Novel internal circulation moving bed biological film reactor

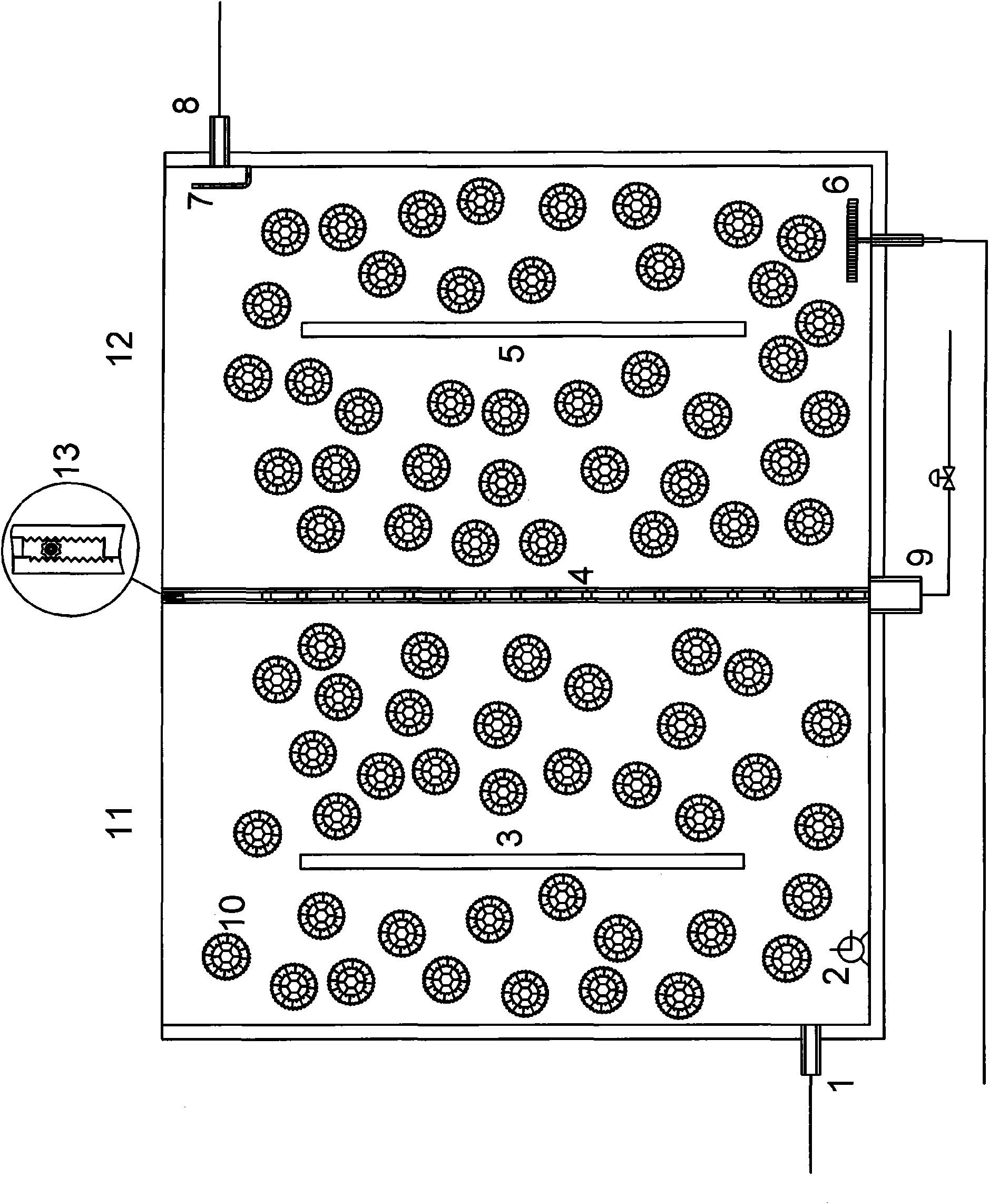

A moving bed biofilm and reactor technology, which is applied in the field of new internal circulation moving bed biofilm reactor, can solve the problems of slow proliferation of nitrifying bacteria, increased infrastructure investment and operating costs, and low efficiency of organic matter treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The simulated wastewater was treated using the above-mentioned embodiment. Reactor size: D 20cm×L 40cm×H 40cm, effective volume 30L, filler filling ratio 40%, flow rate of submerged pump in anoxic section 2.0L / min, aeration rate in aerobic section 1.0L / min, adjust combined perforation The plate porosity is 15%, and the average influent COD 295.5mg / L, NH 4 + -N 37.08mg / L, TN 39.90mg / L, adjust the reactor water flow rate 10L / h, hydraulic retention time 3h, the reactor runs stably for 1 month, the average effluent COD 18.19mg / L, NH 4 + -N 5.07mg / L, TN 6.08mg / L, the average removal rate of pollutants is 93.8% for COD, NH 4 + -N 86.3%, TN 84.8%.

Embodiment 2

[0022] The simulated wastewater was treated using the above-mentioned embodiment. Reactor size: D 20cm×L 40cm×H 40cm, effective volume 30L, filler filling ratio 60%, flow rate of submerged pump in anoxic section 3.0L / min, aeration rate in aerobic section 2.0L / min, adjust combined perforated plate The porosity is 2%, and the average influent COD is 297.0mg / L, NH 4 + -N 36.70mg / L, TN 39.20mg / L, influent flow rate 3.75L / h, hydraulic retention time 8h, reactor running stably for 1 month, effluent COD 14.19mg / L, NH 4 + -N 3.44mg / L, TN 4.33mg / L, the average pollutant removal rate is 95.2% for COD, NH 4 + -N 90.6%, TN 89.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com