Composite microelectrolytic/biomembrane reaction apparatus and its sewage treating method

A reaction device, biofilm technology, applied in sustainable biological treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high investment and operating costs, complex process flow, electrode passivation, etc. Achieve the effect of low investment and operating costs, simple process flow and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

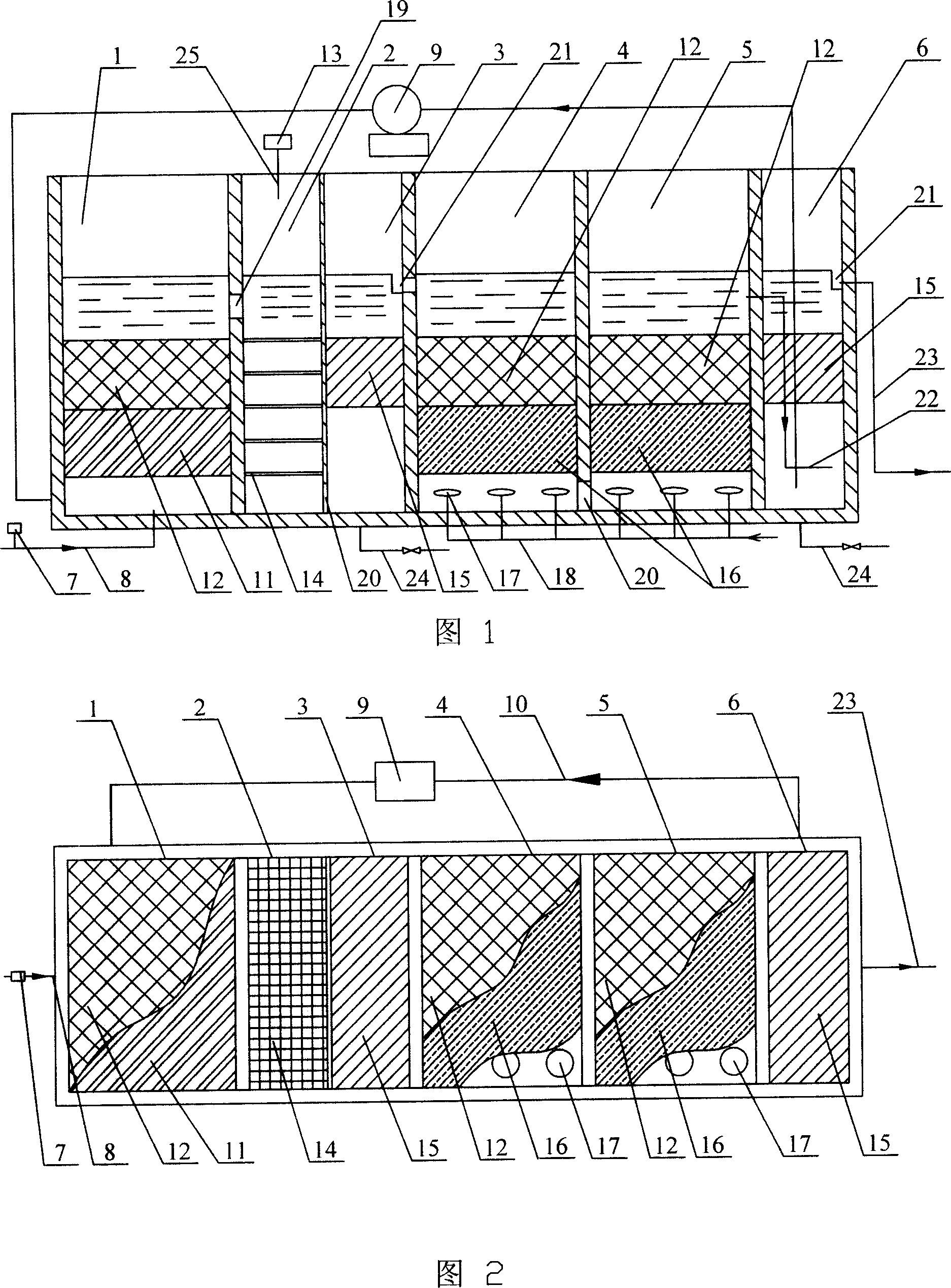

[0027] Specific embodiment one: (referring to Fig. 1 and Fig. 2) the composite micro-electrolysis / biofilm reaction device of the present embodiment is composed of the first micro-electrolysis / biofilm reaction tank 1, the flocculation tank 2, the first sedimentation tank 3, the second micro-electrolysis tank The electrolysis / biofilm reaction tank 4, the third micro-electrolysis / biofilm reaction tank 5 and the second sedimentation tank 6; It is hydraulically connected with the first sedimentation tank 3 through the bottom hole 20, the first sedimentation tank 3 is in hydraulic communication with the second micro-electrolysis / biofilm reaction tank 4 through the sump 21, and the second micro-electrolysis / biofilm reaction tank 4 is connected with the third micro-electrolysis / biofilm reaction tank 4. The electrolysis / biofilm reaction tank 5 is hydraulically connected through the bottom hole 20, the third micro-electrolysis / biofilm reaction tank 5 communicates with the second sediment...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the first micro-electrolysis / biofilm reaction tank 1, the second micro-electrolysis / biofilm reaction tank 4 and the third micro-electrolysis / biofilm reaction tank 5 adopt coke , fly ash or slag to replace the activated carbon particles in the activated carbon packing layer 12. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the thickness of the activated carbon packing layer 12 in the first micro-electrolysis / biofilm reaction tank 1 of the present embodiment, the second micro-electrolysis / biofilm reaction tank 4 and the 3rd micro-electrolysis / biofilm reaction tank 5 is 0.1~2m, the activated carbon particle diameter of activated carbon packing layer 12 is 1~5mm; 5-10mm; the thickness of the copper and iron filing layer 16 in the second micro-electrolysis / biofilm reaction tank 4 and the third micro-electrolysis / biofilm reaction tank 5 is 0.1-2m, and the copper and iron filing layer 16 of the copper filings The diameters of copper and iron filings are 5-10mm, and the content ratio of copper filings and iron filings is 1:2-10. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com