Industrial basket type pipeline heating device and heating method thereof

A heating device, basket-type technology, applied in the direction of pipeline heating/cooling, pipeline protection, pipeline system, etc., can solve the problems of small heating area, low heating efficiency, etc., achieve strong corrosion resistance, small post-maintenance, and few limiting factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

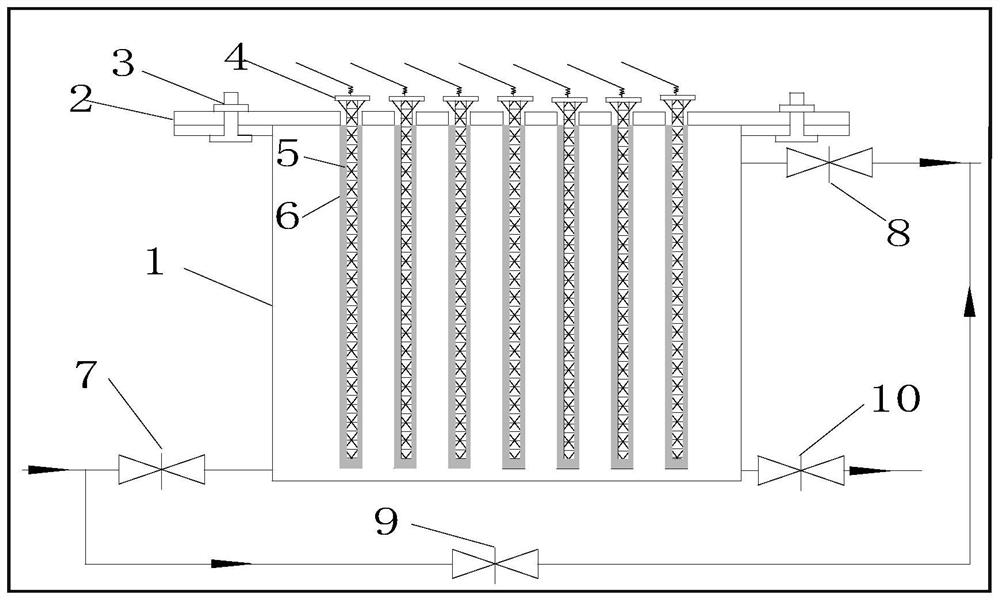

[0020] Such as figure 1 As shown, an industrial basket-type pipeline heating device, firstly use carbon steel plate to make a basket-type container 1 and stainless steel 316L to make a fixed flange 2, and prepare bolt fasteners 3 and silicone rubber seals of appropriate size for sealing pad. 49 heating sleeves 6 are made of stainless steel 316L, with a length of 900mm. The heating sleeves 6 pass through the customized flange 2 and are inserted into the basket container 1. They are welded to the fixed flange 2 and evenly distributed on the fixed flange 2. Above, the heat-conducting silicone oil 5 is embedded in the heating sleeve 6, and a 2kW electric heating rod 4 is installed in each heating sleeve 6, and the heat-conducting silicone oil 5 is heated after being energized. When the temperature gun measures the temperature of the heat-conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com