Electro-hydraulic fully variable air distribution device and control method

A control method and a variable technology, applied in the direction of valve devices, non-mechanically actuated valves, engine components, etc., can solve the problems that the electromagnetic drive mode is difficult to meet at the same time, and achieve simple structure, increased service life, and low processing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

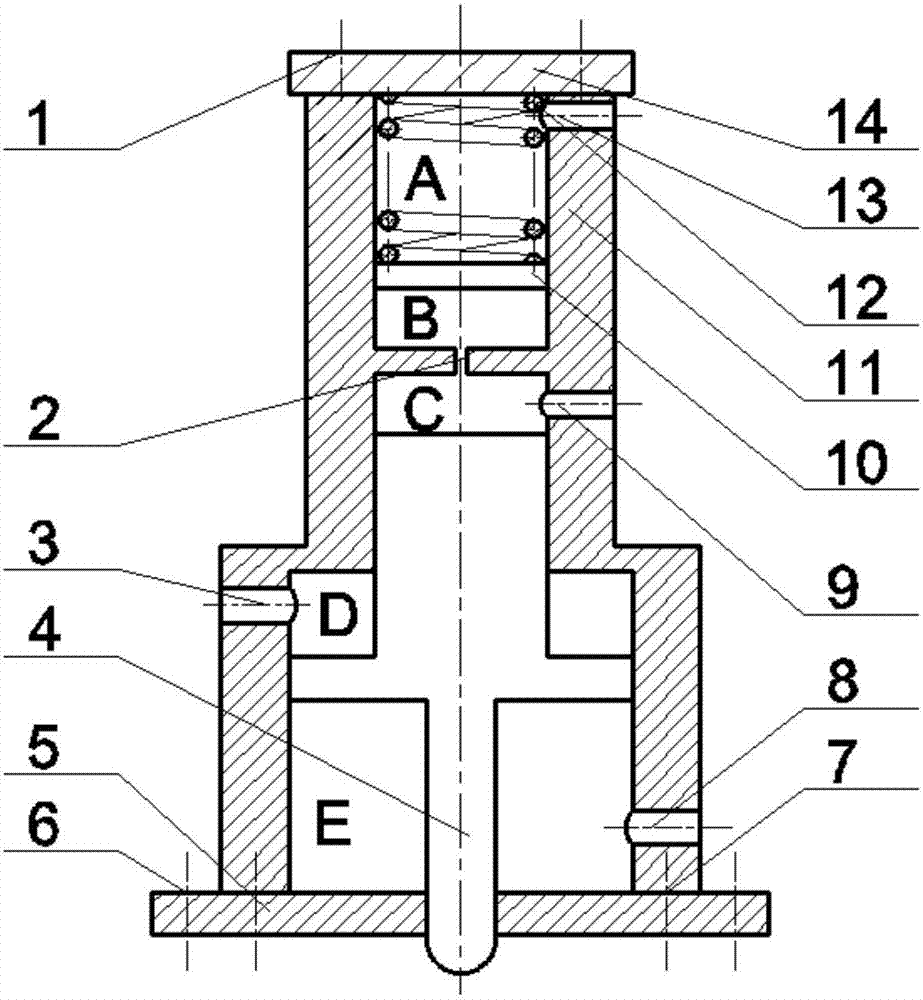

[0042] The invention discloses an electro-hydraulic fully variable gas distribution device and a control method. The specific implementation and principle of the control method are as follows:

[0043] (1) combination Figure 4 , the cylinder valve is closed, the buffer control valve, lift control valve and electromagnetic reversing valve are in a power-off state, and the A, B, C, D, E hydraulic chambers of the electro-hydraulic fully variable air distribution actuator are all in a low-pressure state. Among them, the A hydraulic cavity is filled with hydraulic oil, and the hydraulic oil is always in a low pressure state;

[0044] (2) Power on the electromagnetic reversing valve, and the high-pressure hydraulic oil is poured into the D hydraulic chamber through the high-pressure oil port, and the A, B, C, and E hydraulic chambers are in a low-pressure state. Under the action of the hydraulic pressure, the main piston pushes the air valve Move down, the air valve opens;

[0045]...

Embodiment 2

[0062] combine Figure 4 , an electro-hydraulic fully variable gas distribution device disclosed in the present invention includes an electro-hydraulic fully variable gas distribution actuator 23, an electromagnetic reversing valve 22, a lift control valve 16, a buffer control valve 15, a low-pressure oil tank 17, a filter There are three parts: the device 18, the hydraulic motor 19, the accumulator 20, the relief valve 21, the oil pipe and other auxiliary components, and the solenoid valve control system.

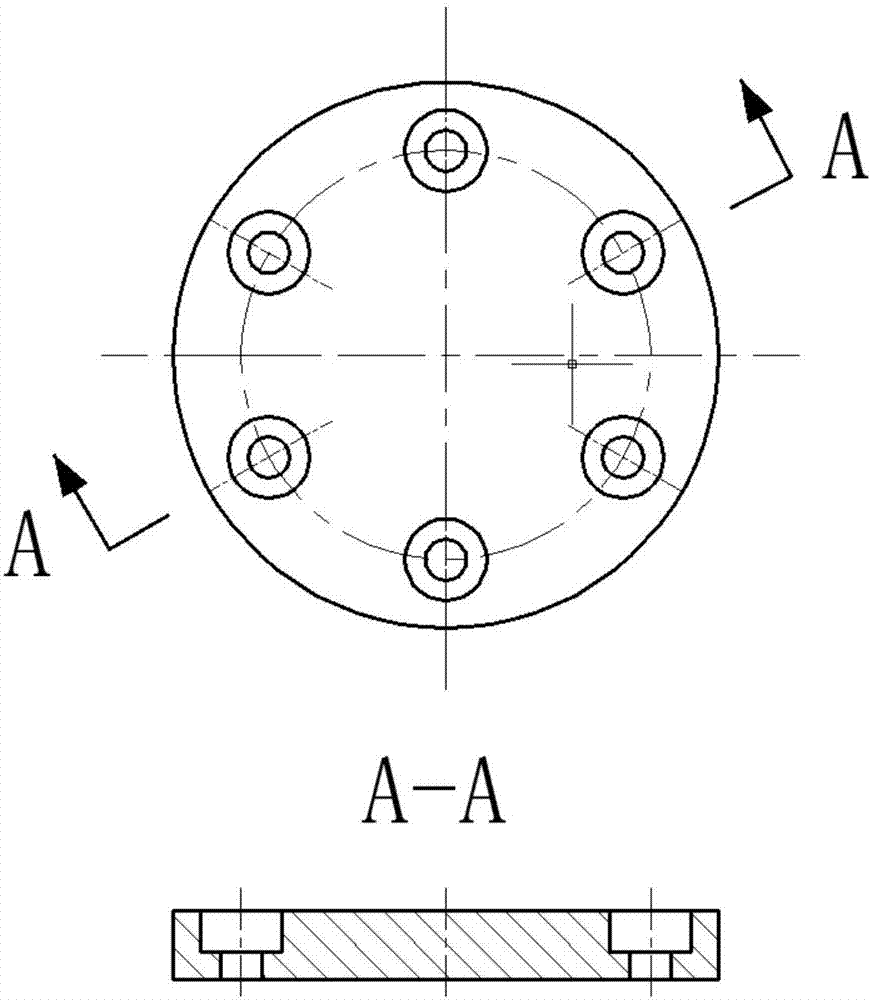

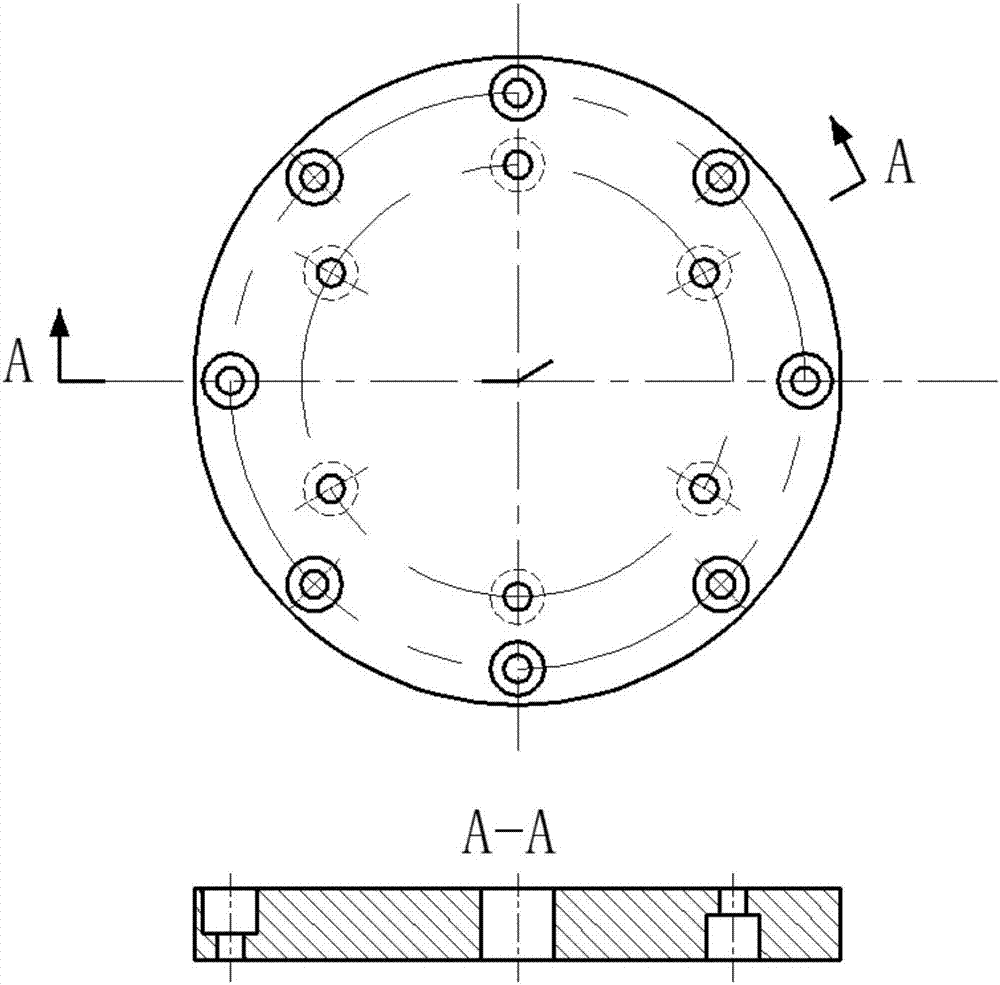

[0063] The invention includes an electro-hydraulic fully variable gas distribution actuator, which is characterized in that it includes five chambers A, B, C, D, and E, wherein the hydraulic oil in chamber A is always in a low-pressure state, and the hydraulic oil in chamber A Oil port 13 is connected to the low pressure oil rail. The pressure of the hydraulic oil in the remaining four chambers will change with the movement of the piston. By controlling the pressure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com