Cleaning method and system for dyeing kettle of supercritical CO2 dyeing system

A dyeing system and a cleaning system technology are applied in the field of cleaning methods and cleaning systems for dyeing kettles after dyeing, which can solve the problems of prolonging the passage time of supercritical fluid, difficult cleaning, and high cleaning costs, so as to overcome separation efficiency and use efficiency. Low, wide adaptability, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

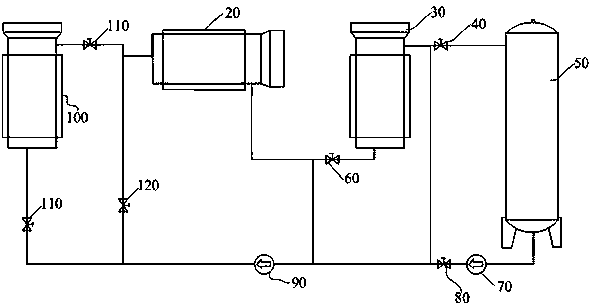

[0035] refer to figure 1 and figure 2 , the present invention is a supercritical CO 2 The specific embodiment of the cleaning method of the dyeing system dyeing still, comprises the following steps,

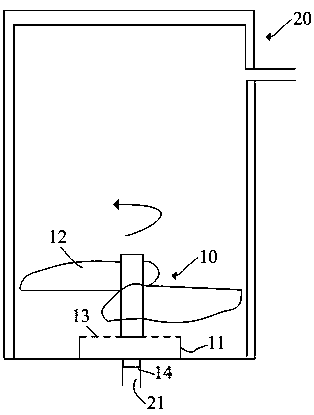

[0036] 1) After staining, turn off the supercritical CO 2 Dyeing system, take out dyed thing, install spoiler impeller 10 in dyeing kettle 2, as figure 2 shown;

[0037] 2) Close the valve 110 between the dyeing kettle 100 and the dyeing kettle 20, and turn on the booster pump 70, and inject an appropriate amount of CO into the dyeing kettle 20 2 , while heating to make the CO in the dyeing kettle 20 2 When the set value of supercritical process parameters is gradually reached, supercritical CO 2 fluid, spoiler impeller 10 in the incoming CO 2 Rotate under the drive of the air flow, the supercritical CO formed in the dyeing still 20 2 The fluid is disturbed and agitated to change the supercritical CO 2 The flow velocity and flow direction of the fluid make it fully flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com