Flexible seal coal powder injection ball valve

A flexible sealing and pulverized coal technology, which is applied to the valve details, valve device, valve housing structure, etc., can solve the problems affecting the normal operation of the valve, the increase of valve opening and closing torque, and valve leakage, so as to achieve simple structure and prevent valve clogging , the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

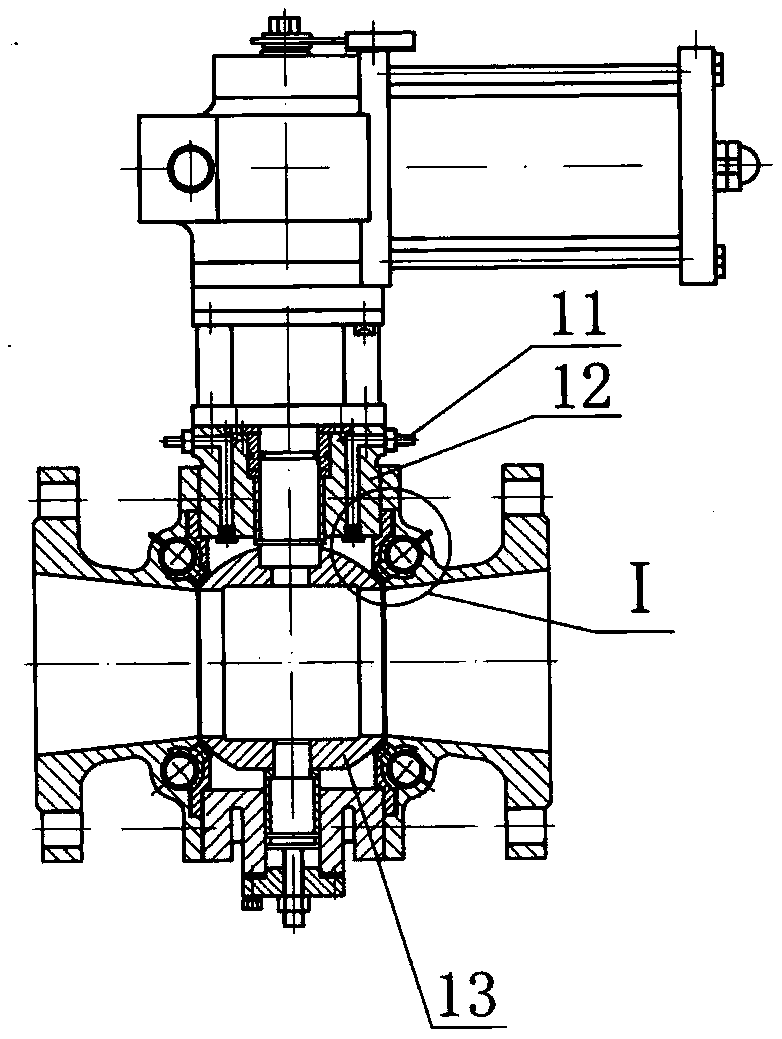

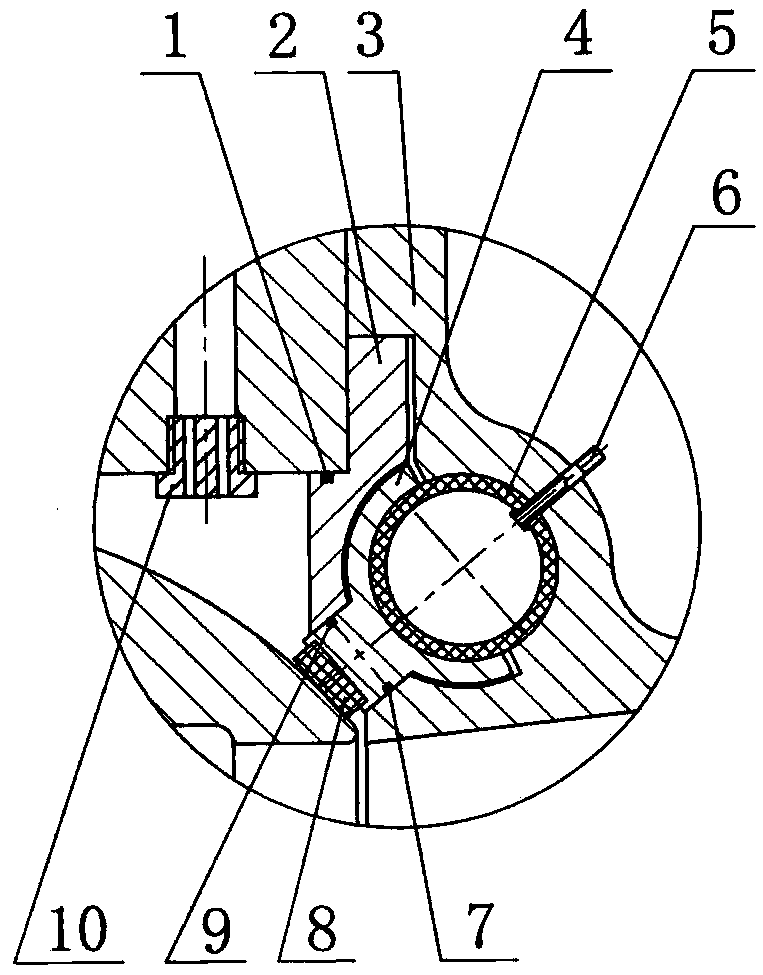

[0011] A flexible sealed pulverized coal injection ball valve, including a valve body 12, a valve cover 3, a ball 13, an insert 2, a sealing ring support ring 4, an air bag 5, an air valve 6, and a sealing ring 8; the insert includes a The stepped structure and the concave ring surface integrated with the stepped structure, one end of the stepped structure is in contact with the valve body, and the concave ring surface is in contact with the inner side of the valve cover; The spherical surface is in sliding contact with the insert and the valve cover, the head is equipped with a sealing ring, and the side is equipped with O-shaped sealing rings 7 and 9, and the O-shaped sealing rings are installed in the sealing groove on the side; the sealing ring is opposite to the sphere; The airbag is a ring-shaped sealing body made of rubber, and the airbag is equipped with an air valve 6. The airbag is installed between the valve cover and the sealing ring support ring, and the valve cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com