Antibacterial medical catheter coated with nano silver polymer cellular structure film

A honeycomb structure, medical catheter technology, applied in catheters, balloon catheters, stents, etc., can solve the problems of low surface coverage efficiency, low release efficiency, and poor firmness of antibacterial components, and achieve firm load, reduce adsorption, and firm surface. attached effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

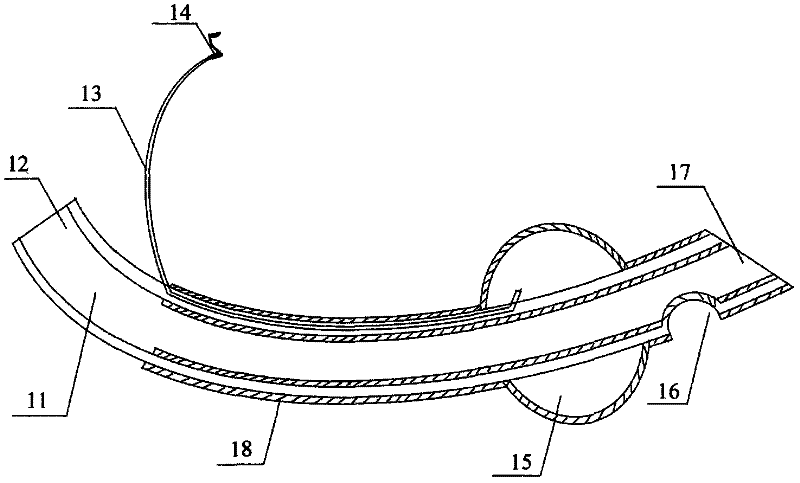

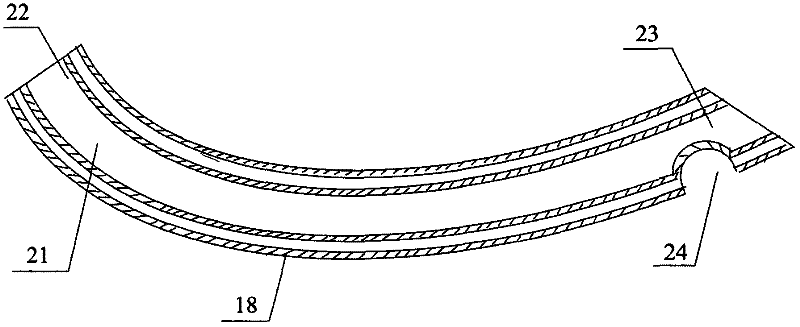

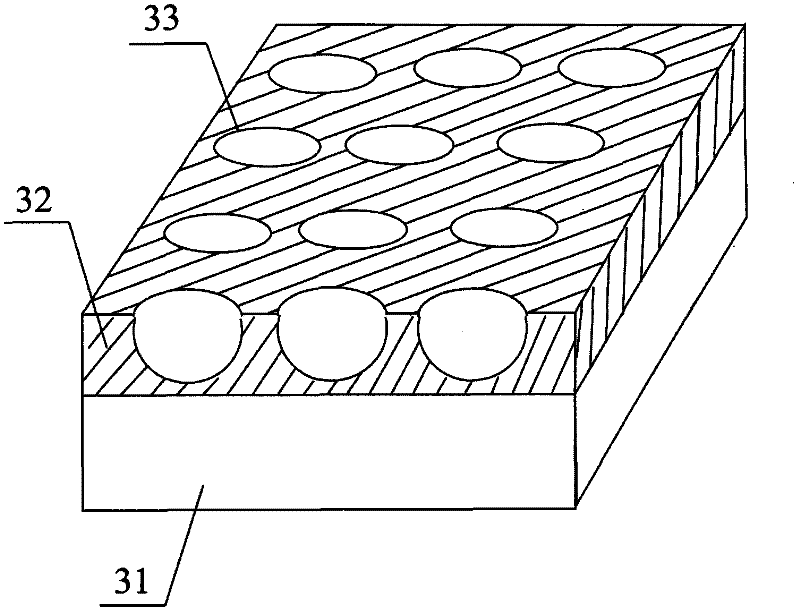

[0039] Dissolve 1 g of medical polyurethane masterbatch in 50 ml of tetrahydrofuran. Add 0.1 g of silver nitrate, and add 1 ml (0.001 g / ml) of sodium borohydride ethanol solution under the condition of vigorous stirring to prepare a nano-silver / polymer composite solution for use.

[0040] Ordinary endotracheal tubes are washed and dried, immersed in the composite solution for 30 seconds, taken out, and naturally volatilized to form a film at a humidity of 90% for about 5-10 minutes to prepare a nano-silver / polymer honeycomb structure-coated antibacterial endotracheal tube. The average thickness of the coating is 50 μm, the average pore diameter of the honeycomb structure is about 5 μm, and the silver content is 10%.

Embodiment 2

[0042] Dissolve 5g of medical polyurethane masterbatch in 50ml of tetrahydrofuran. Add 0.1 g of silver nitrate, and add 5 ml (0.001 g / ml) of sodium borohydride ethanol solution under the condition of vigorous stirring to prepare a nano-silver / polymer composite solution for use.

[0043] After washing and drying the ordinary endotracheal tube, immerse in the composite solution for 30 seconds, take it out, and naturally volatilize to form a film at a humidity of 90%, about 5-10 minutes, and make a nano-silver / polymer honeycomb structure coated antibacterial endotracheal tube , the average thickness of the coating is 200 μm, the pore size of the honeycomb structure is about 3 μm, and the silver content is 2%.

Embodiment 3

[0045] Dissolve 1 g of medical polyvinyl chloride masterbatch in 50 ml of tetrahydrofuran. Add 0.01 g of silver nitrate, and add 1 ml (0.001 g / ml) of sodium borohydride ethanol solution under the condition of vigorous stirring to prepare a nano-silver / polymer composite solution for use.

[0046] After washing and drying the ordinary endotracheal tube, immerse in the composite solution for 30 seconds, take it out, and naturally volatilize to form a film at a humidity of 90%, about 5-10 minutes, and make a nano-silver / polymer honeycomb structure coated antibacterial endotracheal tube , the average thickness of the coating is 50 μm, the pore size of the honeycomb structure is about 5 μm, and the silver content is 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com