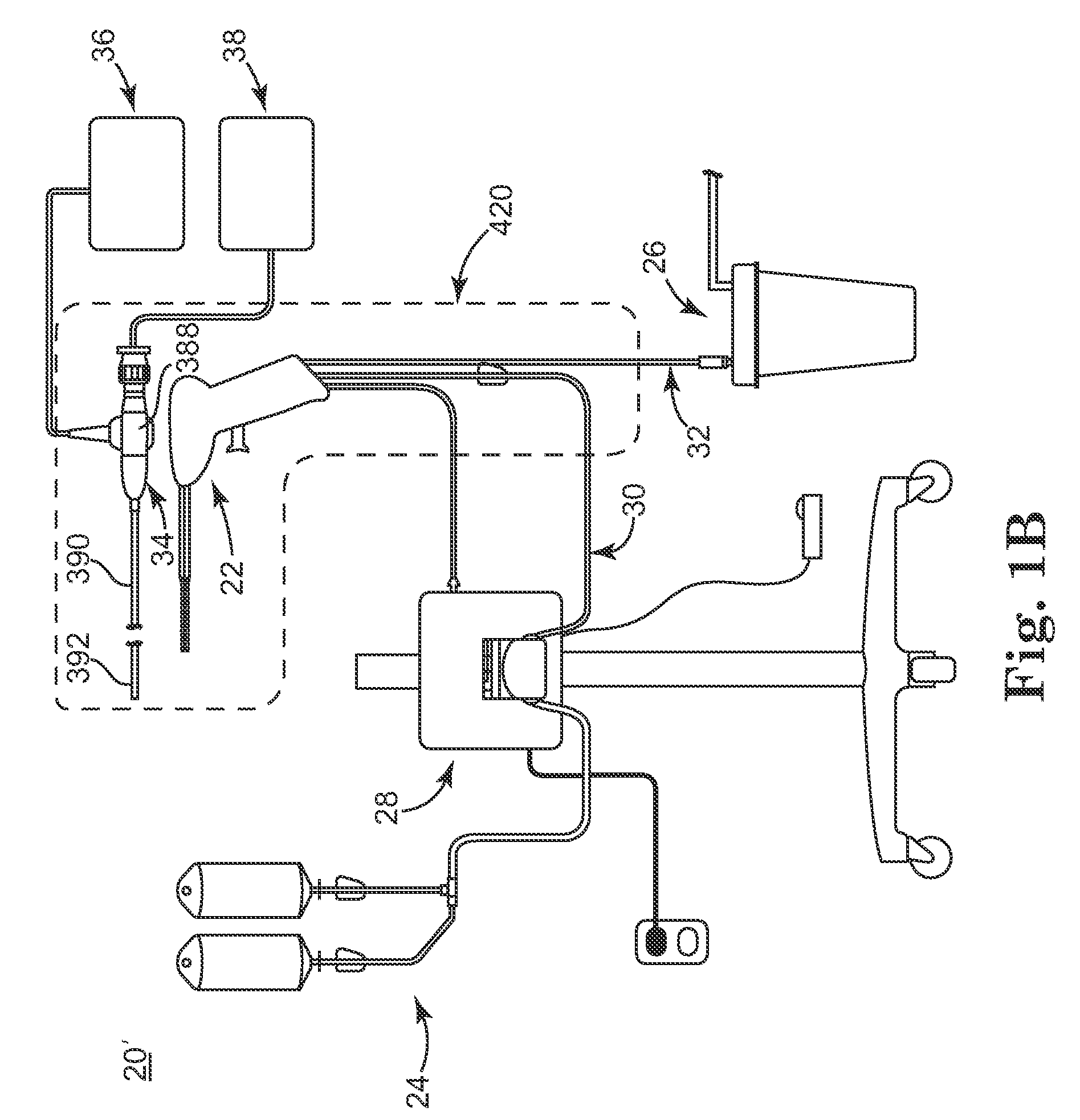

Surgical instrument, system, and method for biofilm removal

Systems and methods for removal of bacterial biofilm from a target site of a human patient includes a surgical instrument having an introducer for bodily insertion and maintaining an irrigation duct and a nozzle. A distal portion of the introducer is transitionable between a plurality of bend angles relative to a proximal portion thereof. In particular, the instrument is adapted to independently maintain the distal portion at each of the plurality of bend angles relative to the proximal portion. The nozzle is maintained relative to the distal portion of the introducer and is adapted to dispense pressurized irrigant from the irrigation duct toward a layer of bacterial biofilm.

Owner:MEDTRONIC XOMED INC

Bio-Film Resistant Surfaces

The present invention relates to methods and compositions for rendering a surface resistant to bio-film formation by a combination of an alkanediol and an antimicrobial agent (and, optionally, an organic hydroxy acid). The invention provides for compositions which may be used to render surfaces bio-film resistant, articles having bio-film resistant surfaces, and methods for their preparation. The present invention may be advantageously applied to medical articles as well as articles used in non-medical contexts, such as child care or food preparation.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

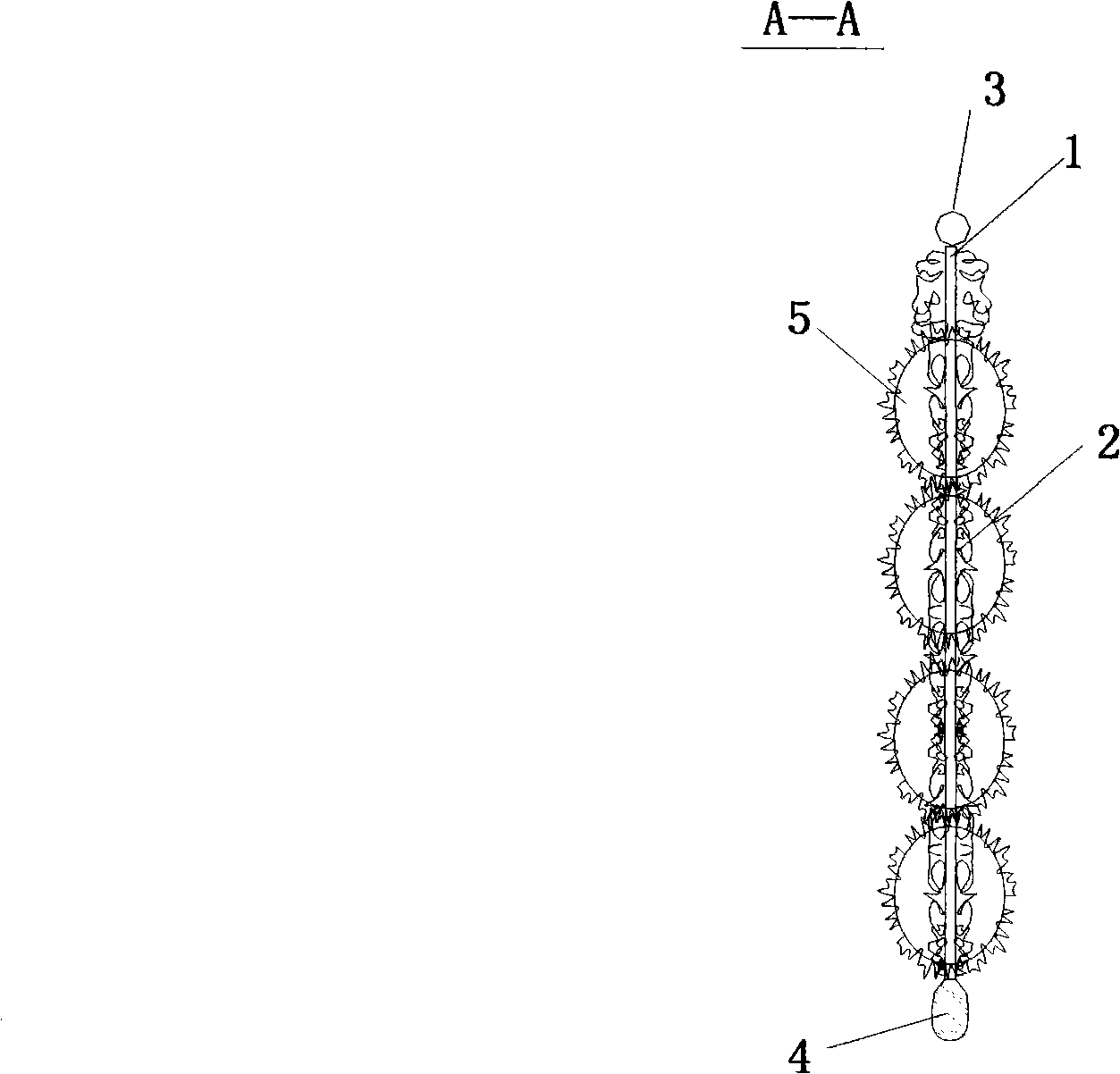

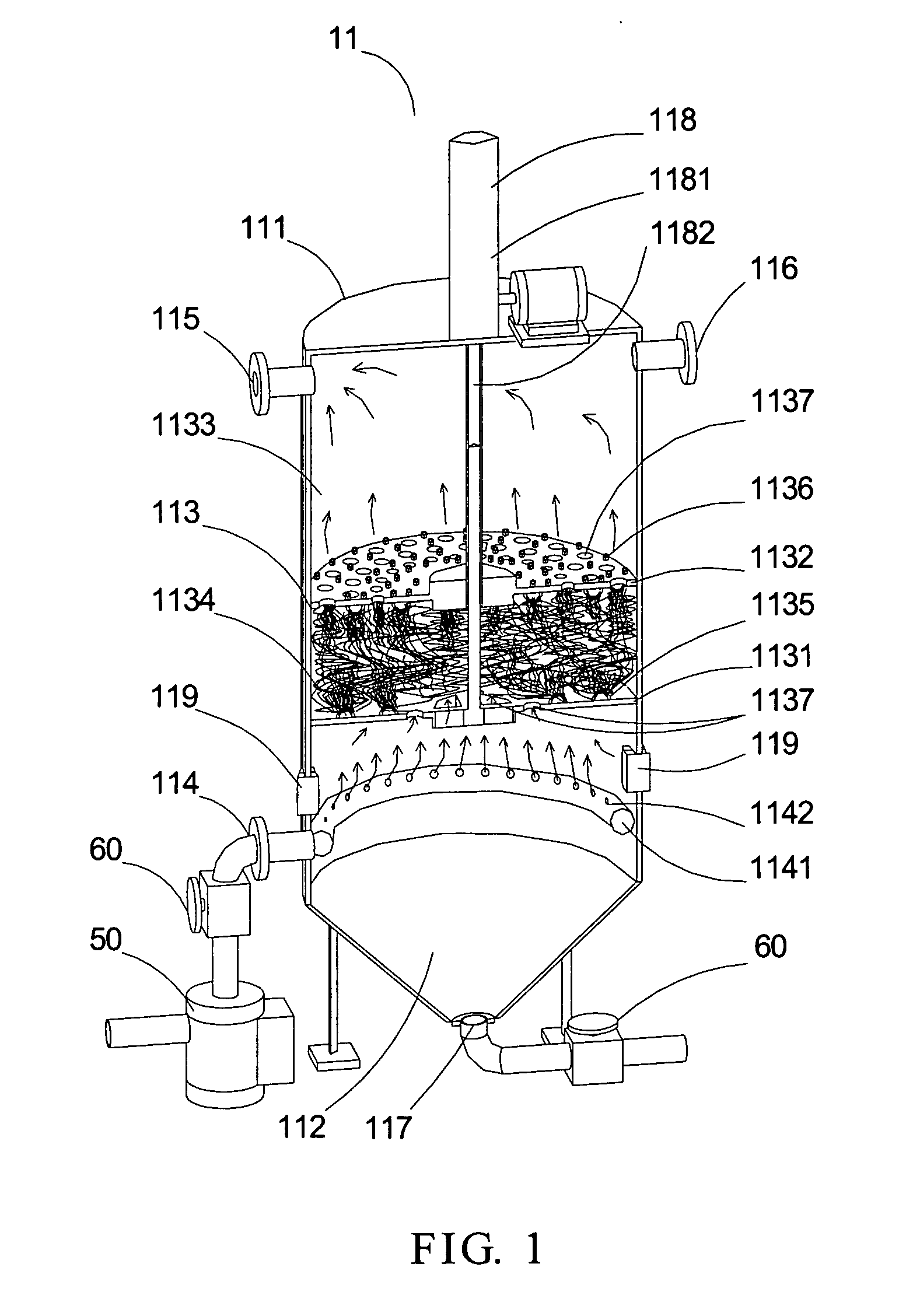

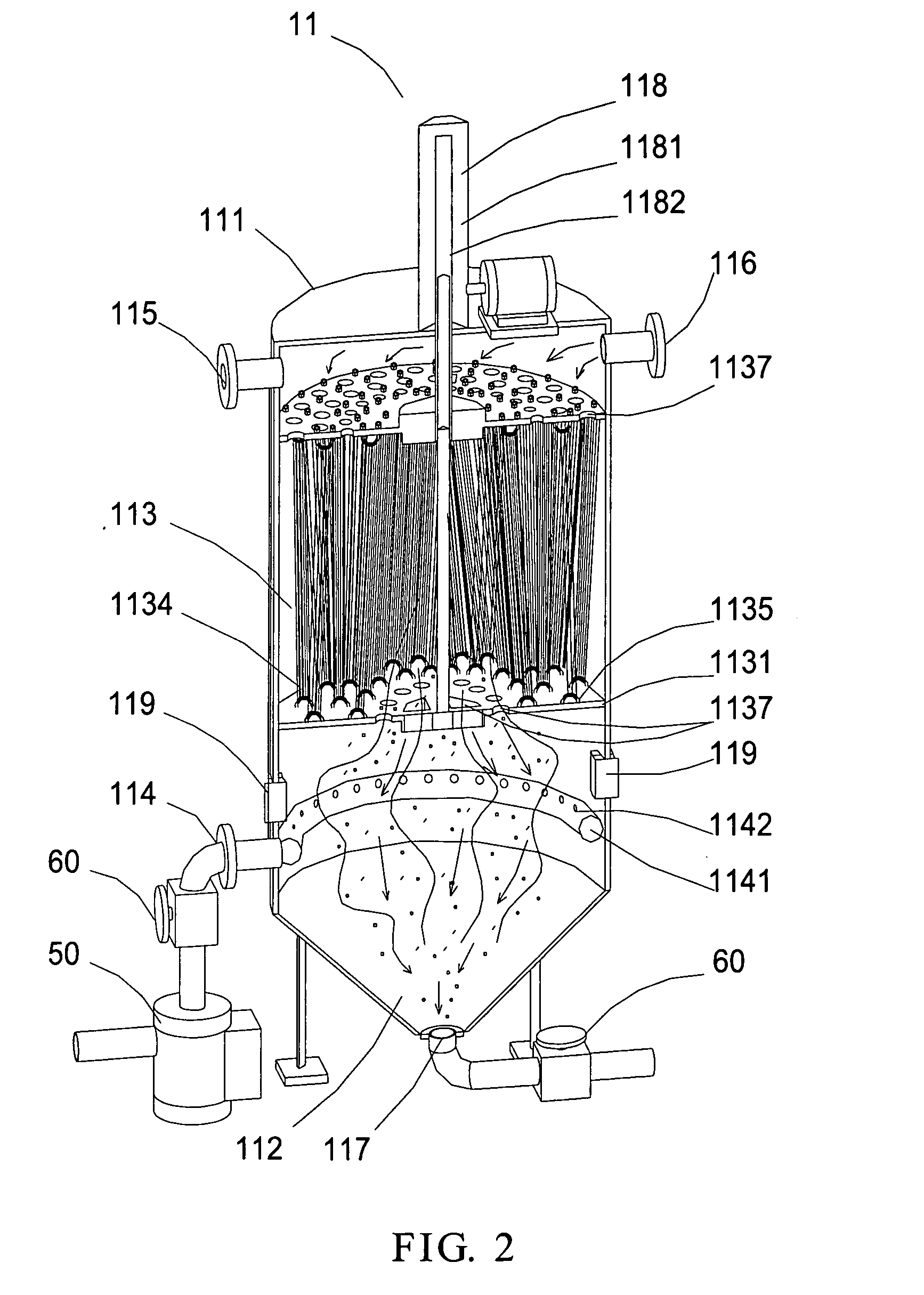

Hydrophilic active biological film suspend carrier and method for making the same

InactiveCN101284694AImprove adhesionSufficient dissolved oxygenSustainable biological treatmentBiological water/sewage treatmentActive agentCatalytic oxidation

The invention discloses a hydrophilic and active biological film suspended carrier as well as the manufacturing method thereof. The carrier substrate adopts polyethylene or polypropylene resin, and hydrophilic and polymeric surfactant, biological enzyme accelerator and microbial affinant mixing granulations are added, thereby being molded by extrusion. The carrier is characterized in that firstly, the carrier has good hydrophilicity and mass transferring property; secondly, the carrier has the characteristics of catalyzing the oxidation reaction and the reduction reaction; thirdly, the carrier has microbial affinity; fourthly, the carrier has the characteristics of large specific surface area, fast biological film cultivation speed and high load impact resistance; and fifthly, the manufacturing cost is low, and the processing technology is simple.

Owner:于春荣

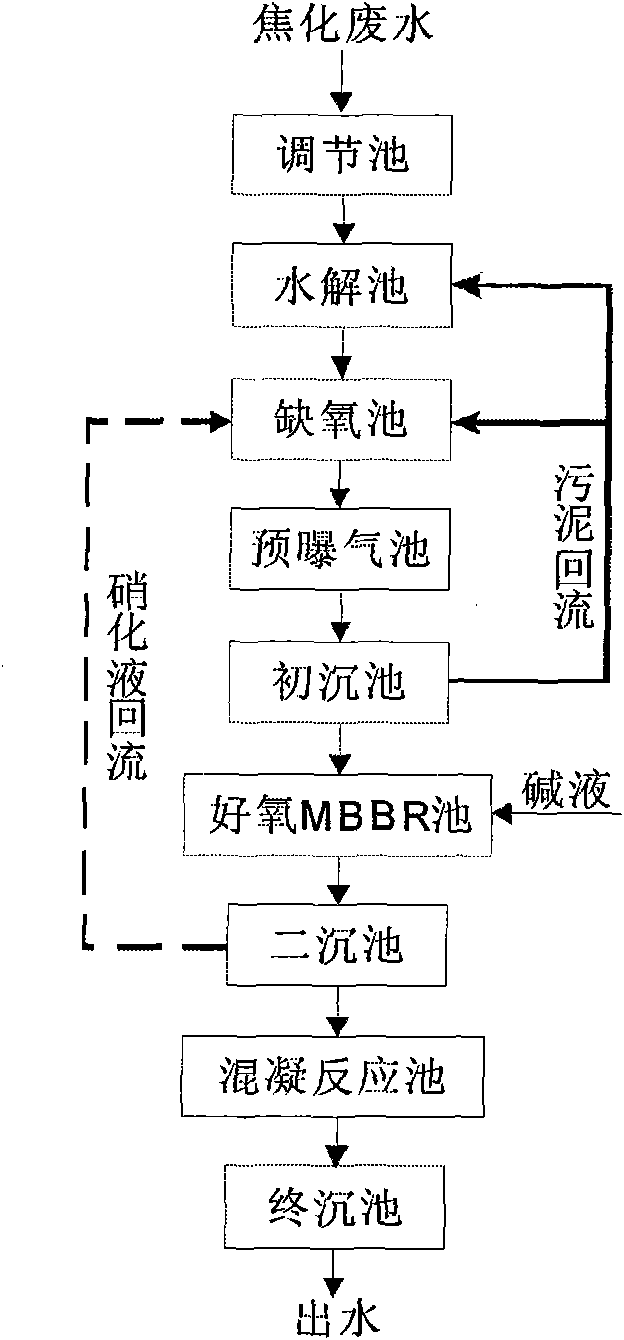

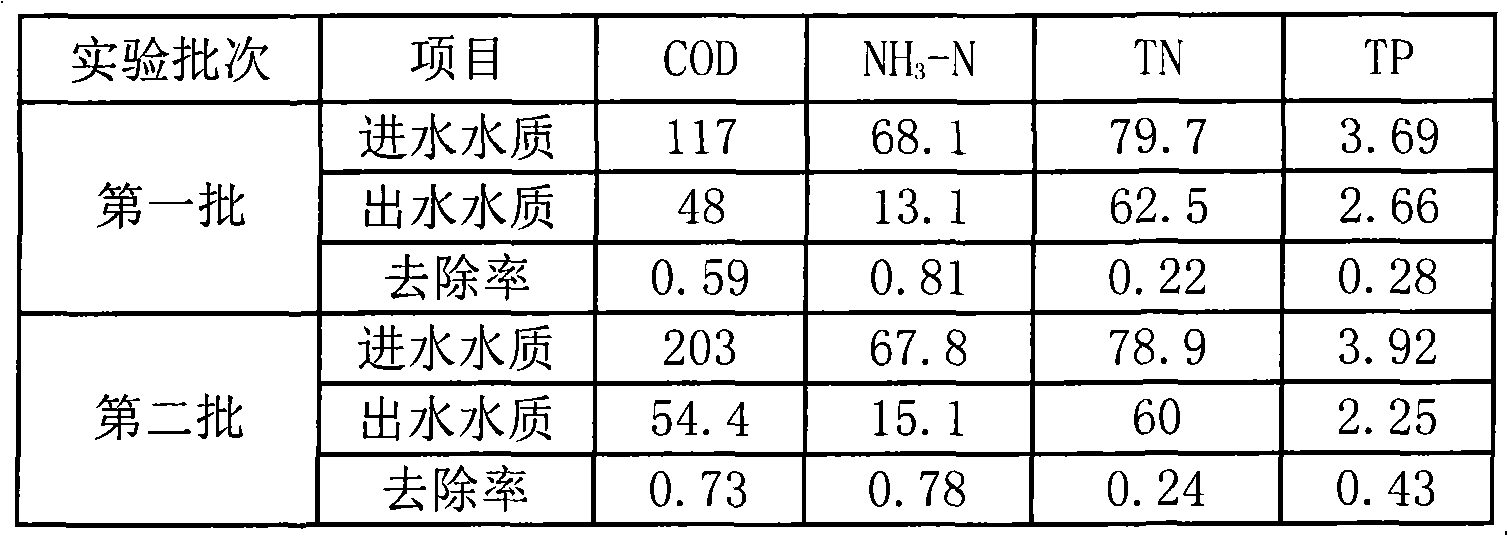

Method for treating coking wastewater

InactiveCN101602564AHigh activityNo reflow requiredTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationSludge

The invention discloses a method for treating coking wastewater, which belongs to the field of wastewater treatment. The method comprises the following steps that: wastewater of a coking plant enters a regulating reservoir for the adjustment of water quality and water amount, and orderly enters a hydrolytic tank, an anaerobic tank, a preaeration tank, a preliminary sedimentation tank, an aerobic tank, a secondary sedimentation tank and a coagulation reaction tank for treatment, wherein the hydrolytic tank and the preaeration tank are filled with a bio-cord filler; the sludge of the preliminary sedimentation tank refluxes into the hydrolytic tank and the anaerobic tank respectively; a clarifying solution of the secondary sedimentation tank refluxes into the anaerobic tank; and the aerobic tank adopts a moving bed bio-film reactor. The bio-cord filler adopted in the invention has short film formation time and high biomass, does not need repeated washing, and has strong shock resistance; and the moving bed bio-film reactor can fix a large amount of nitrobacteria with long generation time, and has no the problem of blocking. The method can remove high-concentration ammonia nitrogen and organic substances in the coking wastewater, and the COD and the ammonia nitrogen of treated effluent can synchronously achieve the primary standard of the national integrated wastewater discharge standard (GB9878-1996).

Owner:NANJING UNIV

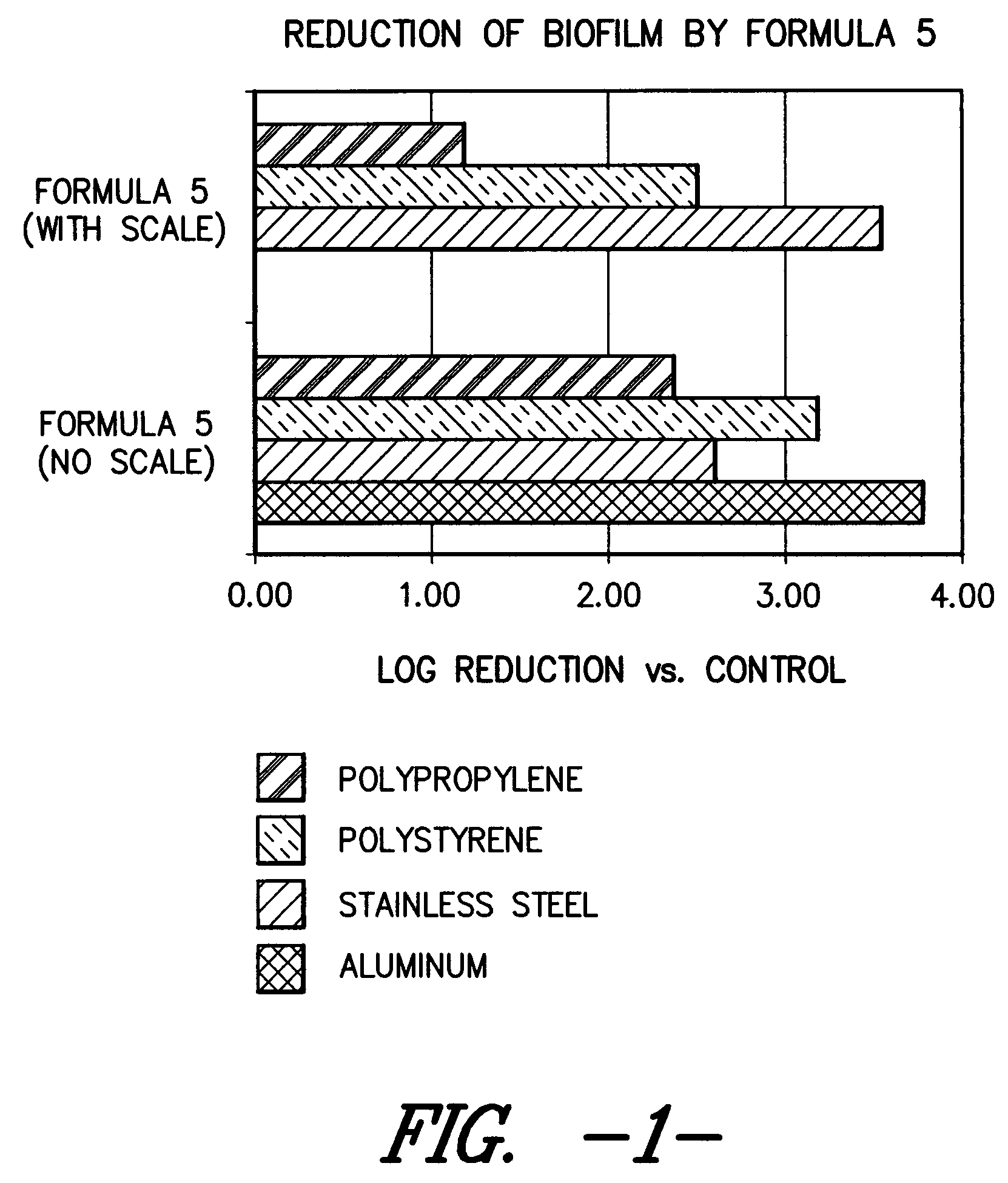

Rhamnolipid-based formulations

InactiveUS20080213194A1Improve skin appearanceHigh purity rhamnolipidBiocideCosmetic preparationsRhamnolipidWorking environment

The present invention relates to rhamnolipid-based formulations to clean, disinfect, deodorize, and act as an antimicrobial and antifungal agent for living and working environments. In addition, the present invention relates to the use of rhamnolipids to create a bio-film when applied to a surface, which prevents the growth of bacteria and fungus. This technique is especially useful to create clean surface areas for medical procedures, chemical testing, during food preparation, as well as for daycare centers and hospitals.

Owner:AURORA ADVANCE BEAUTY LABS

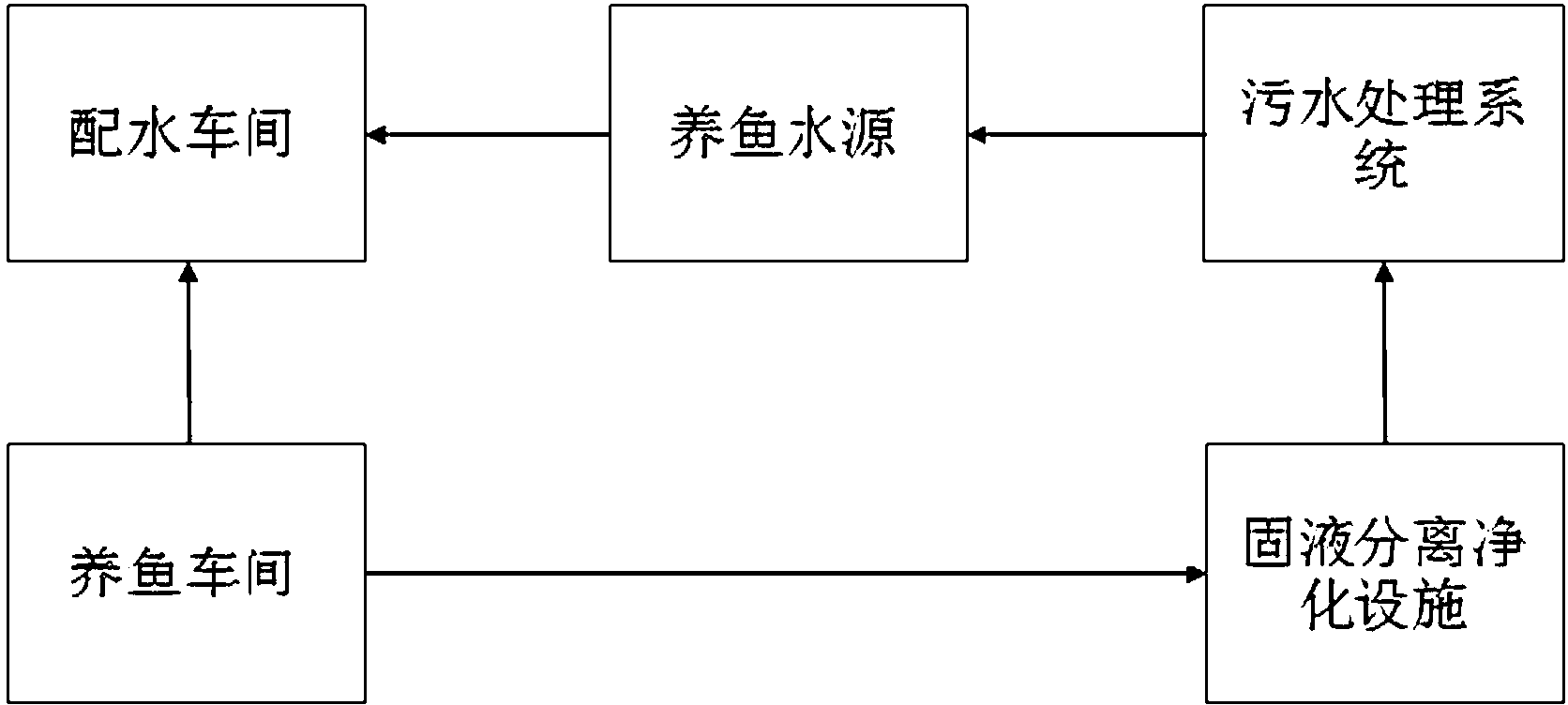

Ecotype enclosed method for culturing fish through circulation water

InactiveCN103238554AEasy to interceptEasy to sinkPisciculture and aquariaFiltrationUltraviolet lights

The invention discloses an ecotype enclosed method for culturing fish through circulation water. Natural seawater, underground salt water, underground fresh water and geothermal water are mainly utilized and mixed, and an industrial culture foundation for producing pollution-free healthy seafood is built and used. A solid-liquid separation purification device is used for replacing sand filtration of a biological filter, ammonia nitrogen and nitrite nitrogen are degraded after water passing through a biological film on biological filler in the biological filter, and the total purification rate of water body particles is over 99%. An aeration pond is arranged to conduct aeration and oxygenation on a culture water body to enable the content of dissolved oxygen in water in a fish culture pond to be kept at 8-14mg / L, finally the water body is sterilized through ultraviolet light, clean ecological water is input into the fish culture pond, and the return water in the fish culture pond is purified repeatedly and utilized in a circulating mode. Sewage discharged from a culture system is purified by an open-air pond and flows back to a water storage sedimentation pond to achieve zero-discharge complete enclosed circulation water factory-like fish culture.

Owner:天津市兴盛海淡水养殖有限责任公司

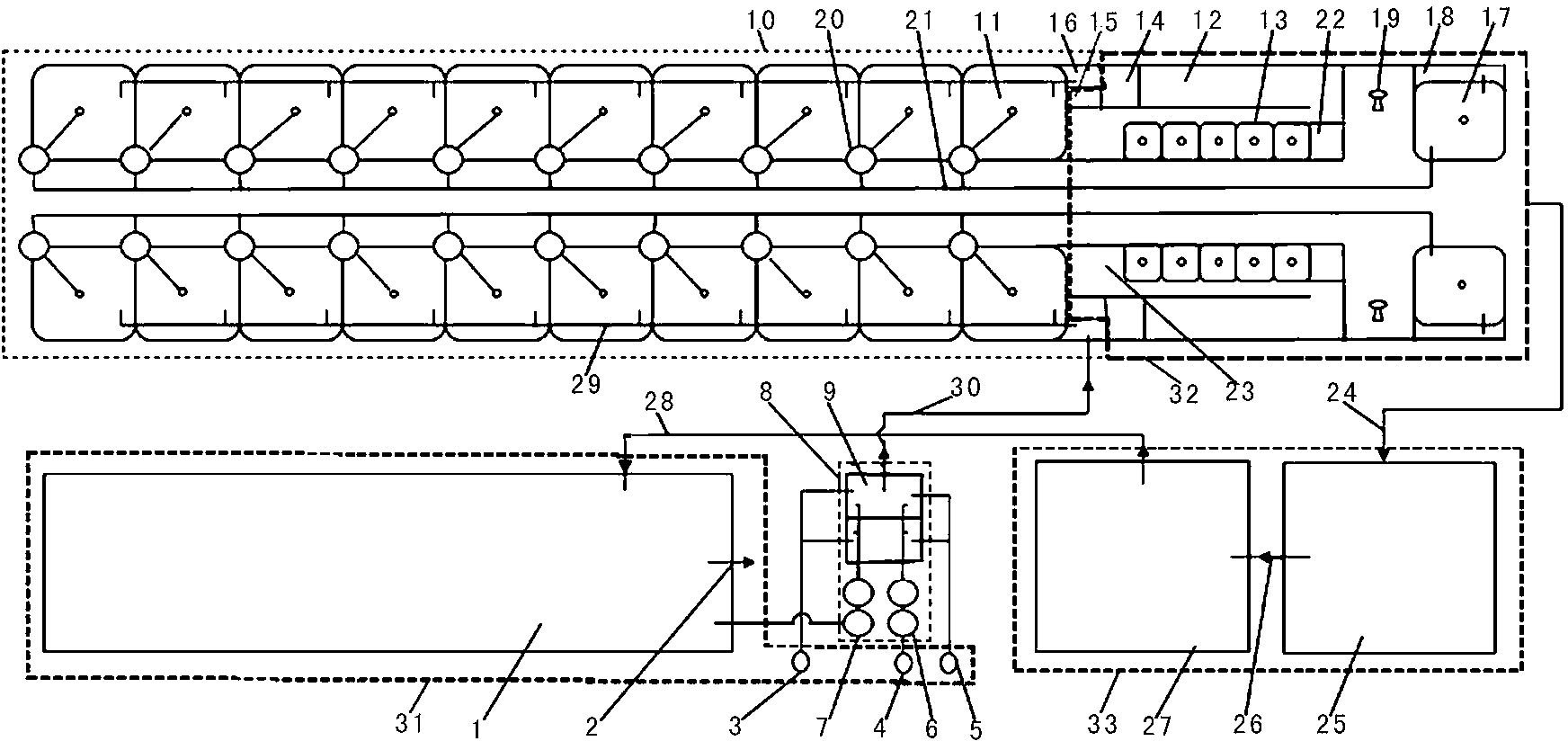

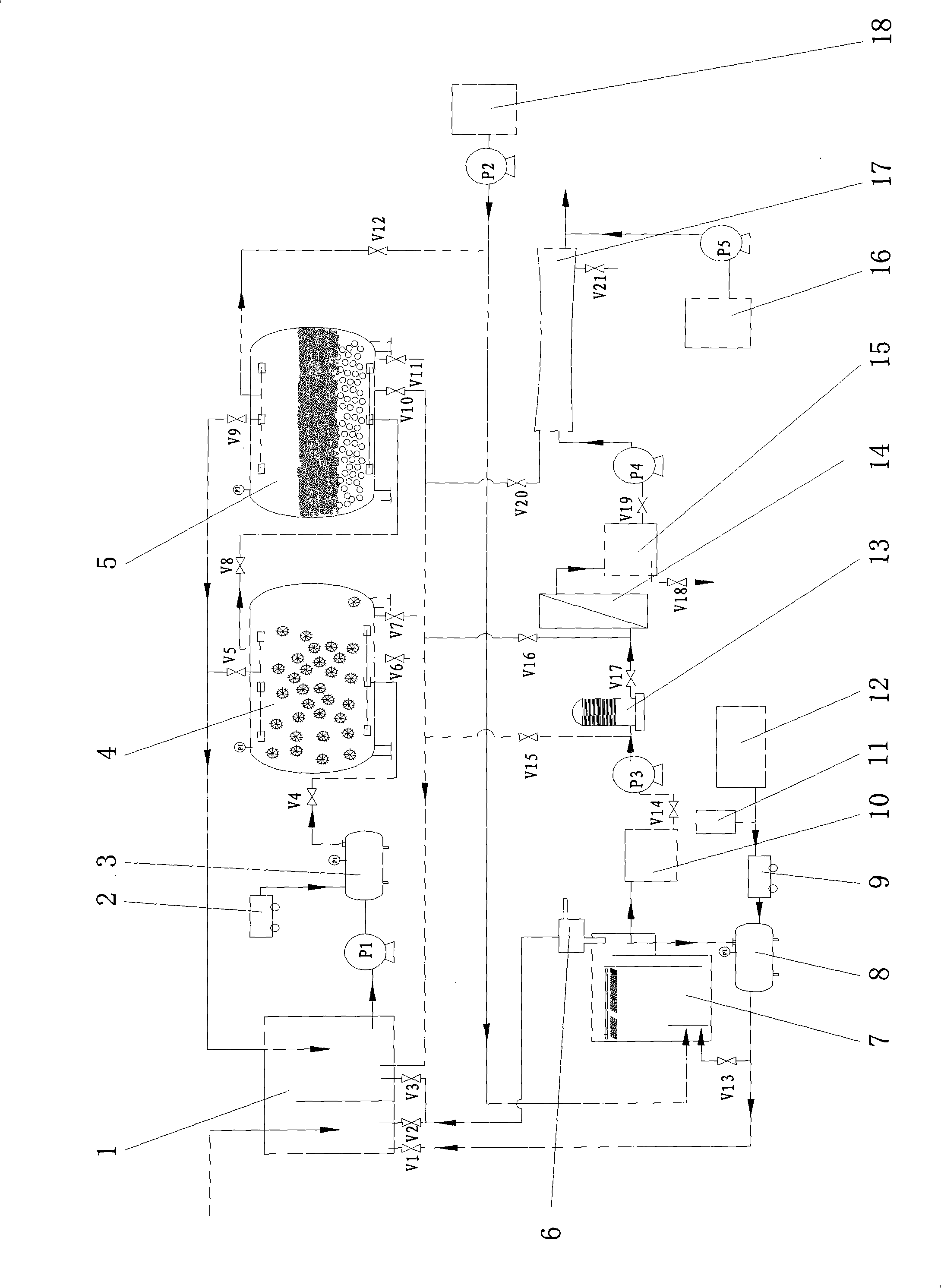

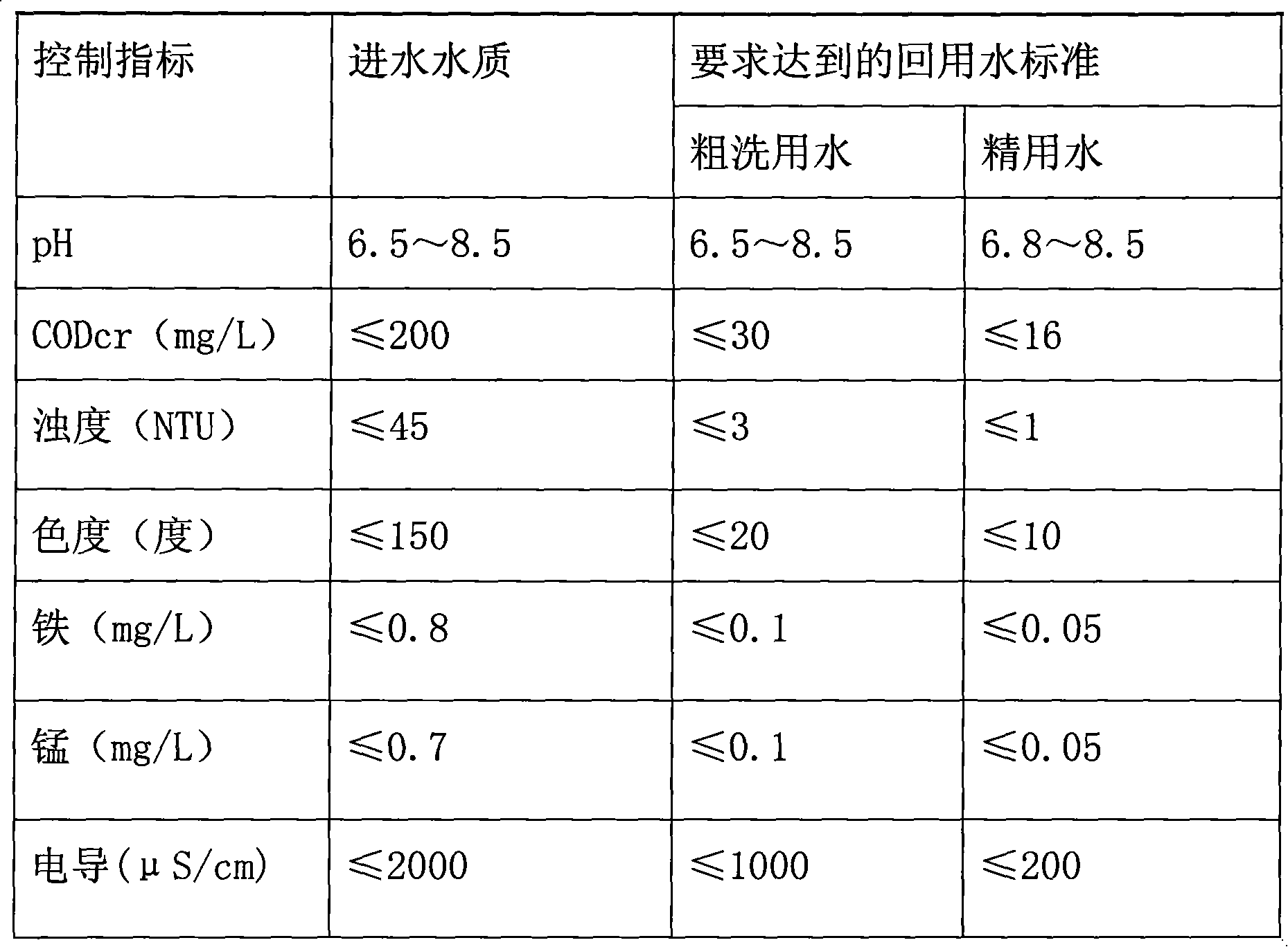

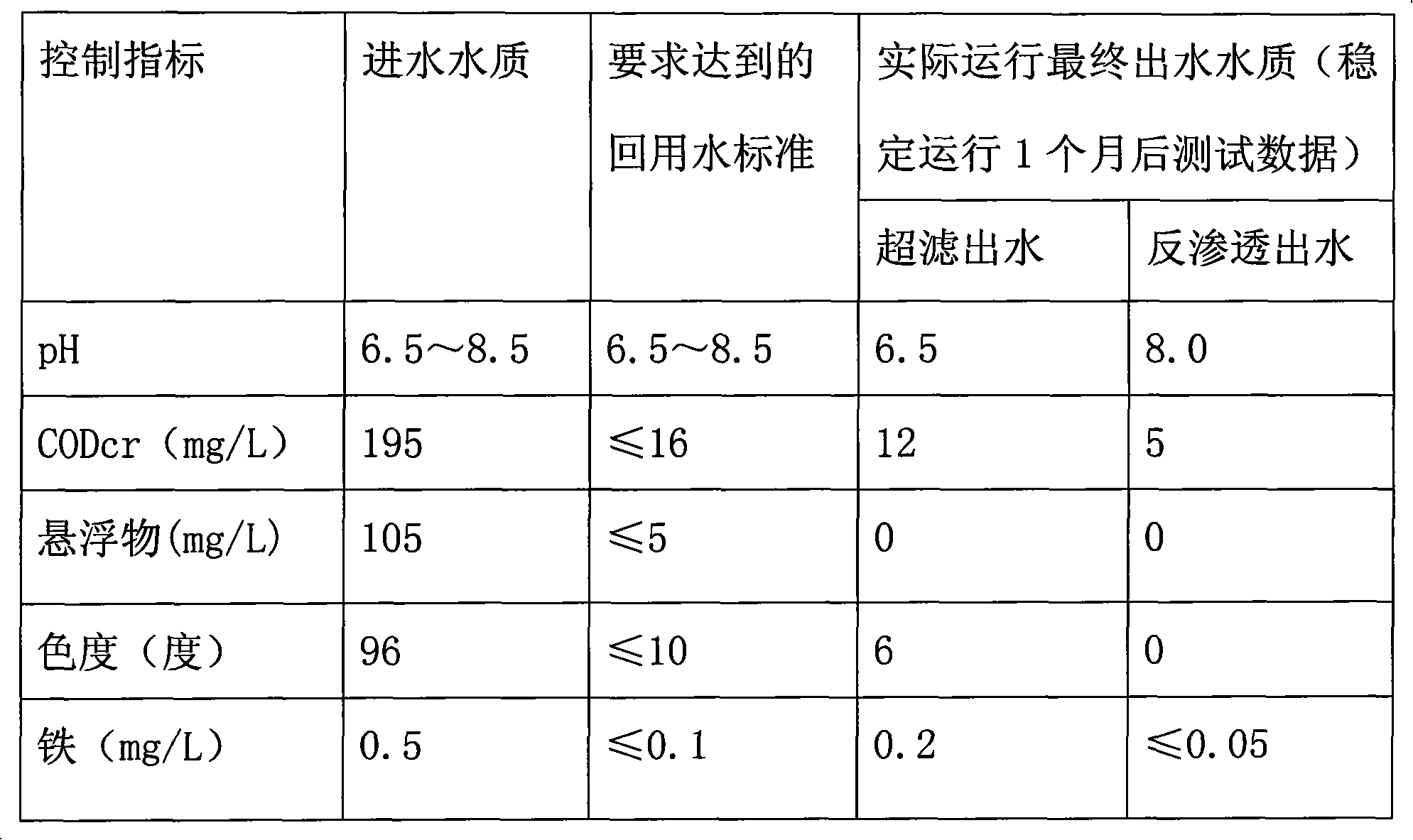

Integrated technology for deep purification treatment for printing and dyeing waste water

InactiveCN101633541AReduce ozoneEnough time to stayTreatment using aerobic processesWater/sewage treatment bu osmosis/dialysisFiltrationBiological filter

The invention discloses integrated technology for reclaiming lightly-polluted printing and dyeing waste water or printing and dyeing waste water achieving a certain discharge standard through deep purification treatment for production. A related process of the technology mainly comprises an adjusting tank, a pressure moving bed bio-film reactor, a ceramsite and activated carbon biological filter, an air floating system, a laminated filter and an ultra-filtration and reverse osmosis system. The technology is characterized in that the technology improves the prior biochemical technology, and carries out process integration by combining technology such as ozone oxidation, air flotation, membrane separation and the like. The regeneration of the printing and dyeing waste water can be realized by adopting the treatment technology, and the regenerated water quantity can reach 70 to 80 percent; and the technology not only can effectively solve the pollution problem of the printing and dyeing industry and protect the environment, but also can provide theoretical and technical support for realizing closed-loop circulation of the printing and dyeing waste water and popularizing clean production in the printing and dyeing industry.

Owner:ZHEJIANG STONE ENVIRONMENTAL ENG CO LTD +2

Beverage manufacture, processing, packaging and dispensing using electrochemically activated water

ActiveUS20090199866A1Reducing eliminating needEliminate the problemWater treatment parameter controlSpecific water treatment objectivesBiofilm growthAdditive ingredient

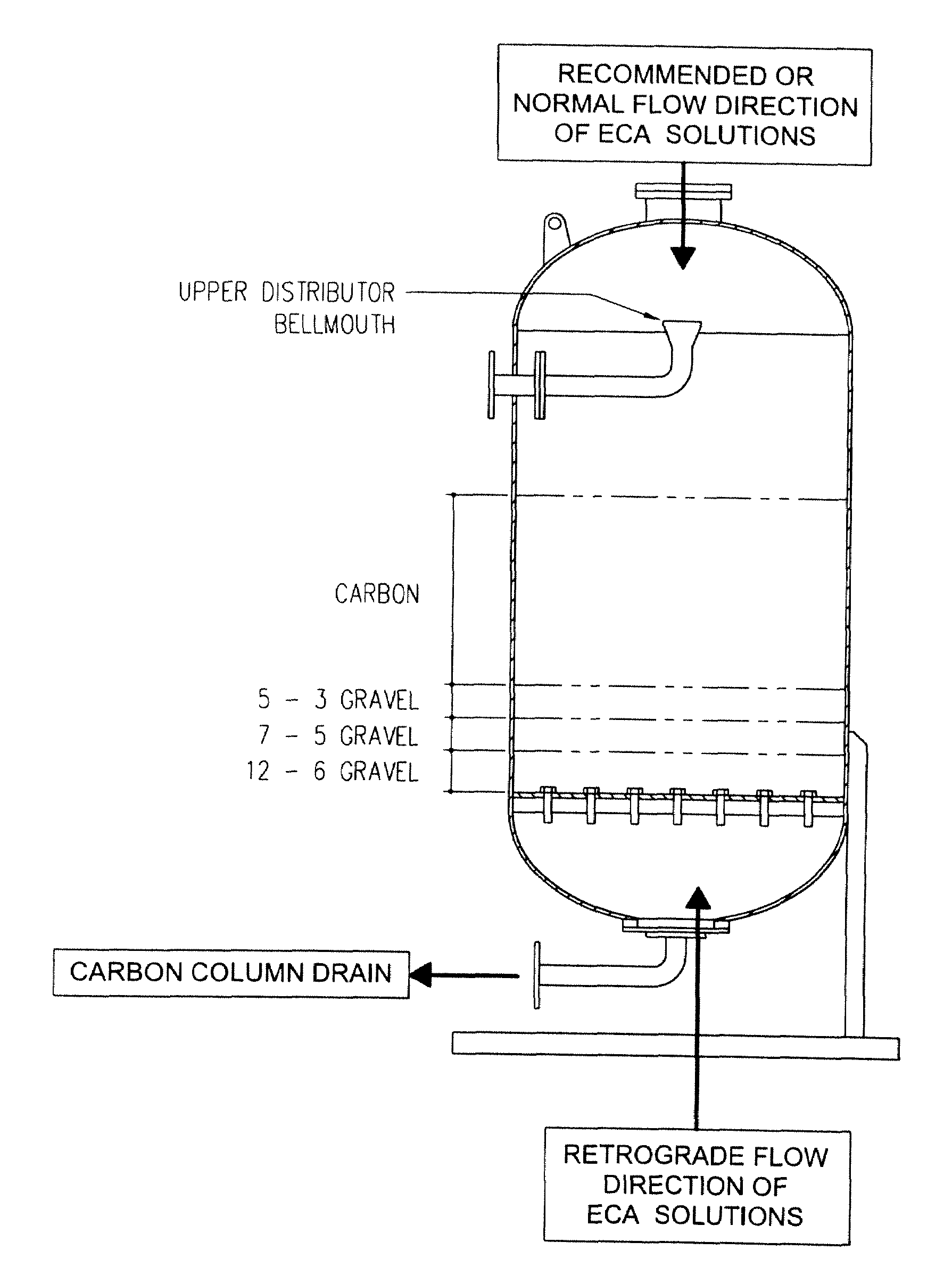

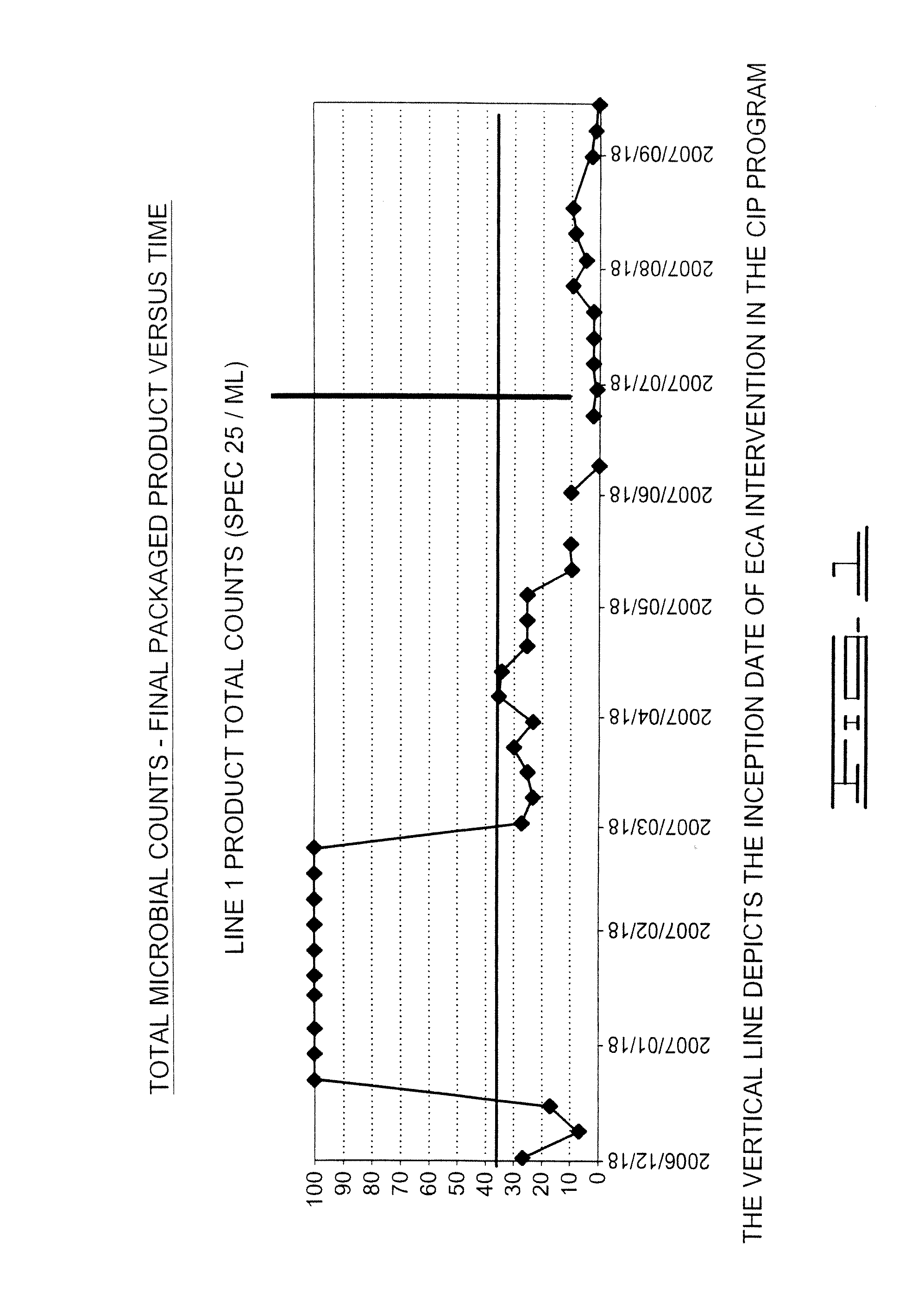

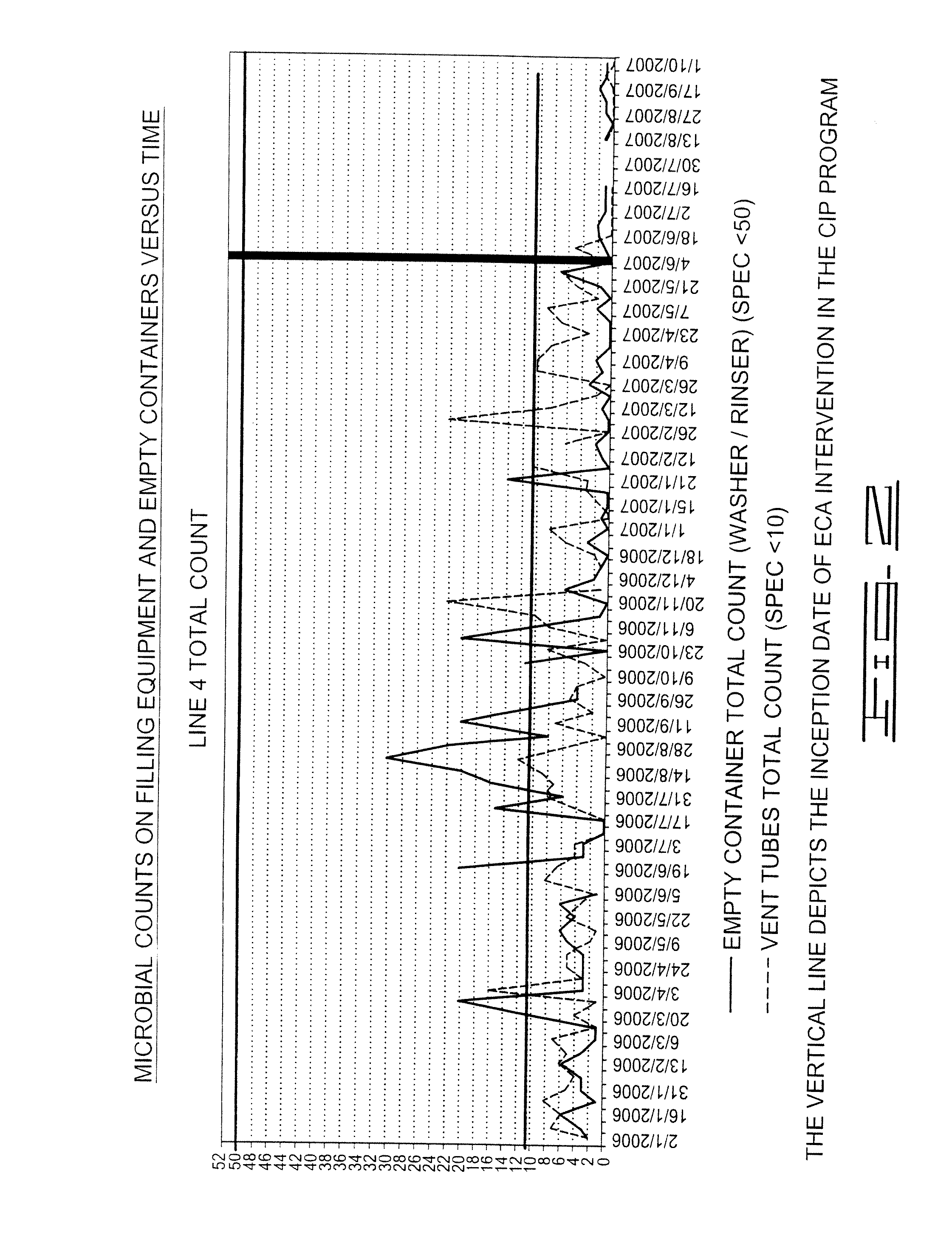

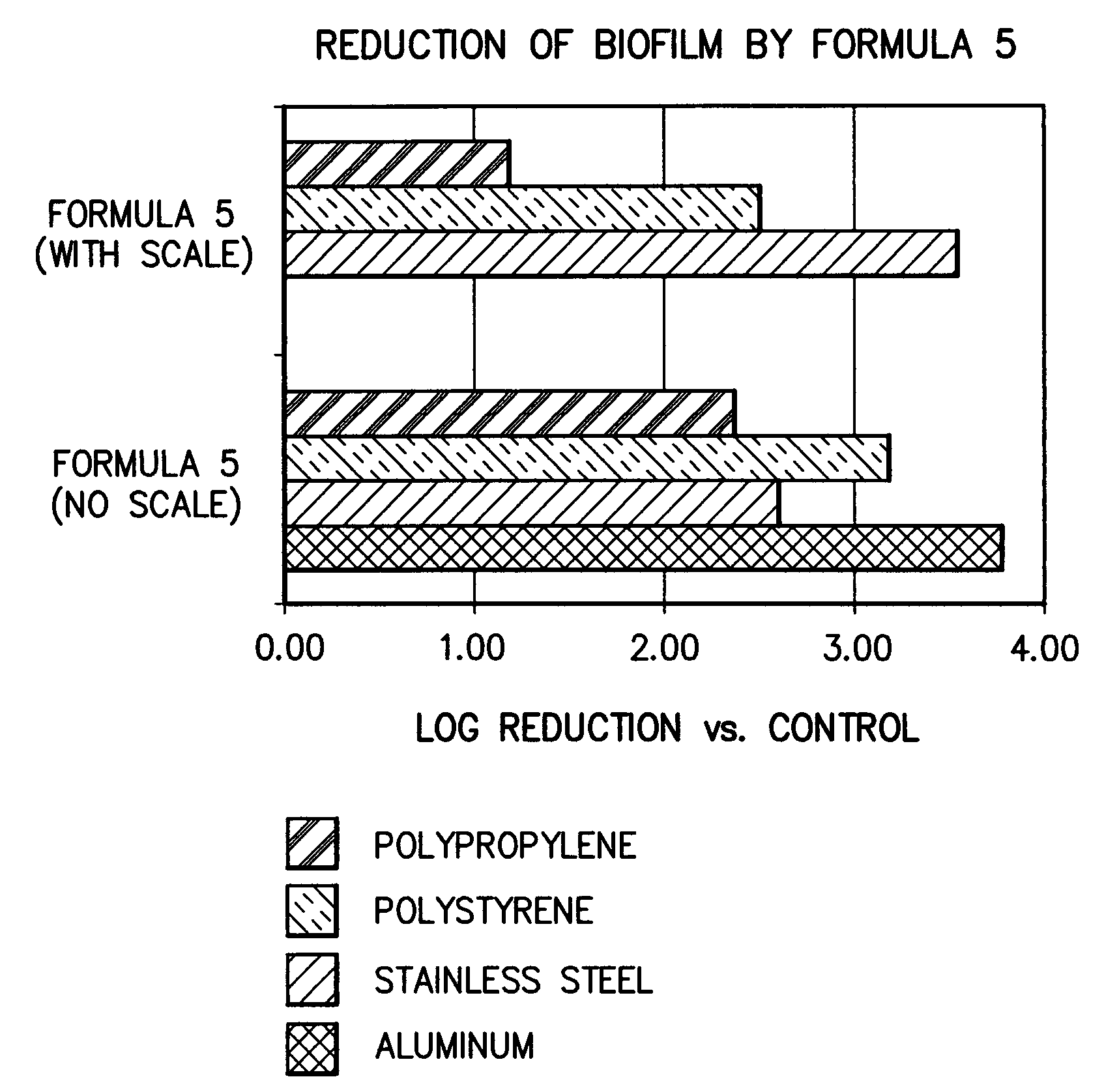

A system using electrochemically-activated water (ECAW) for manufacturing, processing, packaging, and dispensing beverages including: (a) using ECAW to neutralize incompatible residues when transitioning from the production of one beverage to another; (b) using ECAW to rehabilitate and disinfect granular activated charcoal beds used in the feed water purification system; (c) producing a carbonated ECAW product and using the carbonated ECAW for system cleaning or disinfecting; (d) using ECAW solutions in the beverage facility clean-in-place system to achieve improved microbial control while greatly reducing water usage and reducing or eliminating the use of chemical detergents and disinfectants; (e) further reducing biofilm growth in the processing system, and purifying ingredient water without the use of chlorine, by adding an ECAW anolyte to the water ingredient feed stream; and / or (f) washing the beverage product bottles or other packages with one or more ECAW solutions prior to packaging.

Owner:RADICAL WATERS INT LTD +1

Solid cleaning composition and method of use

InactiveUS20090032063A1Reduce microbial growthReduce or eliminate both the biological and the abiotic build upInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBiofilm growthAdditive ingredient

This invention relates to solid cleaning compositions and the method for using the solid compositions to clean appliances and other soiled surfaces. The solid cleaning composition is generally comprised of a majority by weight of a cleaning active system; ingredients for forming the cleaning active system into a solid form; and optionally, a fragrance. The solid cleaning composition is ideally suited for reducing and / or eliminating microbial growth, including biofilm growth, contained within and / or on appliances, particularly those appliances that have water contact surfaces such as washing machines and dishwashers. The solid cleaning composition further provides reduction and / or elimination of undesirable odor and staining typically associated with such microbial growth.

Owner:HAAS GEOFFREY R +4

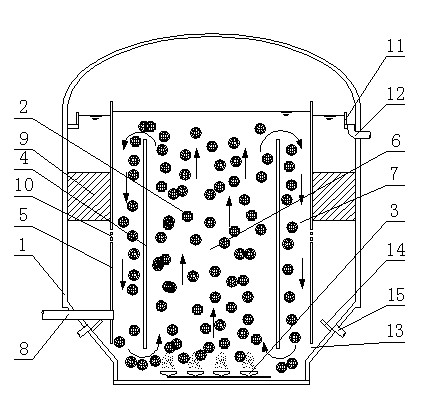

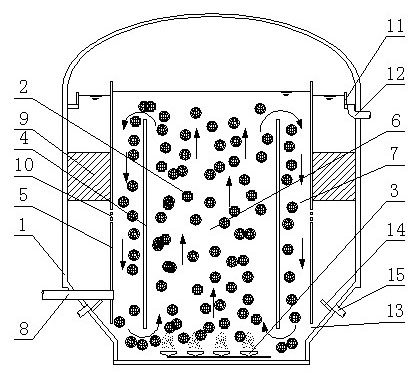

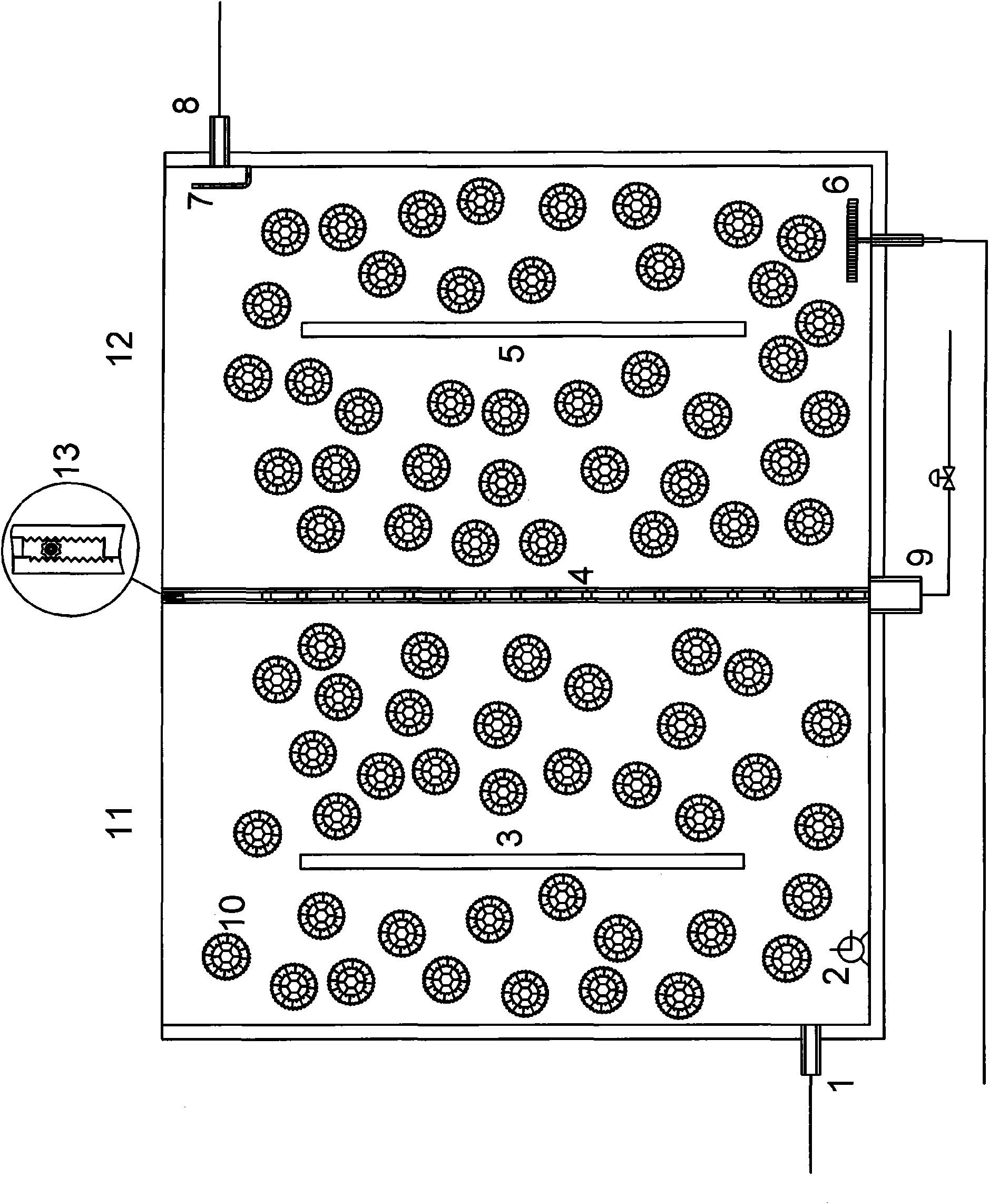

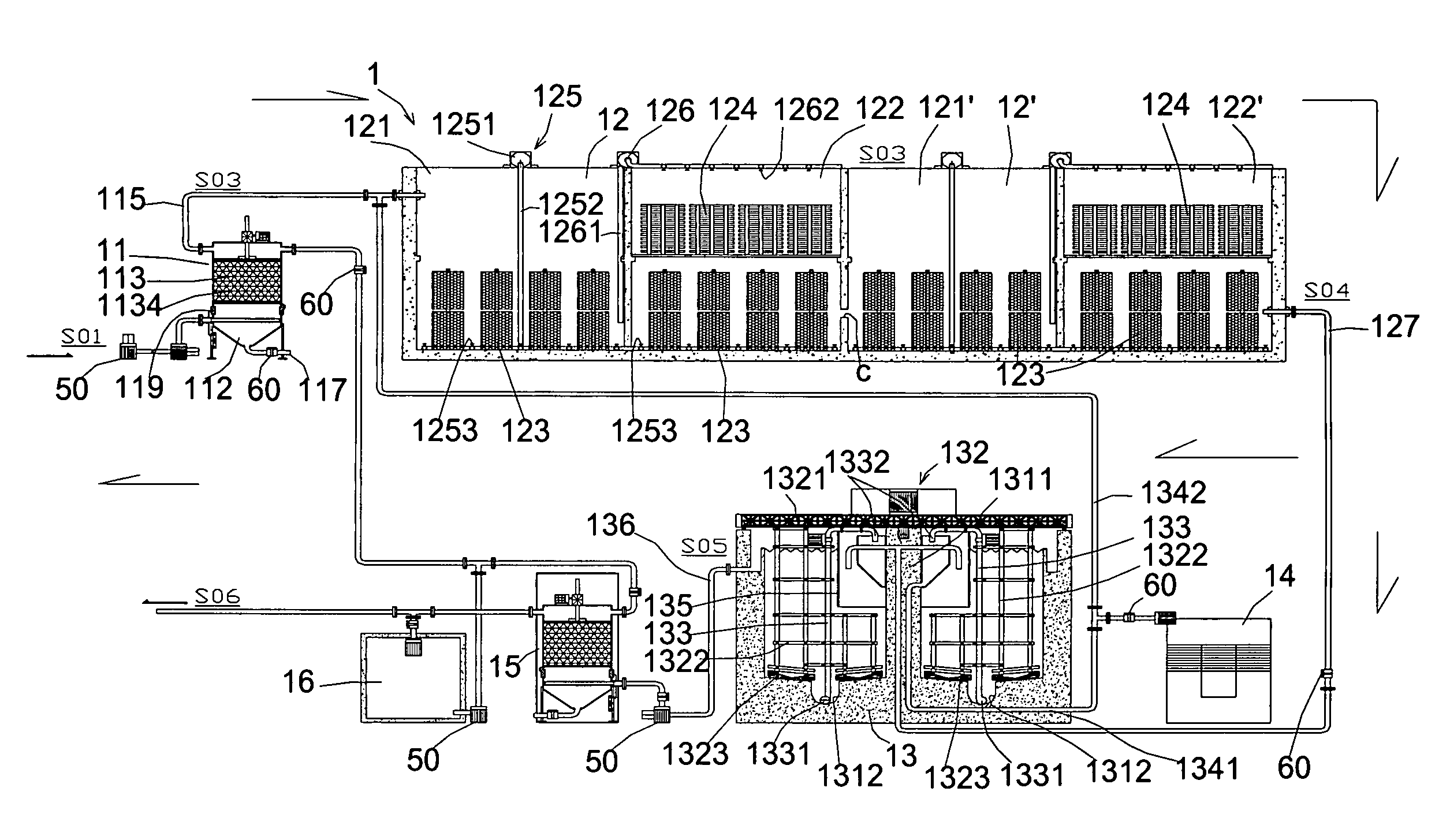

Composite moving bed bio-film reactor

InactiveCN102134149AFunction as a water pumpImprove the aeration effectTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeMoving bed biofilm reactor

The invention discloses a composite moving bed bio-film reactor. The composite moving bed bio-film reactor comprises a reactor body; a hollow sphere filler is filled in the reactor body; an aeration device is arranged at the bottom in the reactor body; an inner cylinder and an outer cylinder which are sleeved are also arranged in the reactor body; the upper and lower ports of the inner cylinder and the outer cylinder are completely opened; the lower part of the outer cylinder wall is provided with a water inlet pipe; an inclined tube sedimentation tank is arranged between the outer cylinder and the reactor body; the outer cylinder wall below the inclined tube sedimentation tank is provided with a sedimentation tank water inlet; and the reactor body above the inclined tube sedimentation tank is provided with an overflow channel, the upper edge of the overflow channel is lower than the outer cylinder wall, and the bottom of the overflow channel is provided with a water outlet pipe. According to the technical scheme of the composite moving bed bio-film reactor with simple structure, low manufacturing cost and small floor area, the advantages of a traditional moving bed bio-film reactor, a three-phase biological fluidized bed, a biological contact oxidation method and an active sludge method are organically combined.

Owner:SHANDONG JIANZHU UNIV

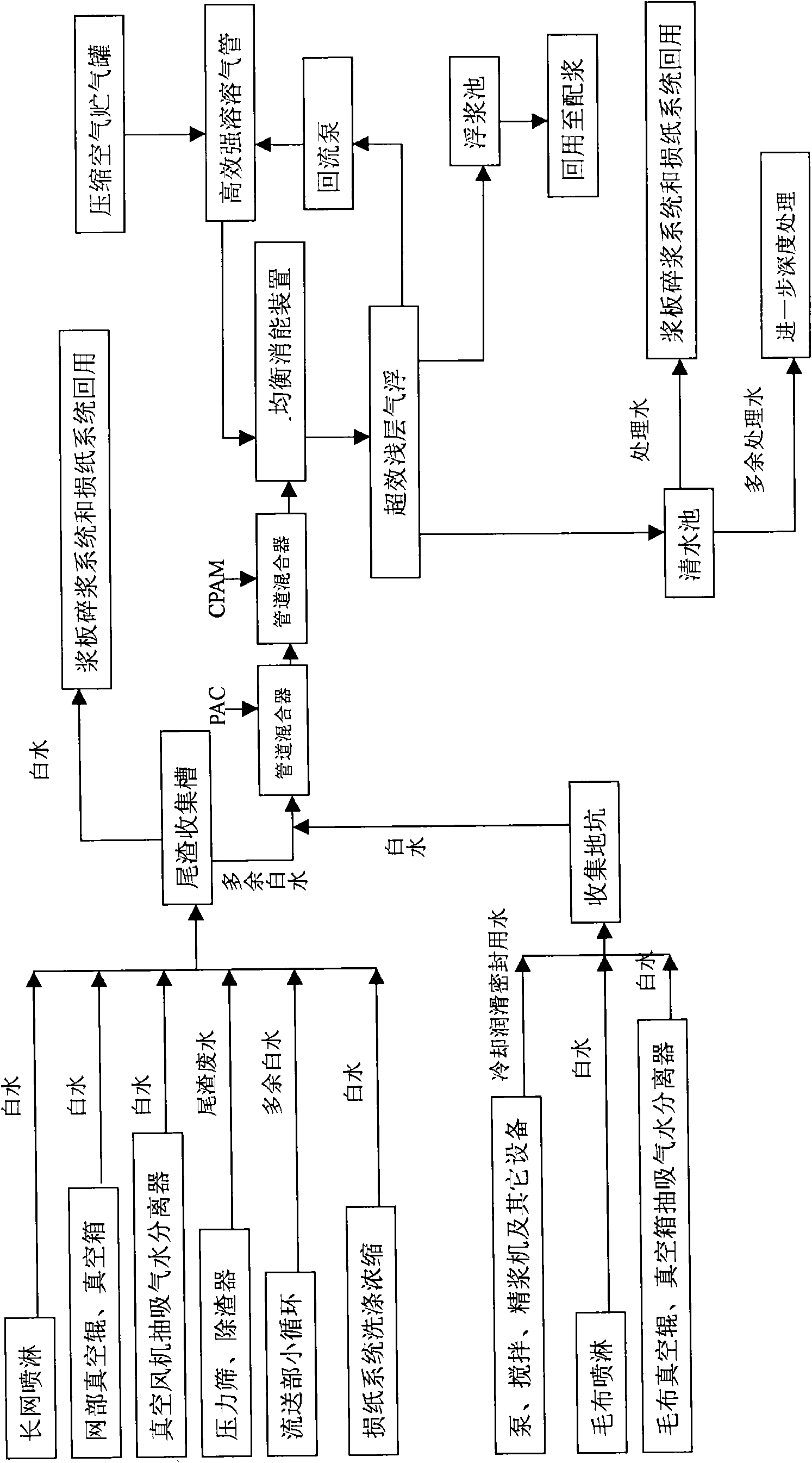

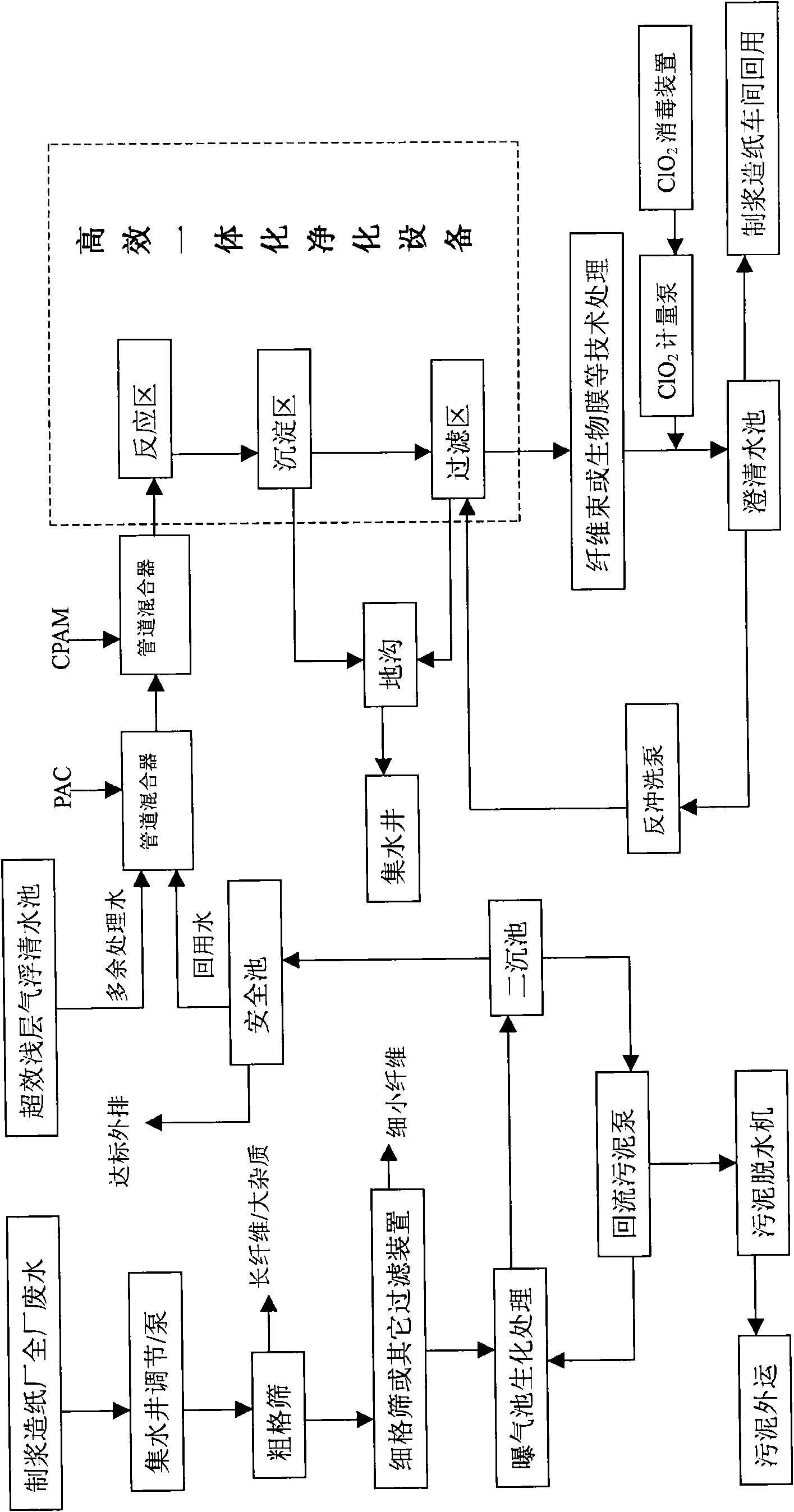

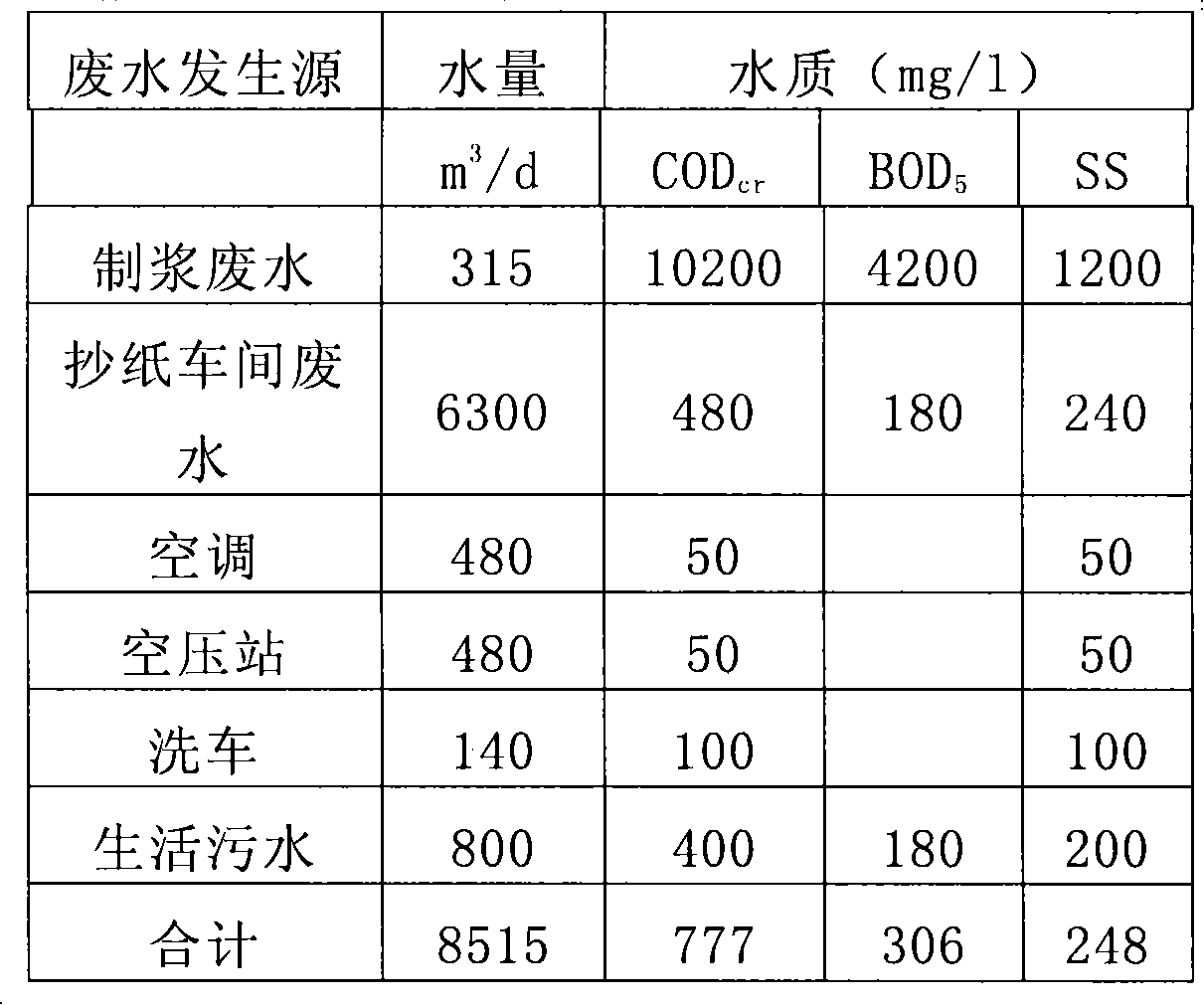

Wastewater treatment and reuse technology for paper mill

InactiveCN101591085AEmission reductionEasy to handleMultistage water/sewage treatmentWaste water treatment from plant processingPaper millReclaimed water

The invention provides a wastewater treatment and reuse method for a paper mill. The method comprises the following steps: (a) physical treatment: providing wastewater from the paper mill, and removing the cellulose and other foreign impurities in the wastewater from the paper mill to obtain the wastewater from the paper mill after the physical treatment; (b) biochemical treatment: performing biochemical treatment and deposition to the paper mill wastewater obtained in the step (a) after the physical treatment to obtain safe pool water conforming to the required emission standard; and (c) advanced treatment: providing air-floatation water after super-efficient shallow air-floating treatment in a machine room and merging the air-floatation water with the safe pool water obtained in the step (b) to obtain intermediate water, and then performing intermediate water advanced treatment, i.e. adding drugs into the intermediate water, coagulating, depositing and filtering to obtain purified water; and performing fiber bunch or the biological film technical treatment to the purified water to obtain effluent.

Owner:CHINA BANKNOTE PRINTING & MINTING

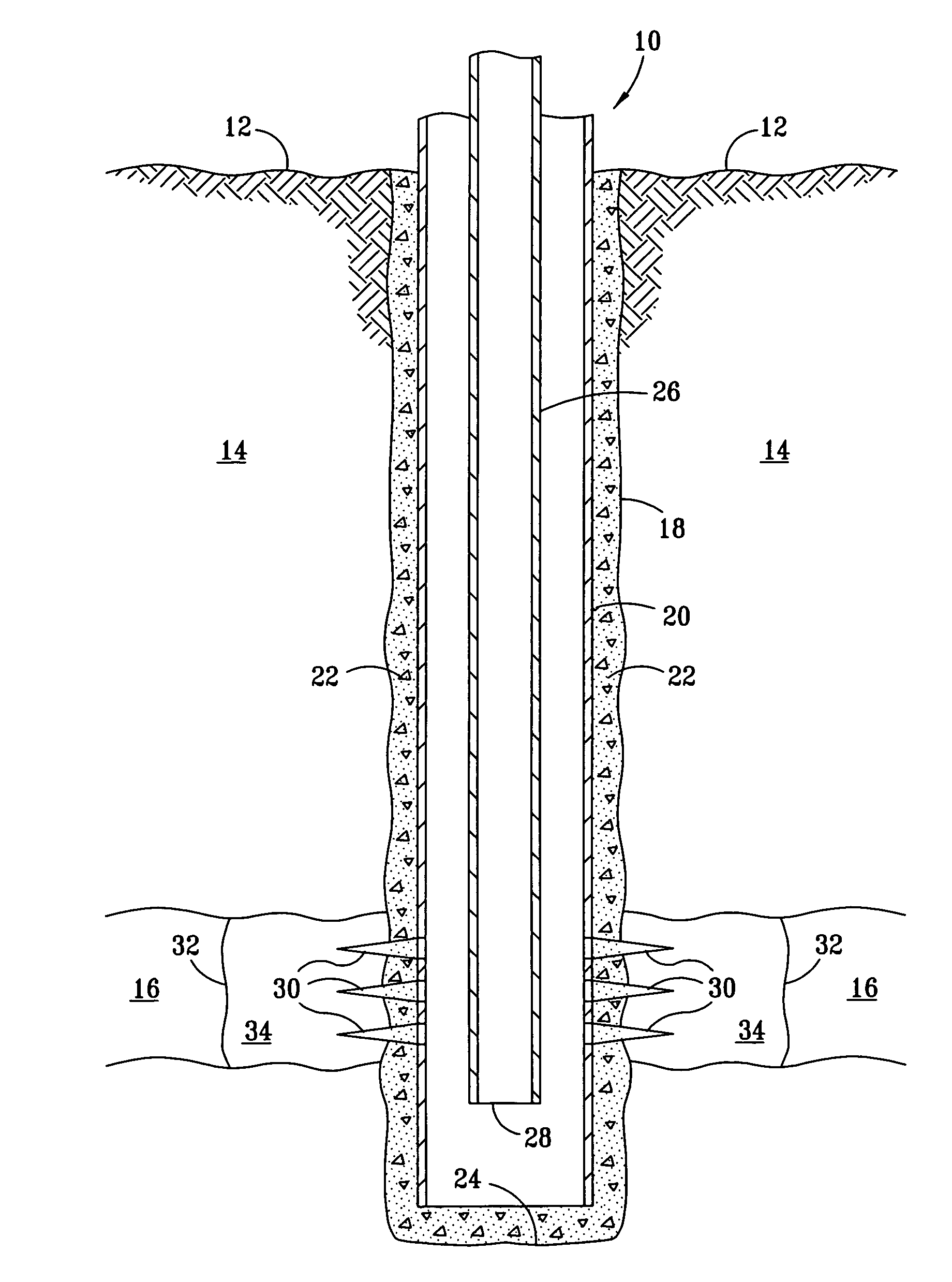

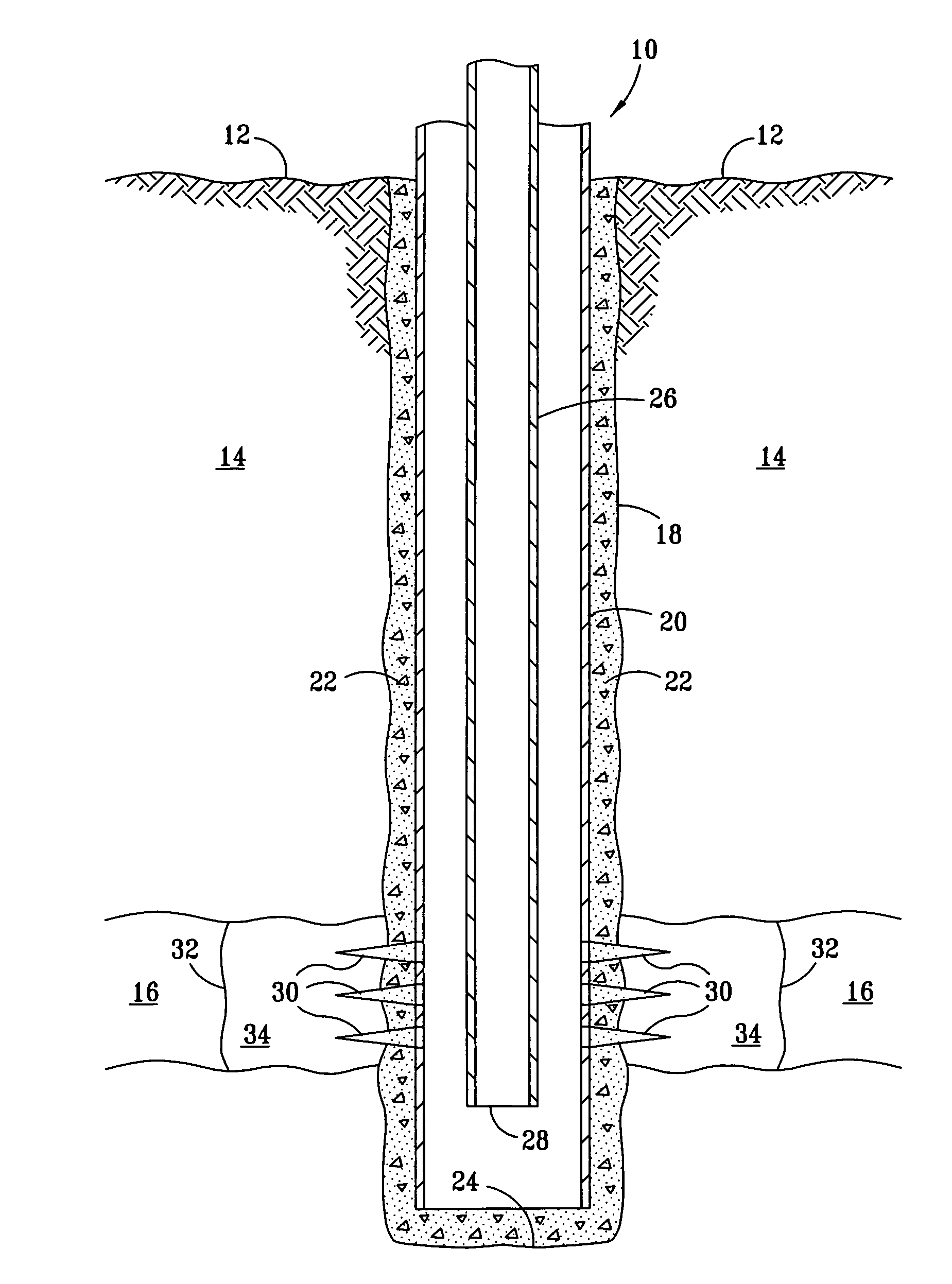

Method for removing iron deposits in a water system

InactiveUS7563377B1Waste water treatment from quariesSpecific water treatment objectivesSodium chloriteSediment

A method and composition and system which for the oxidation, clean up, removal and control of iron and iron deposits in water and the removal of iron deposits and bacterial bio-films from surfaces in water systems. The composition contains sodium chlorite, sodium hypochlorite and citric acid.

Owner:CHEMCAL INC

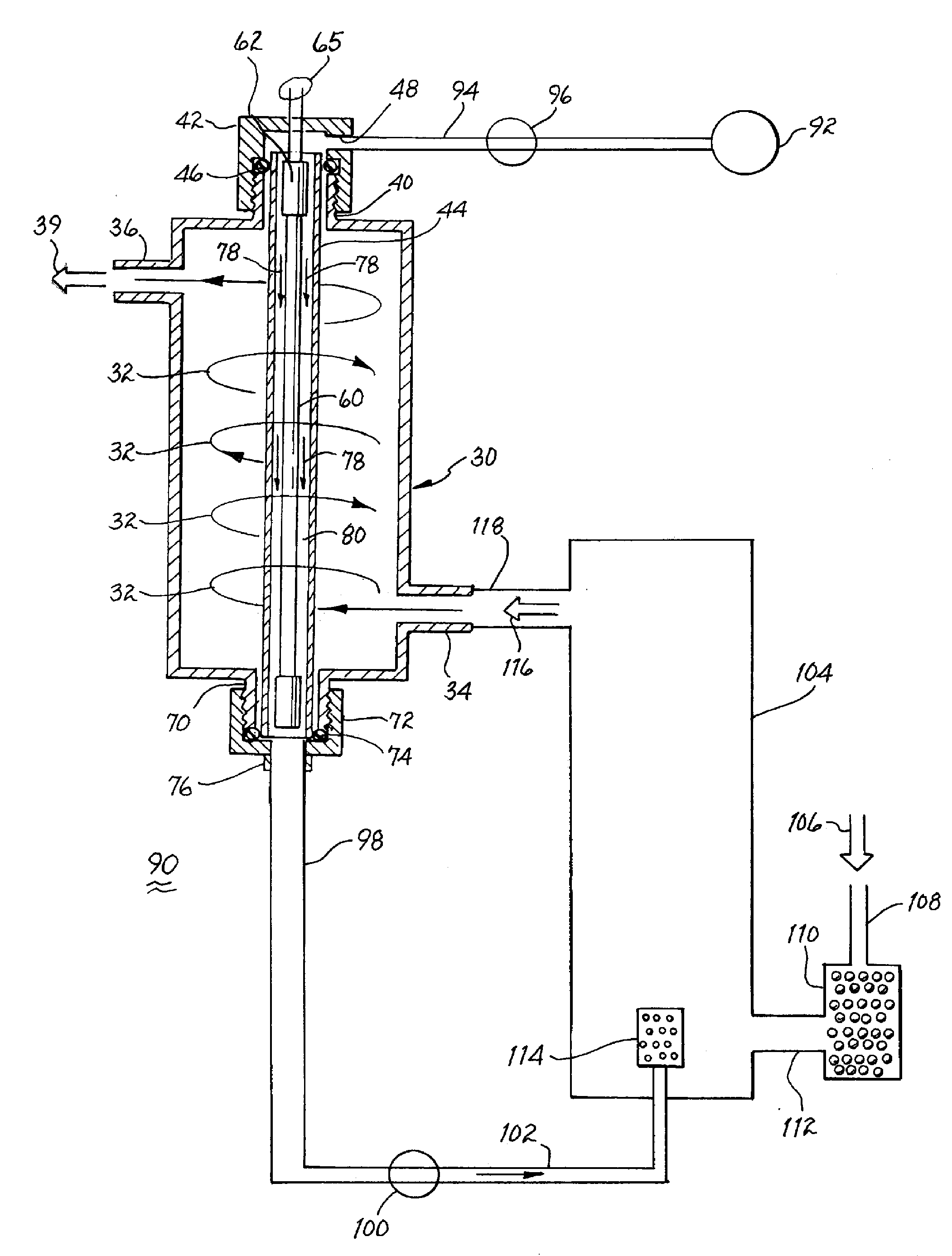

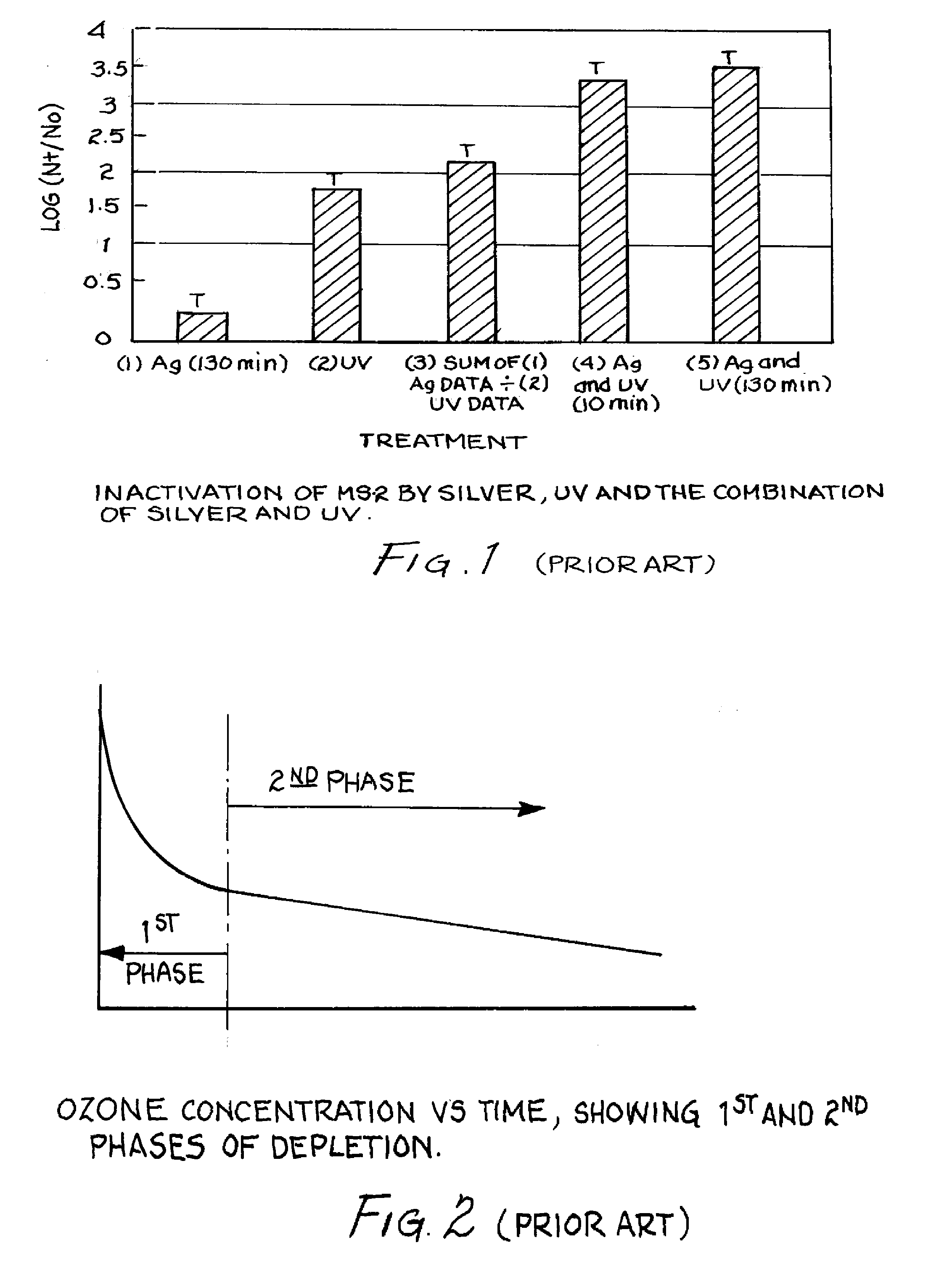

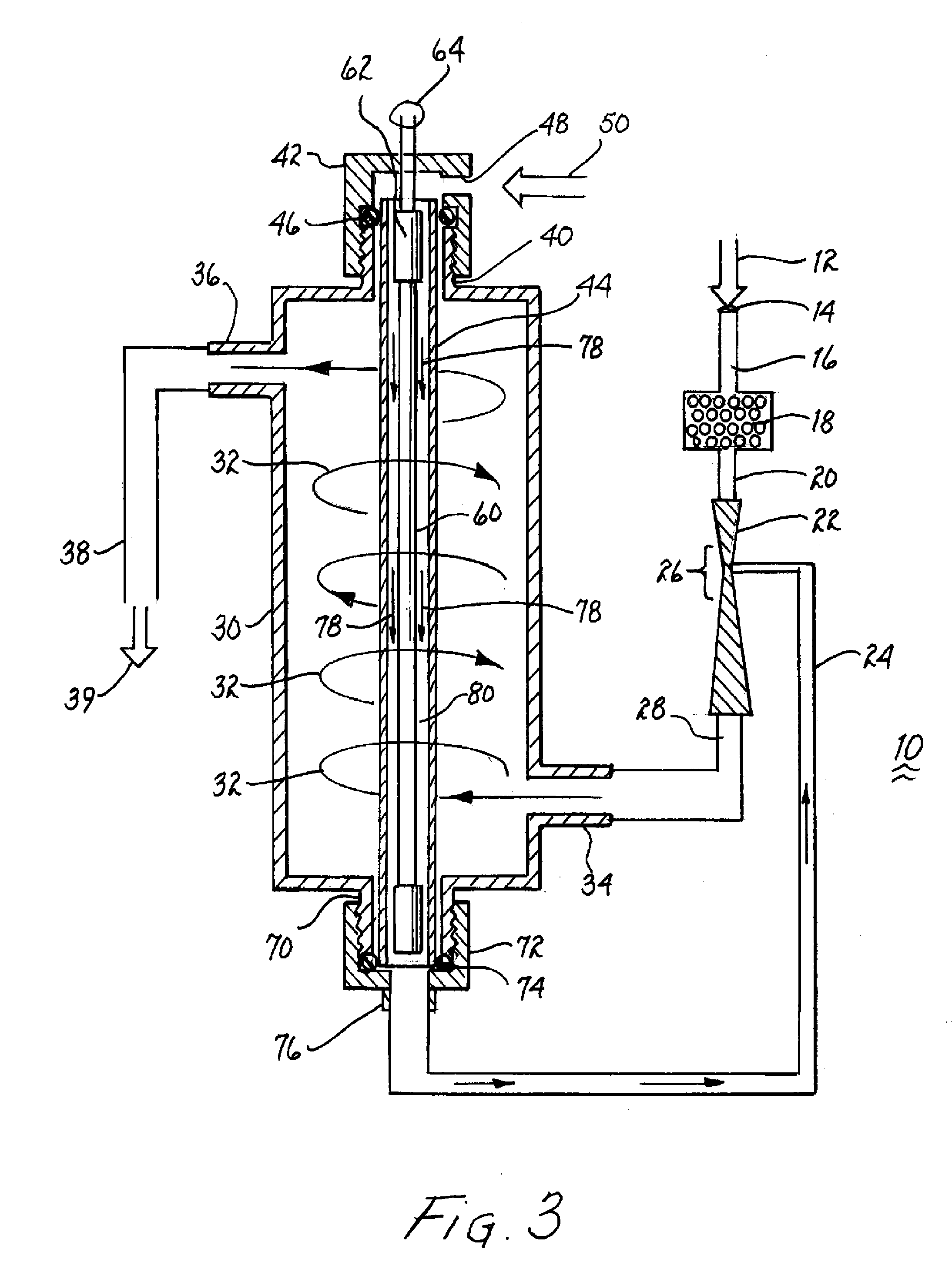

Apparatus and method for preventing biological regrowth in water

InactiveUS20080142452A1Prevent biological regrowthUnexpected levelSemi-permeable membranesWater/sewage treatment by irradiationOrganic matterOxygen

A flow of oxygen containing gas is irradiated with UV light to convert oxygen molecules to ozone molecules and produce an ozonated gas. Water to be treated is augmented with silver prior to entraining the ozonated gas in the water. The ozone enriched water containing silver is irradiated with UV light to produce hydroxyl radicals. Whereby, microorganisms are killed by the UV radiation, organic matter is oxidized by the ozone and the combination of silver and hydroxyl radicals prevent downstream growth of bio-film contamination.

Owner:ZUCO WATER LLC

Constructed wetland composite filling material for water treatment and preparation method thereof

InactiveCN102485663AWide variety of sourcesLow costOther chemical processesBiological water/sewage treatmentPorosityConstructed wetland

The invention discloses a constructed wetland composite filling material for water treatment and a preparation method thereof. The constructed wetland composite filling material for water treatment is composed of small balls having sizes of 8 to 17 millimeters and comprises: by weight, 10 to 20% of sludge, 20 to 30% of red mud, 5 to 10% of straw carbon, 3 to 8% of sodium silicate, 1 to 5% of kaolin, 6 to 15% of white cement and the balance water. The preparation method comprises the following steps of carrying out dehydration, drying and crushing processes respectively on sludge and red mud, crushing and carbonizing straw, mixing sodium silicate, kaolin, white cement, the obtained straw carbon, the crushed red mud and the crushed sludge according to a certain ratio, adding water into the mixture, stirring to obtain small balls having sizes of 8 to 17 millimeters, heating the small balls at a temperature of 80 to 250 DEG C, carrying out heat preservation, naturally cooling to room temperature, and drying in air. The constructed wetland composite filling material for water treatment has wide raw material sources, a low cost, good hydrophily, a large specific surface area, high porosity, strong adsorptivity and good bio-film formation effects, and improves sewage pollutant removal effects produced by a constructed wetland.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Composite microelectrolytic/biomembrane reaction apparatus and its sewage treating method

InactiveCN1935690AImprove processing efficiencySmall footprintTreatment using aerobic processesSustainable biological treatmentActivated carbonFlocculation

The invention relates to a combined microelectrolytic / biological membrane reactor and the sewage treating method thereof, relating to a sewage treating reaction device and method. And it comprises first microelectrolytic / biological reaction tank, flocculation tank, first settling tank, second microelectrolytic / biological reaction tank, third microelectrolytic / biological reaction tank and second settling tank, where the first microelectrolytic / biological reaction tank holds microbe inoculating iron chips filling layer and activated carbon filling layer. And the invention has advantages of high organic pollutant treating efficiency, sewage denitrification, no electrode passivation, simple process flow, less occupied area, etc.

Owner:HARBIN INST OF TECH

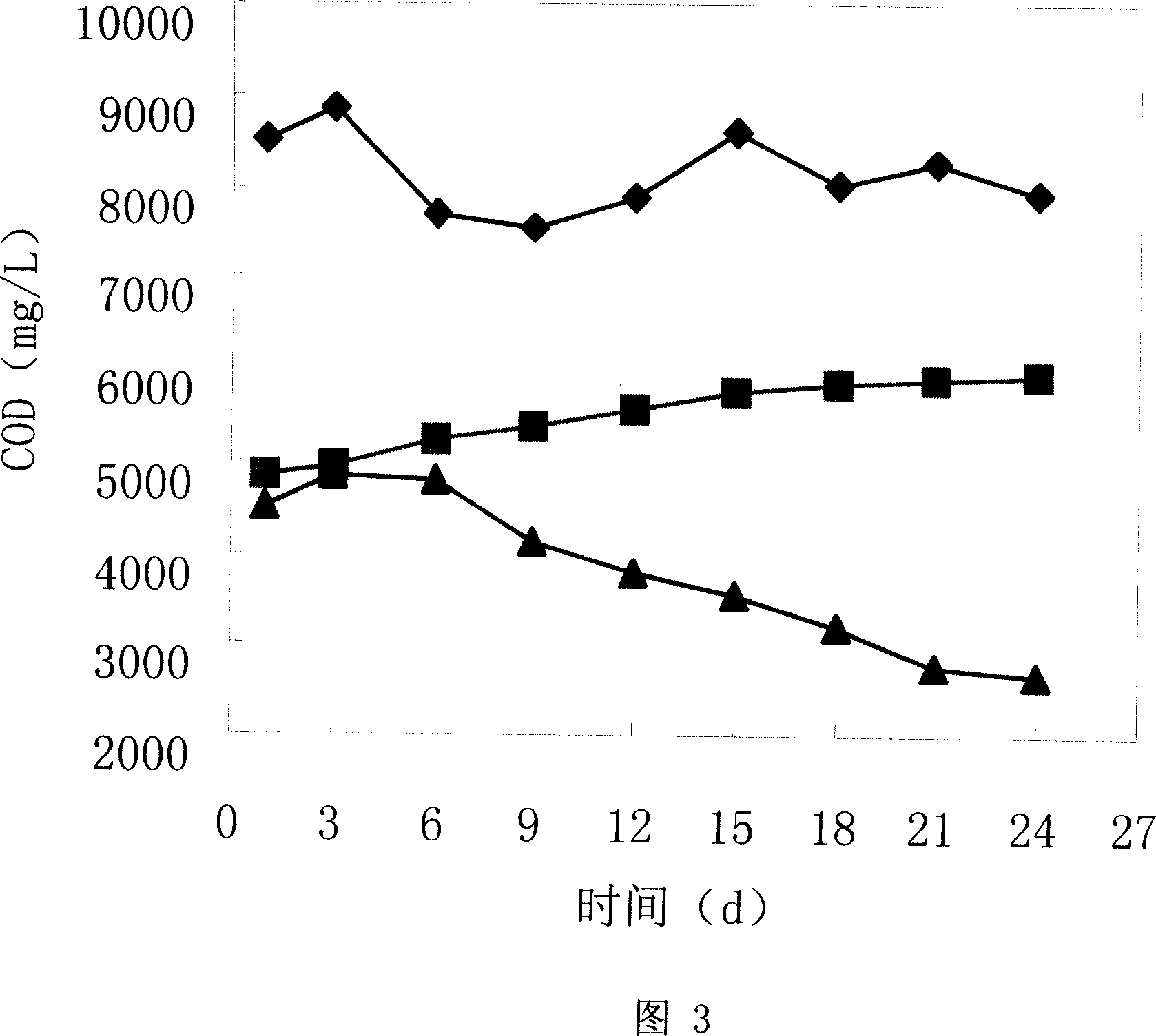

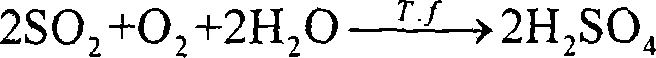

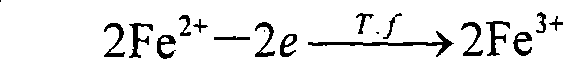

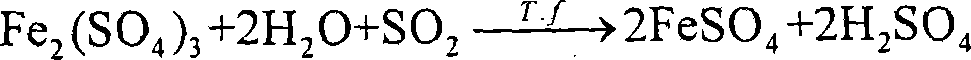

Method for removing sulfur-dioxide in smoke by bamboo-carbon filler biological drip filtering tower

InactiveCN101073745AHigh removal rateImprove sulfur recoveryDispersed particle separationAir quality improvementSulfateSulfur

The invention is concerned with a method to remove sulfur dioxide of gas and smoke through bio-trickling filter tower with bamboo-carbon filler. The nutrient source spray on the filling inside the tower form the top of bio-trickling filter tower and run into the filling from up to down and enter the circulation gutter on the bottom of tower, then go back to the top of tower by circulation gutter. Meanwhile the gas and smoke with sulfur dioxide enter form the bottom of tower, during the rising process, it is cleaned by the bio-film with fixed desulfuration bacteria and discharged form the top of tower. The filling is the pretreatment bamboo-carbon and it is fit for getting Ferrous Sulfate desulfuration byproduct. The bamboo-carbon owns developed holes and strong adsorption ability to form steady and high active bio-film and to remove the sulfur dioxide. It has wide application future to callback sulfur with low cost.

Owner:NANJING UNIV

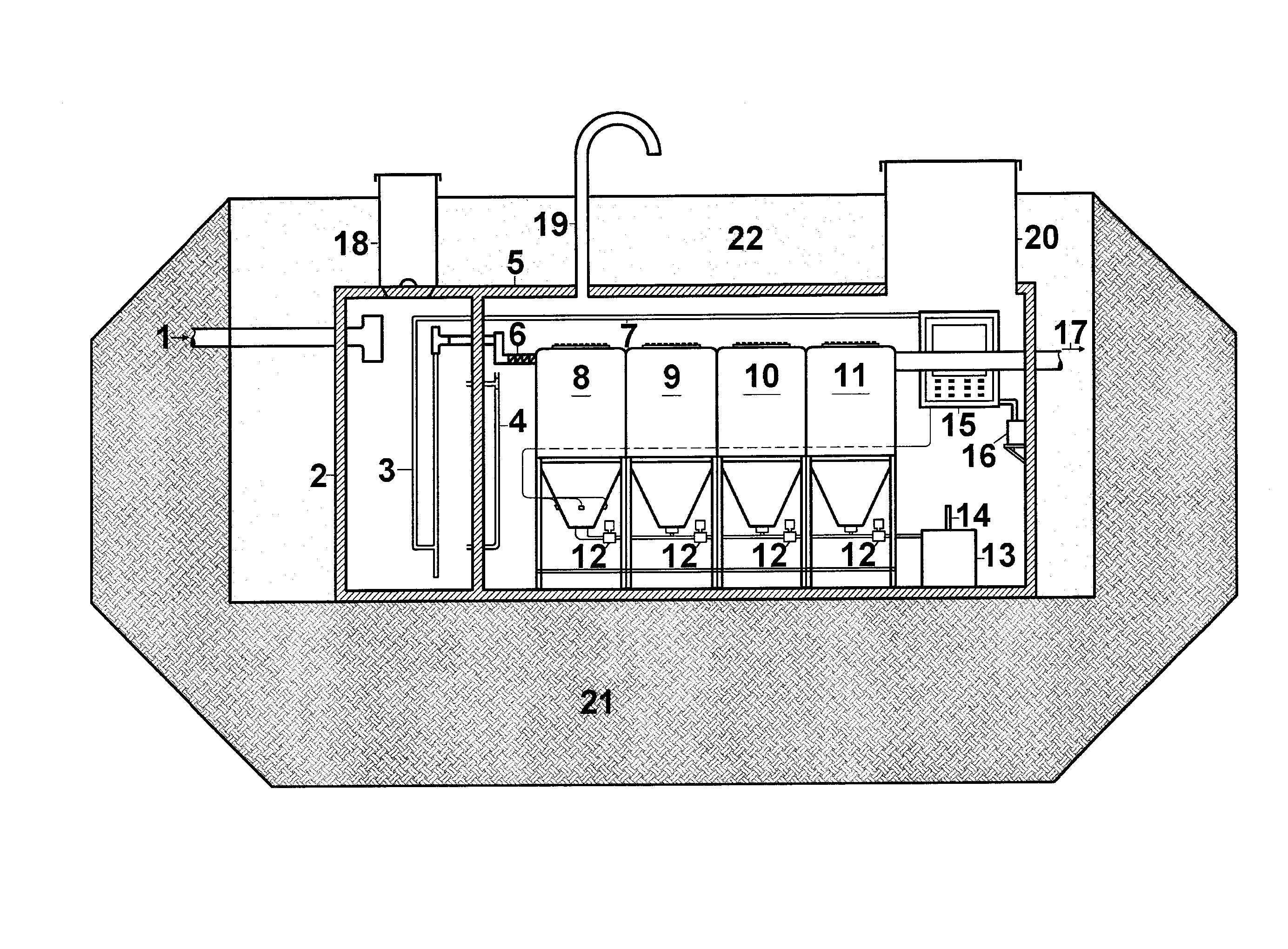

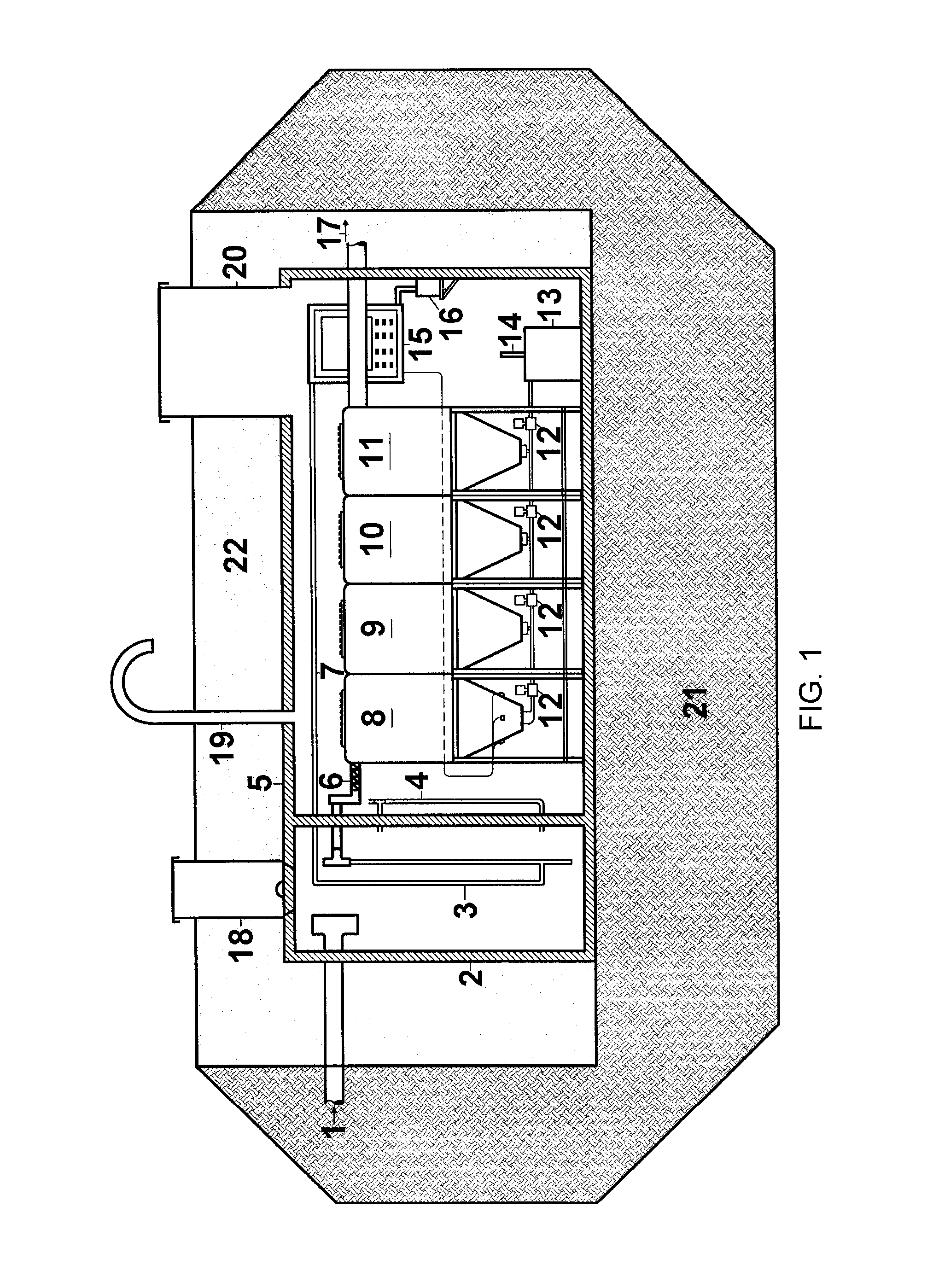

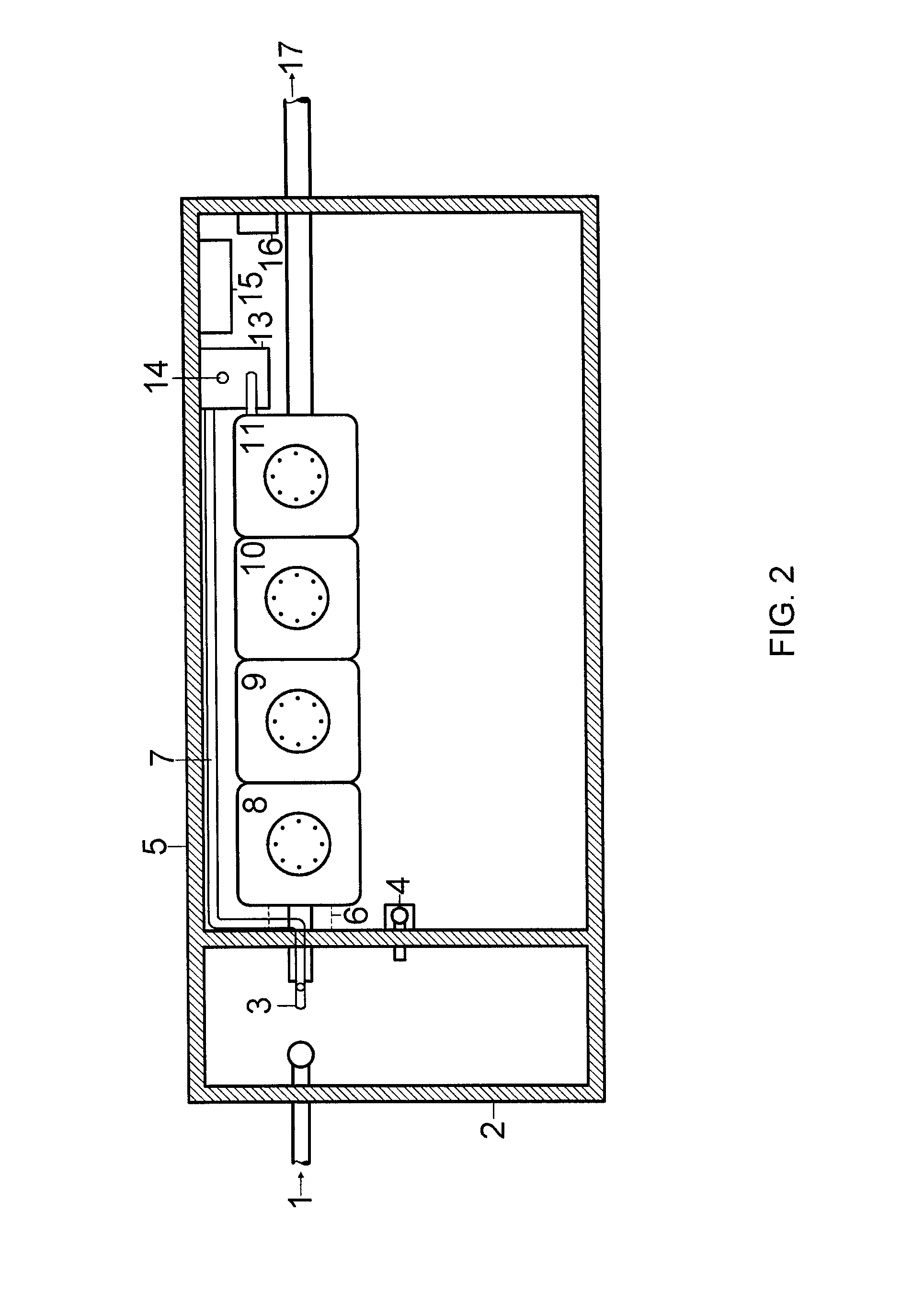

Modular individual wastewater nutrient removal system

ActiveUS8318008B1Avoid disturbanceMixing methodsBiological treatment regulationTotal nitrogenNitrogen gas

A modular, on-site, wastewater treatment system removes total nitrogen, phosphorus, BOD, and TSS. A flow equalization module provides a constant flow rate to the system eliminating the adverse effects from variations in flow rate throughout the day. Treatment modules are similarly sized to provide a compact, modular system. The nitrification module is a fixed-film, flooded packed bioreactor to facilitate bioconversion of ammonia to nitrate. Aeration of the module provides the oxygen needed for the bioconversion as well prevents clogging of the film. Solids from the nitrification process are removed in a first cone-shaped settling tank. De-nitrification where nitrate is converted to nitrogen gas takes place in an anaerobic fixed-film bioreactor. Carbon-based bio-film carriers provide a carbon source for de-nitrification. A final cone-shaped settling tank separates solids from the treated wastewater. Additional modules to address removal of phosphorous or other contaminants can be added to the modular system.

Owner:SEPTICNET

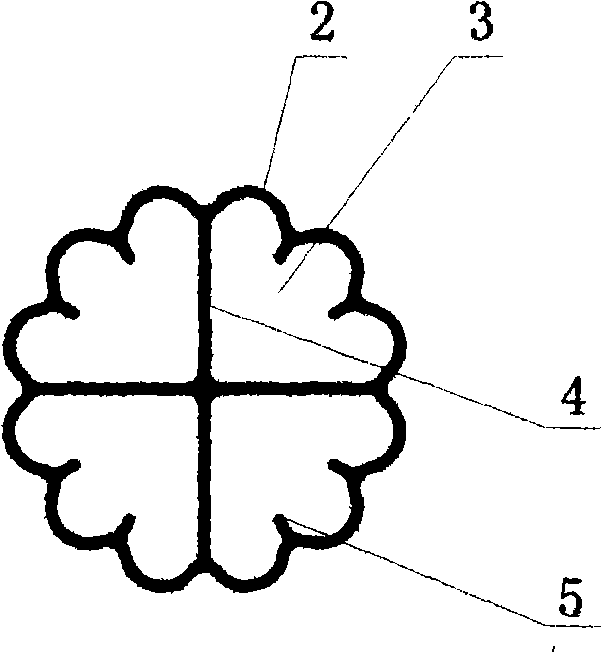

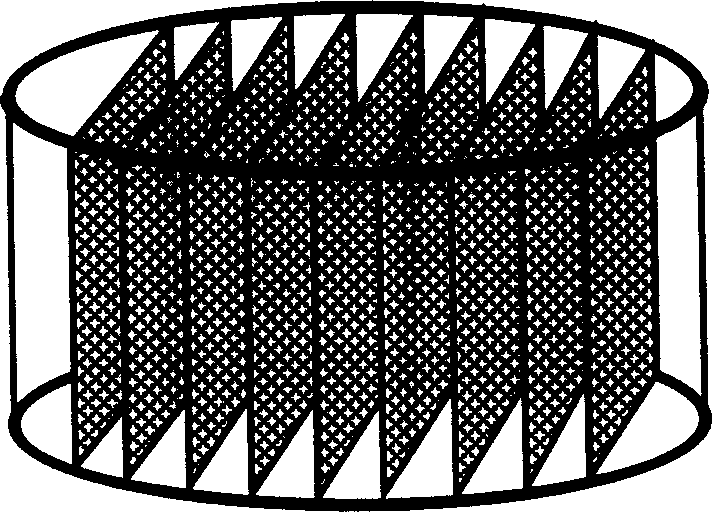

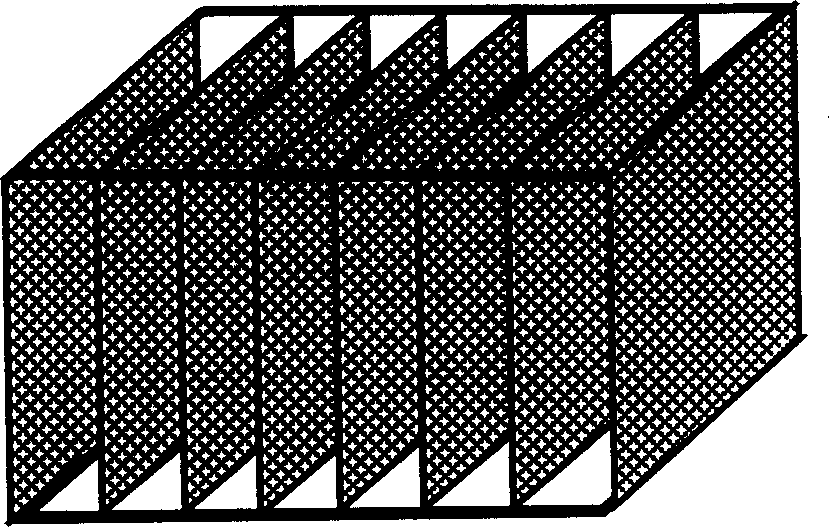

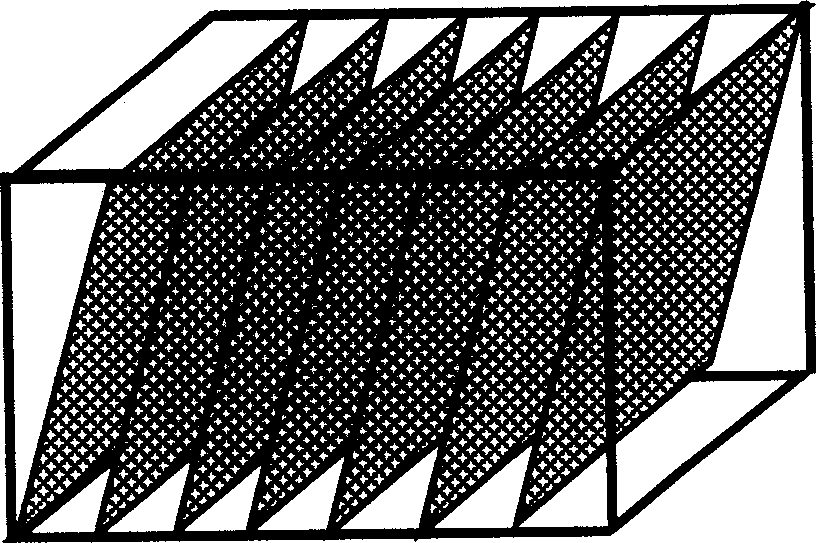

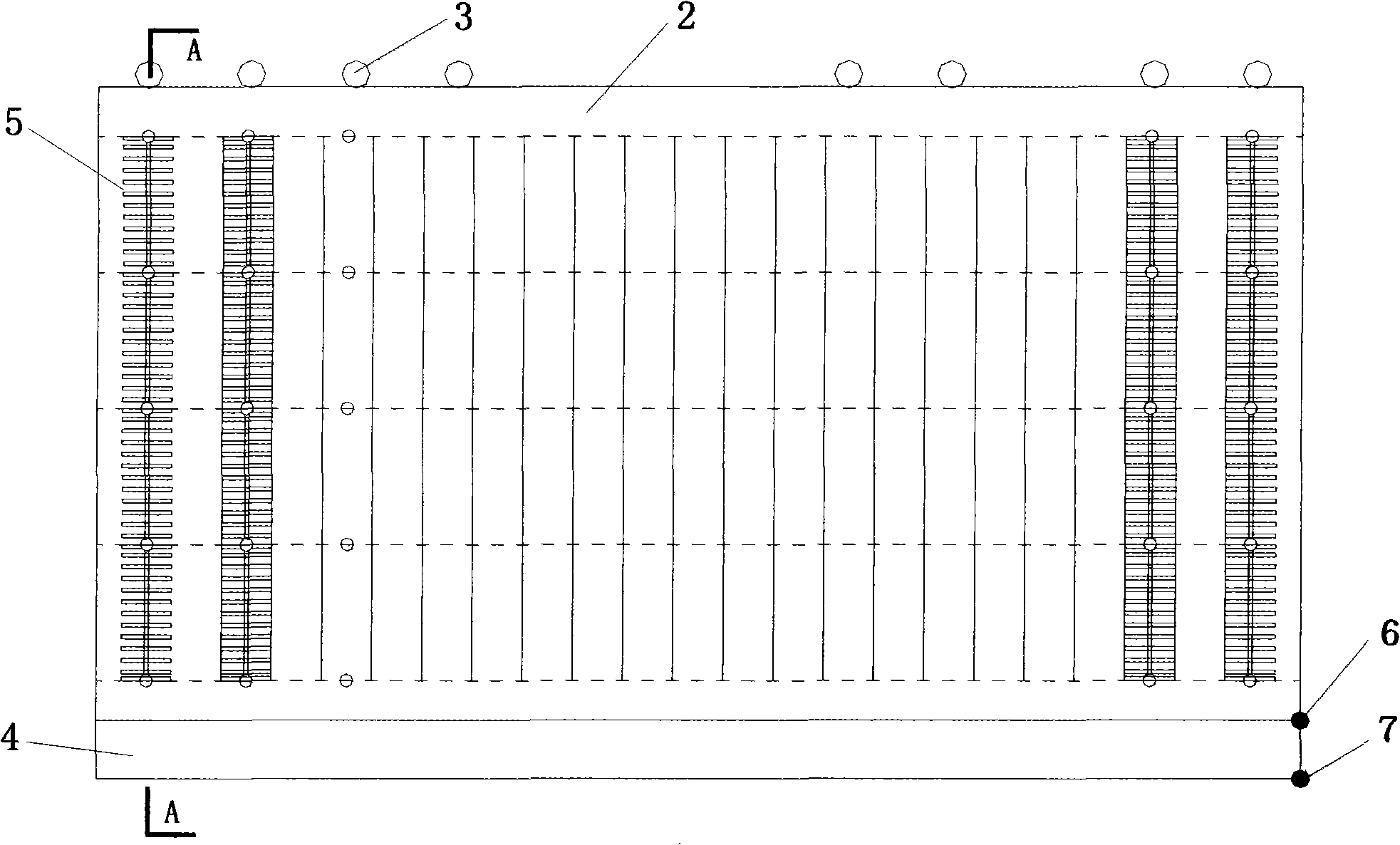

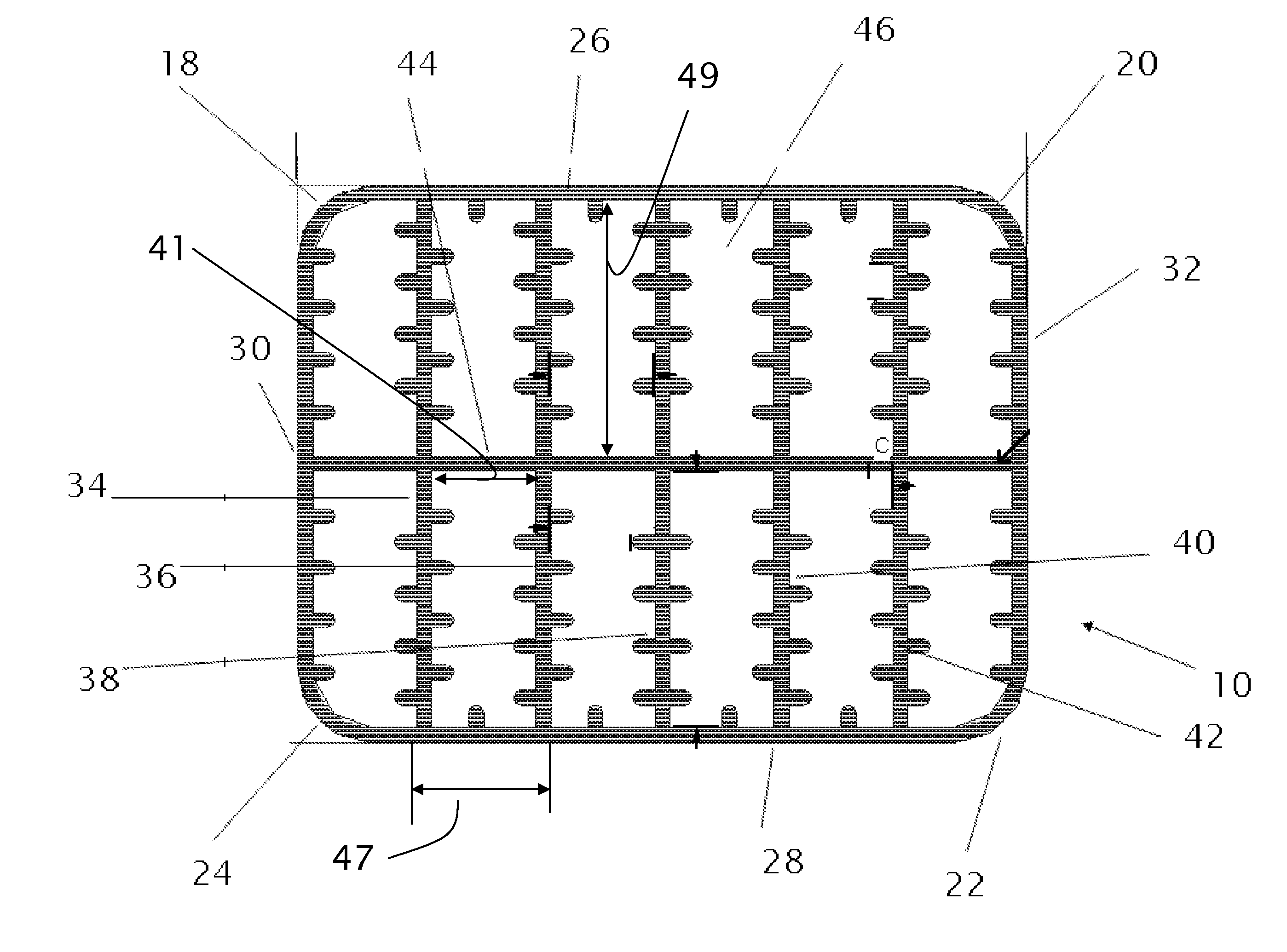

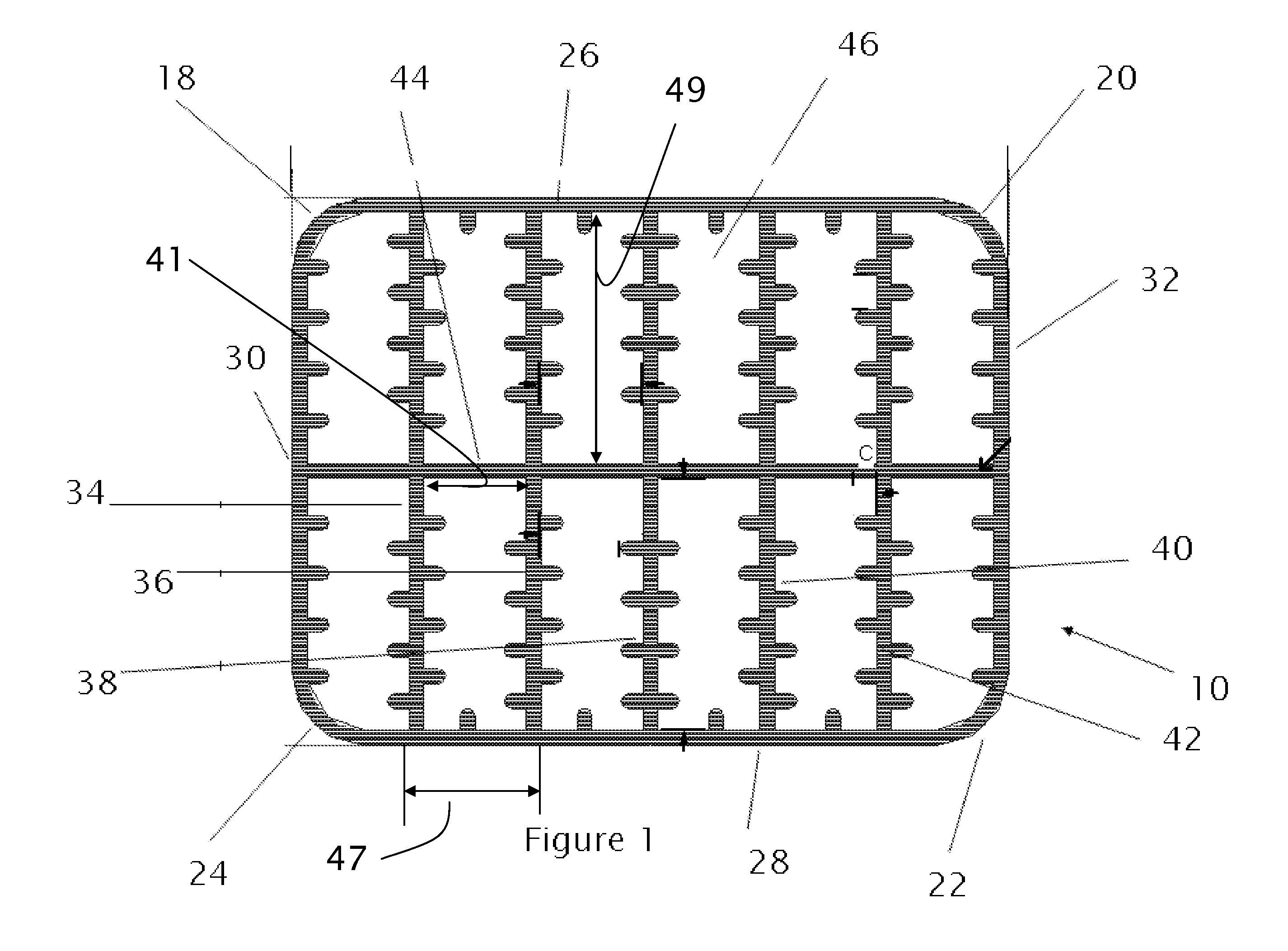

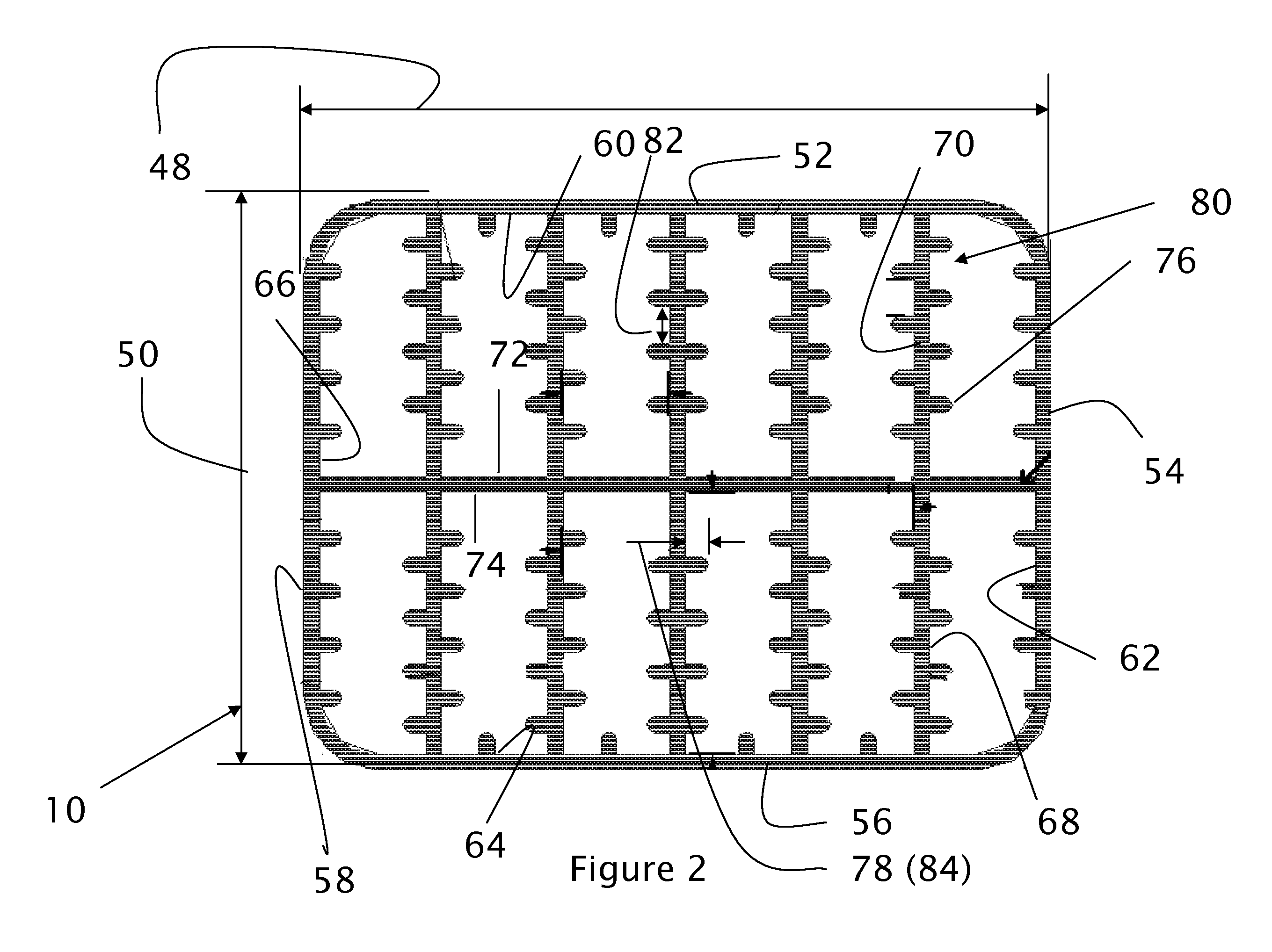

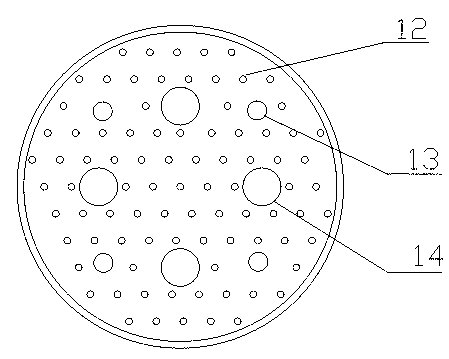

Biological filler and preparing method and apparatus constructed thereof and use

InactiveCN1508081AGood adhesionPromote growthDispersed particle separationSustainable biological treatmentCross-linkBiological filter

The present invention relates to a biological filter, its preparation method, equipment formed from it and its application. Said invention comprises peripheral structure frame, carrier which is formed from biomembrane leaf frame and is placed in the above-mentioned peripheral structure frame and high-molecular material cross-linked polymer biomembrane on which the effective mycetocyte is inlaid, and every biomembrane leaf frame and bottom plane of the peripheral structure frame are formed into 10 deg-90 deg. angle. Said invention can be used for treating industrial waste gas containing malodor and organic pollutant components so as to attain the goal of purifying gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

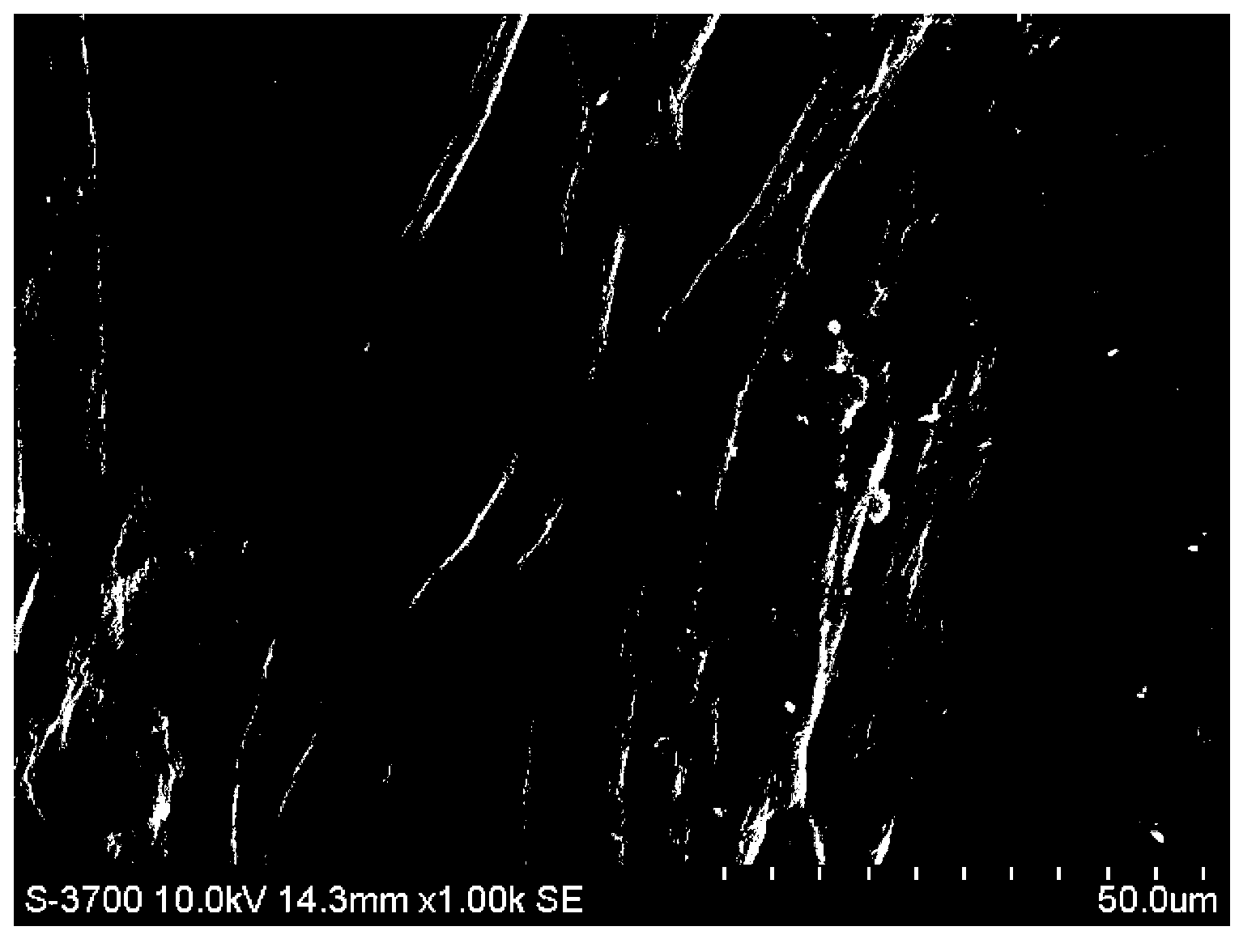

Method for preparing modified composite biological filler

InactiveCN106867607AImprove stabilityGood effect of hanging filmGaseous fuelsBiological water/sewage treatmentPolyvinyl chlorideGrowth promoting

The invention discloses a method for preparing a modified composite biological filler and belongs to the technical field of environmental protection. According to the method, polyvinyl chloride polyhedral hollow spheres serve as a carrier, are subjected to compound-acid oxidation and then are subjected to acrylic acid grafting modification; through introducing oxo polar groups, the surface roughness and microbial film hanging performance are improved, the specific surface area and microbial attachment area are increased; due to adsorption removal capability of zeolite, vermiculite and activated charcoal to wastewater, luffa cylindrica is subjected to carbonizing treatment and then is compounded with the zeolite and the vermiculite, and FeAl precipitates are adsorbed; FeAl oxide doped composite powder is prepared through high-temperature calcination, so as to further improve the adsorption removal capability; meanwhile, due to biological film growth promoting action of Fe, the film hanging time is shortened; and finally, the composite powder is stuck to surfaces of the modified polyvinyl chloride polyhedral hollow spheres treated with polyvinyl alcohol, so as to prepare the modified composite biological filler. The prepared modified composite biological filler has the advantages that the stability is good, the specific surface area is large, the surface is rough, and biological films are difficult in falling-off.

Owner:CHANGZHOU UNIV

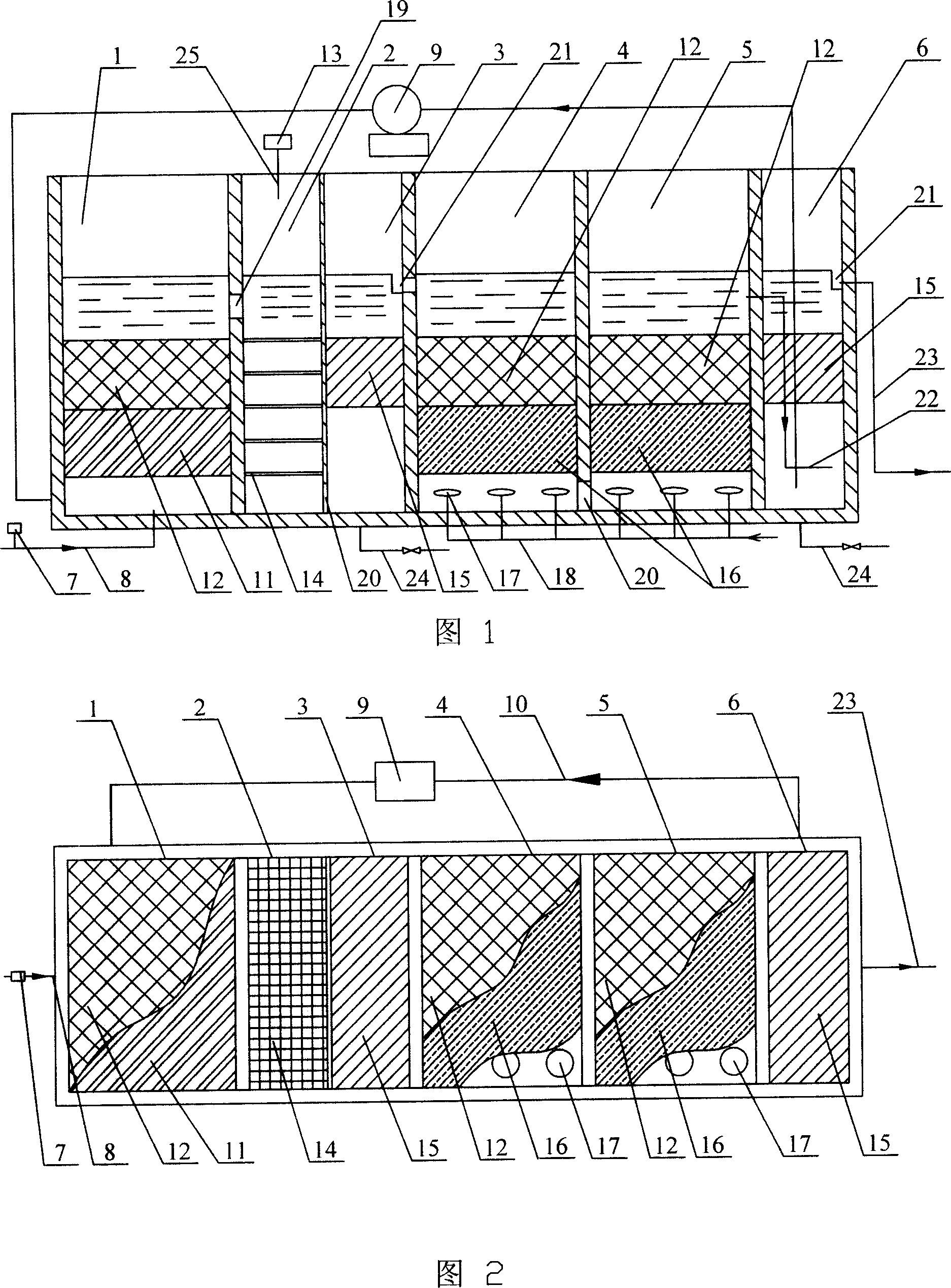

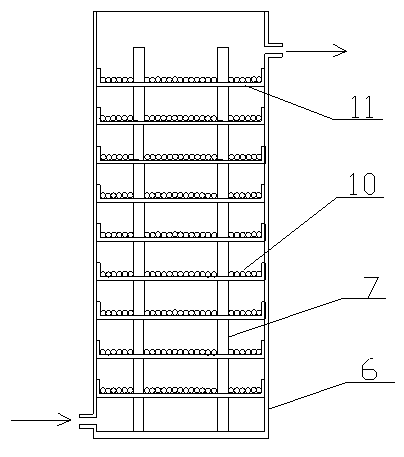

Novel internal circulation moving bed biological film reactor

InactiveCN101565238ACompact structureSimple and fast operationTreatment with aerobic and anaerobic processesNitrogen removalSludge

The invention relates to an internal circulation moving bed biological film reactor, which is separated into an anaerobic zone and an aerobic zone by three layers of combined perforated boards. The top of the combined perforated boards is provided with a porosity regulating bolt. A suspension filler is filled in the reactor. The anaerobic zone is installed with an undercurrent pump on the bottom in front and a guide plate in middle. A clockwise hydraulic circular flow is formed in the anaerobic zone under the pushing of the undercurrent pump. The aerobic zone is equipped with an aeration head on the bottom at back and a guide plate in middle. An anticlockwise hydraulic circular flow is formed in the aerobic zone under the action of aeration. The mixing liquid is refluxing from the aerobic zone to the anaerobic zone, driven by the opposite circular flows of two zones, thus efficiently removing the organic matter and realizing nitrogen removal by nitrifying and denitrifying. A waterinlet is arranged on the bottom in the front of the reactor. An overflow weir and a water outlet are arranged on the top of the back end. A sludge outlet is located on the bottom. The reactor has compact conformation and high treatment efficiency.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method for manufacturing artificial float grass and uses thereof

InactiveCN101254975AThe purpose of strengthening water purificationIncrease concentrationWater resource protectionSustainable biological treatmentAquatic weedsEngineering

The invention provides an artificial simulated aquatic weed manufacturing method. The invention adopts the method that natural aquatic weed is used as a template, a platy soft foam plastic floating type framework in a middle layer is used as a solid bracket, mixed fiber layers are bonded on the both sides of the surface, and therefore an artificial simulated aquatic weed main body is manufactured by adopting the three-layer composite structure; a plurality of floating balls are arranged at the upper end of the artificial simulated aquatic weed main body equidistantly, a balance sand bag is arranged at the lower end, and therefore the artificial simulated aquatic weed is manufactured. The mixed fiber of hydrophilic fiber and hydrophobic fiber is used as a biological film carrier, the surface characteristic and the physicochemical index parameter of the manufactured artificial simulated aquatic weed are good, the specific surface area is large, the hanging of the biological film is perfect, and the operating performance is steady; the structural design is reasonable, the installation is simple, the production cost is low, and the application is diversiform.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Preparation method of collagen matrix composite biological film for guided tissue regeneration

The invention discloses a preparation method of a collagen matrix composite biological film for guided tissue regeneration. The method comprises the following steps of dissolving collagen in an acid solution, adjusting pH (potential of hydrogen) of an obtained solution to be alkaline, continuing to add an inorganic powder material, uniformly stirring, adjusting pH of an obtained solution to be neutral, centrifuging, removing a supernate, collecting a collagen composite film, allowing the obtained collagen composite film to be subjected to mold forming, freeze-drying, using a physical or / and chemical method for crosslinking, and obtaining the collagen matrix composite biological film.

Owner:GUANGZHOU PUDAO LIANXIN BIOTECH CO LTD

Process for cleaning surfaces of medical equipment

InactiveUS7198680B1Effective penetrationProcess environmental protectionSurface-active detergent compositionsDetergent mixture composition preparationDisposal wasteWater soluble

A method for cleaning contaminated surfaces of surgical waste management equipment. The method includes rinsing surfaces of the equipment with water to remove water soluble contaminants and waste material. A rinse solution is applied to the surfaces of the equipment to provide a residual film thereon. The rinse solution includes a first nonionic nonylphenol surfactant having an HLB value ranging from about 10 to about 15, a second nonionic nonylphenol surfactant having an HLB value ranging from about 16 to 20, a bio-film permeation agent, and an aqueous solvent. A total of the first surfactant and the second surfactant in the solution ranges from about 2 to about 20 percent by weight of a total weight of the solution and a ratio of the second surfactant to the first surfactant in the solution ranges from about 2:1 to about 4:1.

Owner:STRYKER CORP

Manufacturing method of biological stuffing for processing degradation-resistant wastewater

InactiveCN103058357ABiodegradableGood biocompatibilityByproduct vaporizationBiological water/sewage treatmentYarnBiocompatibility Testing

The invention relates to a manufacturing method of biological stuffing for processing degradation-resistant wastewater; the method comprises the following steps of: mixing gamma-calcium glutamate polymer with polypropylene with the dose of 0.3% to 0.5% and then spinning, after non-woven fabric through a spinning-binding method is obtained, hot rolling at 150 DEG C to 160 DEG C or sizing by acupuncture or spunlace technology, so as to obtain the biological stuffing for processing degradation-resistant wastewater; or mixing gamma-calcium glutamate polymer with polypropylene with the dose of 0.3% to 0.5%, then extruding to be melt trickle by using a melt-blow die head assembly, stretching and cooling, forming net and binding automatically by using a cylinder type or plain net type receiving device, so as to obtain melt-blow method non-woven fabric, namely the biological stuffing for processing degradation-resistant wastewater is obtained. The biological stuffing prepared by the manufacturing method for processing degradation-resistant wastewater has the following characteristics of biodegradability, excellent biocompatibility, high water-retaining property, no toxicity and harm to human body, high microorganism bio-film culturing amount, high impact resistance, high purifying efficiency, and the like; can be widely used for processing degradation-resistant wastewater; and compared with the biological stuffing made of plastic injection molded parts or chemical fiber yarns, the purifying efficiency is improved by 30%.

Owner:SHANGHAI HONESS ENVIRONMENTAL PROTECTION EQUIP TECH CO LTD

Water purification and treatment apparatus and treatment process using the apparatus

InactiveUS20080011659A1Large amount of processingAddressing slow performanceTreatment using aerobic processesLiquid displacementFiltrationWastewater

The present invention provides a water purification and treatment apparatus using a combination of sedimentation, filtration, and bio-contact aeration processes, which comprises at least one rapid water purification filter having a hopper base for settled sludge and a filtering tank; at least one cylindrical settling basin for sedimentation and filtration; and at least one aeration basin having an under water and an over water bio-film contact parts, for rapidly filtering raw water or wastewater contacted with bio-contact aeration, and performing water purification and treatment.

Owner:CHENG JIAN RUNG +1

Method for domestic sewage treatment

InactiveCN104261632AHigh removal rateGood effectTreatment using aerobic processesWater contaminantsEngineeringSewage

The invention discloses a method for domestic sewage treatment. The method comprises the following steps: enabling the sewage to flow through a grating to remove thick and big solid sundries in the sewage; then feeding the sewage into a settling tank to carry out sedimentation treatment; carrying out aerobic treatment process, carrying out processing by a bio-film carrier layer, finally carrying out flocculation treatment, and carrying out other steps. The processing method is simple in process, good in effect, high in color removal rate, low in COD (Chemical Oxygen Demand) and BOD (Biochemical Oxygen Demand), high in phosphorus removal rate, small in solid residual volume, low in cost and suitable for popularization.

Owner:CHUZHOU YOULIN TECH DEV

Method for mainly cultivating sea cucumber in pond in high-yield and high-efficiency poly-cultivating manner

InactiveCN101822232APromote formationClimate change adaptationPisciculture and aquariaShrimpRhopilema esculentum

The invention discloses a method for mainly cultivating a sea cucumber in a pond in a high-yield and high-efficiency poly-cultivating manner. The method is characterized by comprising (1) putting cucumber reefs into a cultivation pond; (2) then putting and cultivating young sea cucumbers in the cultivation pond; (3) putting and cultivating young jelly fish; (4) putting and cultivating young shrimps; and (5) putting and cultivating young escallops. According to the method for cultivating the sea cucumber, manual cucumber reefs are put in advance to promote the formation of edible biomembranes for the sea cucumber, so that the put young sea cucumbers can obtain abundant natural baits; and the aims of high yield, high efficiency and environmental protection are achieved by using the different diets, cultivation water layers and cultivation time of the sea cucumber, the jelly fish, the shrimps and the escallops and putting and cultivating the sea cucumber, the jelly fish, the shrimps and the young escallops in a vertical and time interleaving manner.

Owner:OCEAN UNIV OF CHINA

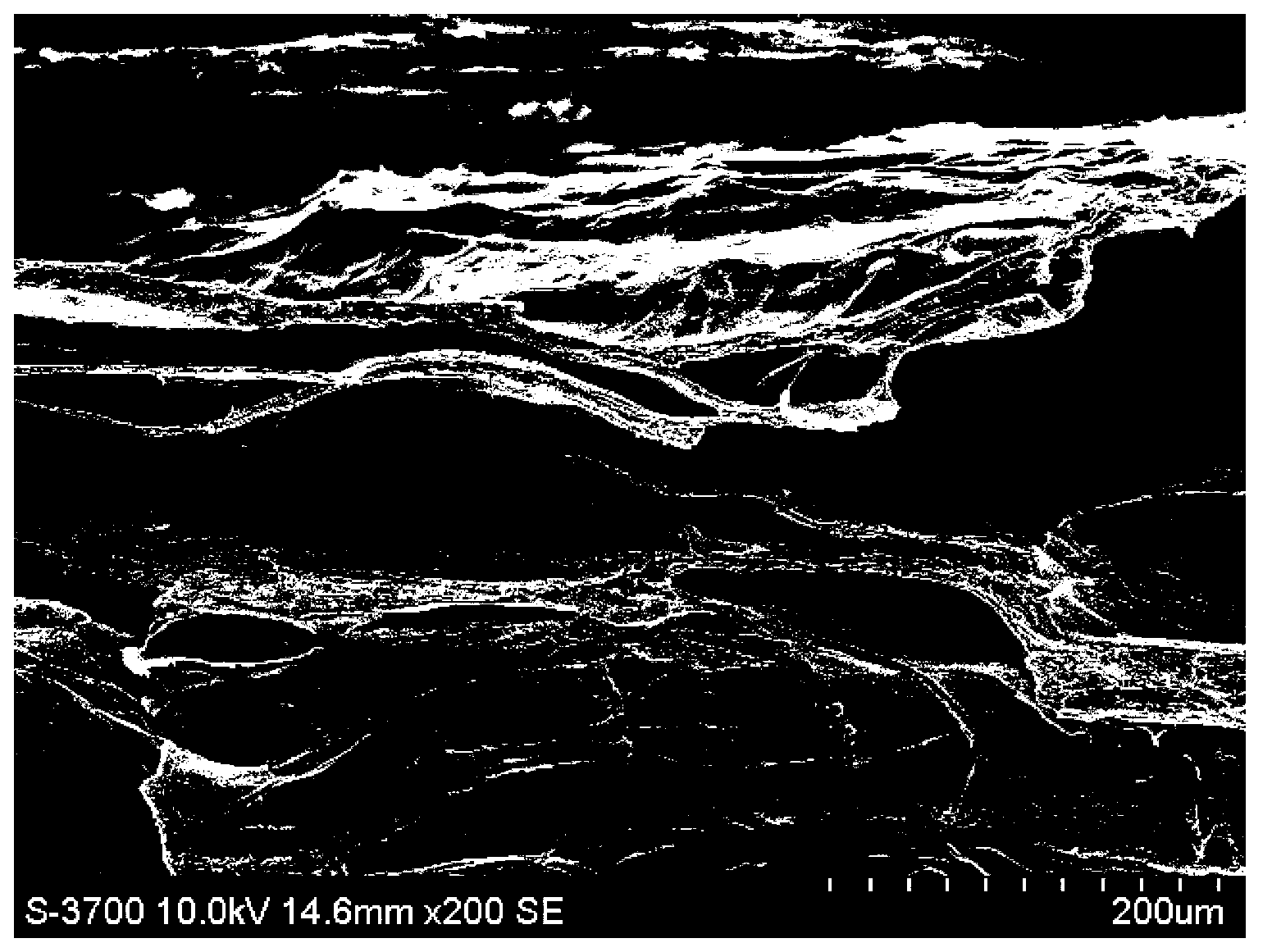

Biomass carrier promoting simultaneous nitrification-de-nitrification

InactiveUS7527728B2Improve abilitiesLow yieldSynthetic resin layered productsCellulosic plastic layered productsWastewaterBio film

Owner:JACKSON DAVID

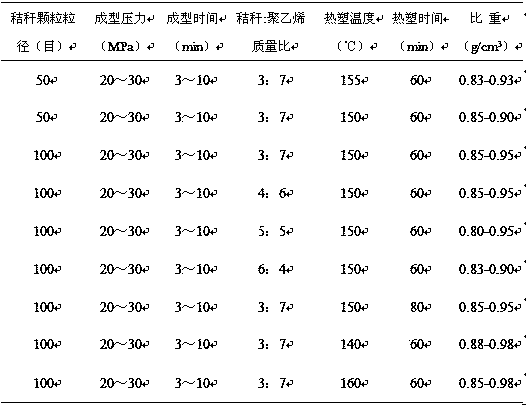

Method for preparing biomass microbial carrier

InactiveCN103818998AHigh efficiency loadOptimal loadBiological water/sewage treatmentWastewaterMicrobiology

The invention discloses a method for preparing a biomass microbial carrier. The method comprises the following steps: smashing a biomass to obtain particles of 50 to 200 mesh; adding a polyethylene raw material according to the proportion of 10 to 90 percent; mixing the raw materials to be uniform; weighing 2 to 20 g of the mixture for a single piece; putting the weighed mixture into a mold; pressing for 1 to 15 minutes under 5 to 40 MPa; demoulding; carrying out thermal shaping for 10 to 80 minutes at 140 to 160 DEG C; taking out the shaped product; cooling to obtain a biomass microbial carrier sample. The method is simple in process and low in product cost, and is a new method for preparing a high-load durable biological film carrier simply and easily; the product can be used in the microbe treatment technology of various special waste water, and has a wide market prospect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

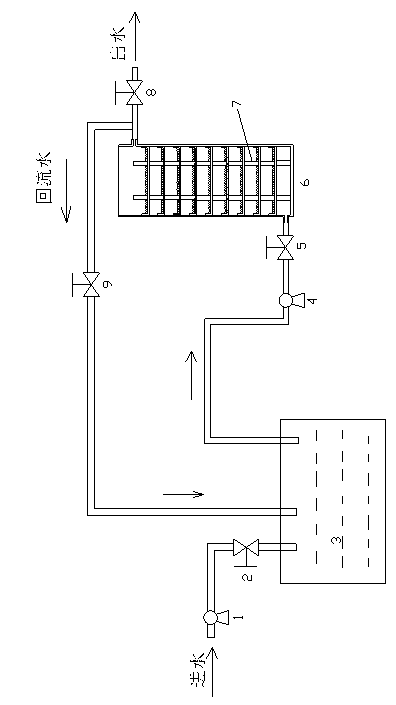

Novel photocatalysis filter tank device and water treatment system

InactiveCN102701317APrevent slippingEasy to disassembleWater/sewage treatment by irradiationWater/sewage treatment by oxidationSludgeLight energy

The invention discloses a novel photocatalysis filter tank device and a water treatment system. The filter tank device consists of a device outer wall, an ultraviolet lamp tube, a tower tray support column, a filter material and a filter material tower tray, wherein a transparent glass bead carrier is taken as the filter material, and waste water is treated by a nanometer TiO2 film with the capability of effectively degrading organic pollutants through photo-catalytic oxidation under the irradiation of ultraviolet light.. The water treatment system mainly comprises a filter bed, an illumination system, a water distribution system and a backflow system. The novel photocatalysis filter tank device organically combines the conventional biomembrane filtering tank with the advanced photocatalysis treatment process, is ingenious in design and compact in layout, allows a light source to be uniformly distributed in the filter material, has a good hydraulic power condition, can fully utilize light energy, does not need aeration, does not generate sludge and secondary pollution, is convenient to operate and simple to maintain, is high in water-quality purification efficiency and sterilization capability, and is mainly applied to the fields of reclaimed water reuse, deep sludge (waste) water treatment and the like.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com