Efficient air purifier core

A high-efficiency air and air purification technology, applied in the field of air purification, can solve the problems of high ozone generation rate, low electric field intensity, low purification efficiency, etc., and achieve the effect of reducing the occurrence of ozone, increasing the dust collection effect, and increasing the distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

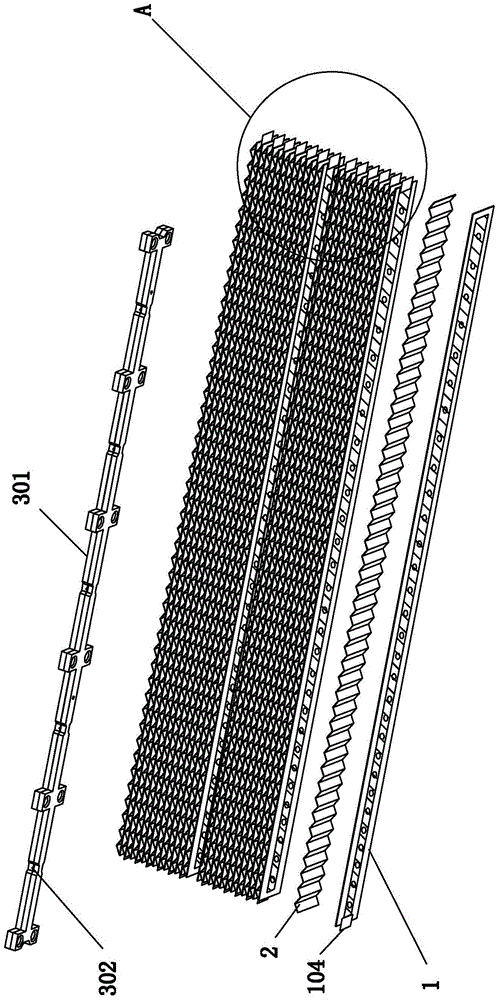

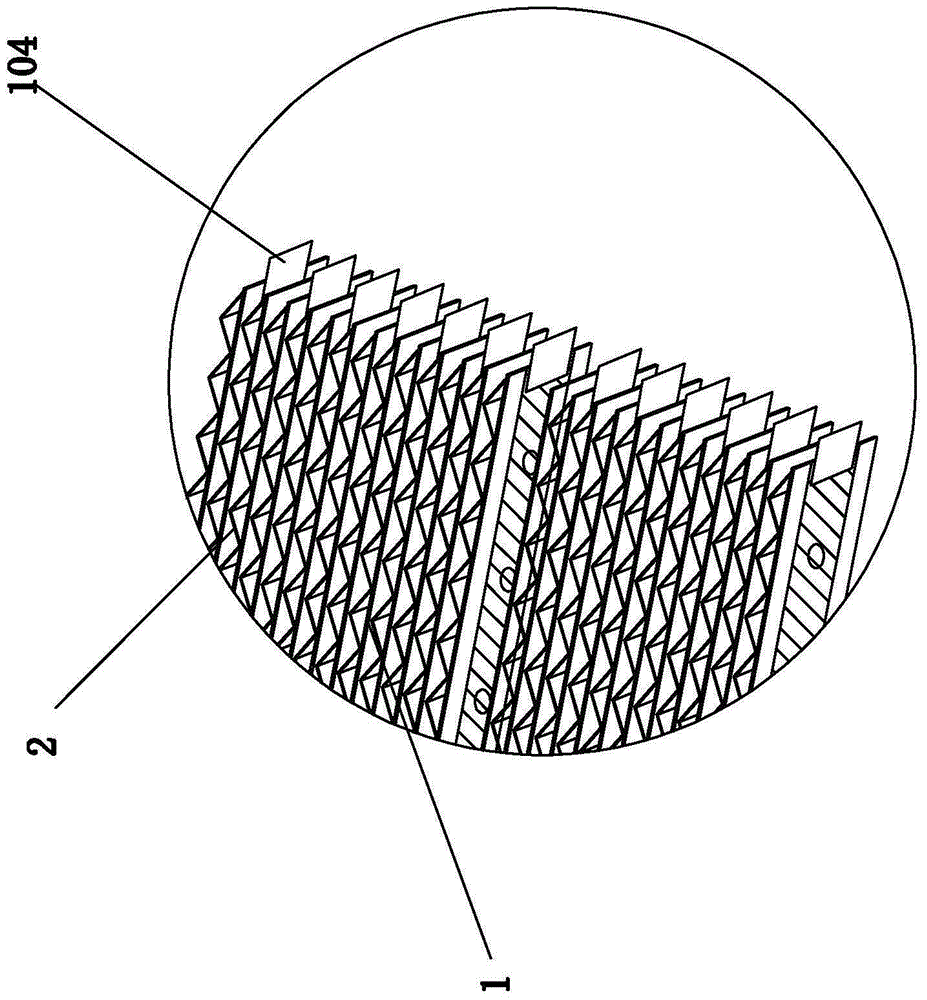

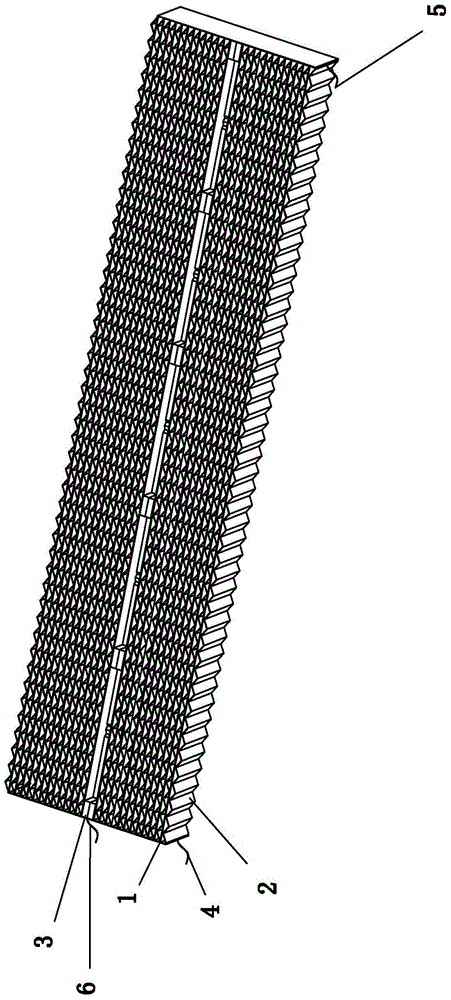

[0047] Such as Figure 1-1 to Figure 5-2 As shown, a high-efficiency air purification mechanism is a through-hole laminating air purification mechanism, including through-hole laminating conductive tape 1, corrugated inter-board 2, discharge needle assembly 3, positive power cord 4, negative power cord 5 and Discharge needle power cord 6;

[0048] The through-hole laminated conductive tape 1 is a composite layer structure, which includes PET tape 101, high-resistance carbon paste conductive tape 102 and through-hole laminated tape 103 from bottom to top. The product model of PET tape 101 is 6021; The product model is UV hardening insulating ink, the product name is QS-18. The high-resistance carbon paste conductive tape 102 is printed on the PET tape 101 by a printing process to form a high-resistance carbon paste conductive tape component A; the through-hole composite film conductive tape 1 also includes a copper sheet 104, the copper sheet 104 Pasted or riveted on one end of ...

Embodiment 2

[0074] The two ends of the through-hole laminating air purifier core adopt the PET tape 101 with hot melt ends respectively.

[0075] In the assembling step of the through-hole laminating air purification mechanism, the PET tape 101 at both ends of the hot-melt through-hole laminating air purification mechanism is finally used.

[0076] The same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com