Tower type solar heat absorber with heat storage capacity

A technology of solar heat absorber and heat storage capacity, which is applied to solar heat collectors, solar heat collectors in specific environments, and solar heat collectors using working fluids, etc. Problems such as the temperature of the hot working medium and the bursting of the heat-absorbing tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The patent application of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments (embodiments). The specific embodiments described here are only used to explain the patent application of the present invention, but not as a basis for limiting the patent application of the present invention.

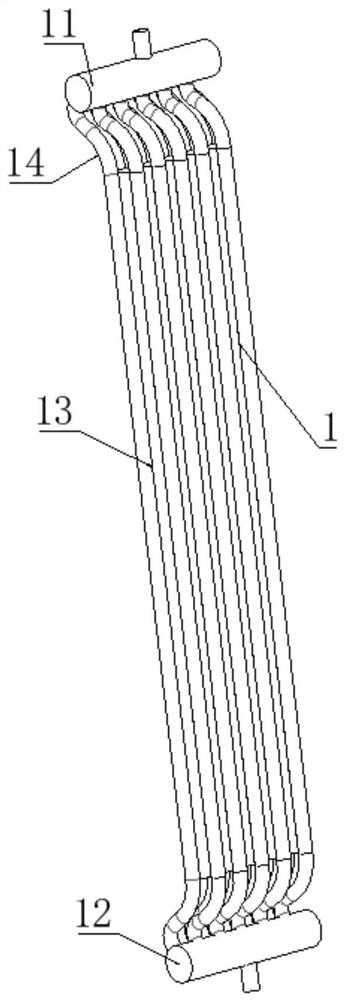

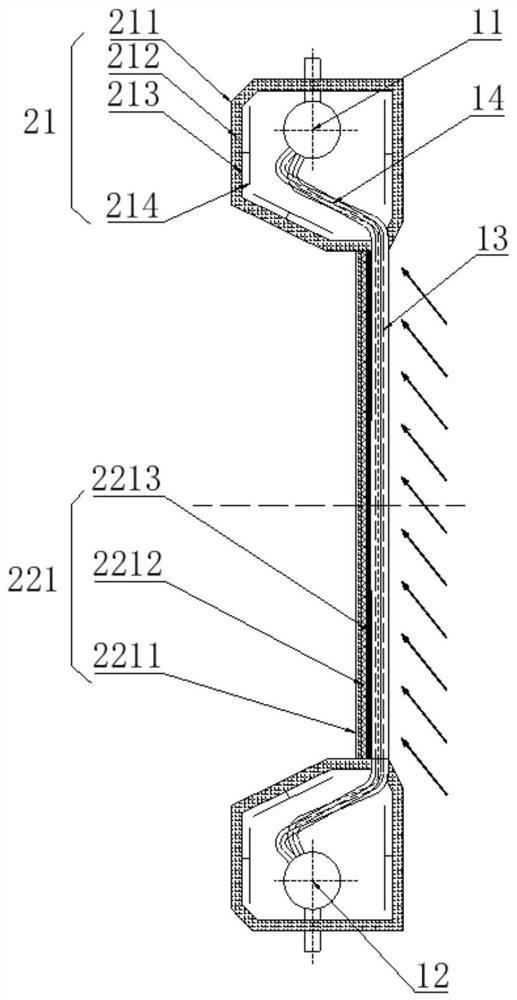

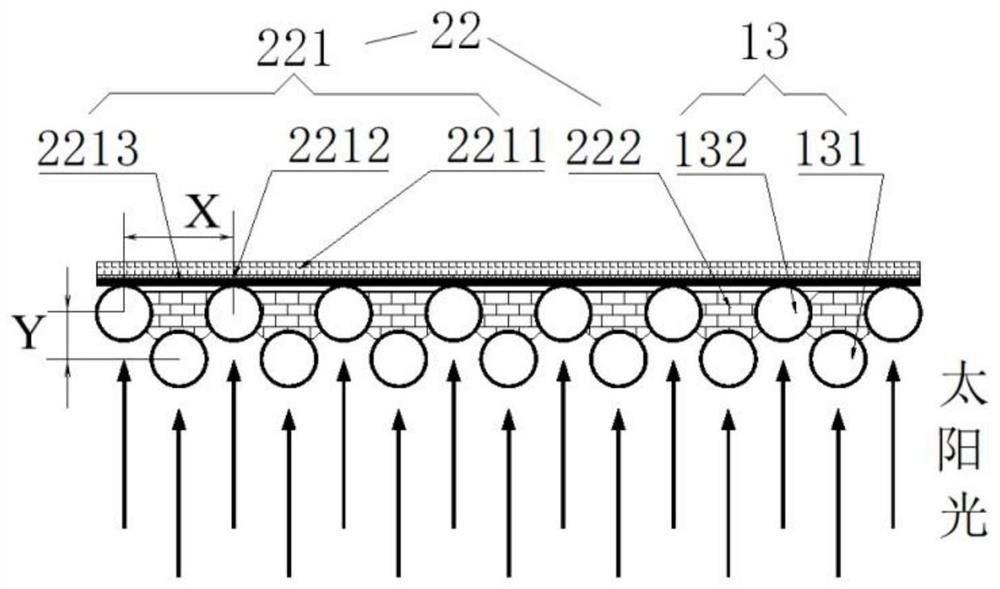

[0037] see Figure 1-2 , the present invention provides a tower-type solar heat absorber with heat storage capacity, including a heat absorbing panel 1, which is upright and arranged circumferentially around the center of the heat absorber, characterized in that: the heat absorbing panel 1 includes the upper header 11, the lower header 12, and the heat-absorbing pipes 13 fixedly connected to the upper header 11 and the lower header 12 through the connecting pipe 14; the heat-absorbing panel 1 is also provided with heat storage Heat preservation device 2, described heat storage heat preservation device 2 comprises h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com