Integrated technology for deep purification treatment for printing and dyeing waste water

A technology for deep purification of printing and dyeing wastewater, applied in textile industry wastewater treatment, flotation water/sewage treatment, oxidized water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

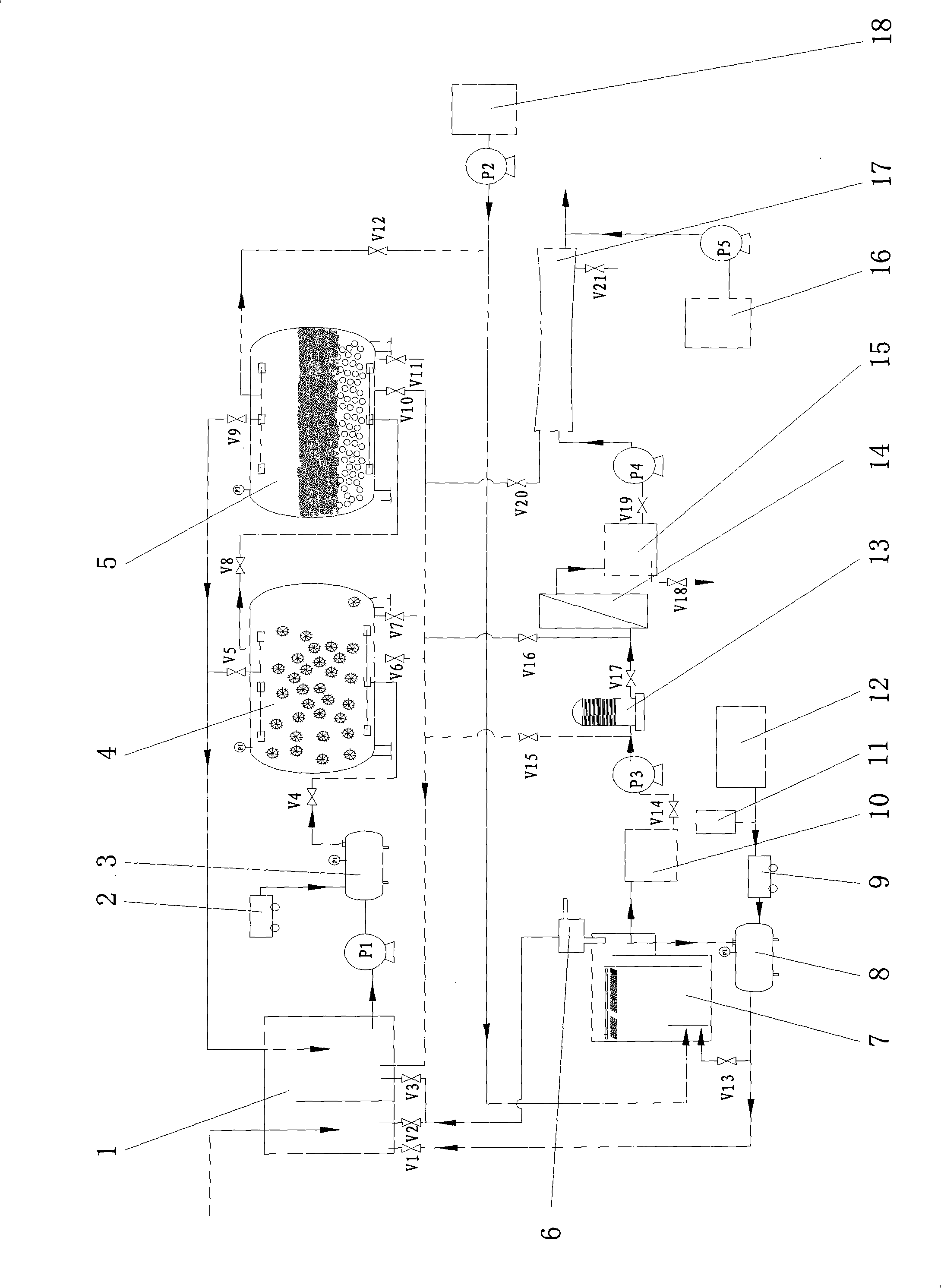

Method used

Image

Examples

Embodiment 1

[0020] A textile printing and dyeing company has a dyeing and finishing wastewater treatment facility, and the effluent quality meets the secondary discharge standard of the "Discharge Standard of Water Pollutants for Textile Dyeing and Finishing Industry" (GB 4287-1992). In order to reduce the total discharge of COD, improve the water environment in the area, save water resources, and reduce production costs, the company requires advanced treatment of printing and dyeing wastewater and reuse in production. This process is now being used for a pilot test with an influent water volume of 100t / d.

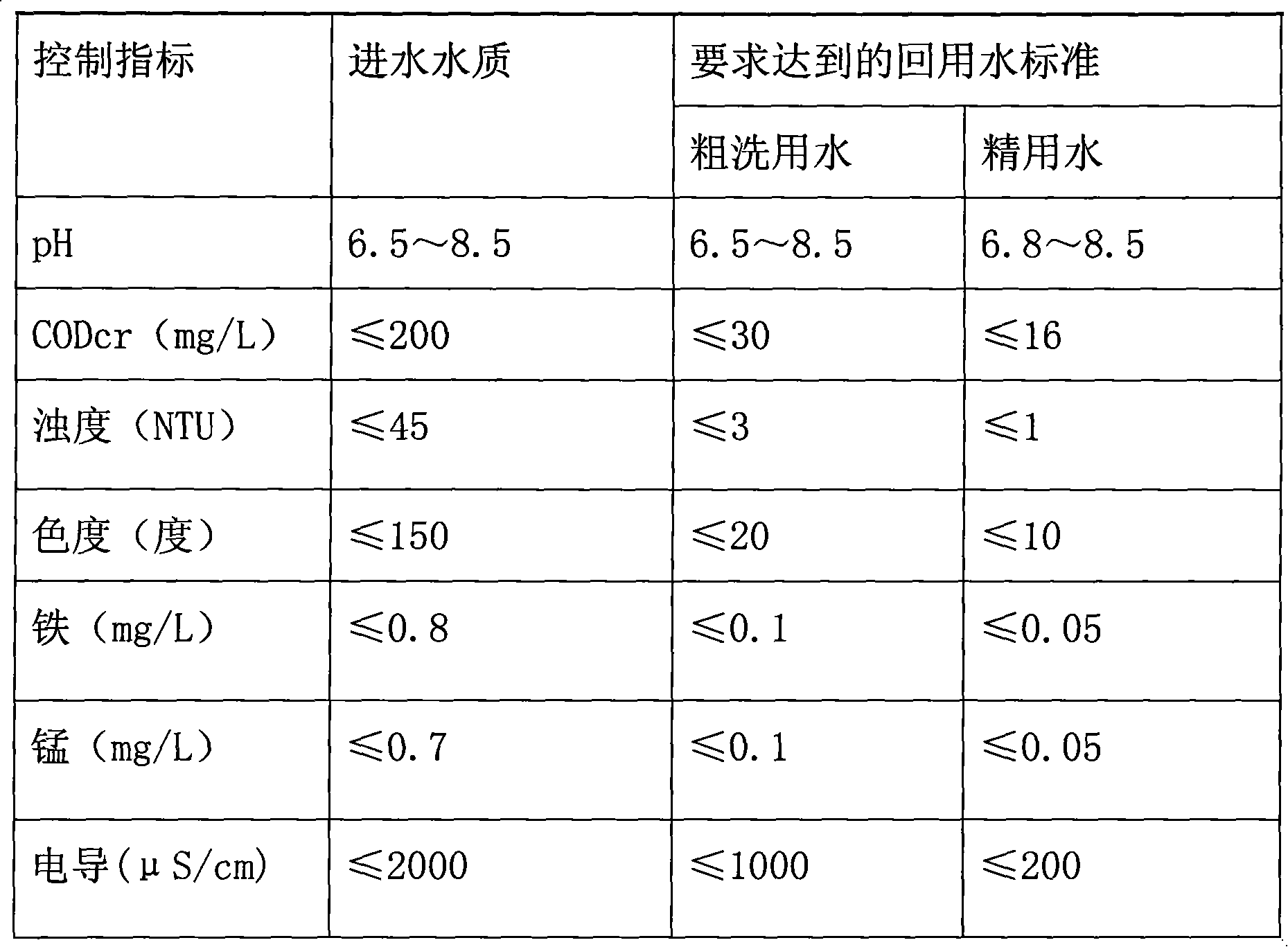

[0021] The following table shows the water quality of the system feed water and the recycling standards applicable to the textile wet treatment requirements of the production workshop.

[0022]

[0023] Three months after the pilot project was officially implemented, the treatment effects of each treatment unit are as follows:

[0024] control index

[0025] The water re...

Embodiment 2

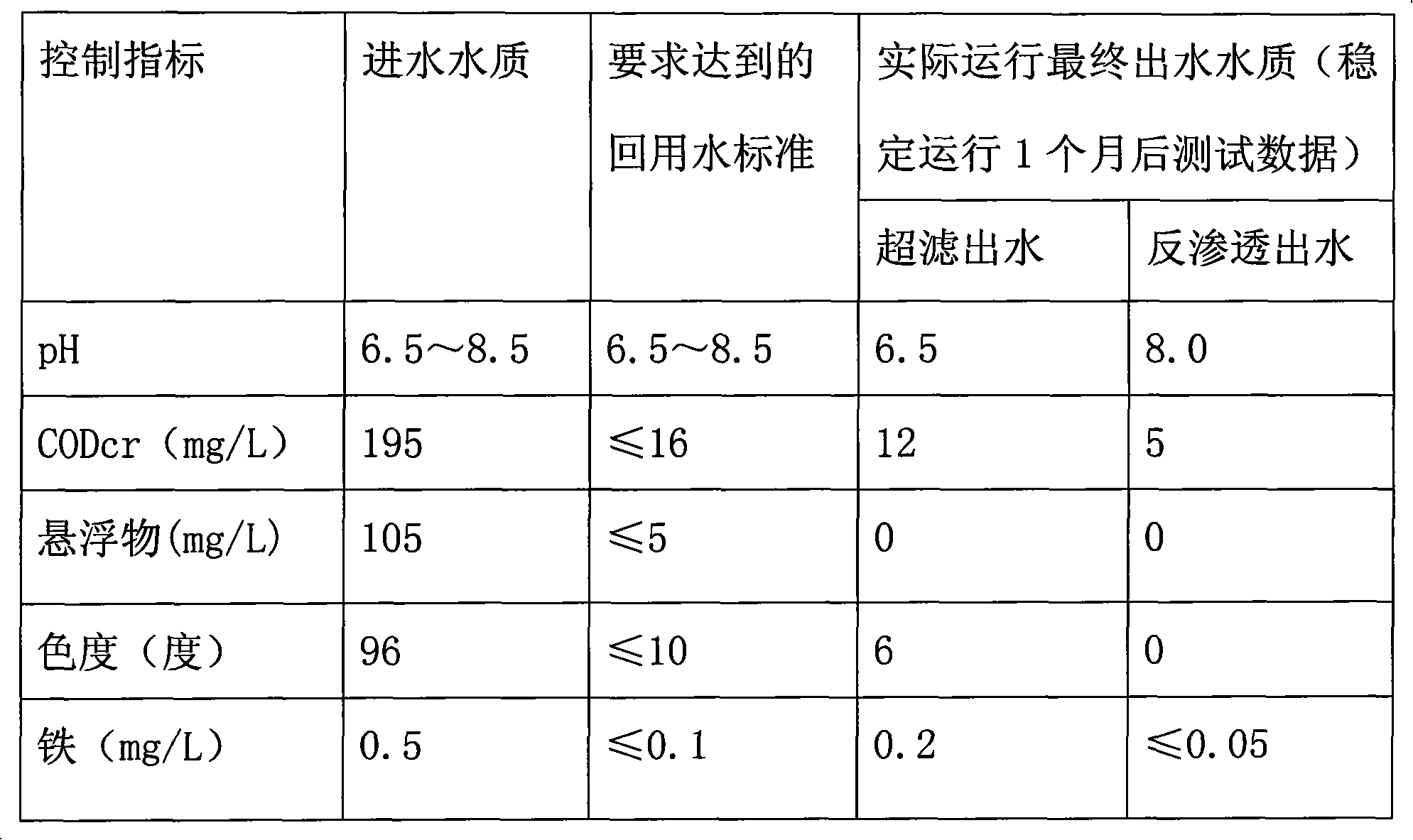

[0027] A company's printing and dyeing wastewater deep purification treatment project, the main source of wastewater is pre-treatment, dyeing and post-treatment in the printing and dyeing process, the treatment capacity is 150t / d, the dyes used are mainly reactive dyes, some are disperse dyes, and the auxiliaries used are alkali and The original starch and so on. The wastewater enters the process system after being treated by the company's internal wastewater station. The following are the relevant indicators of this process:

[0028]

[0029]

[0030] According to the above measured data, all water quality indicators of the project’s effluent have met or exceeded the requirements for reused water, and the effluent has been reused for pre-treatment and dyeing processes in the printing and dyeing process, with about 75% of the reused water used. According to the quality analysis of dyed products, its color fastness and soaping fastness are above grade 4. Therefore, the p...

Embodiment 3

[0032] A Knitting Co., Ltd. is an enterprise mainly engaged in the production of knitted gray fabrics and dyeing and finishing. The wastewater discharged from production contains a large amount of residual dyes, auxiliaries, sizing, waste alkali, fibers and inorganic salts, etc., with high organic content and large chroma. , pH changes greatly. The factory discharges 3000m of waste water every day 3 / d, wastewater CODcr is 1400mg / L, BOD is 200mg / L, SS is 400mg / L, color is 700 times, pH value is 7-9. The plant currently has a set of sewage treatment equipment. The treatment process is coagulation-sedimentation-hydrolytic acidification-aerobic-coagulation-sedimentation-biological filter. The first-level emission standard of the National Waste Emission Standard (GB4287-92). The discharged wastewater is now carried out a pilot test of 120t / d deep purification treatment using this process flow. The following is the relevant data after the process has been running stably for 3 mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com