Method for removing sulfur-dioxide in smoke by bamboo-carbon filler biological drip filtering tower

A biological trickling filter and sulfur dioxide technology, applied in the field of microbial desulfurization, can solve the problems of high cost of alloy fiber preparation, limited large-scale application, and non-environmental protection, achieve good economic and environmental benefits, realize resource utilization, high Effect of Sulfur Recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

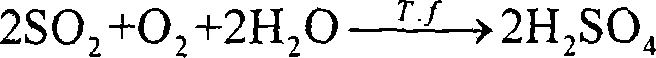

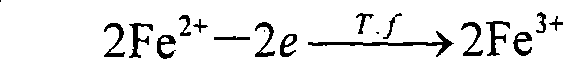

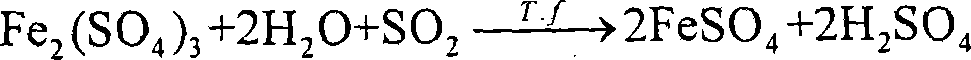

Method used

Image

Examples

Embodiment 1

[0029]The reaction system consists of a packed tower, a liquid circulation system and a gas circulation system. The test operation method adopts countercurrent operation. The nutrient solution is sprayed down from the top of the tower to the packing, flows in the packing from top to bottom, and finally enters the circulating water tank from the bottom of the tower, and then is pumped back to the top of the tower by the circulating water pump. The gas to be treated enters the biotrickling filter tower from the bottom of the tower, and is purified by contacting with the wet biofilm of Thiobacillus ferrooxidans in the packing during the rising process, and the purified gas is discharged from the top of the tower. The packing tower is a conventional biological trickling filter tower, but the packing used is pretreated bamboo charcoal. As the reaction proceeds, the SO in the circulating tank 4 2- The concentration is constantly increasing, and part of the liquid in the circulatio...

Embodiment 2

[0033] Change the dilute sulfuric acid of pH=2.0 in embodiment 1 into the dilute hydrochloric acid of pH=2.0, desulfurization bacteria adopts Leptospira ferrous oxide, other operating conditions remain unchanged, the fixed biomass is 5.606nmolP / g wet, SO 2 The removal rate was 98.3%.

Embodiment 3

[0035] (NH 4 ) 2 SO 4

[0036] Bamboo charcoal was soaked in the dilute sulfuric acid solution of pH=1.0 for 1 day, then dried, the temperature of the desulfurization process was 25°C, other operating conditions were the same as in Example 1, the fixed biomass was 5.269nmolP / g wet, and the SO 2 The removal rate was 98.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com