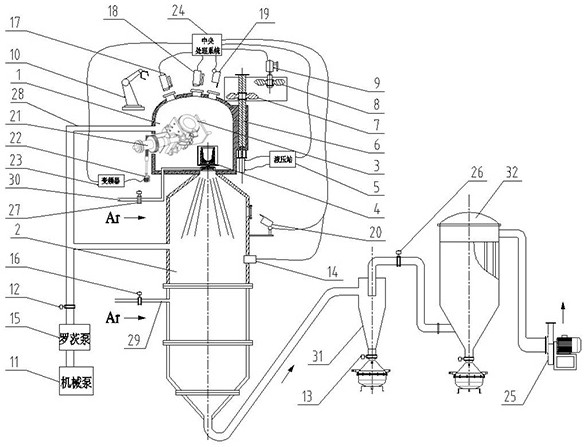

Full-automatic vacuum tight coupling gas atomization device and method thereof

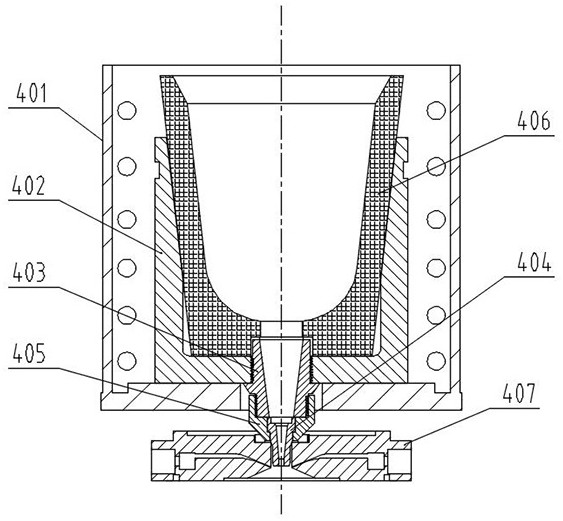

A fully automated, tightly coupled technology, applied in the field of vacuum air atomization to prepare metal powder, can solve the problems of low sensitivity, affecting the industrial production process of VIGA technology, poor stability, etc., to reduce costs, prevent nodules and blockage, prevent The effect of molten steel leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

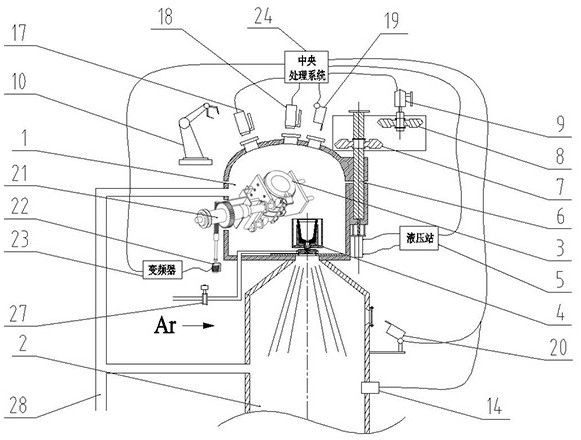

[0052] Taking the preparation of 316L stainless steel metal powder for 3D printing as an example, a fully automatic gas atomization method of a vacuum close-coupled gas atomization device of the present invention includes the following steps:

[0053] (1) Loading: The central processing system 24 issues a "loading" command, and the hydraulic station 5 drives the hydraulic cylinder 6 to drive the furnace cover of the smelting chamber 1 up until the first gear 7 meshes with the second gear 7; then the first motor 9 drives the second gear 7 to rotate, and drives the furnace cover of the smelting chamber 1 to rotate 90° and then stops, and then the feeding manipulator 10 starts to move the 316L rods into the crucible 3; when the charge reaches 220kg, the first motor 9 reverses Turn 90° to return to the initial position, then the hydraulic station 5 drives the hydraulic cylinder 6, and drives the furnace cover of the smelting chamber 1 down until the furnace cover is closed, realizi...

Embodiment 2

[0061] Taking the preparation of 18Ni300 stainless steel metal powder for 3D printing as an example, a fully automatic gas atomization method of a vacuum close-coupled gas atomization device of the present invention includes the following steps:

[0062] (1) Loading: The central processing system 24 issues a "loading" command, the hydraulic station 5 drives the hydraulic cylinder 6, and drives the furnace cover of the melting chamber 1 to rise until the first gear 7 meshes with the second gear 8; then the first motor 9 drives the second gear 8 to rotate, and drives the furnace cover of the smelting chamber 1 to rotate 90° and then stops, and then the loading manipulator 10 starts to move the 18Ni300 rods into the crucible; when the loading reaches 210kg, the first motor 9 reverses Return to the initial position at 90°, then the hydraulic station 5 drives the hydraulic cylinder 6, and drives the furnace cover of the smelting chamber 1 down until the furnace cover is closed, real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com