Synergistic biological polysaccharide anti-hardening agent and preparation method thereof

A technology of anti-caking agent and biological polysaccharide, which is applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve difficult and impossible problems, and achieve the effect of simple preparation method and good anti-caking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

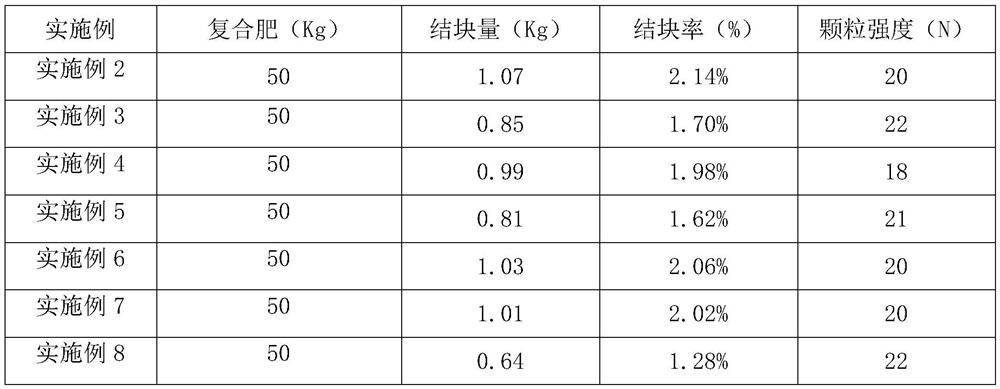

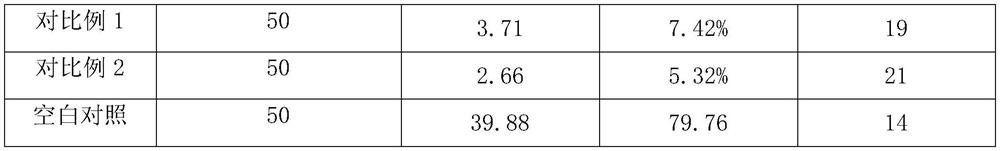

Examples

Embodiment 1

[0022] Preparation of Modified Xanthan Gum Polysaccharide

[0023] (1) Esterification of xanthan gum polysaccharides: dissolving xanthan gum in a sodium hydroxide solution with a pH of 8-10 (the molar ratio of xanthan gum to sodium hydroxide solution is 1:25-50), at a temperature of 20 Carry out swelling at -50°C for 1-3h, then add acetic acid (the molar ratio of xanthan gum to acetic acid is 1:1.2-2), and wait for the reaction to complete;

[0024] (2) separating the xanthan gum polysaccharide after the esterification: cooling the reaction system after the reaction in step (1) at room temperature, then separating crystals, suction filtration, and finally drying to obtain the xanthan gum polysaccharide after the esterification;

[0025] (3) preparation of modified xanthan gum polysaccharide: xanthan gum polysaccharide after the esterification of step (2) and ammonium cerium nitrate are made modified xanthan gum polysaccharide (xanthan gum polysaccharide after esterification) u...

Embodiment 2

[0027] Preparation of anti-caking agent

[0028] 10 parts of sodium lauryl sulfate, 10 parts of paraffin, 23 parts of modified xanthan polysaccharide and 20 parts of polyglutamic acid.

[0029] Weigh the surfactant, paraffin wax, modified xanthan gum polysaccharide and polyglutamic acid in parts by weight, heat to 50° C. to 75° C., and mix uniformly to obtain the anti-caking agent.

Embodiment 3

[0031] Preparation of anti-caking agent

[0032] 25 parts of sodium lauryl sulfate, 15 parts of paraffin, 25 parts of modified xanthan polysaccharide and 25 parts of polyglutamic acid.

[0033] Weigh the surfactant, paraffin wax, modified xanthan gum polysaccharide and polyglutamic acid in parts by weight, heat to 50° C. to 75° C., and mix uniformly to obtain the anti-caking agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com