Equipment and method for producing powdery vanadium oxide

A powdery vanadium pentoxide technology, which is applied in the field of equipment for producing powdery vanadium pentoxide, can solve the problems of lowering the product grade of vanadium pentoxide, insufficient dehydration and deamination of APV, easy agglomeration and ring formation of APV, etc. , to achieve a thorough reaction, ensure an oxidizing atmosphere, and improve the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

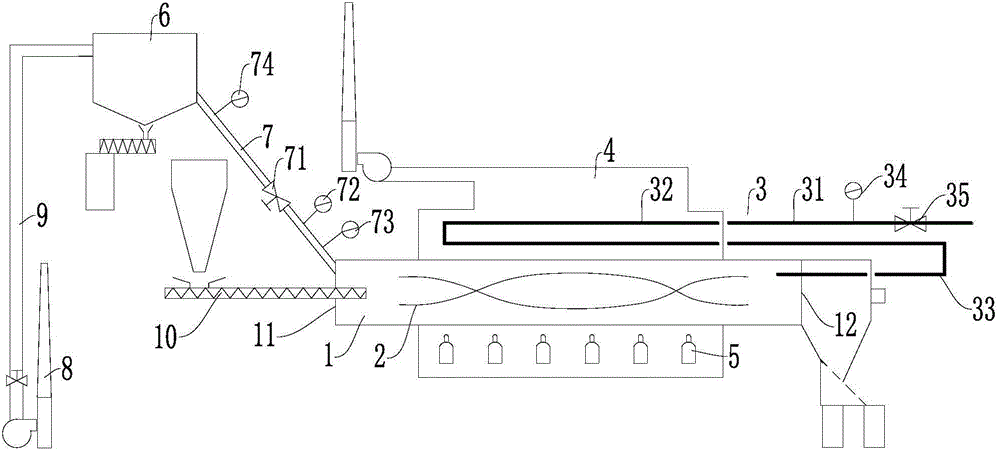

[0049] When the angle between the rotary kiln shell 1 and the horizontal plane is 3°, the ordinary APV: TV: 49.1%, Si: 0.07%, S: 0.17%, Fe: 0.08%, Na 2 O+K 2 O: 0.4%, the production is organized at a feed rate of 50kg / h, the temperature of the hot air blown into the inner cavity of the rotary kiln shell 1 is 200°C, and the flow rate of the hot air is 15m 3 / h, temperature from 1 to 6 points is 520°C, 560°C, 580°C, 580°C, 590°C, 250°C, cylinder speed is 40s / r, cylinder negative pressure is -100pa, oxygen volume concentration is 19.8%, The quality of the powdery vanadium pentoxide produced is V 2 o 5 : 99.13%, V 2 o 4 : 0.6%, Si: 0.08%, Fe: 0.09%, Na 2 O+K 2 O: 0.47%, S: 0.06%, P: 0.005%, As: 0.005%.

Embodiment 2

[0051] When the angle between the rotary kiln shell 1 and the horizontal plane is 3°, the ordinary APV: TV: 48.5%, Si: 0.18%, S: 0.26%, Fe: 0.22%, Na 2 O+K 2 O: 0.93%, the production is organized at a feed rate of 70kg / h, the temperature of the hot air blown into the inner cavity of the rotary kiln shell 1 is 200°C, and the flow rate of the hot air is 25m 3 / h, the temperature from 1 to 6 points is 500°C, 590°C, 590°C, 600°C, 590°C, 200°C, the rotating speed of the cylinder is 55s / r, the negative pressure of the cylinder is -50pa, and the oxygen volume concentration is 19.5%. The quality of the powdery vanadium pentoxide produced is V 2 o 5 : 98.53%, V 2 o 4: 1.3%, Si: 0.21%, Fe: 0.12%, Na 2 O+K 2 O: 1.07%, S: 0.10%, P: 0.005%, As: 0.005%.

Embodiment 3

[0053] When the angle between the rotary kiln shell 1 and the horizontal plane is 7°, the ordinary APV: TV: 49.5%, Si: 0.04%, S: 0.06%, Fe: 0.03%, Na 2 O+K 2 O: 0.21%, the production is organized at a feed rate of 50kg / h, the temperature of the hot air blown into the inner cavity of the rotary kiln shell 1 is 300°C, and the flow rate of the hot air is 40m 3 / h h, temperature from 1 to 6 points is 550°C, 585°C, 600°C, 600°C, 550°C, 270°C, cylinder speed is 25s / r, cylinder negative pressure is -150pa, oxygen volume concentration is 20.8%, The quality of the powdery vanadium pentoxide produced is V 2 o 5 : 99.62%, V 2 o 4 : 0.2%, Si: 0.05%, Fe: 0.04%, Na 2 O+K 2 O: 0.26%, S: 0.04%, P: 0.005%, As: 0.005%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com