Micro-machined ultrasonic transducer

An ultrasonic transducer and micromachining technology, applied in metal processing equipment, metal processing machinery parts, instruments, etc., can solve the problems of no contribution to the performance of the transducer, reduced transducer efficiency, and difficult to change independently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The capacitive micro-machined ultrasonic transducer is the most common micro-machined ultrasonic transducer, so the capacitive micro-machined ultrasonic transducer is taken as a specific example below for illustration.

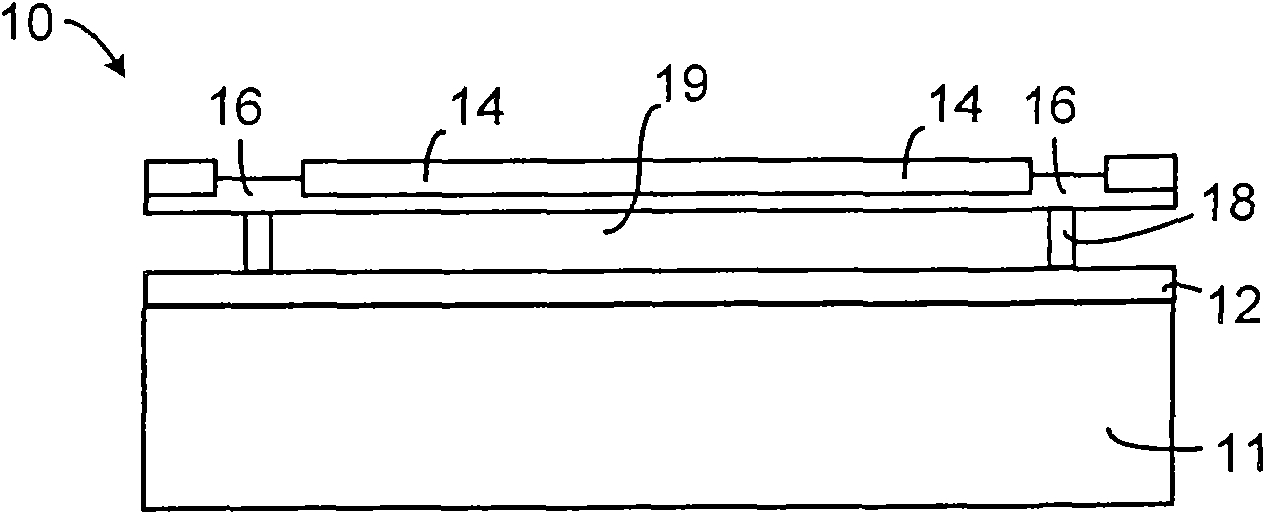

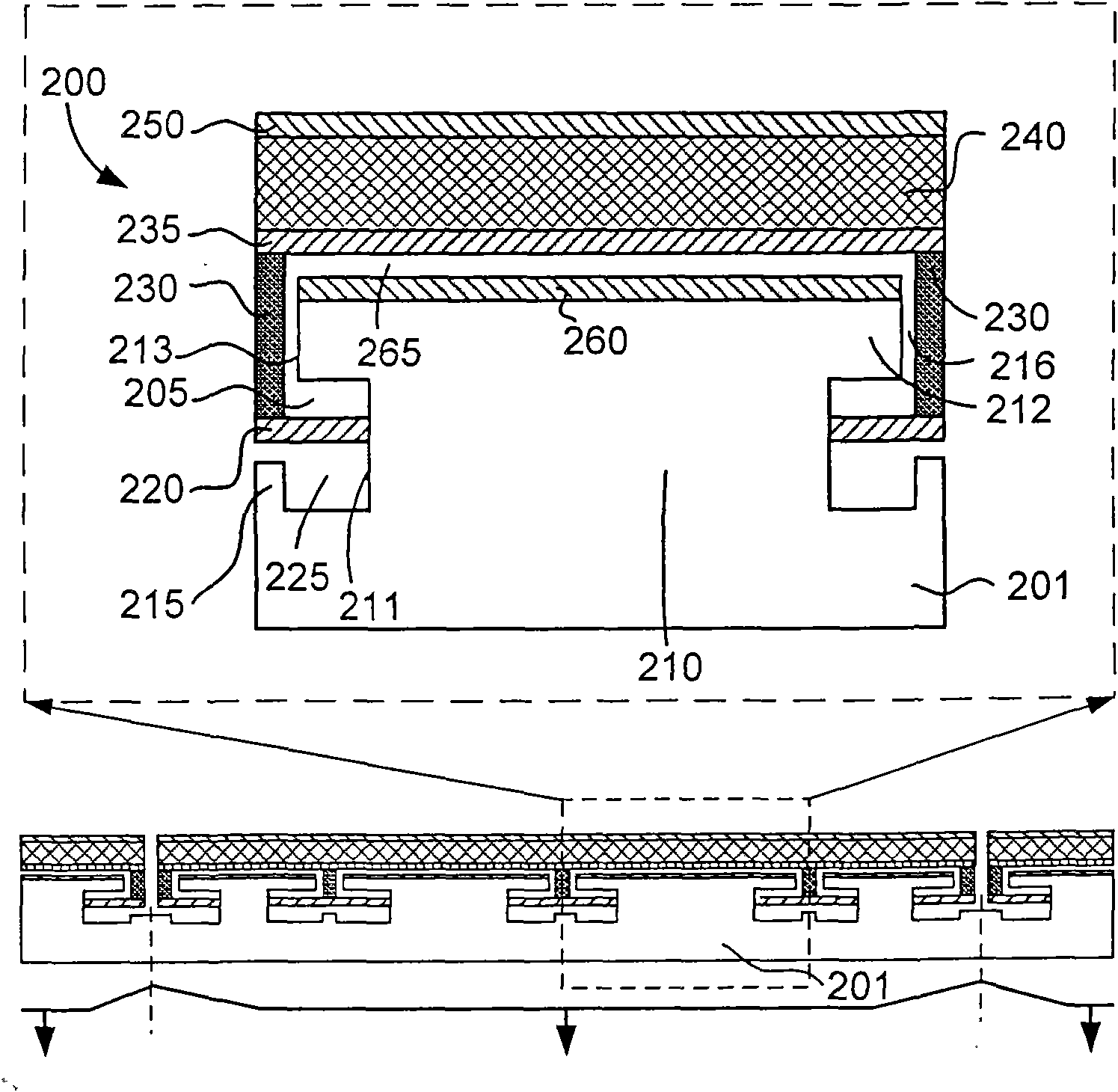

[0075] figure 2A schematic cross-sectional view of specific device embodiments (embodiments) of the spring-embedded capacitive micromachined ultrasonic transducer in the first invention is shown. In the dotted rectangular window is an enlarged view of a basic structural fragment 200 of a capacitive micromachined ultrasound transducer. The basic structural segment 200 of the micromachined ultrasound transducer is a part of a complete transducer or transducer array CMUT1. The transducer or transducer element CMUT1 can be a single device, or a part of a device with multiple elements (eg CMUT1, CMUT2 and CMUT3 as shown).

[0076] The basic structure segment 200 of the transducer is used to illustrate and understand the structure and working principle of ...

Embodiment 2

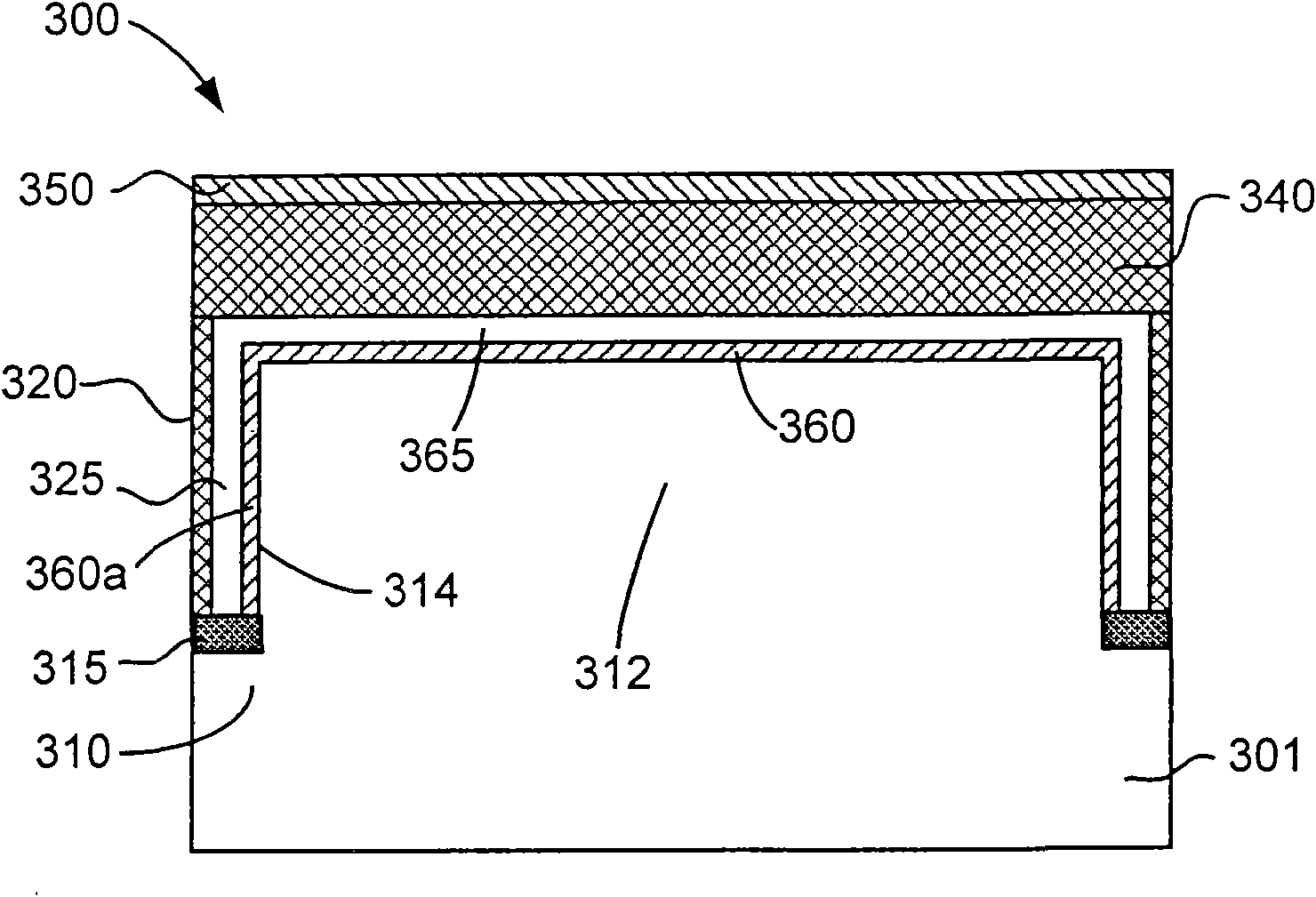

[0094] image 3 A cross-sectional schematic diagram showing the basic structural fragments of specific embodiments of the spring-embedded capacitive micromachined ultrasonic transducer in the second invention. is a spring-embedded capacitive micromachined ultrasonic transducer (the entire transducer is the same figure 2 same, but not in image 3 An enlarged view of the basic structural fragment 300 shown in ). The two spring-like structures shown in the figure are only for the convenience of structural description of the transducer, but according to design requirements, the basic structural segment 300 of the transducer may have different numbers of the same or different spring-like elastic structures.

[0095] The basic structural segment 300 of the spring-embedded capacitive micromachined ultrasonic transducer is made on a substrate 301 . Substrate 301 is a substrate that can be viewed as an upper portion 312 and a lower portion 310 . A surface sheet 340 overlies the uppe...

Embodiment 3

[0100] Figure 4 It shows a cross-sectional schematic diagram of the basic component structure of the specific device device of the spring-embedded capacitive micro-machined ultrasonic transducer in the third invention. Figure 4 is a spring-embedded capacitive micromachined ultrasonic transducer (the entire transducer is the same figure 2 same, but not in Figure 4 An enlarged view of the basic unit 400 shown in ). Two spring-like elastic mechanisms are shown in the figure for the convenience of structural description of the transducer, but according to design requirements, the basic structural segment 400 of the transducer may have different numbers of the same or different spring-like structures.

[0101] The basic structural segment 400 of the transducer is very similar to the basic structural segment 300 of the transducer. The basic structural segment 400 of the transducer has a spring like vertical elastic connector 420 which is curved and connects the surface sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com