Preparation method of modified biochar, modified biochar, composite material and soil repairing agent

A soil remediation agent and composite material technology, applied in the field of biochar, can solve the problems of environmental biological and crop threats, pesticides are difficult to be degraded in time, and large environmental risks, to promote mass reproduction, achieve soil remediation and improvement, and strong pesticides. The effect of degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of modified biochar, comprising the following steps:

[0029] (1) peanut shell powder and graphene oxide suspension are mixed and filtered to obtain the peanut shell powder after the graphene oxide suspension is impregnated; the mass ratio of the peanut shell powder to the graphene oxide suspension is (50~ 100) g: (0.8 ~ 1.2) L;

[0030] (2) the peanut shell powder and nano-SiO after the graphene oxide suspension impregnated that described step (1) obtains 2 Mix to obtain a mixture; the peanut shell powder and nano-SiO after the graphene oxide suspension is impregnated 2 The mass ratio is (80~120):(0.25~0.5);

[0031] (3) mixing the mixture obtained in the step (2) with water to obtain a mixture; the mass of the mixture and the volume ratio of water are (0.8~1.2)kg:(12~18)L;

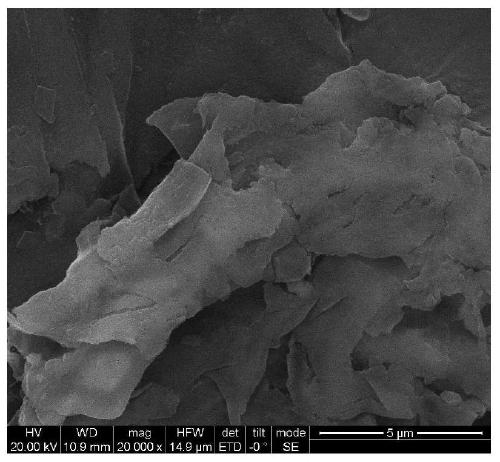

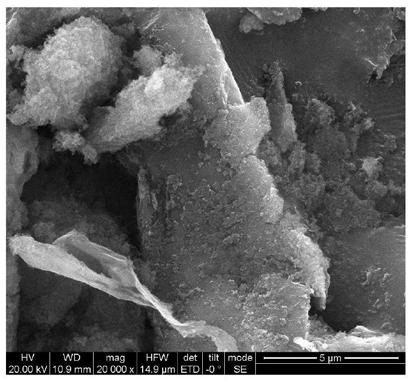

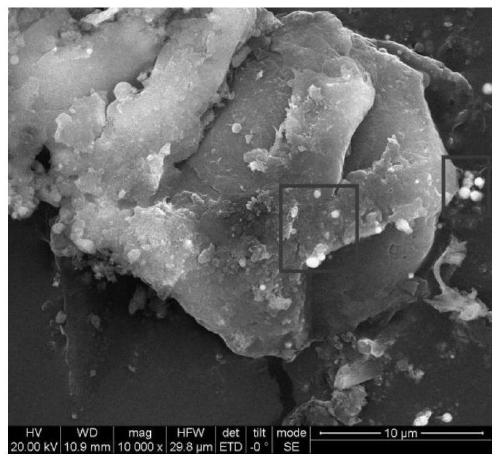

[0032] (4) Carbonize the mixture obtained in the step (3) to obtain hydrated carbon, dry the obtained hydrated carbon to obtain modified bioc...

Embodiment 1

[0063] The preparation method of modified biochar:

[0064]Peanut shells were washed with deionized water, air-dried, crushed, passed through a 60-mesh sieve, and impregnated with 0.1% GO suspension. The impregnation ratio of peanut shell powder and GO solution was 50g:1L, and the impregnation time was 4h. Mix with a medium agitator at 100rpm, stand still for 1.5h after the impregnation, collect peanut shell powder and recover the supernatant for reuse. Peanut shell powder and nano-SiO impregnated with GO 2 Mix according to the ratio of 100g:0.25g in mass ratio, add deionized water after mixing evenly, solid-liquid ratio is 1 kg:12L, stir and mix to obtain solid-liquid mixture. Transfer the solid-liquid mixture into a closed high-pressure reactor for hydrothermal carbonization treatment, and react at a constant temperature of 180 °C for 20 h. After the reaction was completed, the reactor was cooled slowly until the temperature in the reactor dropped to room temperature, and ...

Embodiment 2

[0068] The preparation method of modified biochar:

[0069] Peanut shells were washed with deionized water, air-dried, crushed, passed through a 60-mesh sieve, and impregnated with 0.2% GO suspension. The impregnation ratio of peanut shell powder and GO solution was 100g:1L, and the impregnation time was 5h. Mix with a medium stirrer at 100rpm, stand still for 2 hours after the impregnation, collect peanut shell powder and recover the supernatant for reuse. Peanut shell powder and nano-SiO impregnated with GO 2 Mix according to the ratio of 100g:0.50g in mass ratio, add deionized water after mixing evenly, the solid-liquid ratio is 1kg:18L, stir and mix to obtain a solid-liquid mixture. Transfer the solid-liquid mixture into a closed high-pressure reactor for hydrothermal carbonization treatment, and react at a constant temperature of 190 °C for 18 h. After the reaction was completed, the reactor was cooled slowly until the temperature in the reactor dropped to room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com