Method for preparing biomass microbial carrier

A microbial carrier and biomass technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. problem, to achieve the effect of low product cost, large specific surface area and good durability

Inactive Publication Date: 2014-05-28

SOUTHWEAT UNIV OF SCI & TECH

View PDF9 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

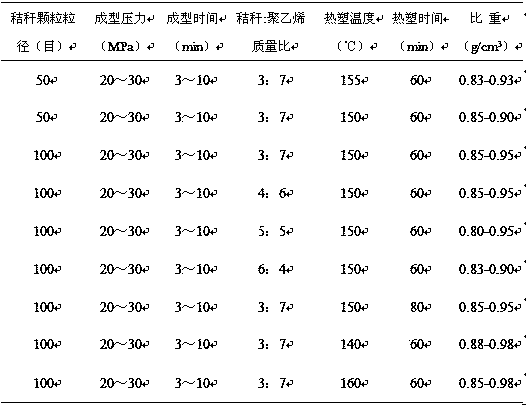

[0025] Example Table 1 Preparation of wheat straw microbial carrier (unit: %)

[0026]

[0027] The percentages involved in the application documents of the present invention are mass percentages unless otherwise specified.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a method for preparing a biomass microbial carrier. The method comprises the following steps: smashing a biomass to obtain particles of 50 to 200 mesh; adding a polyethylene raw material according to the proportion of 10 to 90 percent; mixing the raw materials to be uniform; weighing 2 to 20 g of the mixture for a single piece; putting the weighed mixture into a mold; pressing for 1 to 15 minutes under 5 to 40 MPa; demoulding; carrying out thermal shaping for 10 to 80 minutes at 140 to 160 DEG C; taking out the shaped product; cooling to obtain a biomass microbial carrier sample. The method is simple in process and low in product cost, and is a new method for preparing a high-load durable biological film carrier simply and easily; the product can be used in the microbe treatment technology of various special waste water, and has a wide market prospect.

Description

technical field [0001] The invention relates to a method for preparing a biomass microbial carrier, which belongs to the technical field of resources and environment technology. Background technique [0002] In the water treatment method, the biofilm method is a method of sewage treatment using microorganisms (ie, microbial films) attached to and growing on certain solid surfaces. In recent years, it has been widely used in wastewater treatment due to its advantages of high treatment efficiency, impact load resistance, stable operation, small sludge output, economy and energy saving. Biofilm is an ecosystem composed of highly dense aerobic bacteria, anaerobic bacteria, facultative bacteria, fungi, protozoa and algae. The solid medium to which it is attached is called filter material or carrier. The carrier is the core part of the biofilm process and plays an important role in the aerobic, facultative and anaerobic processes. The material of the carrier, the specific surfa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F3/10C02F3/34

CPCB29B7/007

Inventor 代群威李琼芳黄金秀党政

Owner SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com