Modified charcoal, soil repairing agent and preparation method and application thereof

A soil remediation agent and biochar technology, which is applied in the restoration of polluted soil, application, soil conditioning materials, etc., can solve the problems of heavy metal-pesticide compound pollution, reduce the toxicity of pesticide-heavy metal compound pollution, and have no secondary pollution , significant environmental and economic advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

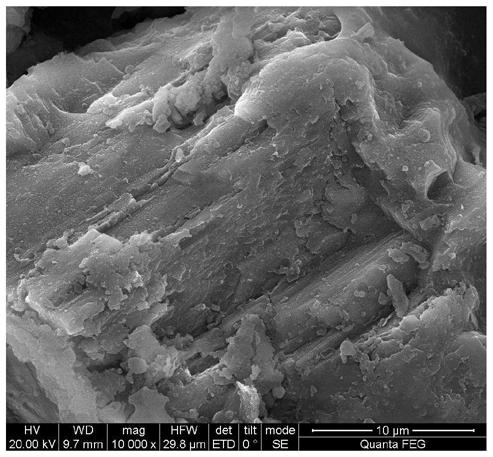

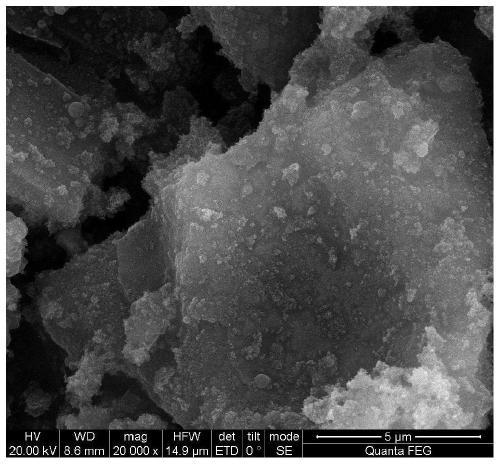

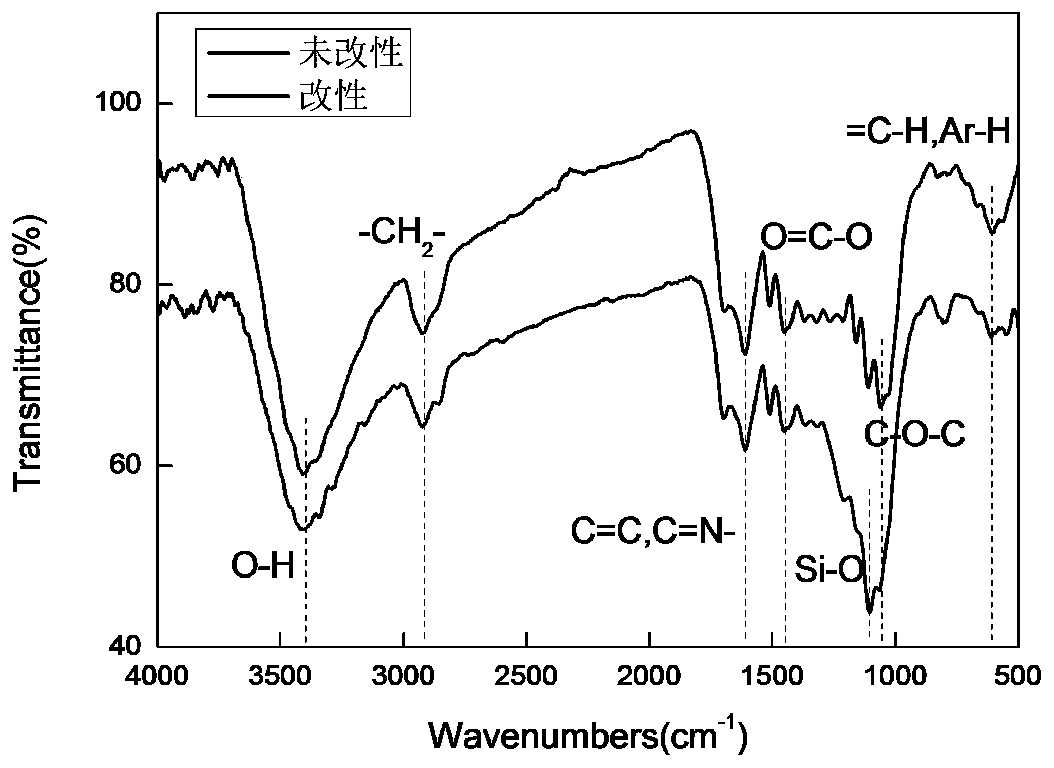

[0032] The present invention also provides a method for preparing the modified biochar described in the above technical solution, comprising: mixing the corn stalks, graphene oxide suspension, nano-SiO 2 Suspension and CaCl 2 After the solutions are mixed, carry out hydrothermal carbonization treatment to obtain hydrated carbon; dry the hydrated carbon to obtain modified biochar; the temperature of the hydrothermal carbonization treatment is 180-200°C; the time of the hydrothermal carbonization treatment For 16 ~ 20h.

[0033]In the present invention, the corn stalks are preferably crushed to obtain corn stalk powder. The method of crushing the corn stalks is not particularly limited in the present invention, and the corn stalks are preferably washed with water, air-dried and then crushed, and the particle size of the corn stalk powder obtained after the crushing is ≤250 μm.

[0034] In the present invention, there is no special limitation on the mixing method. Ultrasonic mi...

Embodiment 1

[0064] The preparation method of modified biochar:

[0065] (1) Wash the corn stalks with deionized water, air-dry, pulverize, and pass through a 60-mesh sieve;

[0066] (2) Preparation of 1% graphene oxide (GO) suspension: Dissolve 1 g of powdered GO in 100 ml of deionized water, and ultrasonically disperse in an ultrasonic disperser for 30 min to obtain a uniformly dispersed 1% GO suspension;

[0067] (3) 2% Nano SiO 2 Suspension preparation: 1g nano-SiO 2 Add it to 50ml of deionized water, move it into an ultrasonic disperser and disperse ultrasonically for 30 minutes to obtain 2% nano-SiO 2 suspension;

[0068] (4) 1.5% CaCl 2 Solution preparation: 1.5g CaCl 2 Add to 100ml deionized water and mix well to get 1.5% CaCl 2 solution;

[0069] (5) 50g of corn stalk powder, 20ml of 1% GO suspension, 2% nano-SiO 2 Suspension 15ml, 1.5% CaCl 2 25ml of the solution was mixed evenly, ultrasonically dispersed for 45min, transferred to a hydrothermal synthesis reactor, sealed...

Embodiment 2

[0073]The preparation method of modified biochar:

[0074] 50g of corn stalk powder, 10ml of 1% GO suspension, 2% nano-SiO 2 Suspension 25ml, 1.5% CaC l2 Mix 15ml of the solution evenly, disperse it ultrasonically for 30min, transfer it to a hydrothermal synthesis reactor, seal it, and react at a constant temperature of 180°C for 20h. After cooling to room temperature, take out the solid phase product, and then place it in an oven at 80°C for drying treatment. After drying for 16h, you can get Modified biochar GO / Si / Ca / BC. Corn straw powder, 1% GO suspension, 2% nano-SiO 2 Suspension and 1.5% CaCl 2 The preparation method of solution is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Effective viable count | aaaaa | aaaaa |

| Effective viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com