Preparation method of collagen matrix composite biological film for guided tissue regeneration

A technology for guiding regeneration and composite membrane, applied in medical science, surgery, etc., can solve the problems of loss of space maintenance ability, fast degradation speed, low strength, etc., to achieve good mechanical properties and degradation controllability, good repair, low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

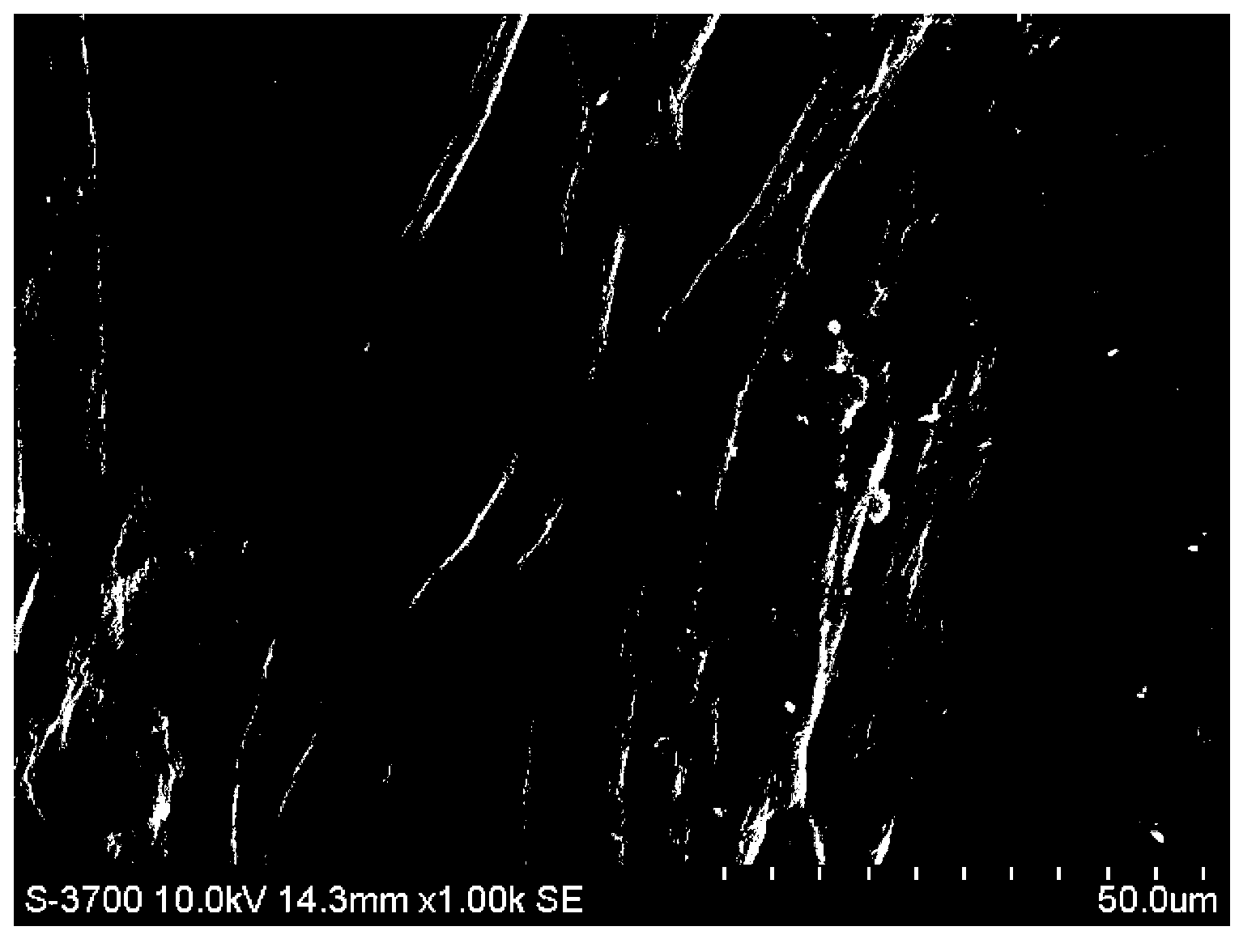

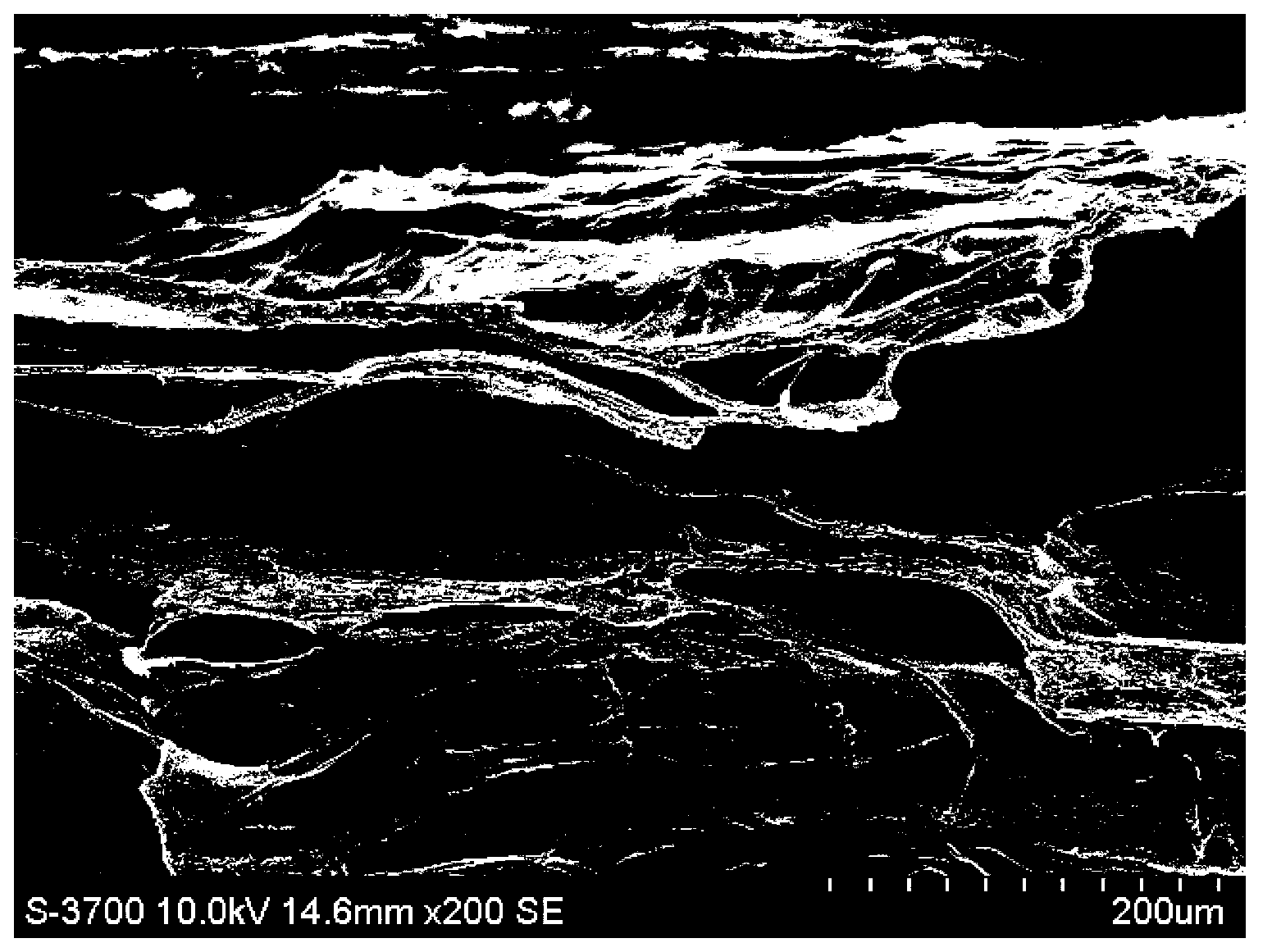

Image

Examples

Embodiment 1

[0033] A method for preparing a collagen-based composite biofilm, comprising the steps of:

[0034] (1) Dissolve collagen in 0.1M hydrochloric acid solution at 25°C to obtain a collagen solution with a concentration of 3mg / ml;

[0035] (2) Slowly adjust the pH value of the solution obtained in step (1) to 10 with 0.1N sodium hydroxide, and keep it for 30 minutes;

[0036] (3) Add bioactive glass (BAG) to the collagen solution in step (2), wherein the weight of BAG is 10% of the dry weight of collagen, and stir with a stirrer to obtain a uniform solution;

[0037] (4) Use hydrochloric acid or sodium hydroxide solution to adjust the pH value of the solution obtained in step (3) to 7, and centrifuge at a speed of 3000r / min for 5 minutes. At this time, the collagen-wrapped BAG precipitates at the bottom of the centrifuge cup to form a film. Remove the supernatant and collect the collagen composite film;

[0038] (5) Forming the collagen composite film collected in step (4), free...

Embodiment 2

[0042] A method for preparing a collagen-based composite biofilm, comprising the steps of:

[0043] (1) Dissolve collagen in 0.1M hydrochloric acid solution at 4°C to obtain a collagen solution with a concentration of 10mg / ml;

[0044] (2) Slowly adjust the pH value of the collagen solution obtained in step (1) to 9 with 0.1N sodium hydroxide, and keep it for 60 minutes;

[0045] (3) Add hydroxyapatite (HA) to the solution obtained in step (2), wherein the weight of HA is 5% of the dry weight of collagen, and stir with a stirrer to obtain a uniform solution;

[0046] (4) Use hydrochloric acid or sodium hydroxide solution to adjust the pH value of the solution obtained in step (3) to 7, and centrifuge at a speed of 4000r / min for 3 minutes. At this time, the collagen-coated HA precipitates at the bottom of the centrifuge cup to form a film, remove The supernatant was collected to collect the collagen composite membrane;

[0047] (5) Forming the collagen composite film collecte...

Embodiment 3

[0052] A method for preparing a collagen-based composite biofilm, comprising the steps of:

[0053] (1) Dissolve collagen in 0.5M acetic acid solution at 4°C to obtain a collagen solution with a concentration of 8 mg / ml;

[0054] (2) Slowly adjust the pH value of the collagen solution obtained in step (1) to 8 with 0.1N ammonia water, and keep it for 5 minutes;

[0055] (3) Add β-tricalcium phosphate (β-TCP) to the collagen solution in step (2), wherein the weight of β-TCP is 1% of the dry weight of collagen, and stir with a stirrer to obtain a uniform solution;

[0056] (4) Adjust the pH value of the solution obtained in step (3) to 7 with acetic acid or ammonia water, centrifuge at a speed of 6000r / min for 3 minutes. Supernatant, collect the collagen composite film;

[0057] (5) Forming the composite collagen membrane collected in step (4), freeze-drying at -20°C, and vacuum thermal crosslinking at 140°C;

[0058] (6) Soak the composite collagen membrane obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com