Ultrasonic in-situ loading device for laser melting deposition forming

A technology of laser melting deposition and in-situ addition, which is applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc., to achieve the effect of realizing microstructure, grain refinement and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

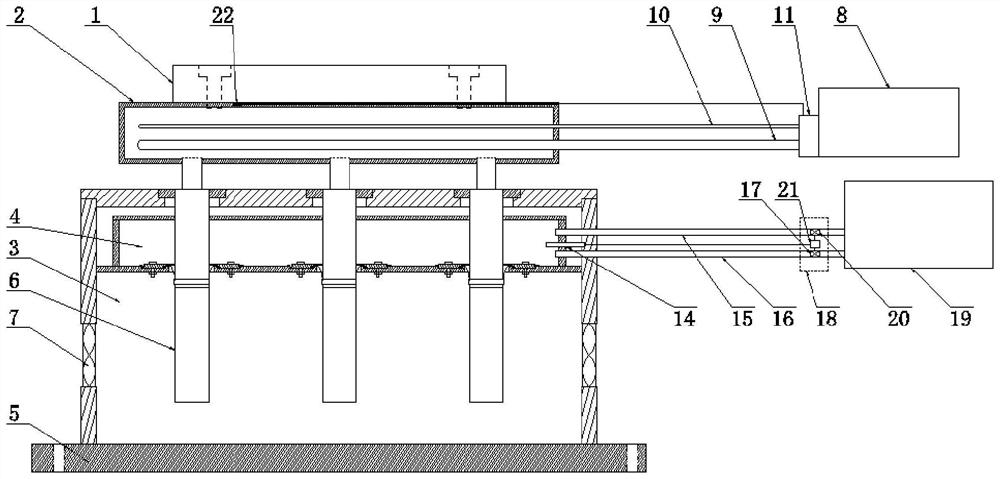

[0021] Embodiment 1: The ultrasonic in-situ loading device for laser melting deposition forming in this embodiment is composed of a substrate 1, a temperature control plate 2, an air-cooled chamber 3, a water-cooled chamber 4, a fixed base 5 and an ultrasonic vibrator 6;

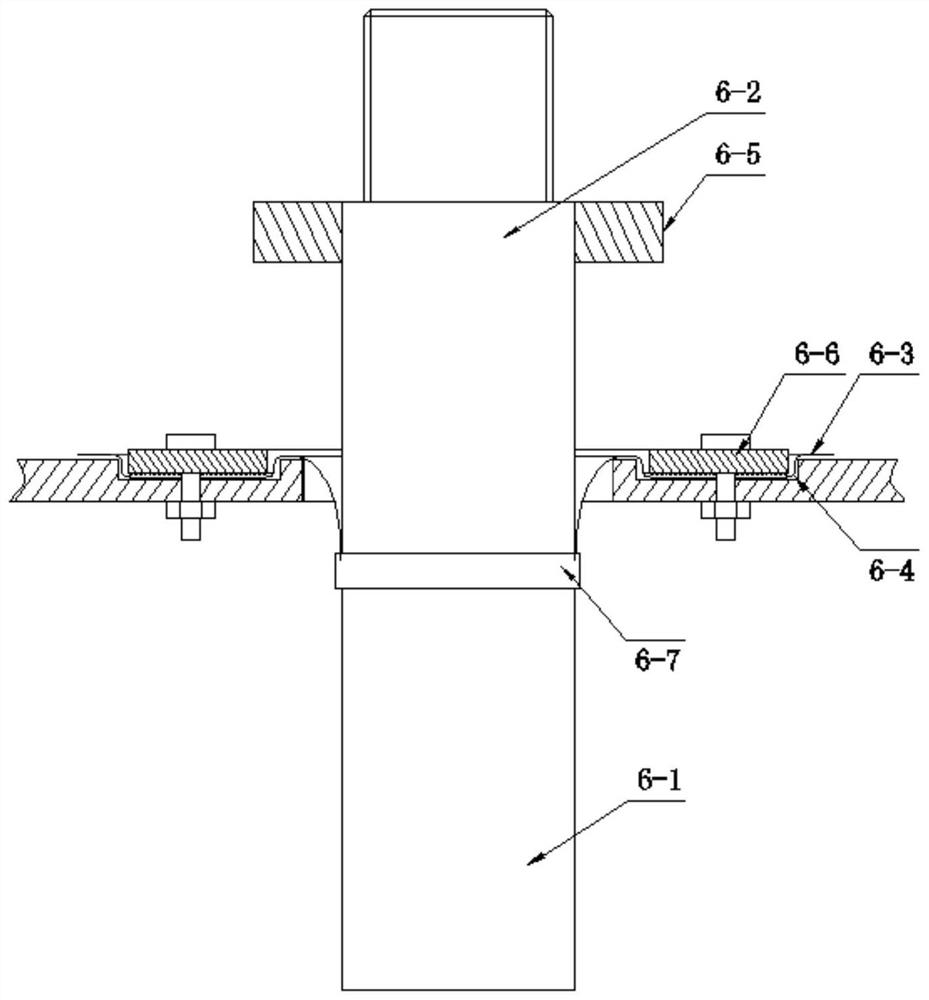

[0022] The base plate 1 is arranged on the upper surface of the temperature control board 2 and fixedly connected by bolts; the air-cooled bin 3 is arranged under the temperature control board 2, the bottom plate 5 of the air-cooled bin 3 is a fixed base, and the side wall of the air-cooled bin 3 is provided with The air vent is provided with a fan 7; the water cooling chamber 4 is arranged in the air cooling chamber 3, and the bottom plate of the water cooling chamber 4 is fixedly connected with the inner wall of the air cooling chamber 3; the top plate of the water cooling chamber 4 is provided with a plurality of through holes, each Mounting holes are provided on the bottom plate of the water-cooled wareho...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the rubber sleeve 6-3 is funnel-shaped.

specific Embodiment approach 3

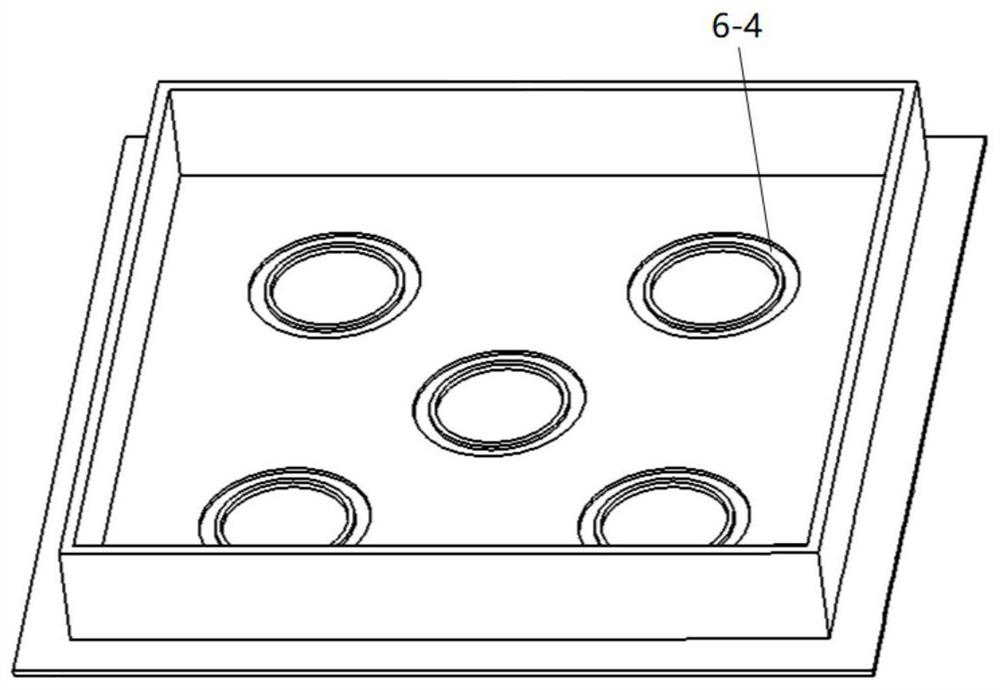

[0031] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the top plate of the water-cooled chamber 4 is provided with 5 through holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com