Biological filler and preparing method and apparatus constructed thereof and use

A bio-filler and bio-film technology, which is applied in the treatment of large-volume waste gas and high-concentration fields, can solve the problems of restricting the thickness of the packing layer, large system resistance, and packing blockage, so as to save the film-hanging time, save the floor area, and improve The effect of processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The biological filler of the invention is used to immobilize nitrifying bacteria for treating ammonia-containing waste gas.

[0038] Immobilized cell gel composition:

[0039] Polyvinyl alcohol 6.5%

[0040] Sodium Alginate 1%

[0041] Nitrifying bacteria wet cells 50%

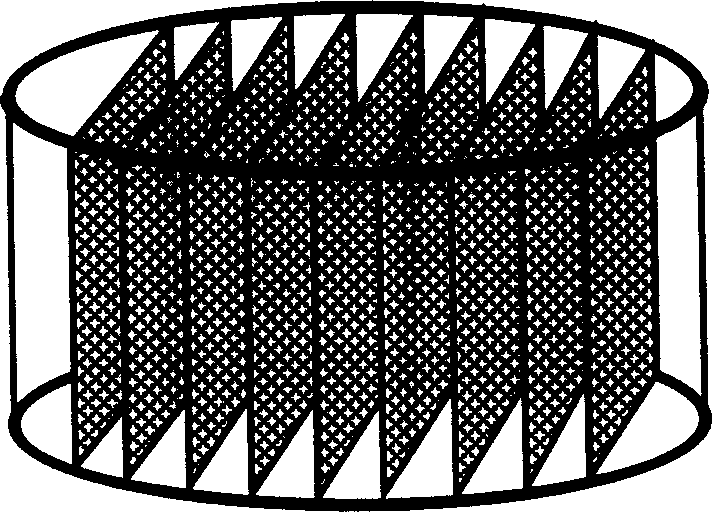

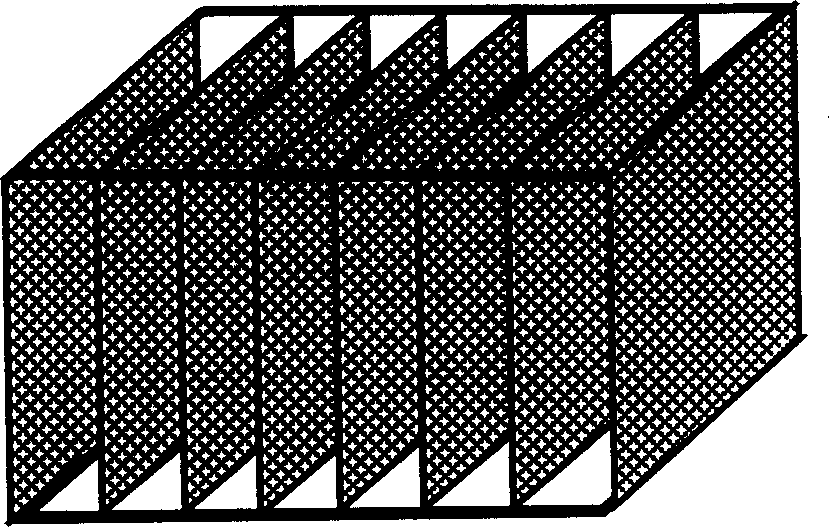

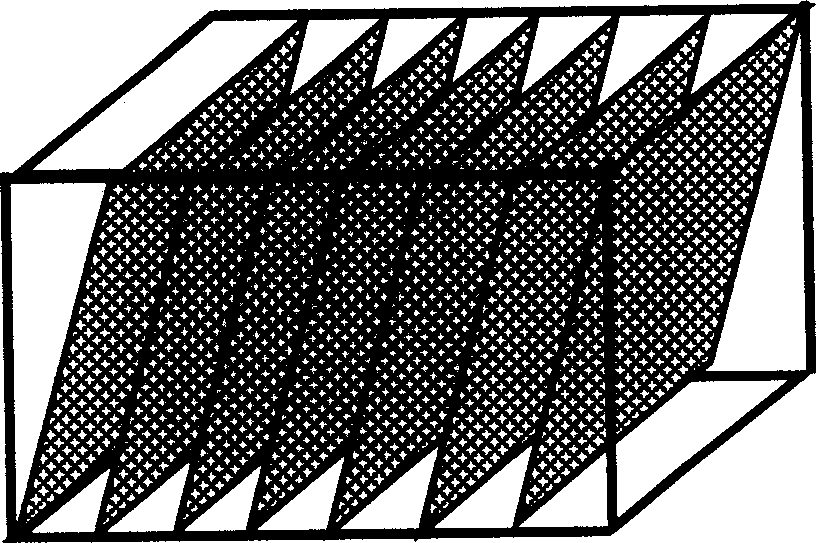

[0042] The filler frame is made of stainless steel plate and stainless steel wire. Its appearance is a cylinder with a height of 85mm and a diameter of 140mm. The mesh fabric is nylon window screen with an aperture of 0.3×0.2mm. The distance between every two screens is 8-10mm.

[0043] The packing frame of the fixed window screen is leached several times in the uniformly mixed bacteria-containing hydrosol, so that the glue is evenly covered on the window screen, and then in 1% CaCl 2 Soak in saturated boric acid solution for 2h, in 8%KH 2 PO4 Soak in the solution for 40 minutes, take it out and rinse with water for later use.

[0044] What this embodiment adopts is a biological filtration tower wi...

Embodiment 2

[0048] Immobilized cell gel composition:

[0049] Polyvinyl alcohol 7.5%

[0050] Sodium Alginate 1%

[0051] Nitrifying bacteria wet cells 10%

[0052] All the other conditions are with embodiment 1. Table 2 shows the effect of using the biological filler of the present invention to immobilize nitrifying bacteria to treat ammonia-containing waste gas.

[0053] biochemical residence time

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com