Circulating drainage assembly of clothes treatment equipment and clothes treatment equipment

A technology for clothing treatment equipment and drainage components, applied in the field of washing machines, can solve the problems affecting the washing water cycle spraying process, reducing the cleaning effect of clothing, and easily blocking the spraying port, etc., and achieves simple structure, easy installation and use, and filtering effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

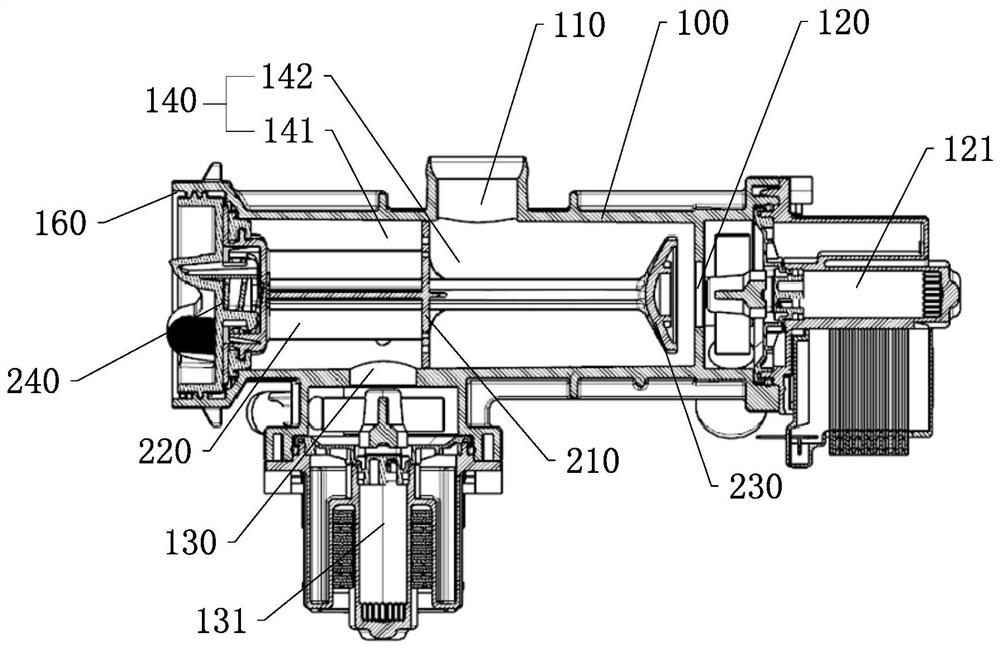

[0048] Circulating drainage assembly of laundry treatment equipment, such as Figure 1 to 5 As shown, including the housing 100 and the filter 200, the inner cavity 140 is formed in the housing, and the housing 100 is provided with an inlet portion 110 that communicates with the inner cavity 140, the drainage water outlet 120 and the circulating water outlet 130, the drain water outlet 120 There is a drain motor 121, and a circulating motor 131 is provided in the circulating water port 130.

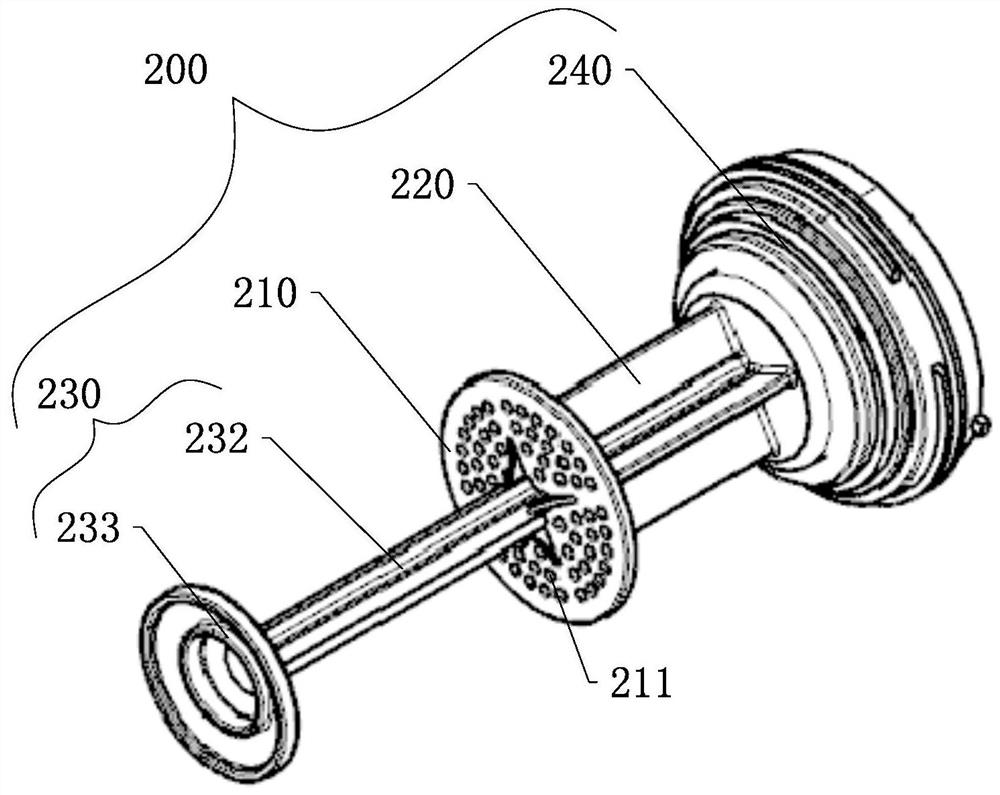

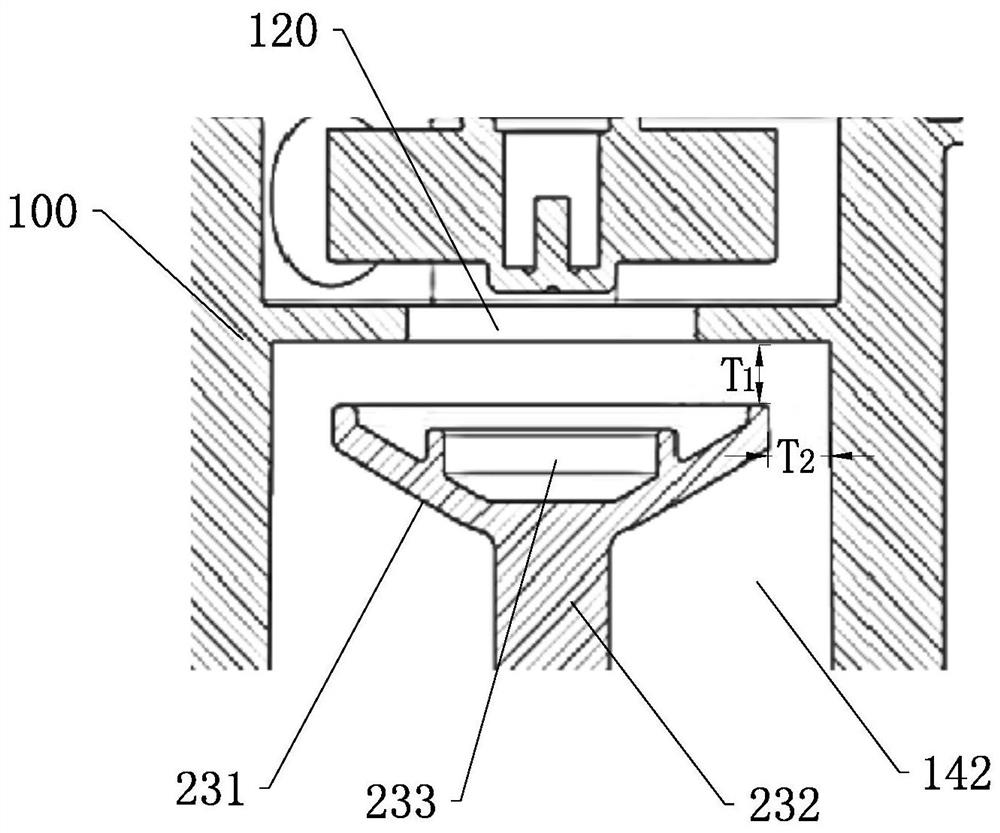

[0049] In this embodiment, one end of the axial direction of the housing 100 is an opening 160 of the inner cavity 140, and the filter 200 is mounted in the lumen 140 by opening 160, and the filter 200 is assembled in the inner cavity 140. 160. The detachable connection structure facilitates cleaning or replacing the filter 200, which is more convenient. The filter 200 includes a first filtering unit 210, a second filter unit 220, a third filtering unit 230, and a mounting cover 240 that fitti...

Embodiment 2

[0060] Clothing treatment equipment, such as Figure 6 As shown, including the body, the circulating drain assembly 400 provided in the bodies 300 and the first embodiment, the bucket 300 includes outer tub 310 and the rotation disposed in the outer tub 310, the inner barrel 320 is used for The clothing and washing water is received, and the barrel 300 is provided with the spray port 330 in communication with the inner bucket chamber, and the bucket 300 communicates with the inlet 100 of the circulating drainage assembly 400, and the spray port 330 is passed through the circulating tube 340. Connect the circulating water outlet 130 of the circulating drainage assembly 400.

[0061] The loop working mode process of the clothing treatment equipment is as follows:

[0062] The washing water in the inner barrel 320 is passed through the inner cavity 140 of the circulating drainage assembly 400 from the inlet tube 500, and the circulation motor 131 operates (at which time the drain mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com