Composite moving bed bio-film reactor

A technology of moving bed biofilm and reactor, which is applied in the field of compound moving bed biofilm reactor, can solve the problems such as unsatisfactory treatment effect, and achieve the effects of less floor space, large amount of loss prevention and long contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

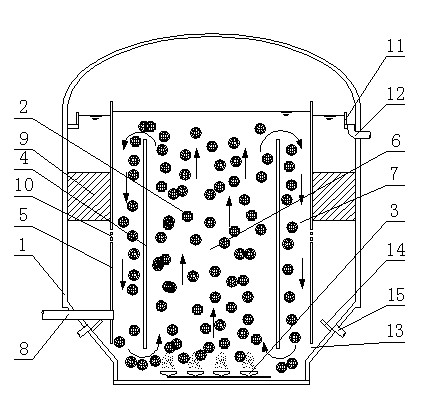

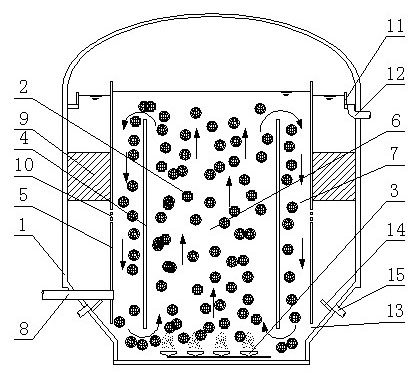

[0037] In order to clearly illustrate the technical characteristics of this program, a specific implementation will be adopted below, combined with its

[0038] Accompanying drawing, this scheme is described.

[0039] As shown in the accompanying drawings, the present invention is a composite moving bed biofilm reactor, which includes a reactor body 1 in which hollow ball fillers 2 are put in, and the inner bottom of the reactor body 1 is provided with a gas device 3, the reactor body 1 is also provided with two sets of inner cylinder 4 and outer cylinder 5, the upper and lower openings of the inner cylinder 4 and outer cylinder 5 are completely open, and the height of the inner cylinder 4 is lower than The outer cylinder 5, the inner space of the inner cylinder 4 is an upflow zone 6, the space between the inner cylinder 4 and the outer cylinder 5 is a downflow zone 7, and the downflow zone 7 is also an oxygen-free zone; the wall of the outer cylinder The lower part of the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com