Grain drying yard paver

A technology for paving vehicles and grains, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., and can solve the problems of cumbersome paving procedures, low paving efficiency, and high labor intensity of paving, and solve the problems of cumbersome paving procedures, Ingenious design and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

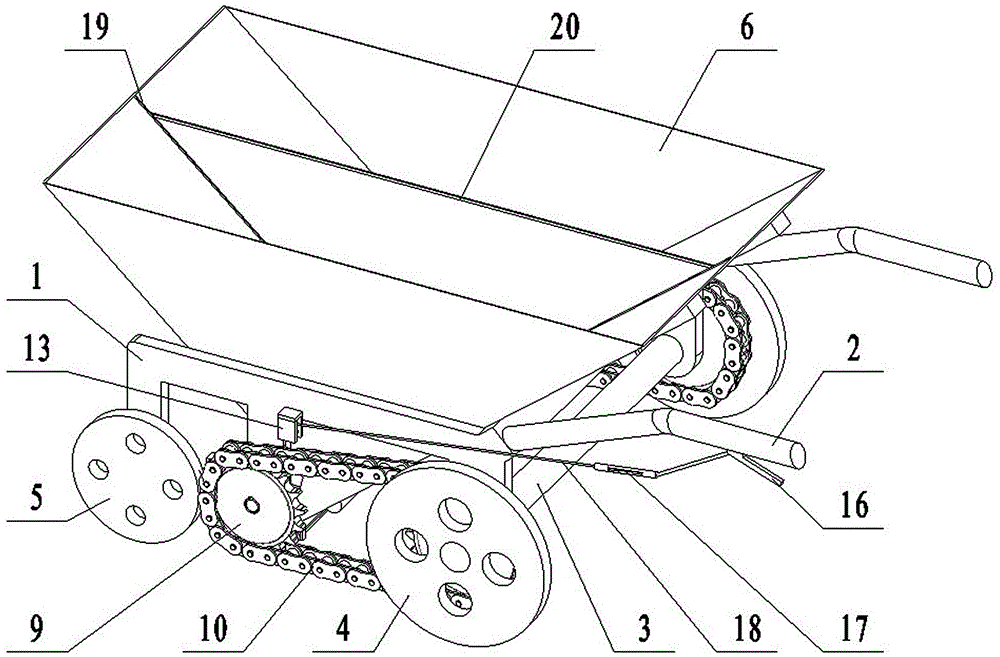

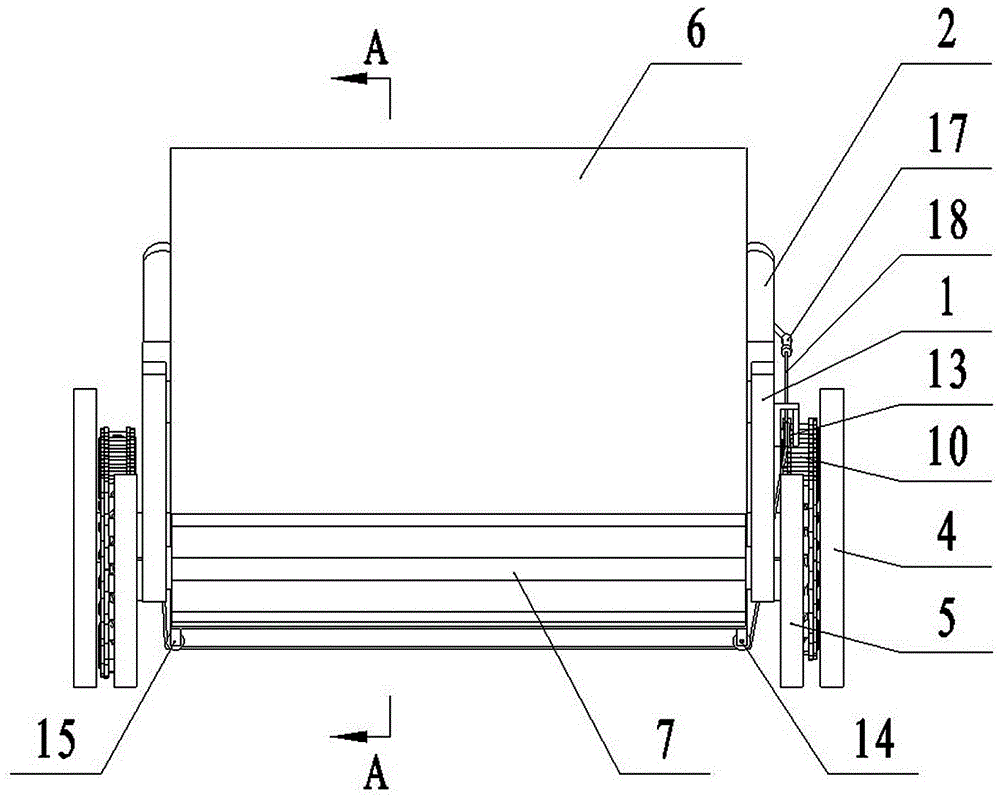

[0014] Grain drying field paving vehicle, including the body part, grain paving part, control and adjustment part;

[0015] The car body part includes a vehicle frame 1, an armrest 2, a wheel shaft 3, a front wheel 4, and a rear wheel 5; the number of the armrests 2 is two, and the two armrests 2 are respectively fixedly assembled on the left front part and the right front part of the vehicle frame 1 The axle 3 is rotatably assembled on the front portion of the vehicle frame 1; the number of the front wheels 4 is two, and the two front wheels 4 are respectively fixedly assembled on the left end and the right end of the axle 3; the number of the rear wheels 5 is two, and the two Two rear wheels 5 are respectively rotated and assembled on the left rear part and the right rear part of the vehicle frame 1;

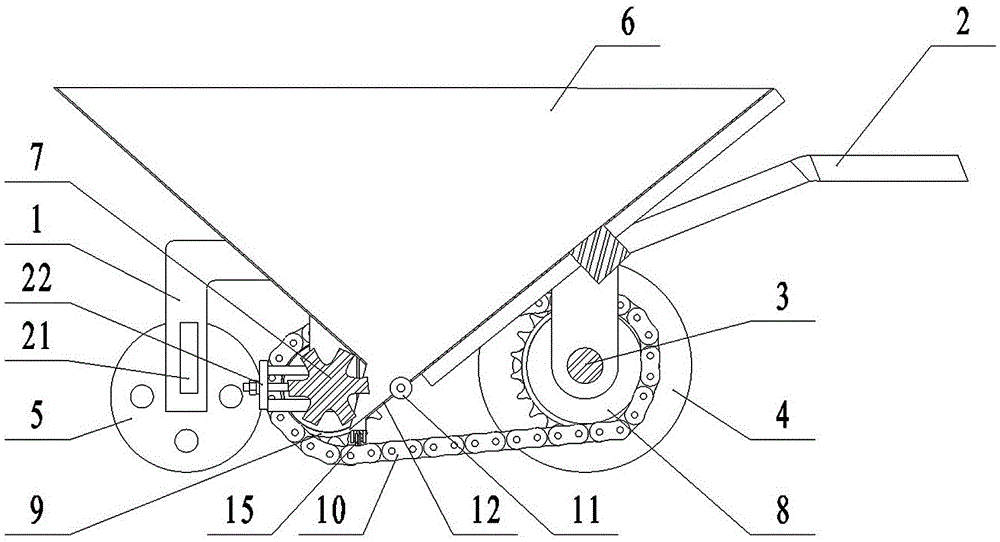

[0016] The grain paving part includes a grain temporary storage bin 6, a discharge drum 7, a driving sprocket 8, a driven sprocket 9, and a chain 10; the grain temporary stora...

Embodiment 2

[0021] Grain drying field paving vehicle, including the body part, grain paving part, control and adjustment part;

[0022] The car body part includes a vehicle frame 1, an armrest 2, a wheel shaft 3, a front wheel 4, and a rear wheel 5; the number of the armrests 2 is two, and the two armrests 2 are respectively fixedly assembled on the left front part and the right front part of the vehicle frame 1 The axle 3 is rotatably assembled on the front portion of the vehicle frame 1; the number of the front wheels 4 is two, and the two front wheels 4 are respectively fixedly assembled on the left end and the right end of the axle 3; the number of the rear wheels 5 is two, and the two Two rear wheels 5 are respectively rotated and assembled on the left rear part and the right rear part of the vehicle frame 1;

[0023]The grain paving part includes a grain temporary storage bin 6, a discharge drum 7, a driving sprocket 8, a driven sprocket 9, and a chain 10; the grain temporary storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com