Chemical intervention in-situ emulsification system

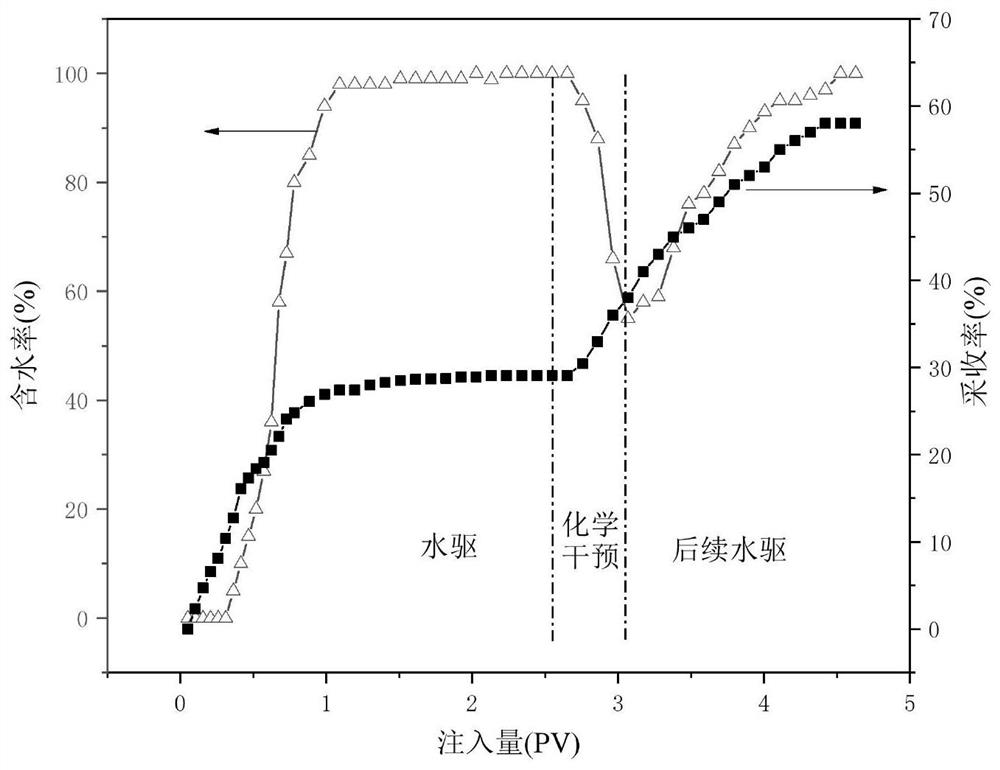

An emulsification system and in-situ technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of complex removal of water components, large energy consumption, and low dehydration efficiency, so as to reduce development contradictions, The effect of reducing the dosage and improving the efficiency of oil washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

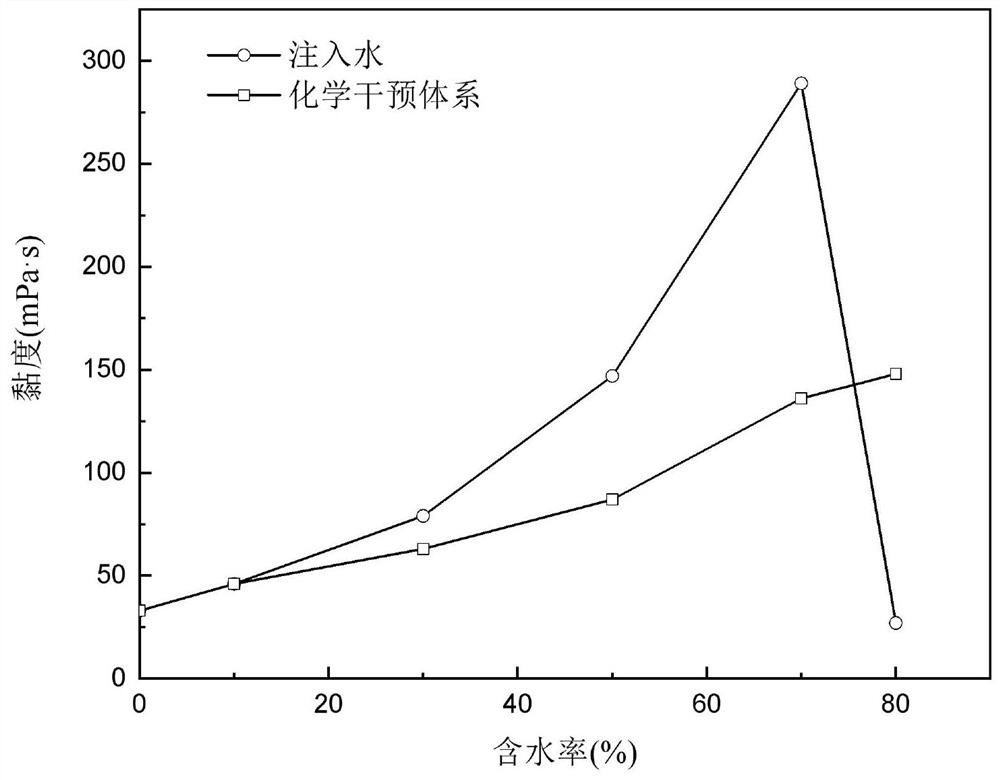

Embodiment 1

[0035] The composition of the chemical intervention in-situ emulsification system: 0.1% oleic acid amidopropyl dimethyl tertiary amine, 0.3% nonyl alcohol polyoxyethylene ether sodium sulfate (the degree of polymerization of polyoxyethylene ether is 7), 0.05% graphene oxide , and the rest is injected water (10×10 4 mg / L NaCl), after adding each component into the injection water, configure a system with a total volume of 100mL, and feed CO into the system at a rate of 300mL / min 2 After 30 minutes, a worm-like micellar system was obtained, which was prepared into chemical intervention emulsification system 1, which is used to adjust the viscosity of the mixture of heavy oil and clear water, so that the viscosity of heavy oil will not change too much during the production process, making it easier to produce.

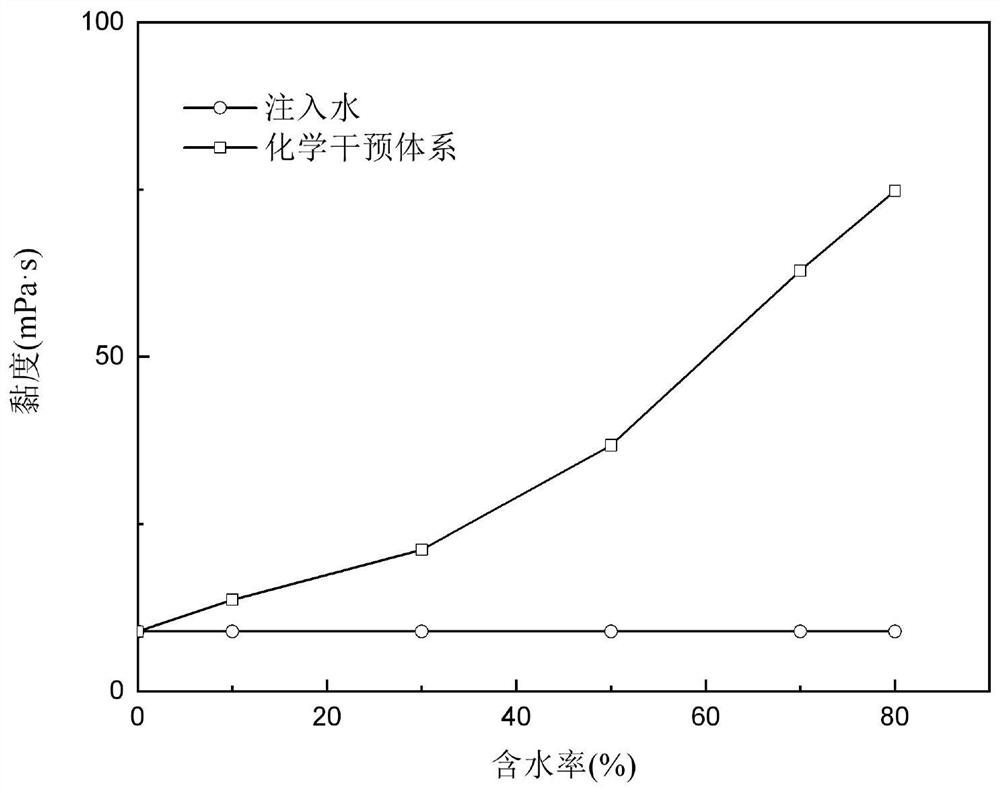

Embodiment 2

[0037] The composition of chemical intervention emulsification system: 0.3% oleic acid amidopropyl dimethyl tertiary amine, 0.15% sodium nonylphenol polyoxyethylene ether carboxylate (the degree of polymerization of polyoxyethylene ether is 7), 0.05% silane coupling agent KH550 modified silica, the rest is injection water. After adding each component into the injection water, configure a system with a total volume of 100mL, and inject CO into the system at a rate of 300mL / min. 2 After 30 minutes, a worm-like micellar system was obtained, which was prepared into chemical intervention emulsification system 2. This system is used to adjust the viscosity of thin oil reservoirs during water flooding, so that the viscosity of the mixture of thin oil and injected water increases, which is convenient for production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com