Wastewater treatment and reuse technology for paper mill

A technology for wastewater treatment and paper mills. It is applied in the direction of processing wastewater treatment, water/sewage multi-stage treatment, flotation water/sewage treatment, etc. It can solve the problems that papermaking methods cannot be applied and cannot be applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] Below in conjunction with accompanying drawing, content of the present invention is described in further detail:

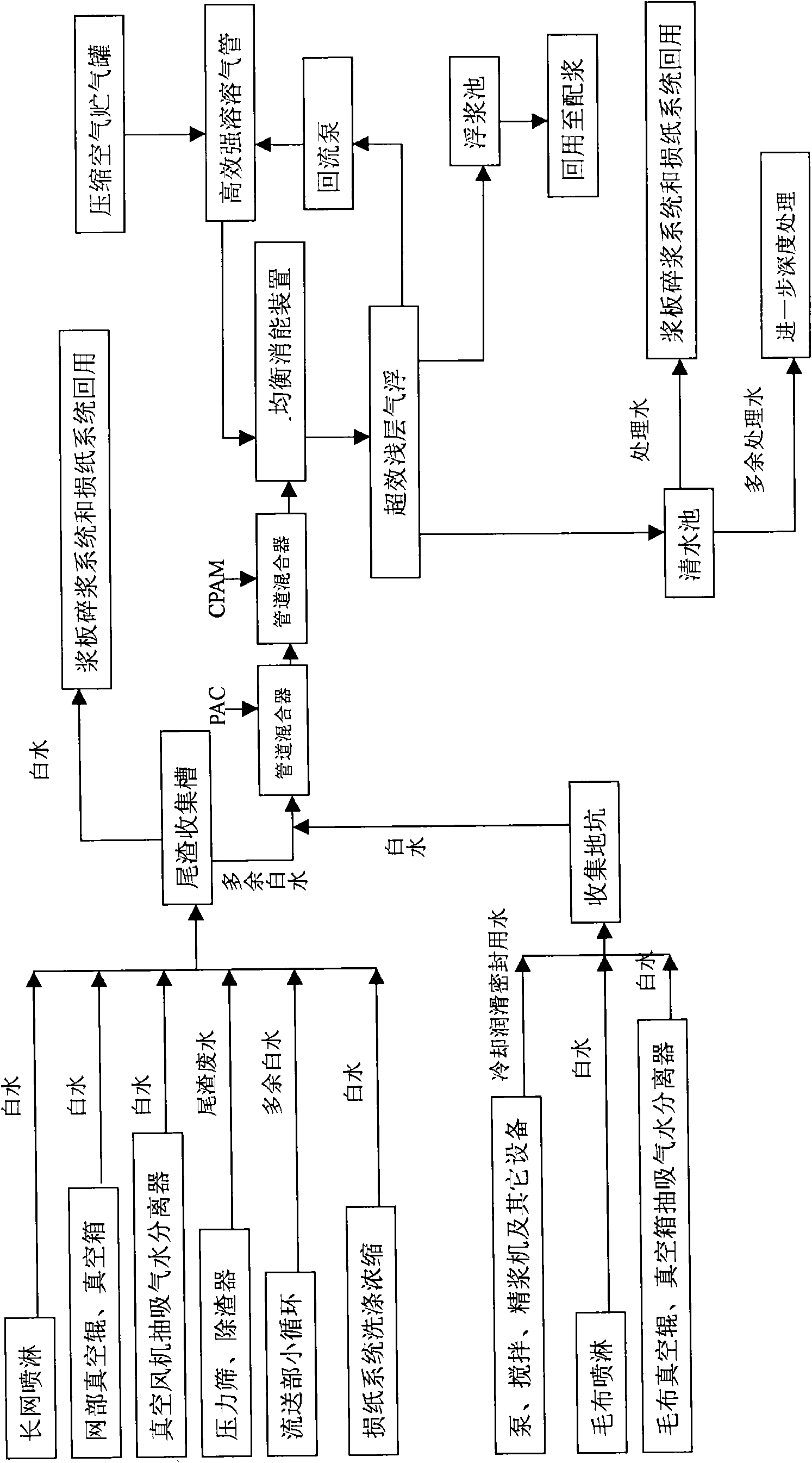

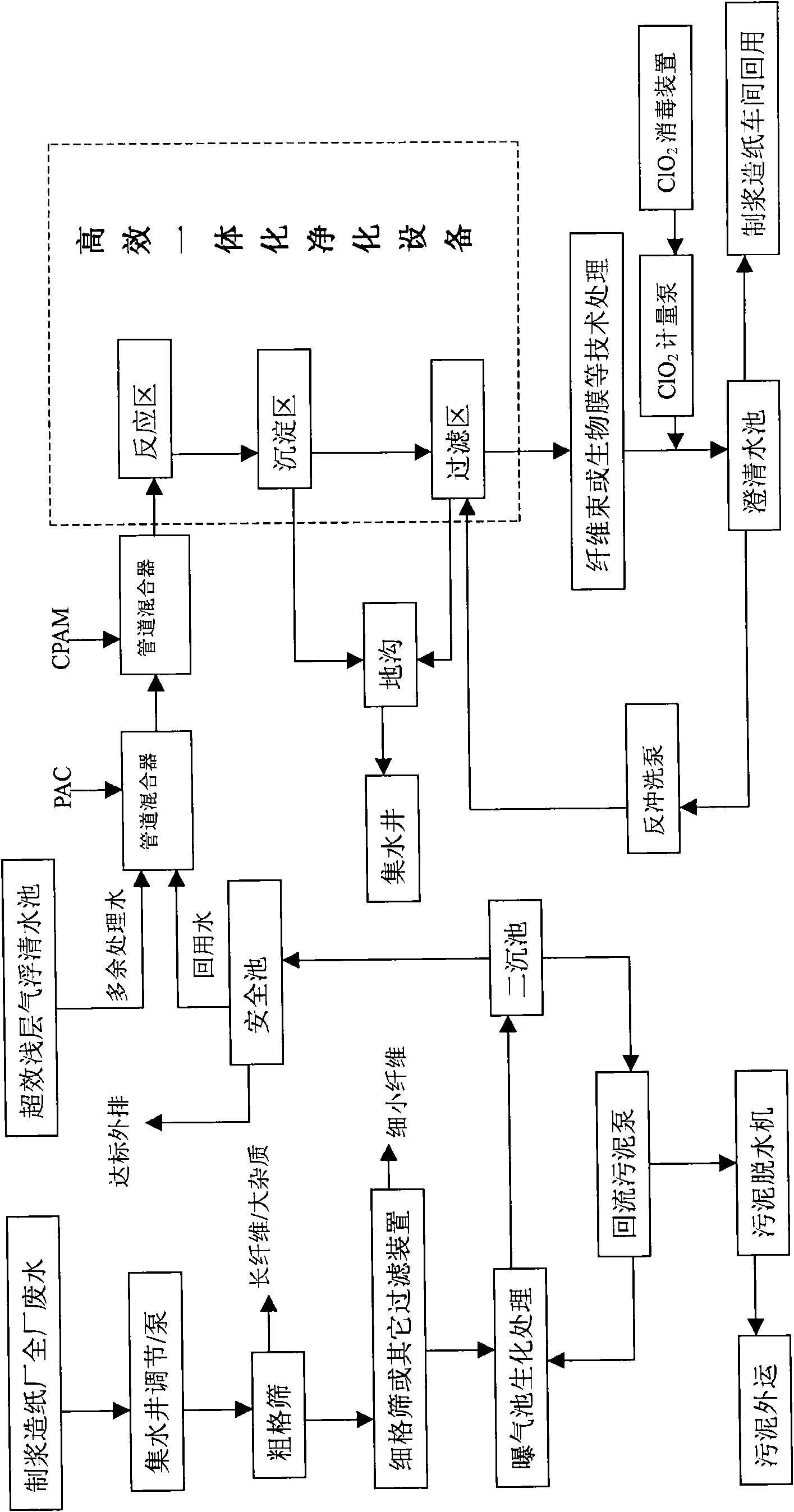

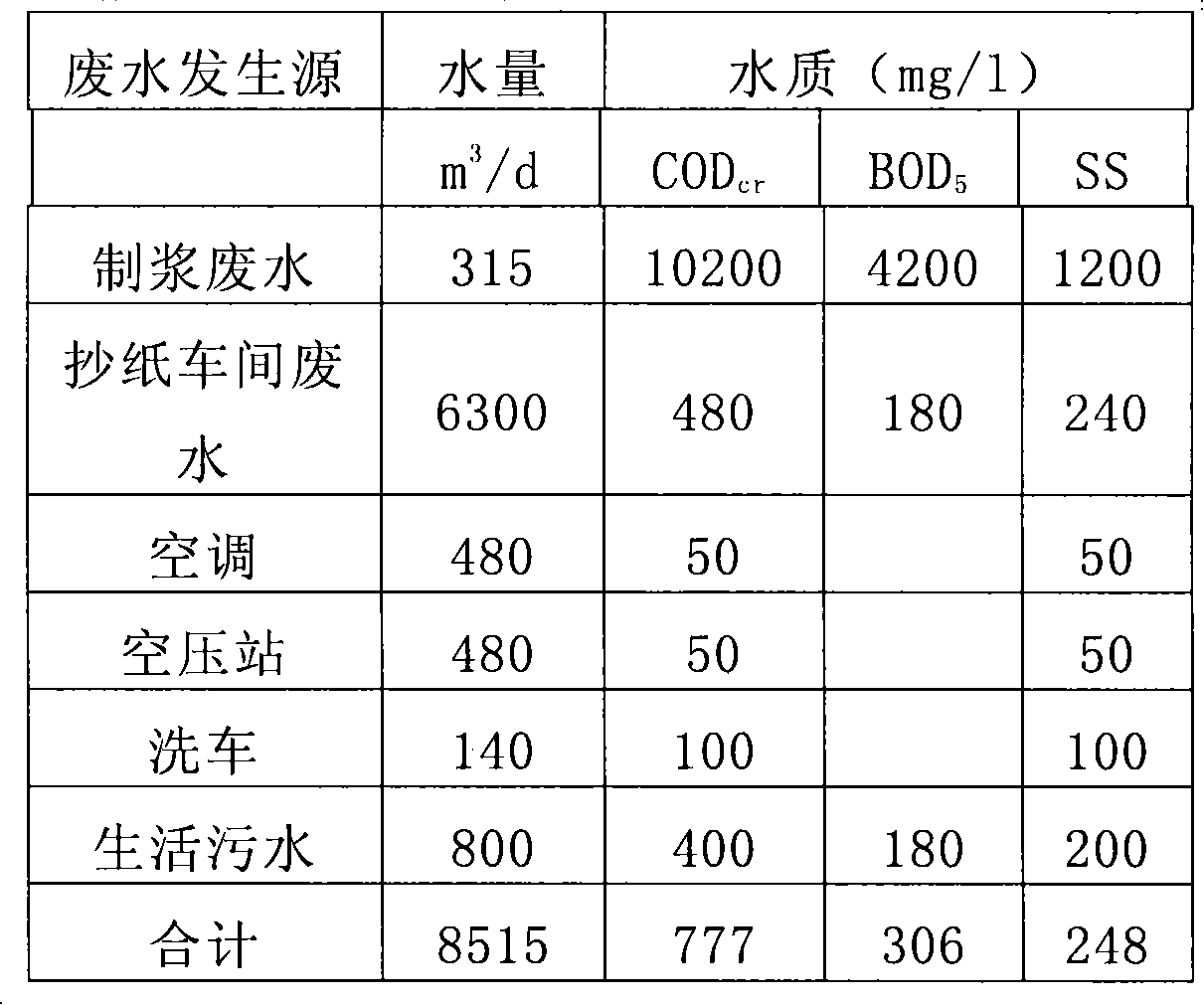

[0112] Copying of commercial pulp boards such as cotton pulp boards, straw pulp boards, hemp pulp boards, coniferous wood pulp boards, and hardwood pulp boards, or the use of pulp from pulping workshops for the production of bond paper, high-grade anti-counterfeiting paper and other high-grade paper In the paper workshop, workshop wastewater is mainly produced by the fine pulp process, paper machine process, auxiliary material process, and broken paper treatment process. Refer to figure 1 ——As shown in the process flow chart of waste water recycling technology in the papermaking workshop, the wet long wire spraying of the paper machine and the vacuum roll, vacuum box and vacuum fan suction air-water separator to separate white water; pressure screen, slag removal and tailing Waste water; the excess white water in the white water circulation of the flow deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com