Method and device for internal and external spherical surface polishing of hollow sphere

A technology of hollow spheres and outer spherical surfaces, which is applied in the direction of grinding devices, grinding/polishing safety devices, grinding machine tools, etc., can solve the problems of high cost, difficult processing, and difficult processing, so as to reduce surface waviness and ensure ball Cardiac coincidence, the effect of reducing limiting factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

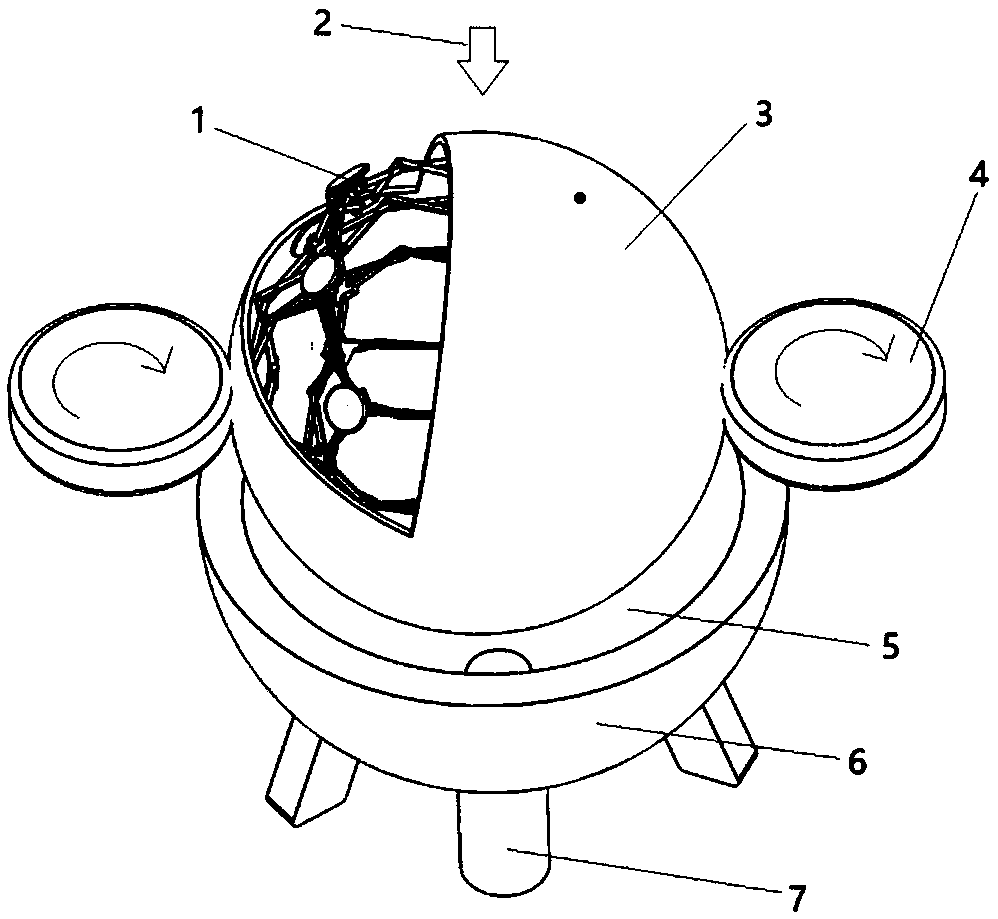

[0024] see Figure 1~4 , The embodiment of the present invention is provided with an extendable inner spherical polishing ball tool 1 and an outer spherical polishing system. The inner spherical surface grinding and polishing tool and the outer spherical surface grinding and polishing system process the hollow spherical workpiece 3 at the same time, so as to ensure the center coincidence degree of the processed inner and outer spherical surfaces.

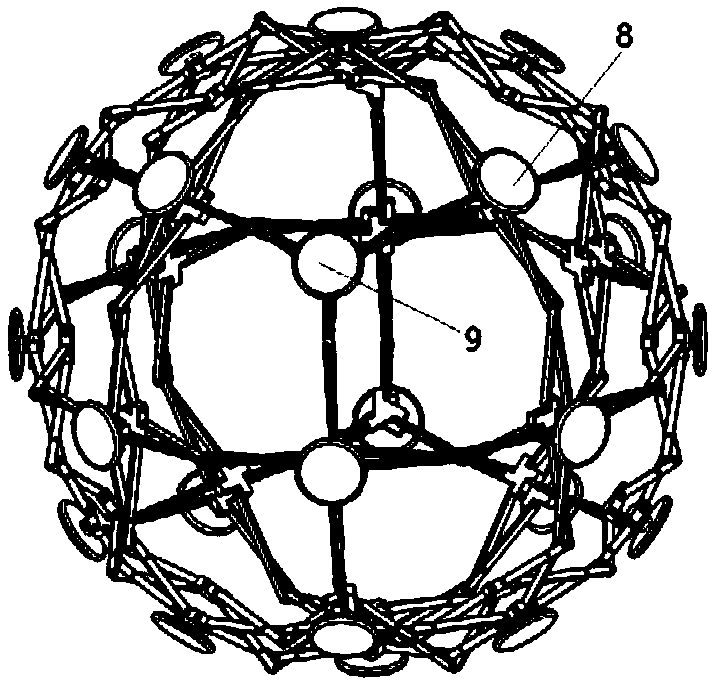

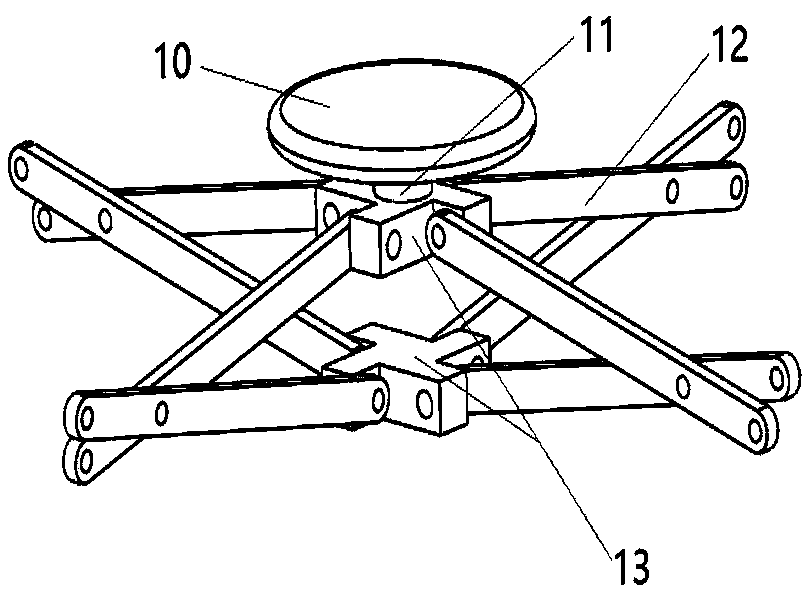

[0025] The extensible inner spherical grinding and polishing ball tool is composed of a three-dimensional expandable spherical support structure, a ball hinge and a small piece of flexible grinding and polishing pad. The three-dimensional stretchable spherical support structure includes unit A (marked as 8) and unit B (marked as 9). The units are connected by hinges. Unit A is connected with unit B to form three circular c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com