Full-automatic assembly device for battery negative electrode and use method of full-automatic assembly device

A battery negative electrode and assembly device technology, which is applied in the field of fully automatic battery negative electrode assembly devices, can solve problems affecting processing quality and efficiency, uneven application of sealant, and inability to grasp time intervals, etc., to solve poor practicability and speed up processing Efficiency, the effect of reducing operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention;

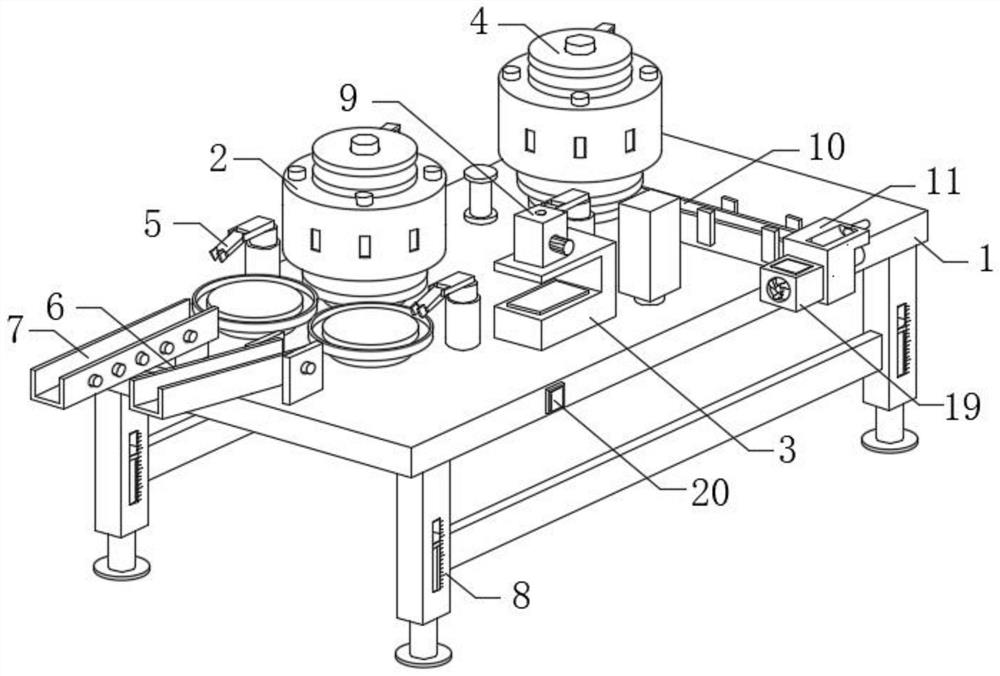

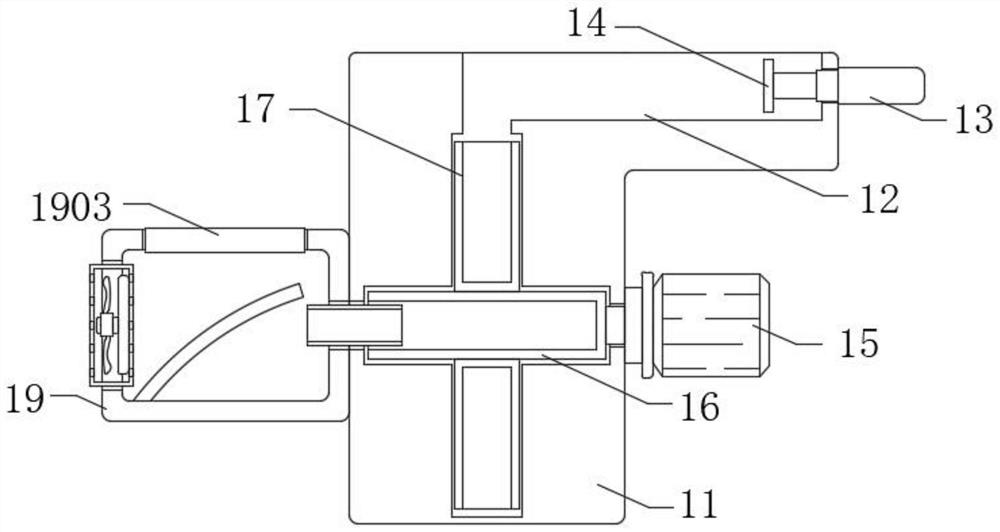

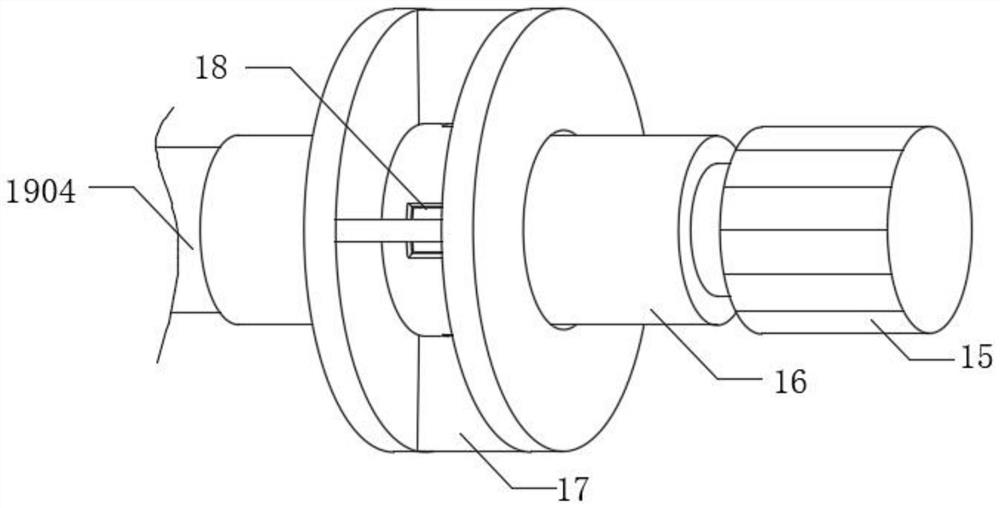

[0037] see Figure 1-8, in the present invention, a battery negative fully automatic assembly device, including a workbench 1, a spot welding piece welding plate 2, a glue application mechanism 3, an assembly piece assembly plate 4 and a mechanical arm 5 evenly distributed, and a spot welding piece welding plate 2 , gluing mechanism 3, assembly assembly disc 4 and mechanical arm 5 are all installed on the top of workbench 1, and the top of workbench 1 is equipped with copper needle inlet chute 6 and negative electrode bottom inlet chute 7, copper needle inlet chute 6 and negative electrode The bottom inlet chute 7 is located on the left side of the spot weldment welding plate 2, the bottom of the workbench 1 is provided with an adjustment mechanism 8, the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com