Inverted umbrella shaped aerator

An aerator and inverted umbrella technology, applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc. It can improve the power efficiency of oxygenation, enhance the oxygenation capacity, and increase the depth of aeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

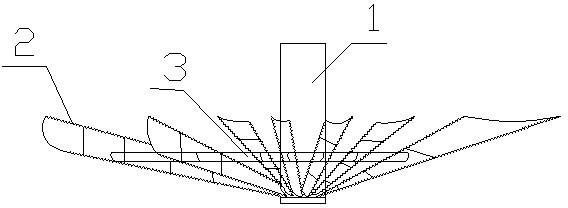

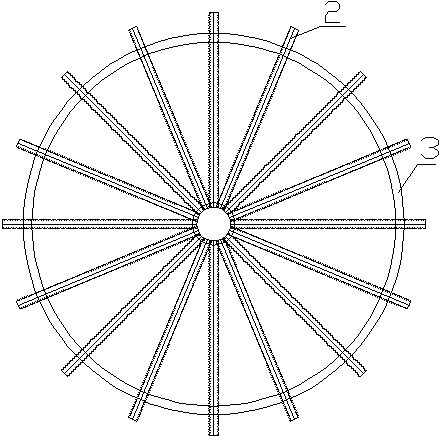

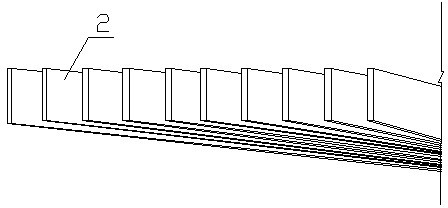

[0023] Embodiment: referring to the accompanying drawings, the inverted umbrella type aerator of the present invention has an inverted umbrella with an angle of 15 degrees with the horizontal plane on the central rotating shaft 1, and the umbrella surface is cut into a plurality of slices 2 with a width of 15 cm, with a slice radius of 1 m and a diameter of 1 m. There is a ring 3 connected and fixed to the near outer end, the bottom edge of the slice is jagged, and the plane of each slice is twisted 10 degrees below the liquid surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com