Multi-variety centralized lubrication system for construction elevator

A technology of centralized lubrication and construction, applied in the direction of elevator, engine lubrication, lubrication parts, etc., can solve the problems of irregularity, uneven refueling point, uneven system injection, etc., to achieve uniform displacement and avoid uneven injection. Uniformity, avoids weak spray or small spray volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

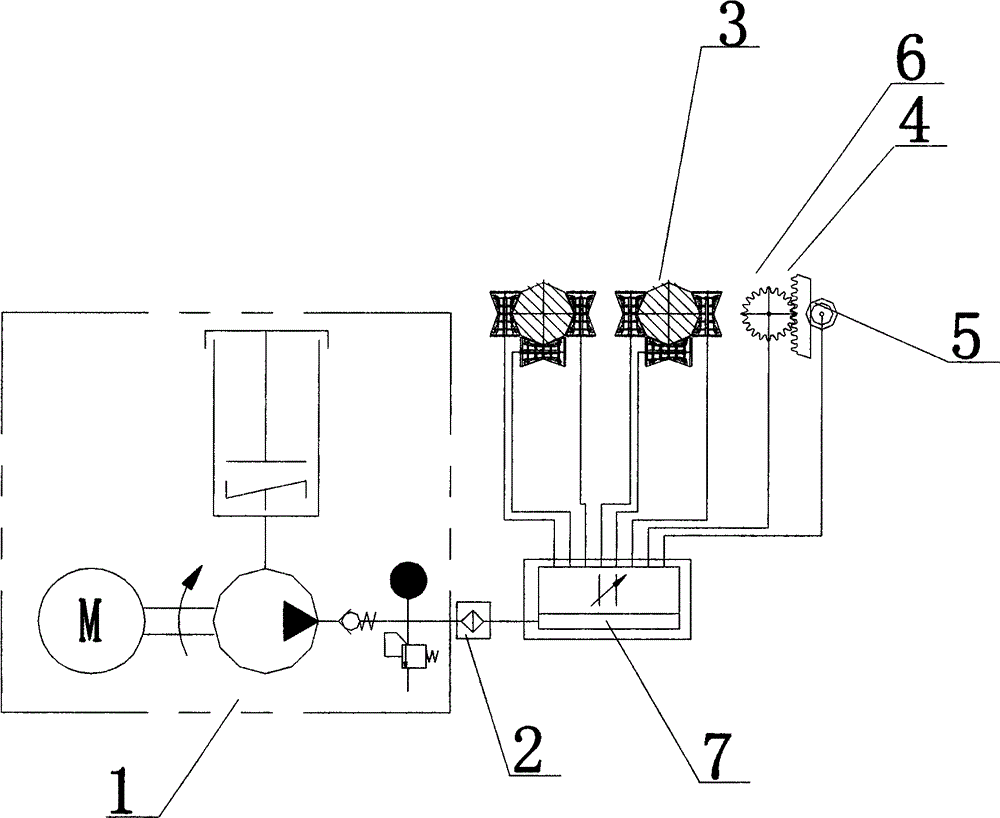

[0018] Such as figure 1 As shown, the various centralized lubrication systems for the building construction elevator include an assembly of an electric lubrication pump 1, a filter 2, an adjustable flow distributor 7, a lubrication guide roller 5 and a lubrication guide gear 6. When working, the electric lubricating pump outputs the lubricating grease with pressure, which is delivered to the adjustable flow distributor through the filter and the main pipeline, and then the adjustable flow distributor delivers the pressure lubricating grease to the lubricating accessories through the branch pipeline. The assembly of the lubricating guide roller and the lubricating guide gear is in close contact with the guide rail of the construction elevator and the rack of the construction elevator within a certain range through the elastic element. When the elevator runs up and down, it drives the assembly of lubricating guide rollers and lubricating guide gears to roll, and the grease pumpe...

Embodiment 2

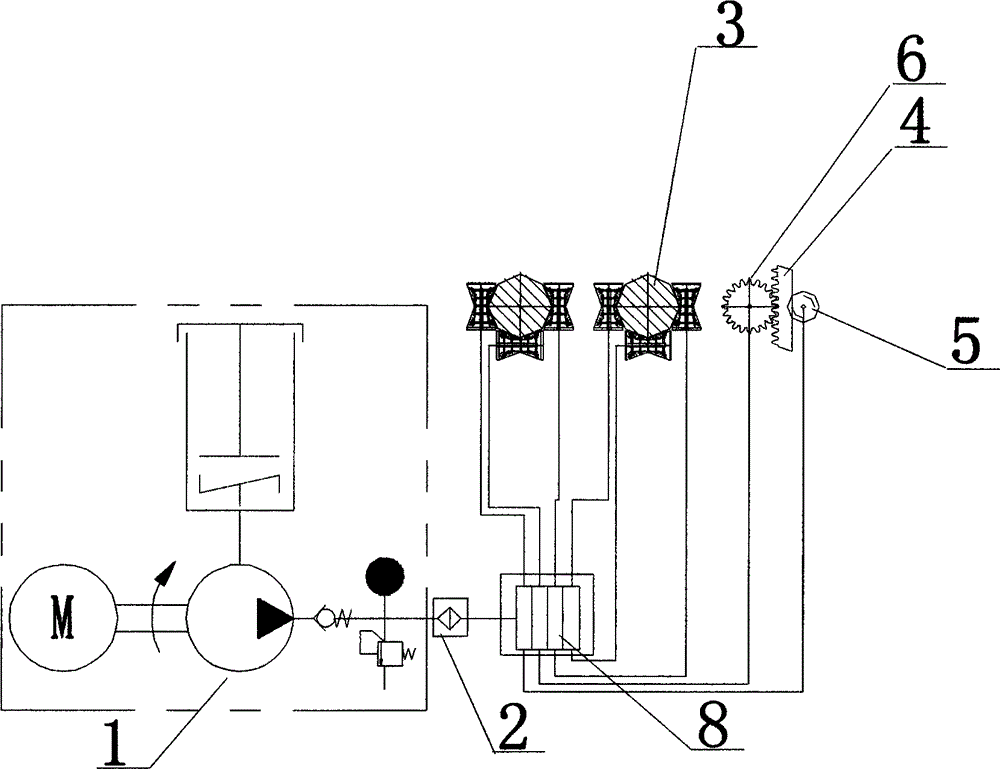

[0020] Such as figure 2 As shown, the various centralized lubrication systems for the building construction elevator include an assembly of an electric lubrication pump 1, a filter 2, a progressive distributor 8, a lubrication guide roller 5 and a lubrication guide gear 6. When working, the electric lubricating pump outputs the lubricating grease with pressure, which is delivered to the progressive distributor through the filter and the main pipeline, and then the progressive distributor delivers the grease with constant quantity and pressure through the branch pipeline to the Lubricate attachments. The combination of the lubricating guide roller and the lubricating guide gear is in close contact with the guide rail of the construction elevator and the rack of the construction elevator within a certain range through the elastic element. When the elevator runs up and down, it drives the lubricating attachment to roll, and the grease pumped continuously is in direct, continuou...

Embodiment 3

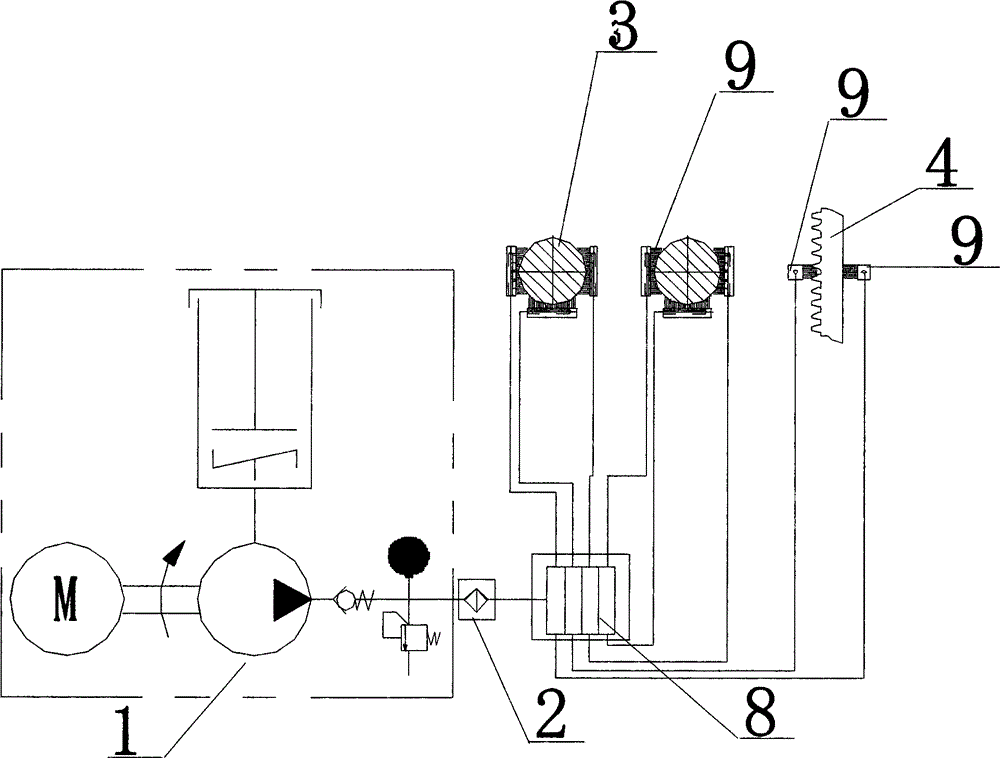

[0022] Such as image 3 As shown, the various centralized lubrication systems for the building construction elevator include an electric lubrication pump 1, a filter 2, a progressive distributor 8, and a lubrication diversion brush 9. During the working process, the electric lubricating pump outputs the lubricating grease with pressure, which is sent to the progressive distributor through the filter and the main pipeline, and then the progressive distributor delivers the quantitative and constant pressure lubricating grease through the branch pipeline to lubricate accessories. The lubricating diversion brush is in close contact with the guide rail of the construction elevator and the rack of the construction elevator within a certain range through the elastic element. When the elevator runs up and down, it drives the lubricating diversion brush to wipe the guide rail and the rack, and the uninterrupted pumped grease passes through the diversion hole system and the bristles to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com