Direction control method of surface oxygen functional groups on coal-based hard carbon for sodium-storing cathodes

A surface oxygen and functional group technology, applied in the field of directional regulation of oxygen functional groups on the surface of coal-based hard carbon, can solve the problems of low oxygen functional group loading efficiency and waste liquid pollution, and achieve high capacity, improve porosity, and efficient loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

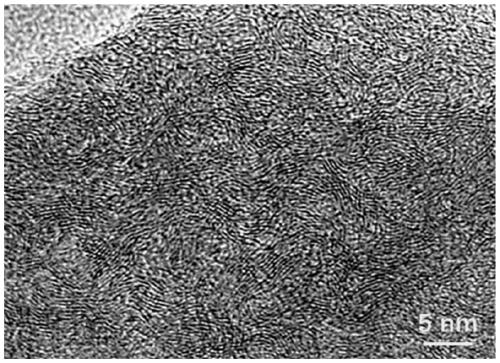

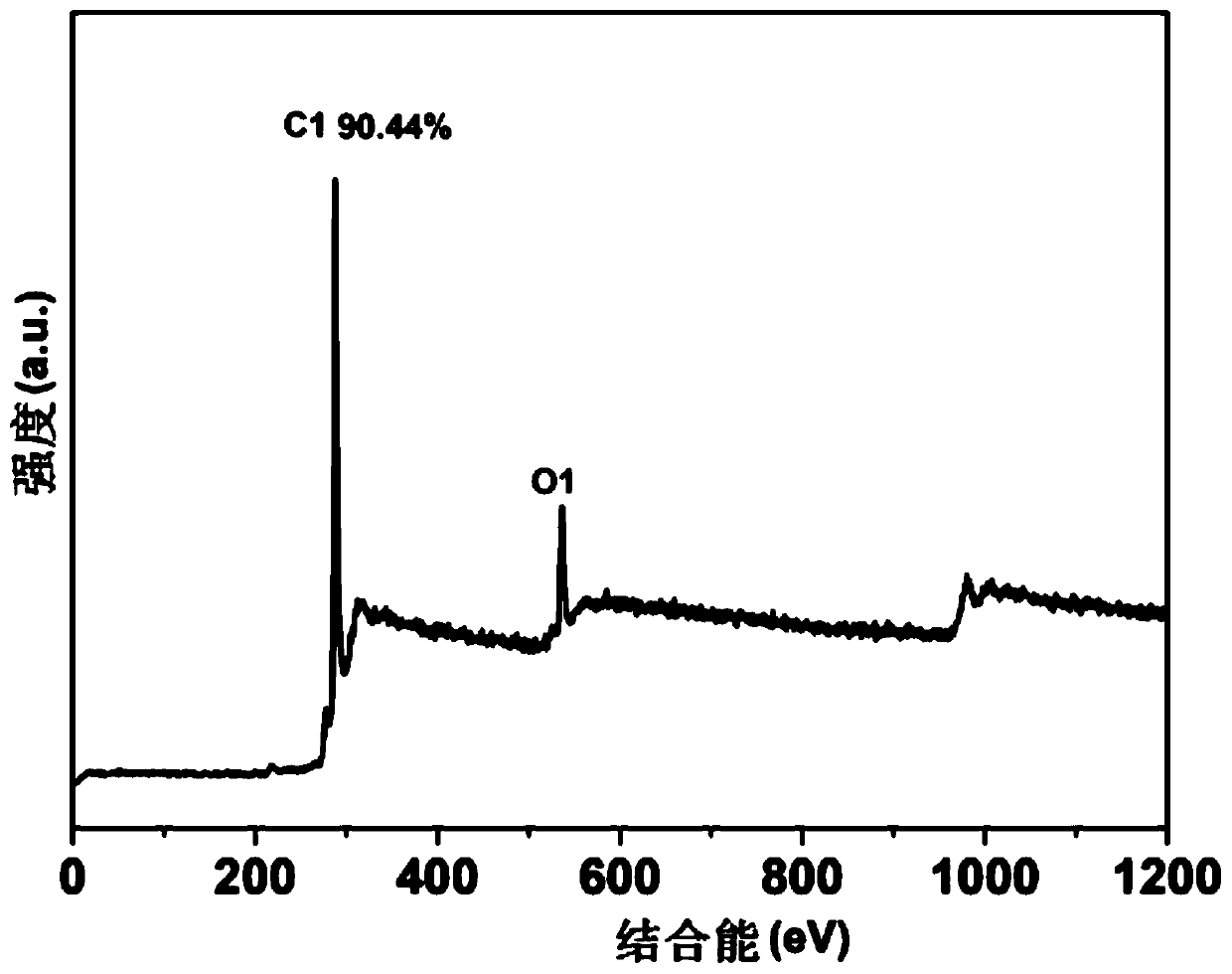

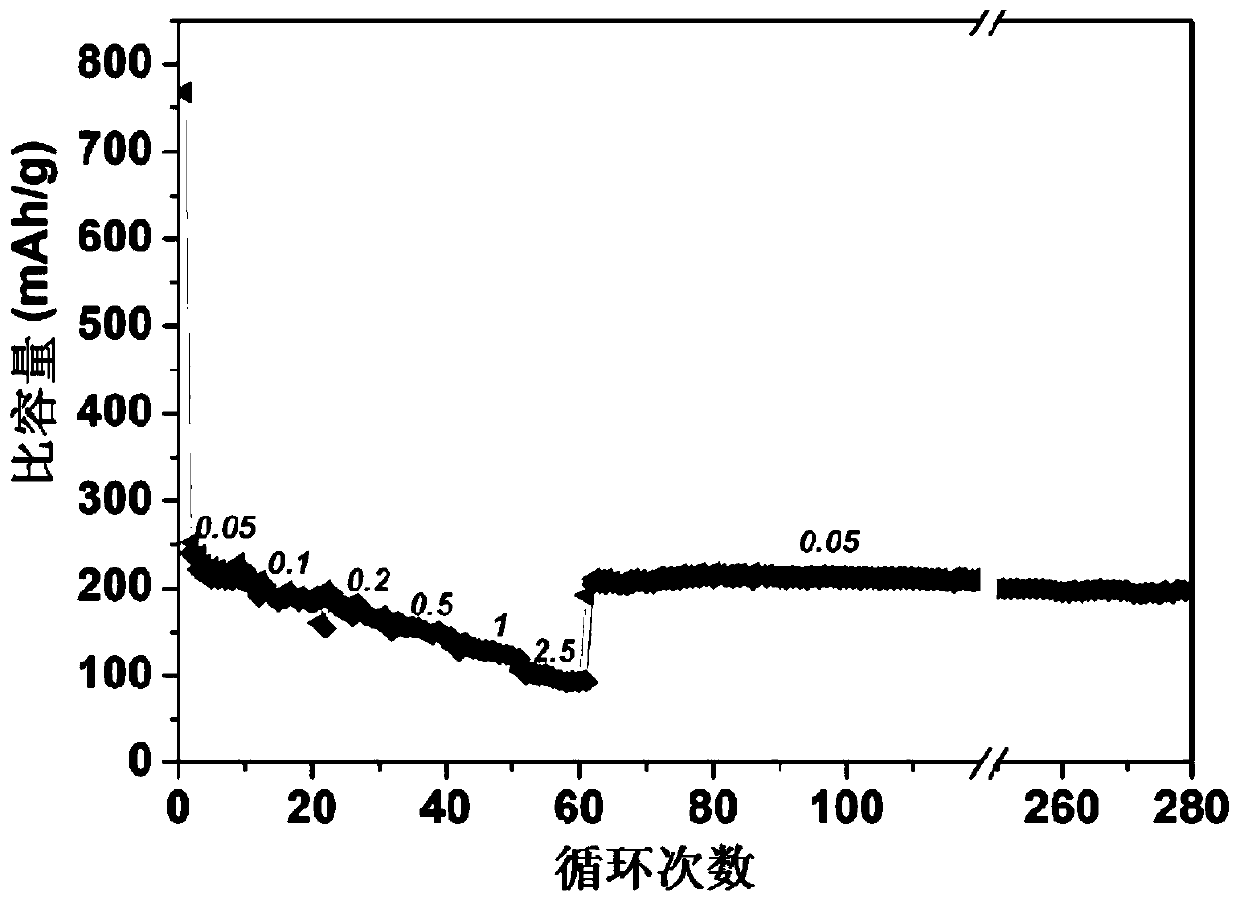

[0036] Specific implementation mode 1: This implementation mode is used for the coal-based hard carbon surface oxygen functional group directional control method for sodium storage negative electrode according to the following steps:

[0037] 1. Raw material refinement

[0038] Crushing, grinding and sieving coal raw materials in sequence to obtain fine coal powder;

[0039] 2. High temperature carbonization

[0040] Put the pulverized coal in an atmosphere furnace, carry out carbonization treatment in an inert atmosphere, and then naturally cool down to room temperature to obtain high-temperature carbonized coke;

[0041] 3. Ball milling treatment

[0042] placing the high-temperature carbonized coke in step 2 in a ball milling tank for ball milling to obtain a ball milling product; during the ball milling, the atmosphere in the ball milling tank is air atmosphere, nitrogen atmosphere or carbon dioxide atmosphere;

[0043] Four, cleaning and drying

[0044] The ball-mille...

specific Embodiment approach 2

[0049] Embodiment 2: This embodiment is different from Embodiment 1 in that: the particle size of the pulverized coal in step 1 is 20-100 mesh. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0050] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the coal raw material in step 1 is a mixture of one or more of lignite, bituminous coal, sub-bituminous coal or anthracite in any proportion. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com