Patents

Literature

61results about How to "Continuously variable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for adjusting lift of intake valve of supercharged engine

InactiveCN102966403AReasonable designSimple structureMachines/enginesNon-mechanical valveEngineeringExhaust valve

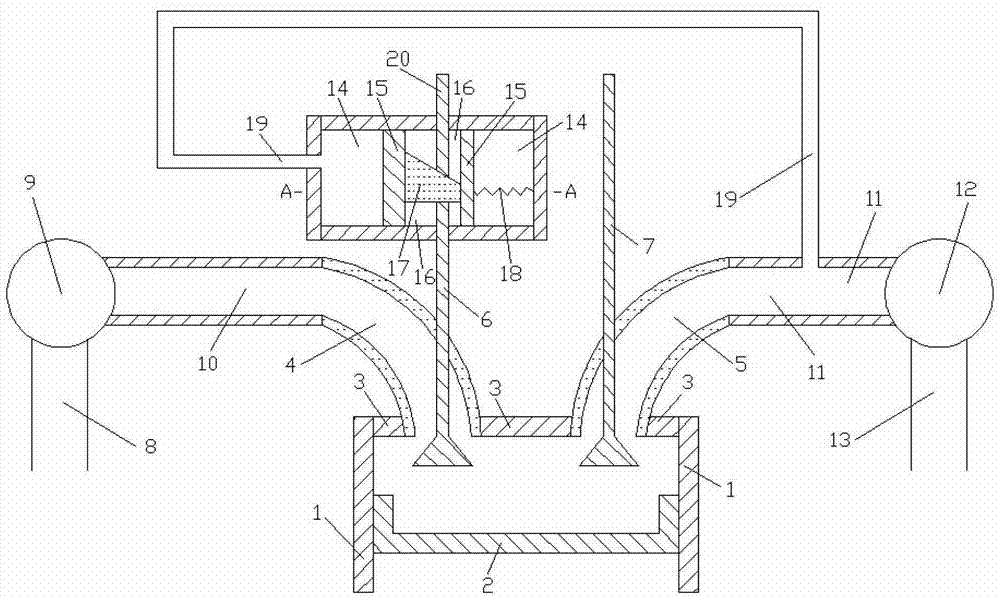

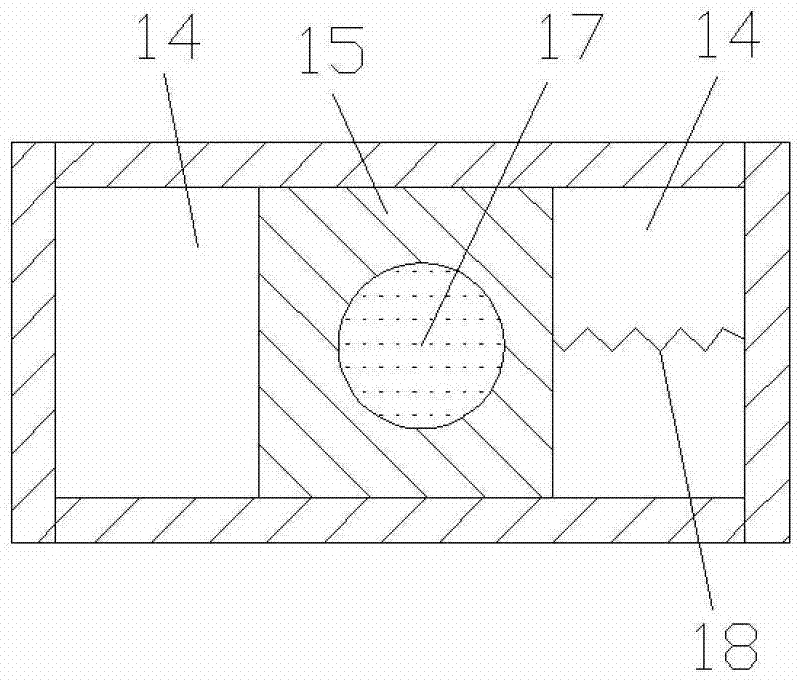

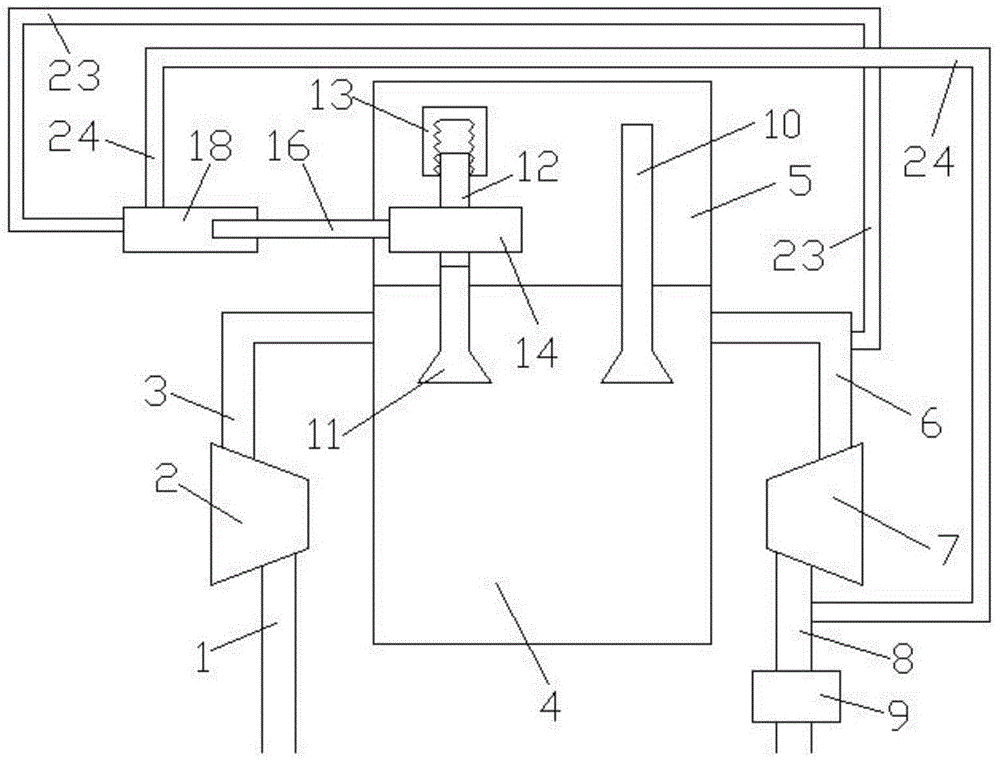

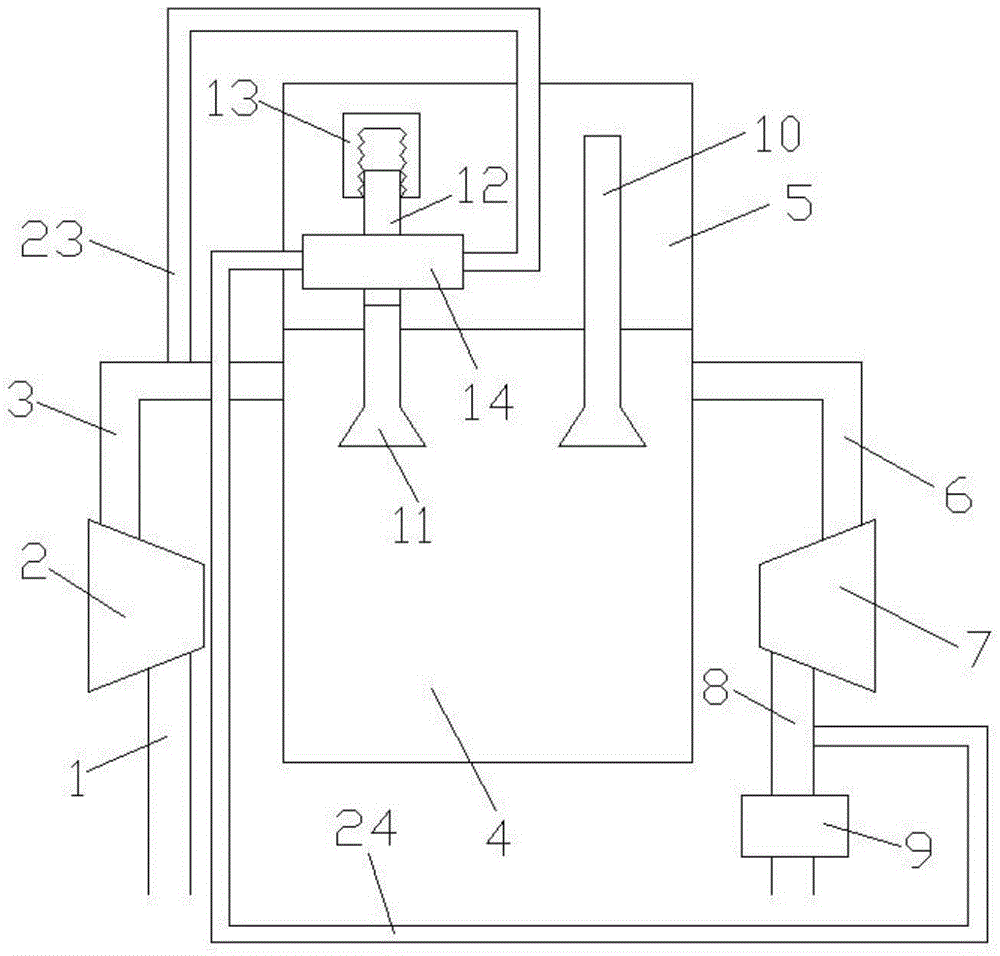

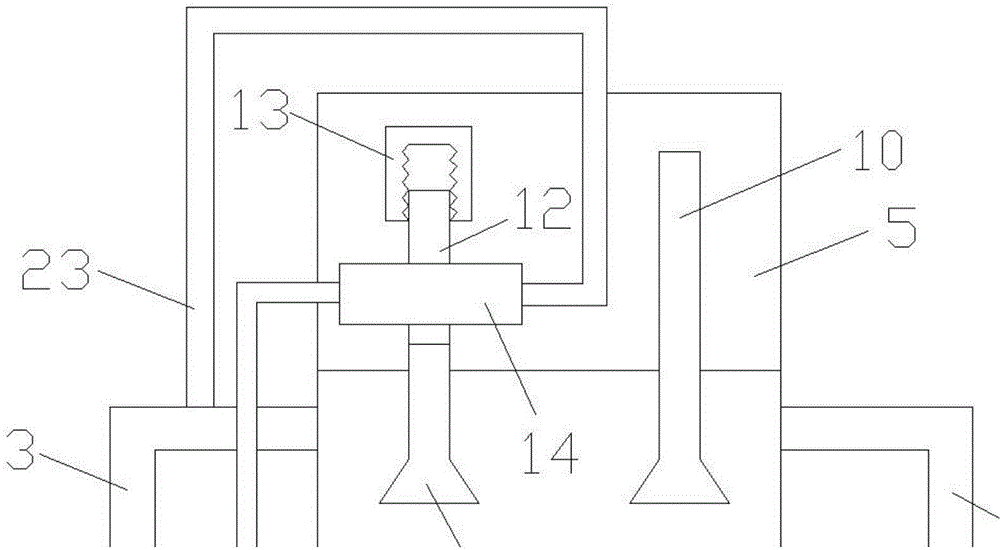

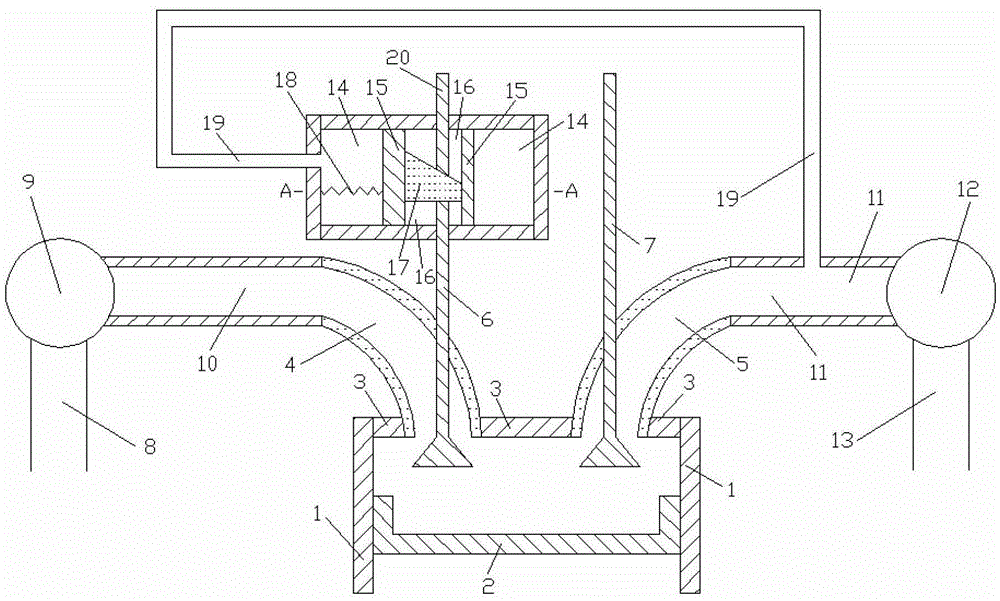

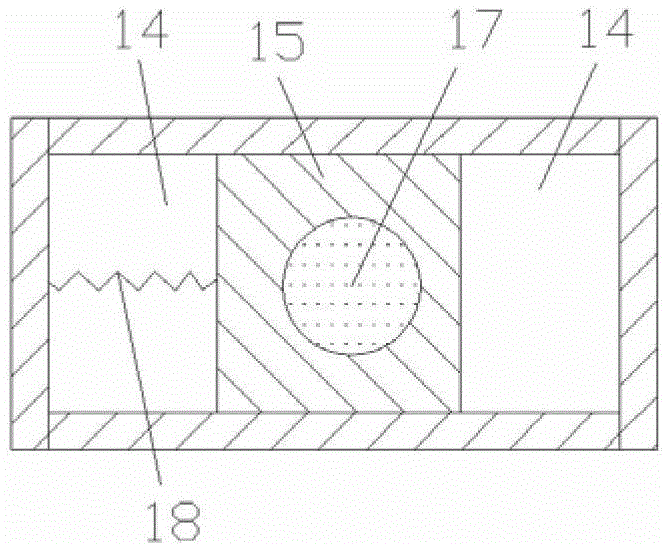

The invention relates to the technical field of an internal combustion engine, in particular to a device for adjusting a lift of an intake valve of a supercharged engine. The device comprises an intake channel, an exhaust channel, a lower intake valve section, an exhaust valve, an upper intake valve section, a volumetric cavity, a moving body, a penetrating tube, a moving block, a connecting tube and a spring, wherein the moving body is arranged in the volumetric cavity and is contacted with the inner wall surface of the volumetric cavity in a sealing way, the penetrating tube is arranged in a way of penetrating the upper wall surface and the lower wall surface of the moving body, the moving block is arranged in the penetrating tube and is contacted with the inner wall surface of the penetrating tube in a sealing way, a plane is adopted by the lower end face of the moving block, a slope is adopted by the upper end face of the moving block, two ends of the connecting tube are respectively communicated with the left wall surfaces of an intake tube and the volumetric cavity, and the right wall surface of the moving body is connected with the right wall surface of the volumetric cavity through the spring. When the pressure in an exhaust tube of the engine is relatively high, the moving body can move rightwards, and the lift of the intake valve can be increased; and when the pressure in the exhaust tube of the engine is relatively low, the moving body can move leftwards, and the lift of the intake valve can be decreased. The device has the advantages of reasonable design and simple structure and is suitable for a variable valve lift system of the supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

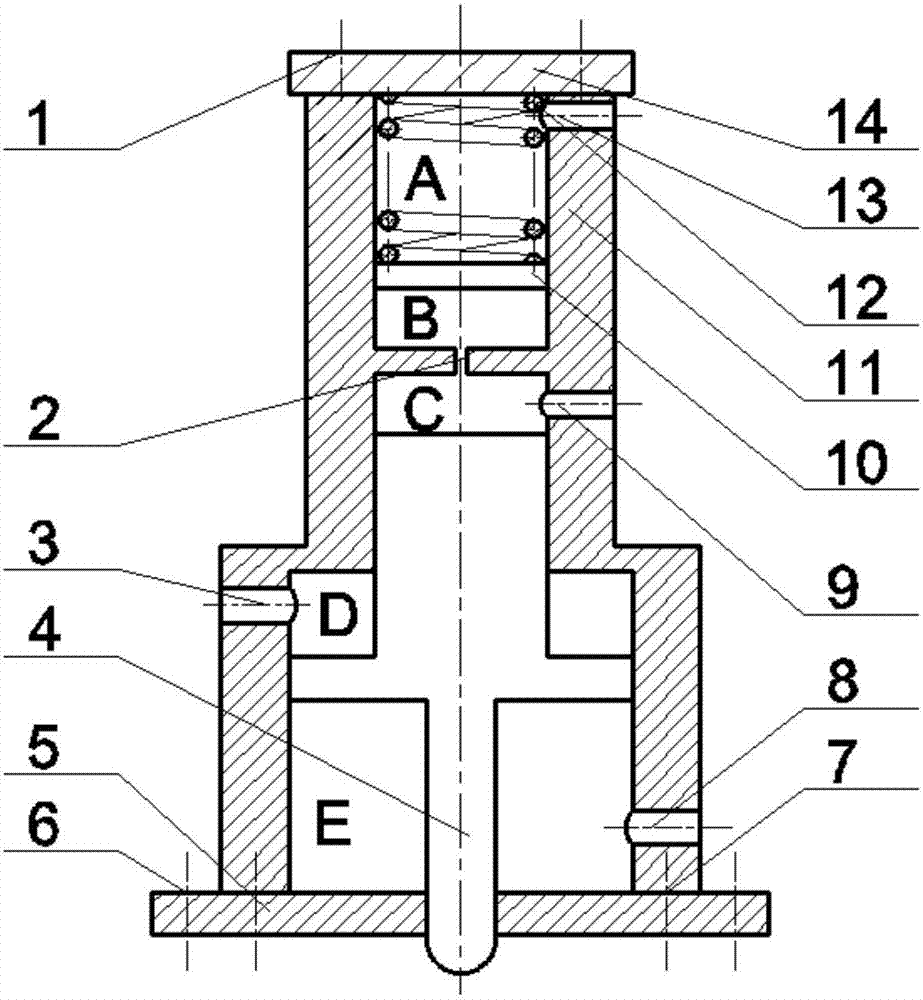

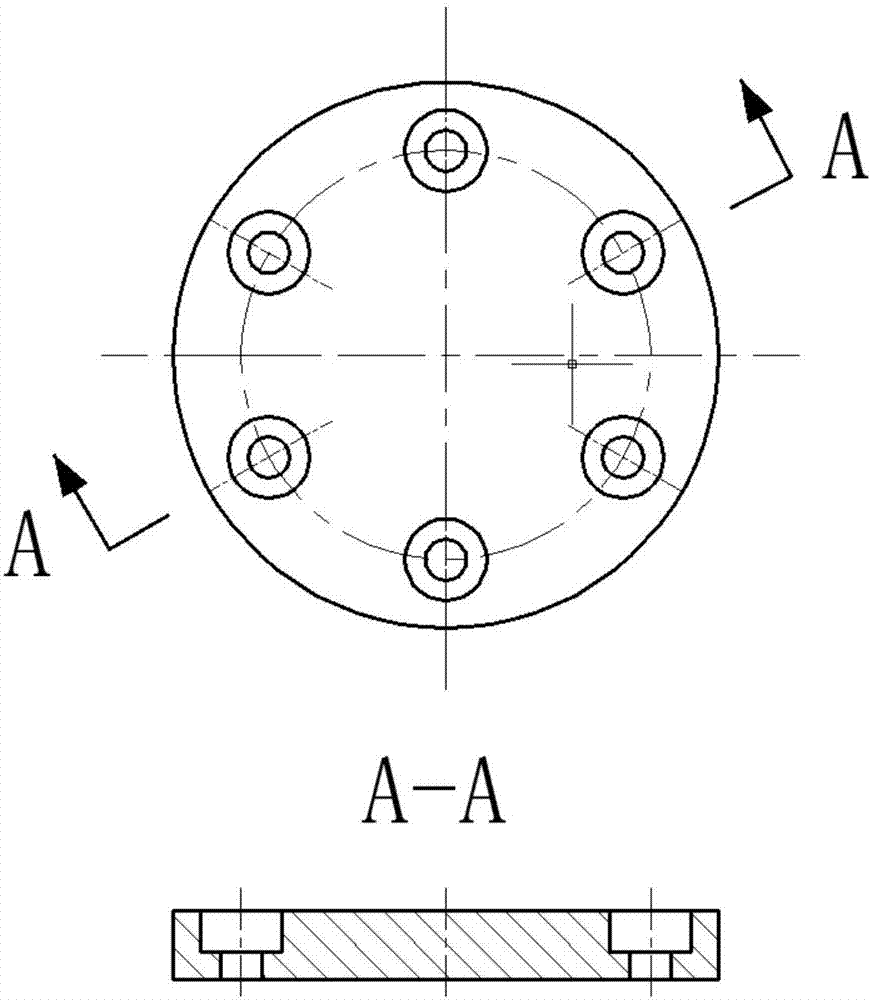

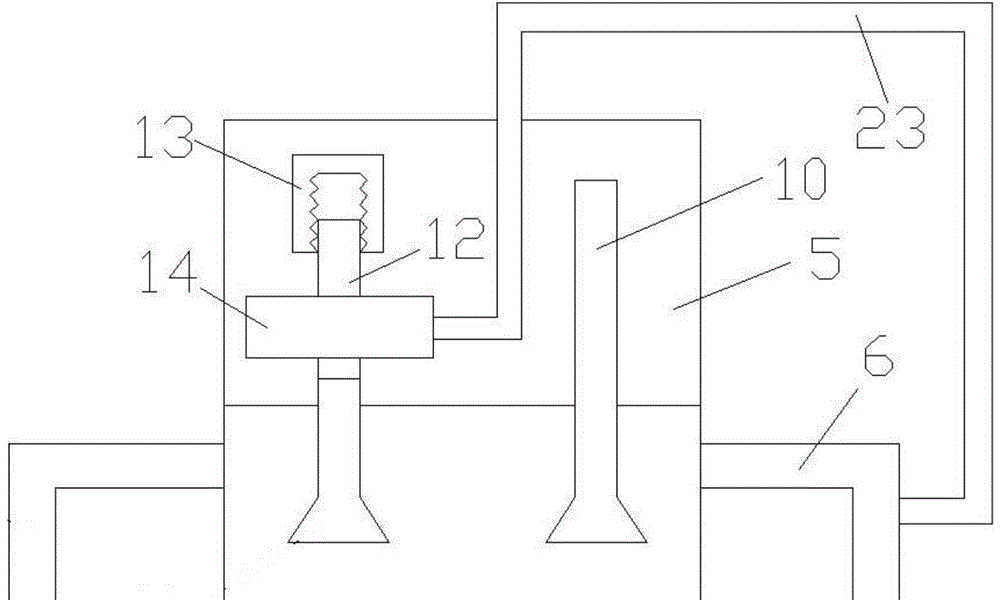

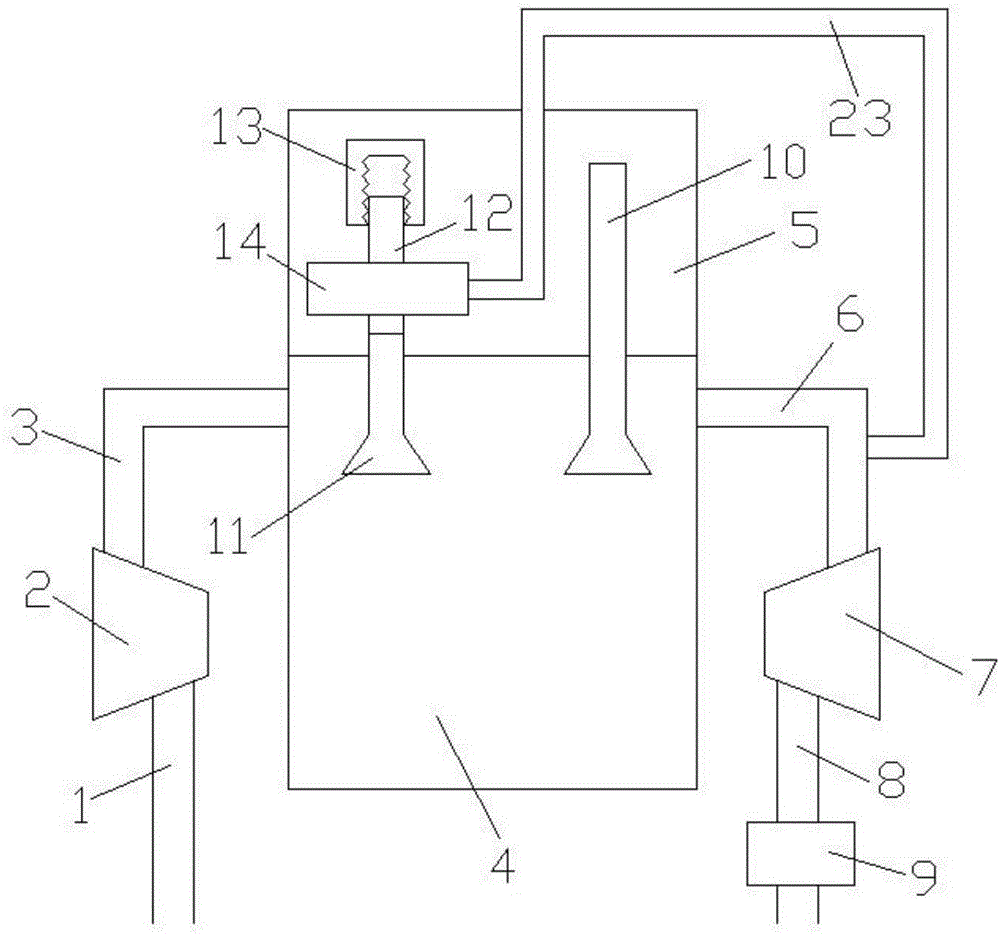

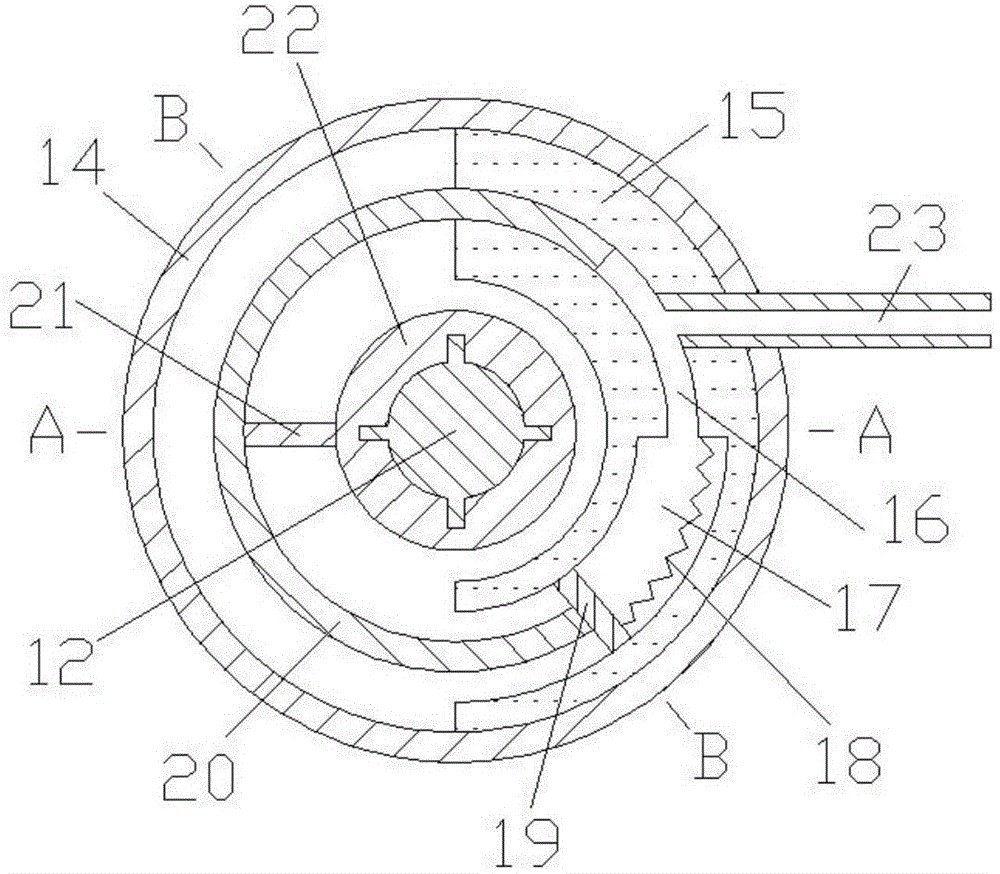

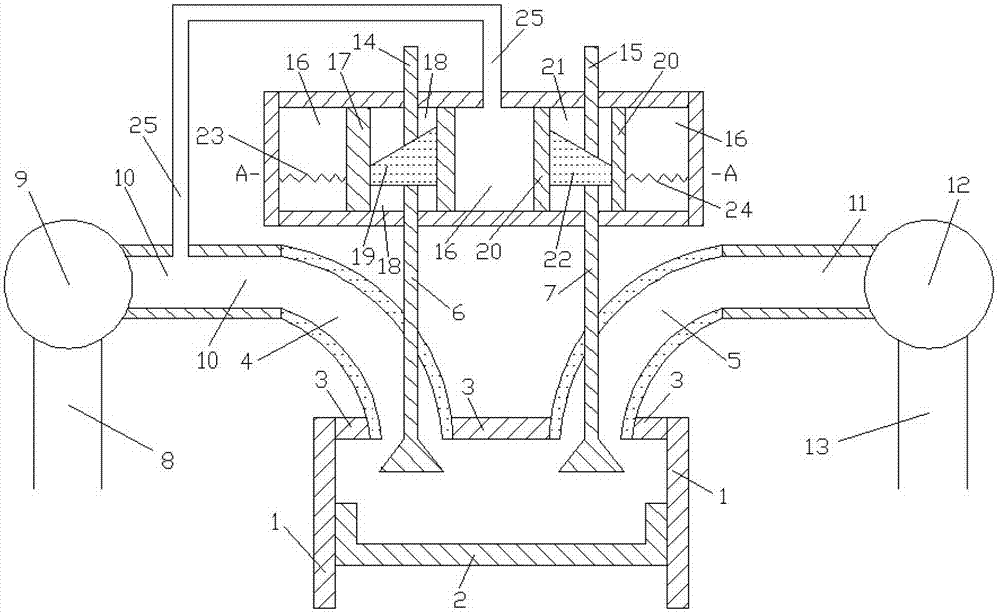

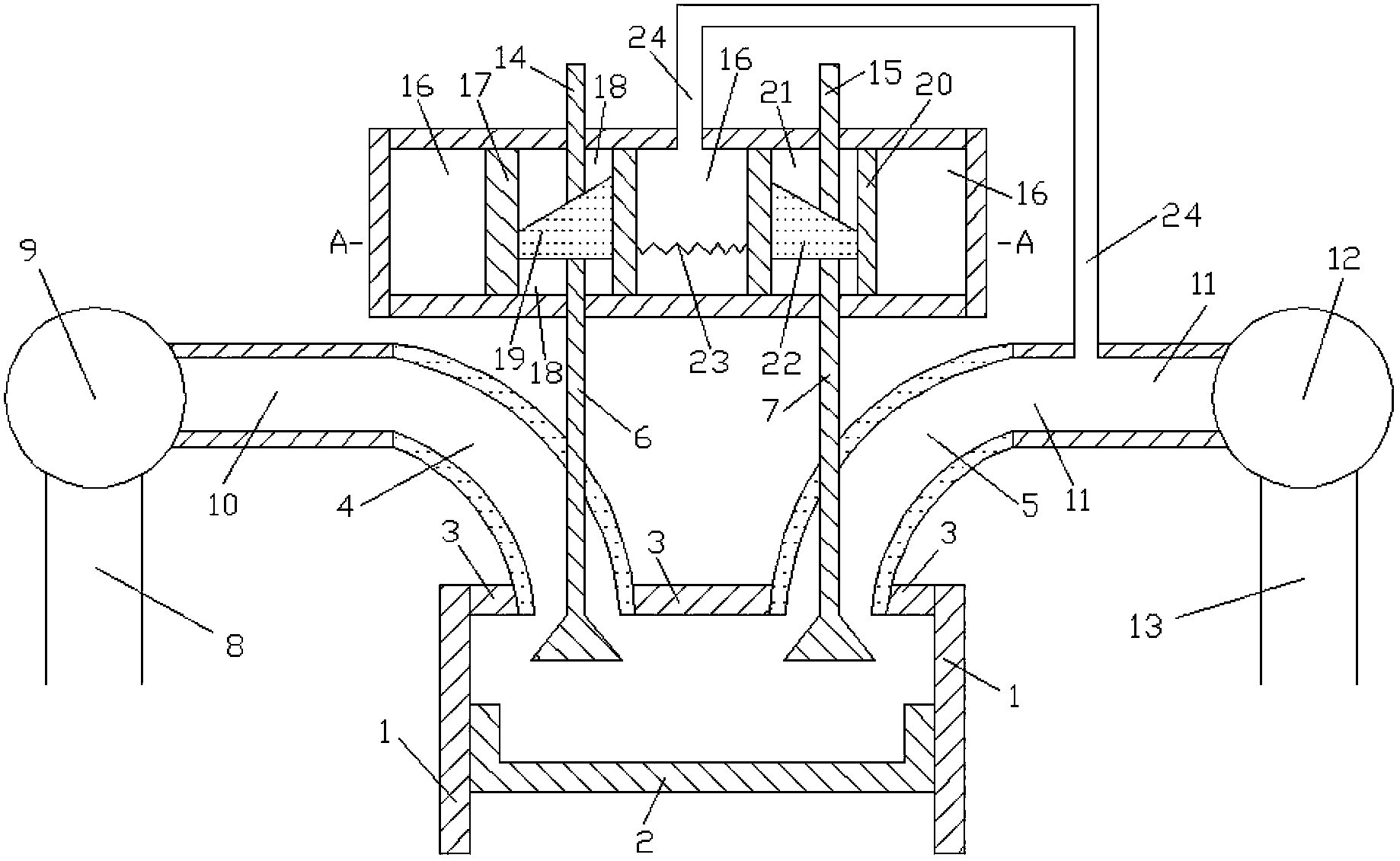

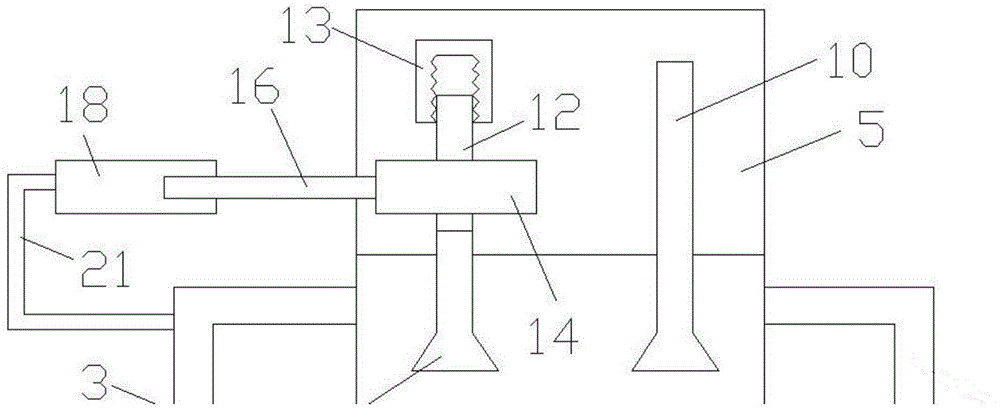

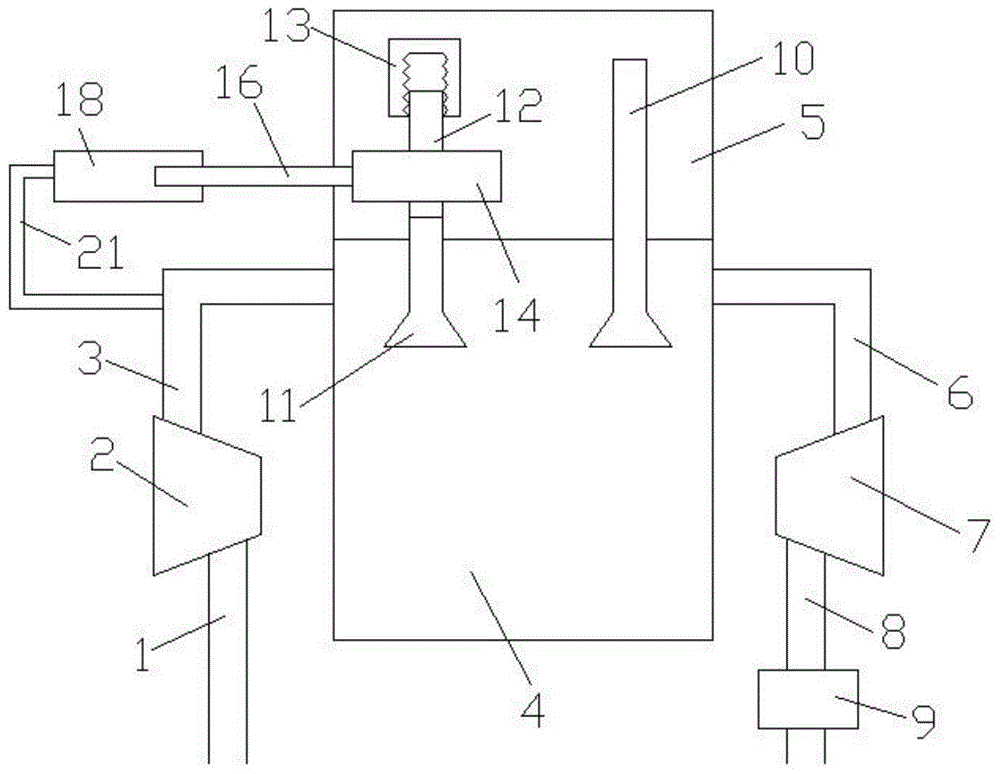

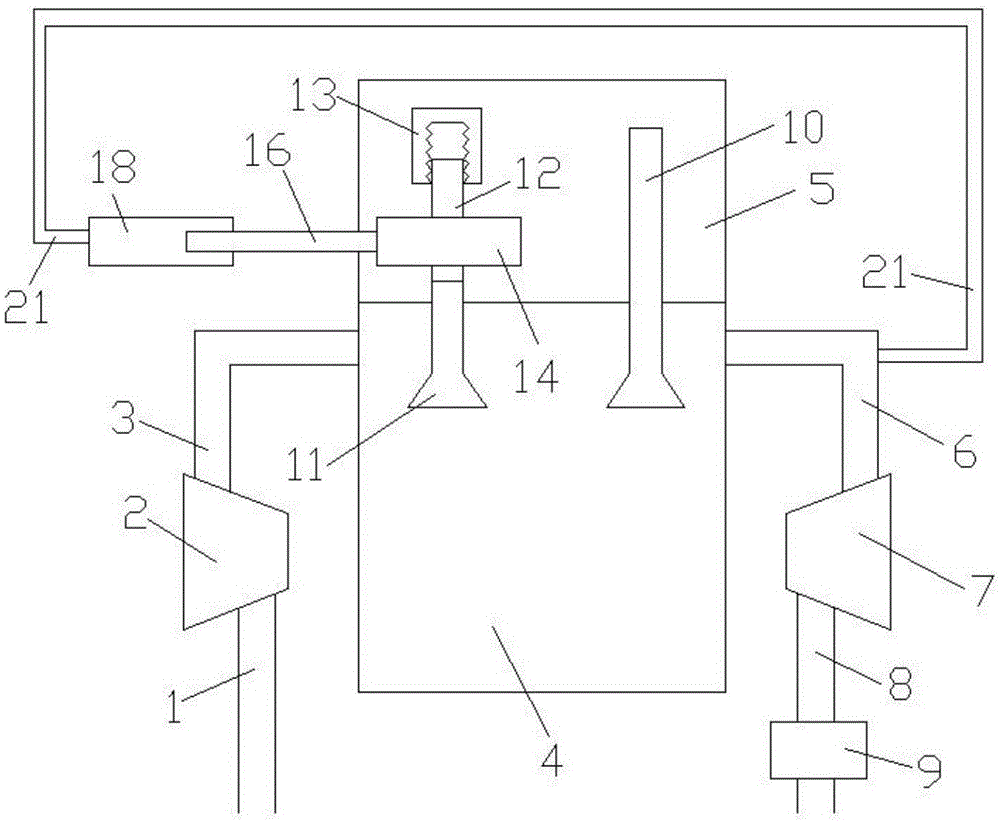

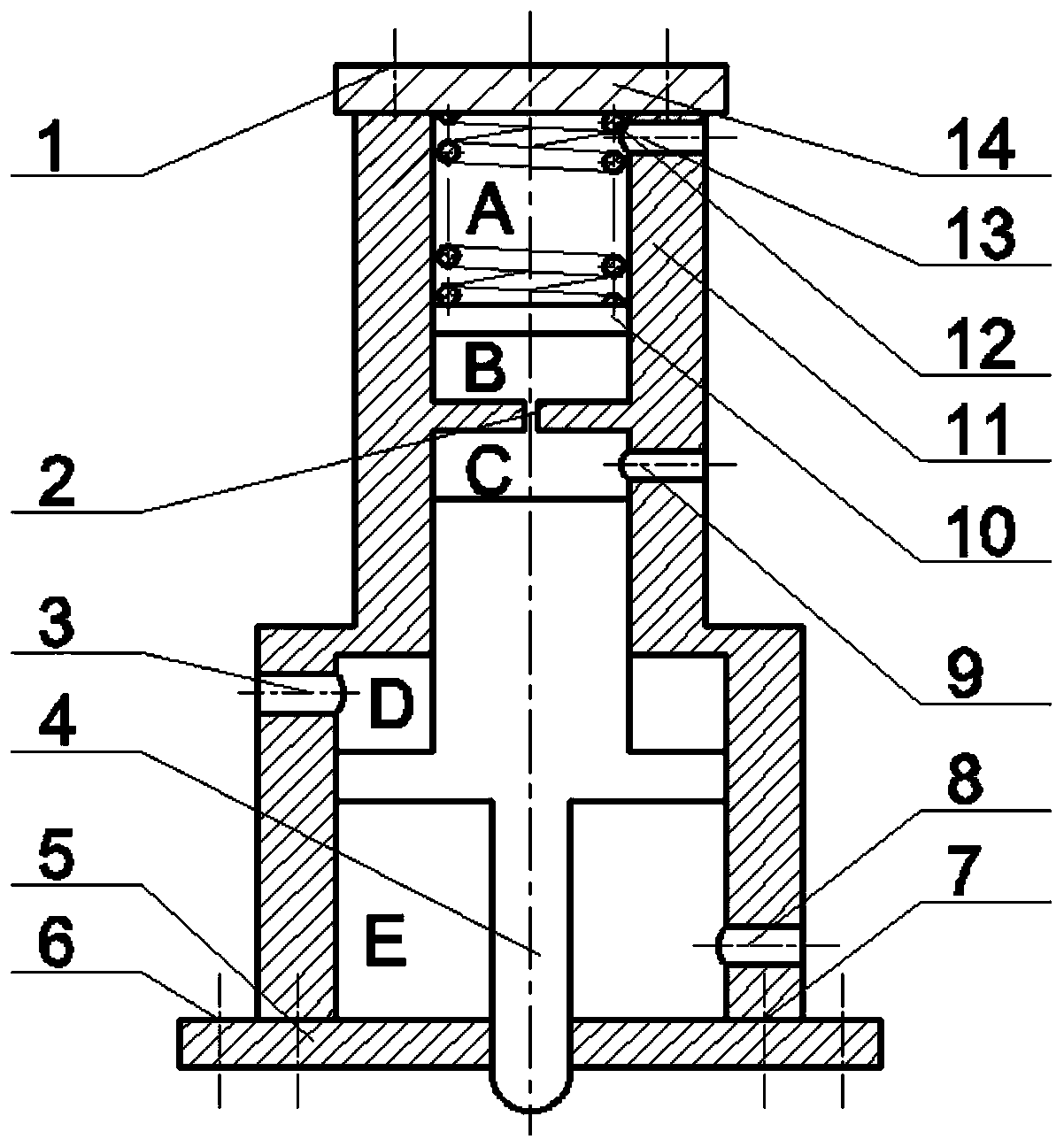

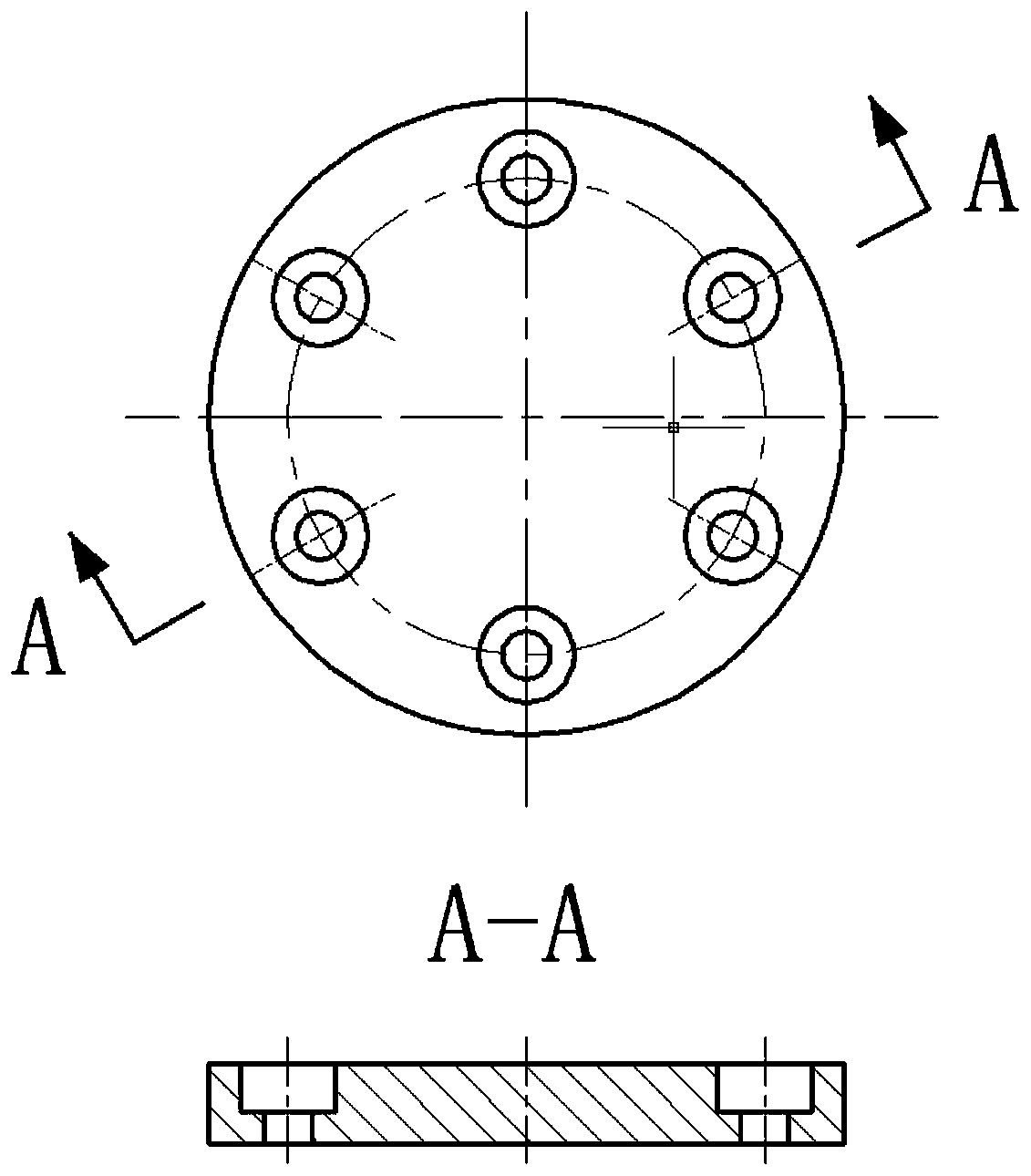

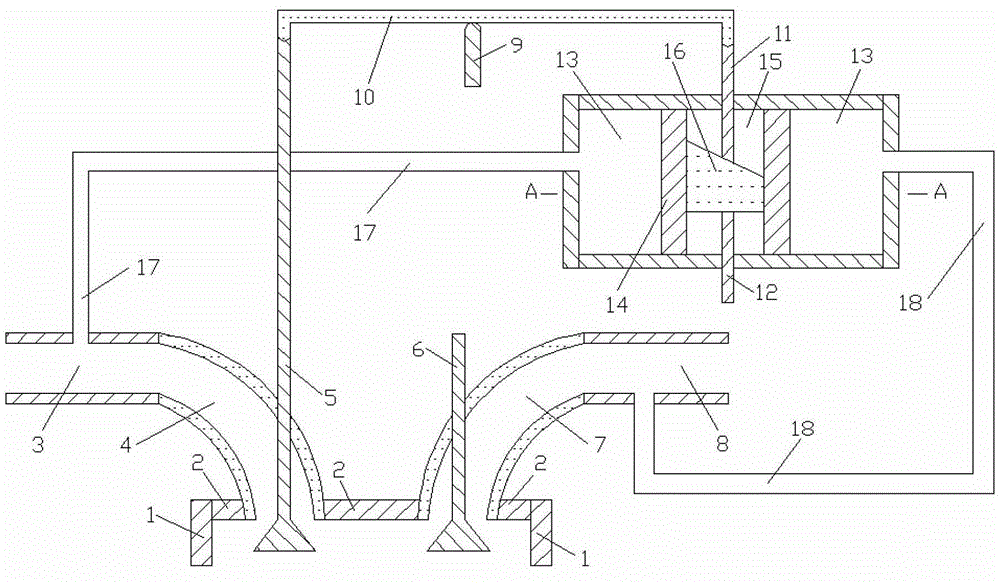

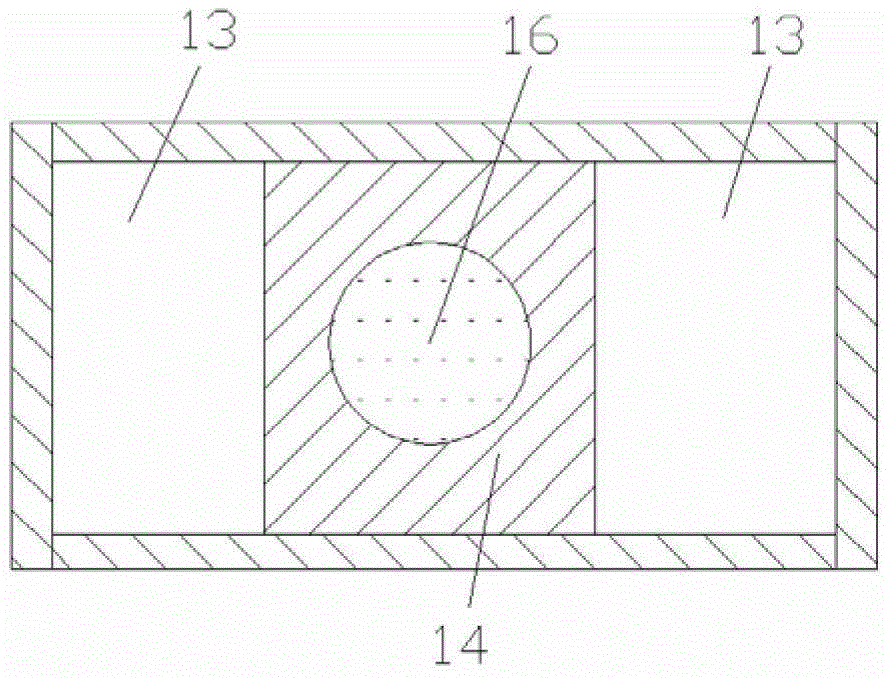

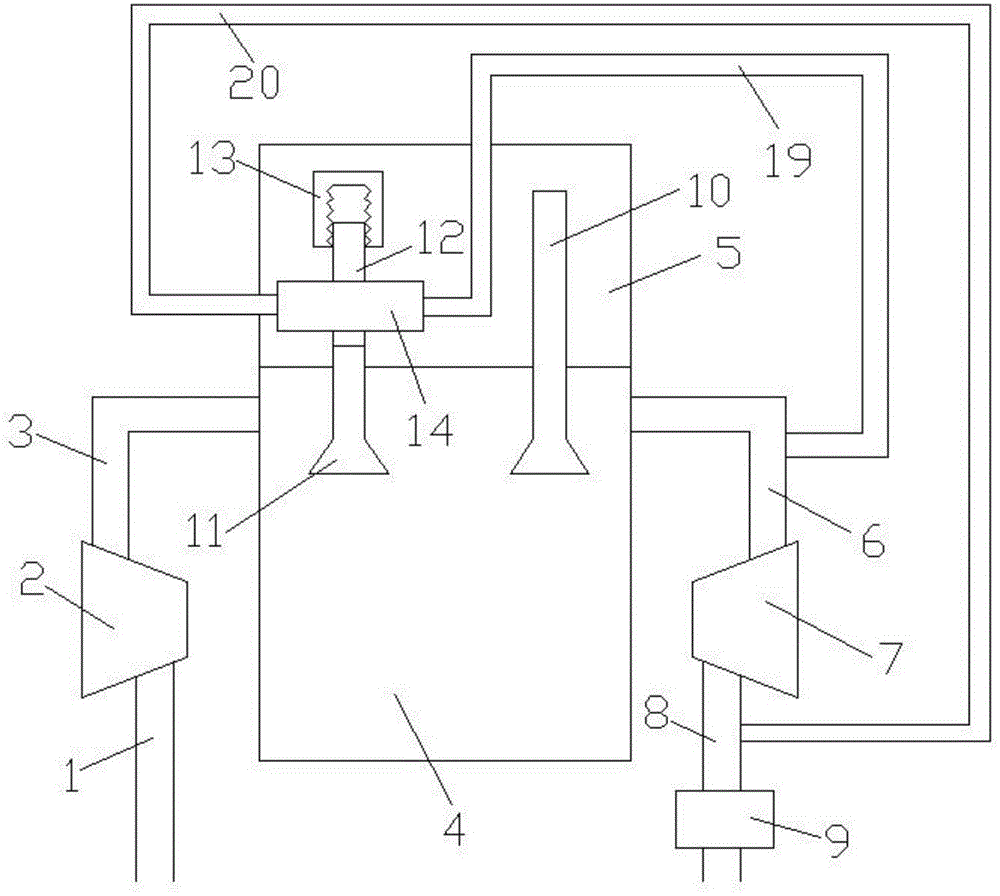

Electro-hydraulic fully variable air distribution device and control method

ActiveCN107327329ASimple structureReduce processing difficultyMachines/enginesNon-mechanical valveHydraulic motorElectronic control system

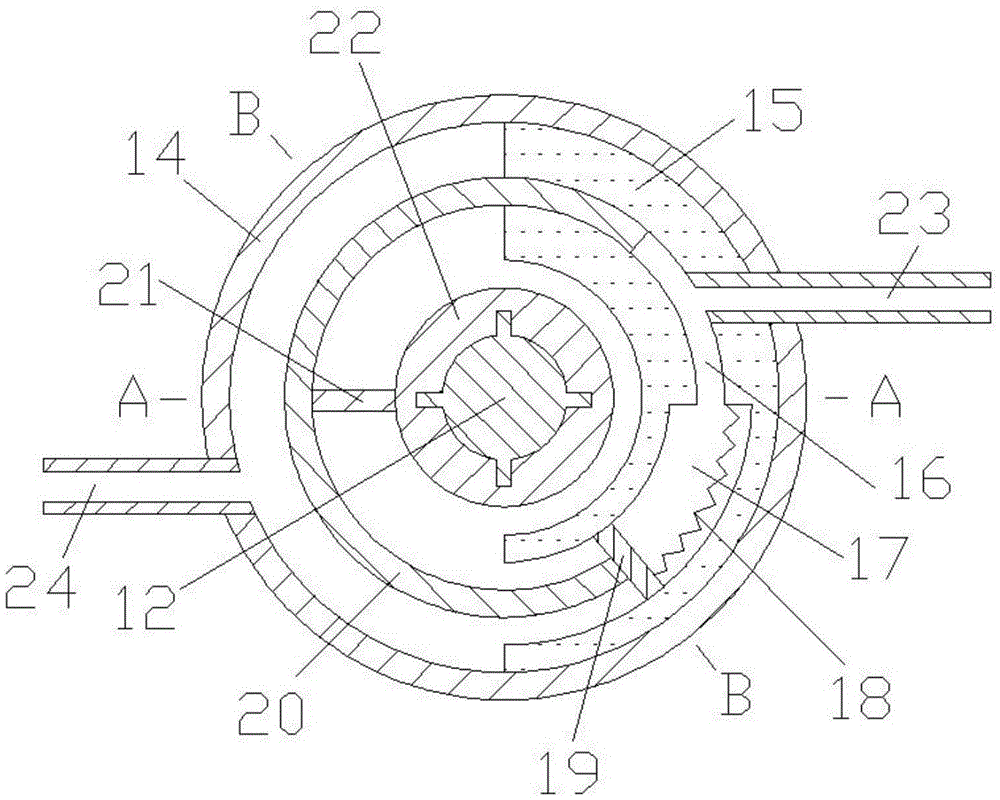

The invention discloses an electro-hydraulic fully variable air distribution device and a control method, and belongs to the technical field of engine air valves. The electro-hydraulic fully variable air distribution device comprises a buffer control valve, a lift range control valve, a low-pressure oil box, a filter, a hydraulic motor, an energy accumulator, an overflow valve, a solenoid directional valve, an electro-hydraulic fully variable air distribution executor, an electronic control system, and attached components like an oil pipe. A high-pressure oil port, a lift range control port, a buffer control oil port, a cylinder body orifice and five hydraulic cavities (A, B, C, D and E) are formed in the electro-hydraulic fully variable air distribution executor, and by controlling pressure of hydraulic oil in the five hydraulic cavities, movement like the opening and seating of one engine air valve can be realized. By changing power losing and power obtaining hours of a two-position three-way valve, the lift range control valve and the buffer control valve, the opening phase and the opening lift range of the engine air valve can be changed, and soft adjustment on the lift range and the phase of the air valve, and the duration of the opening of the air valve are realized, so that fully variable movement of the air valve is realized.

Owner:HARBIN ENG UNIV

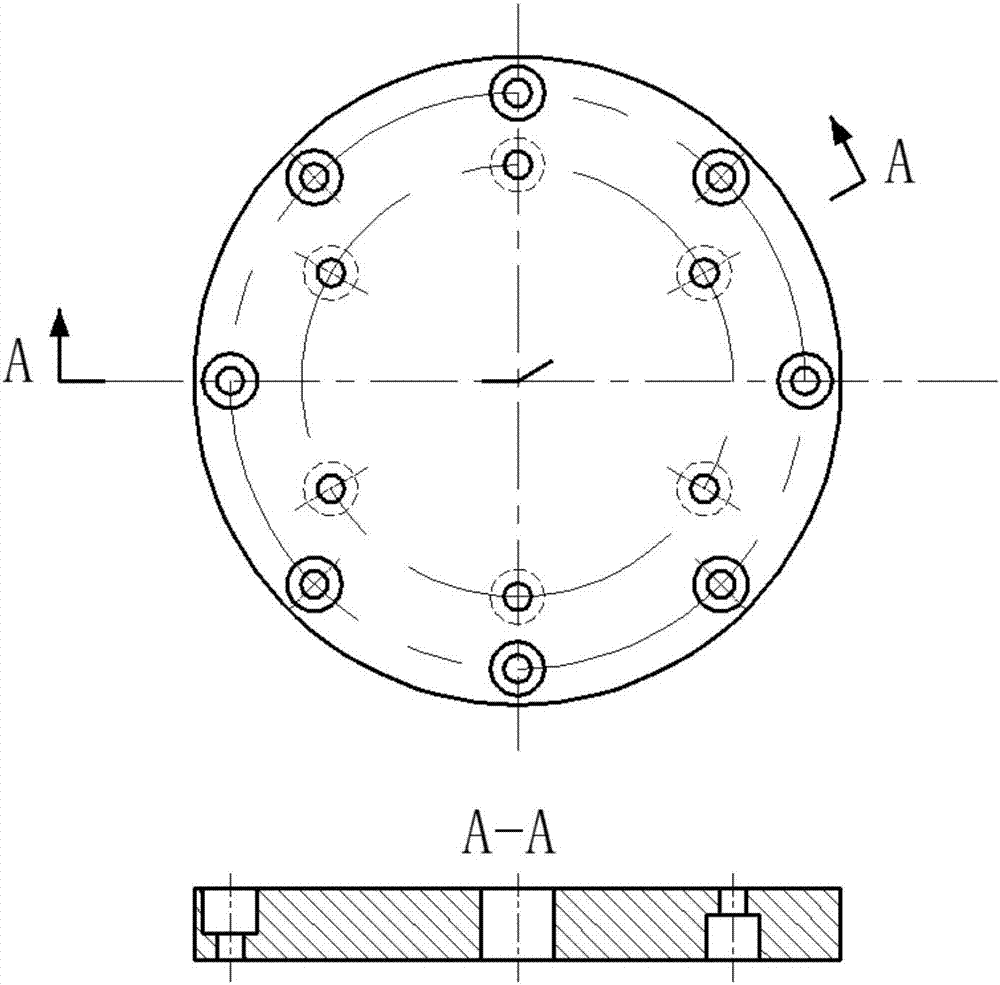

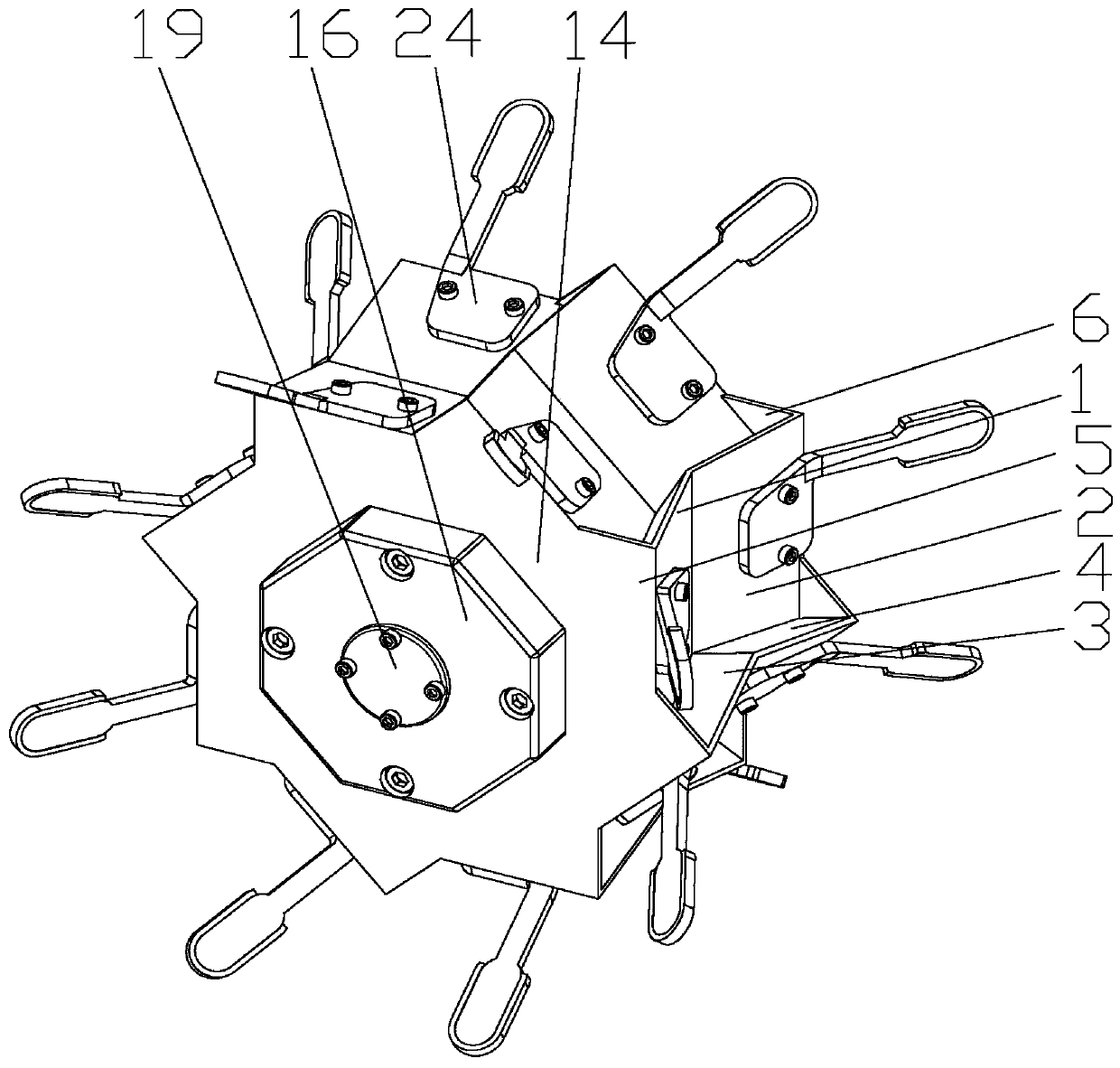

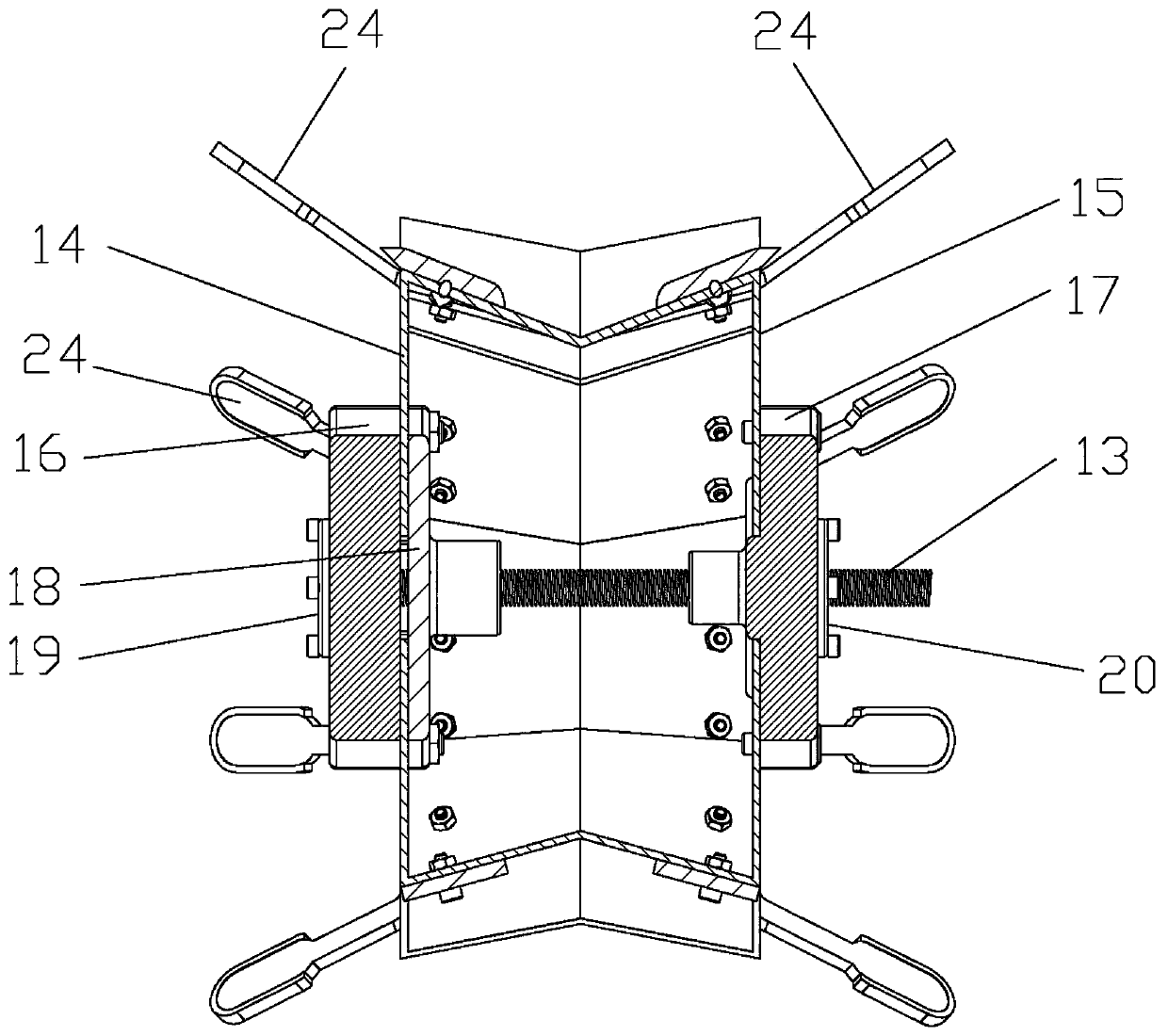

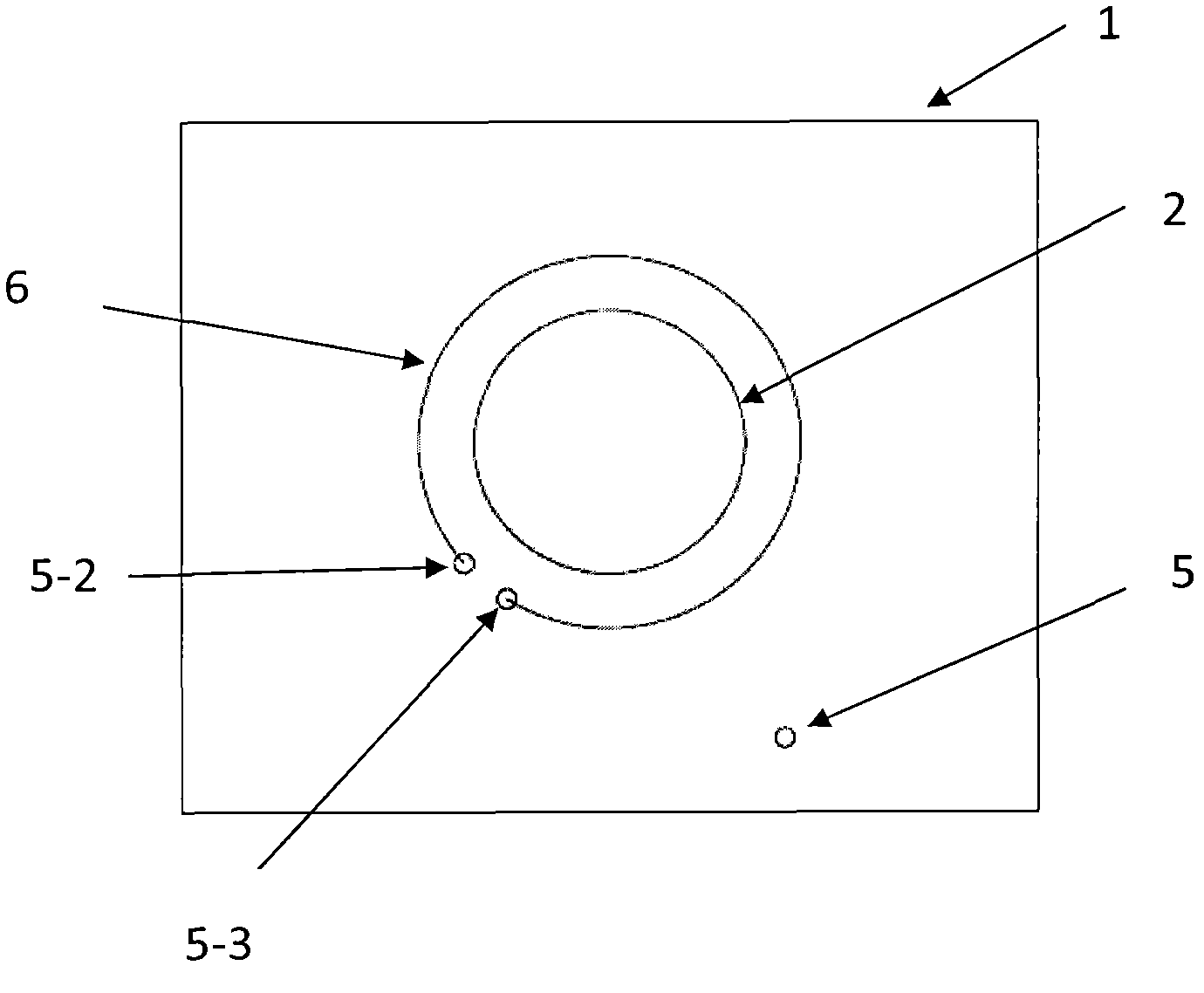

Variable-angle oblique impact test clamp for thin-wall pipe fittings

InactiveCN105500235AContinuously variableMeet more diverse requirements for oblique impact testsWork holdersShock testingFluteImpact test

The invention discloses a variable-angle oblique impact test clamp for thin-wall pipe fittings. The variable-angle oblique impact test clamp is characterized by comprising a base, a rotatable oblique plate, a limited slip supporting block and a clamping frame, wherein double rows of inverted-T-shaped straight flute rails are arranged on the base, and the limited slip supporting block is arranged on the inverted-T-shaped straight flute rails; the base and the rotatable oblique plate are fixed through a pin roll and form a rotation pair between the rotatable oblique plate and the base; the other free end of the rotatable oblique plate is supported on the limited slip supporting block; a circular through slot is formed in the rotatable oblique plate; the center of the clamping frame is superposed with the center of the circular through slot; the clamping frame is fixed on the rotatable oblique plate; and a first wedge block and a second wedge block are arranged in the clamping frame. The clamp design method disclosed by the invention can realize stable and reliable clamping, in an oblique impact test, of thin-wall pipe fittings with different section shapes, so that section dimension variability and stress angle continuous variability can be realized in the test, and therefore, the problems such as a single test angle of a current test sample, a single section shape of the test pipe fittings, and the like are solved.

Owner:DALIAN UNIV OF TECH

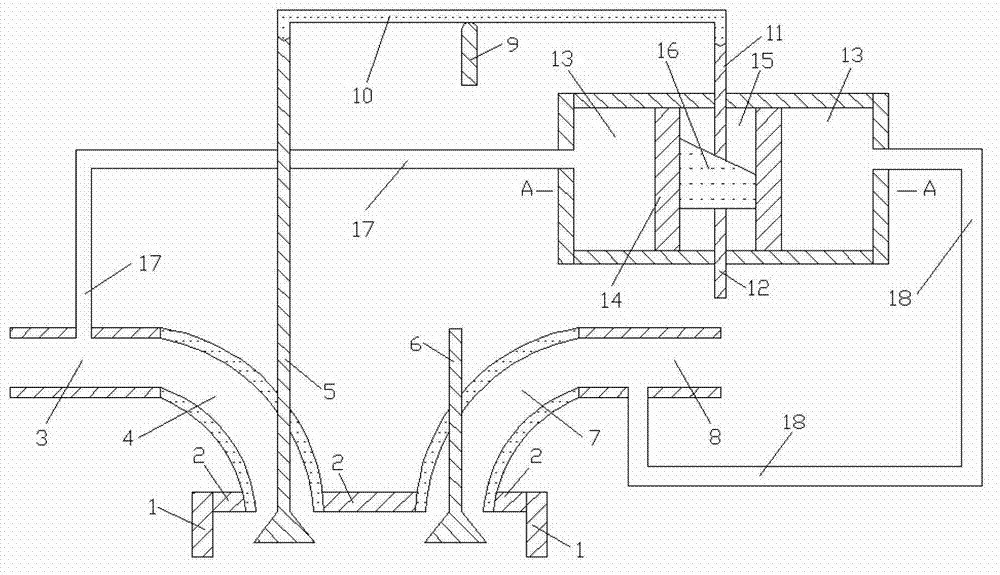

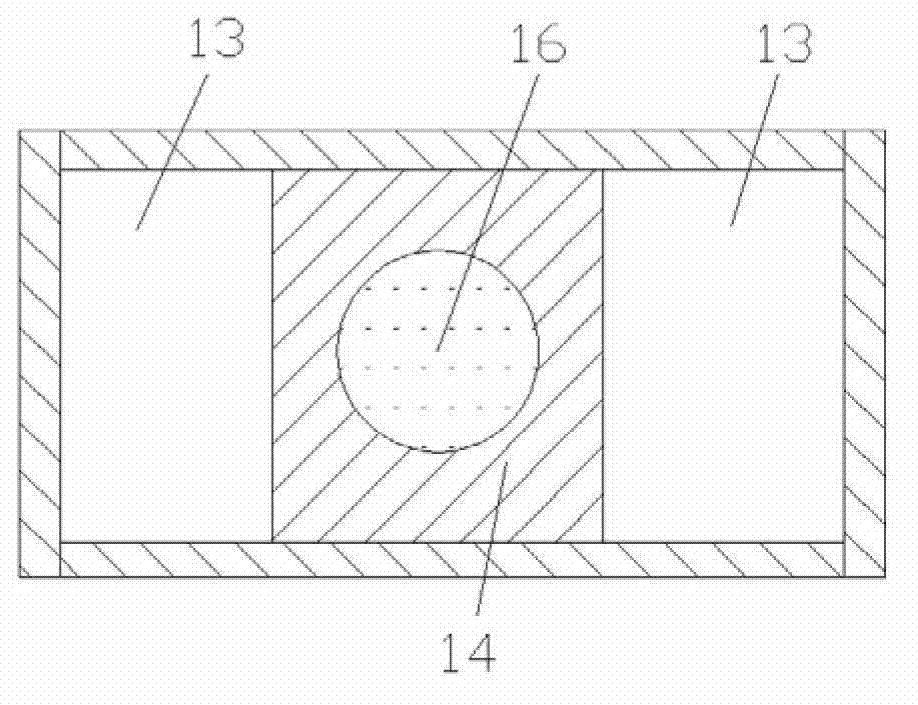

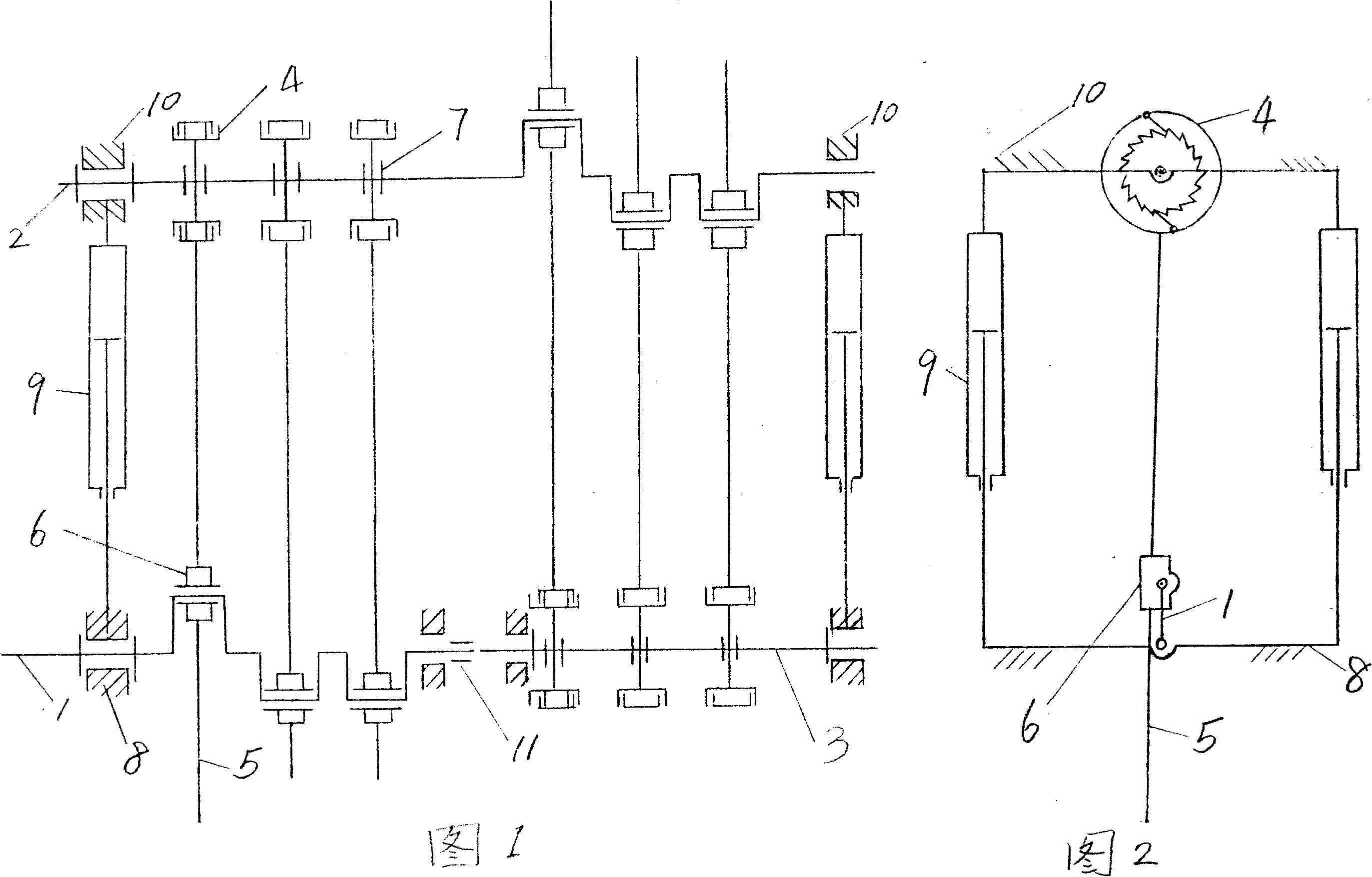

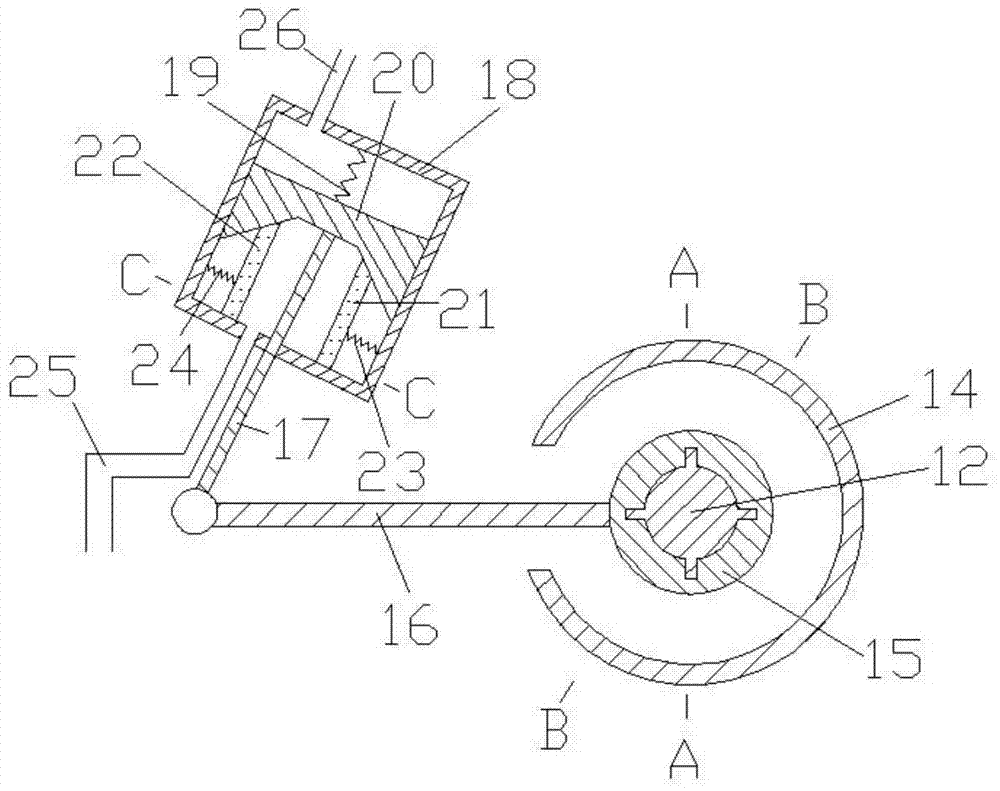

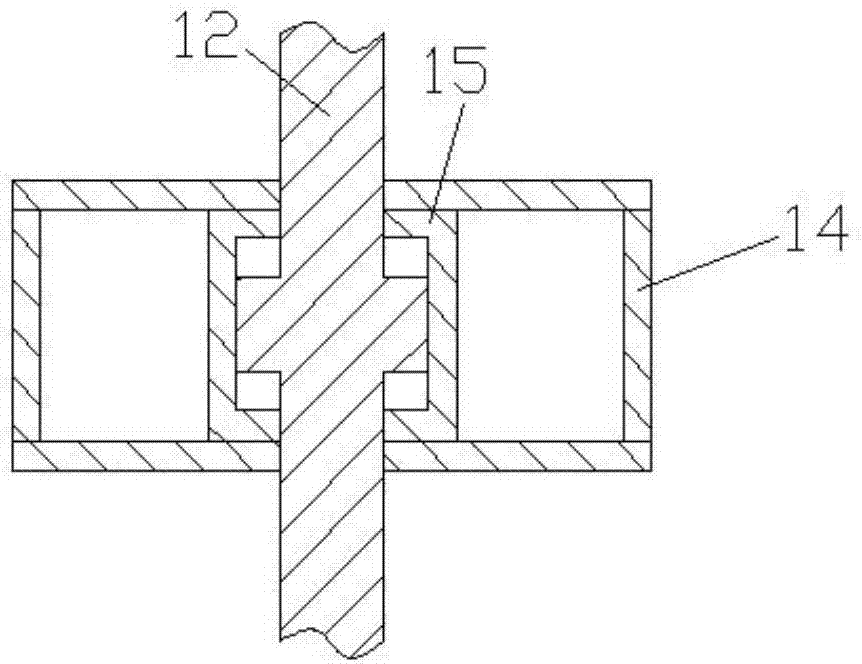

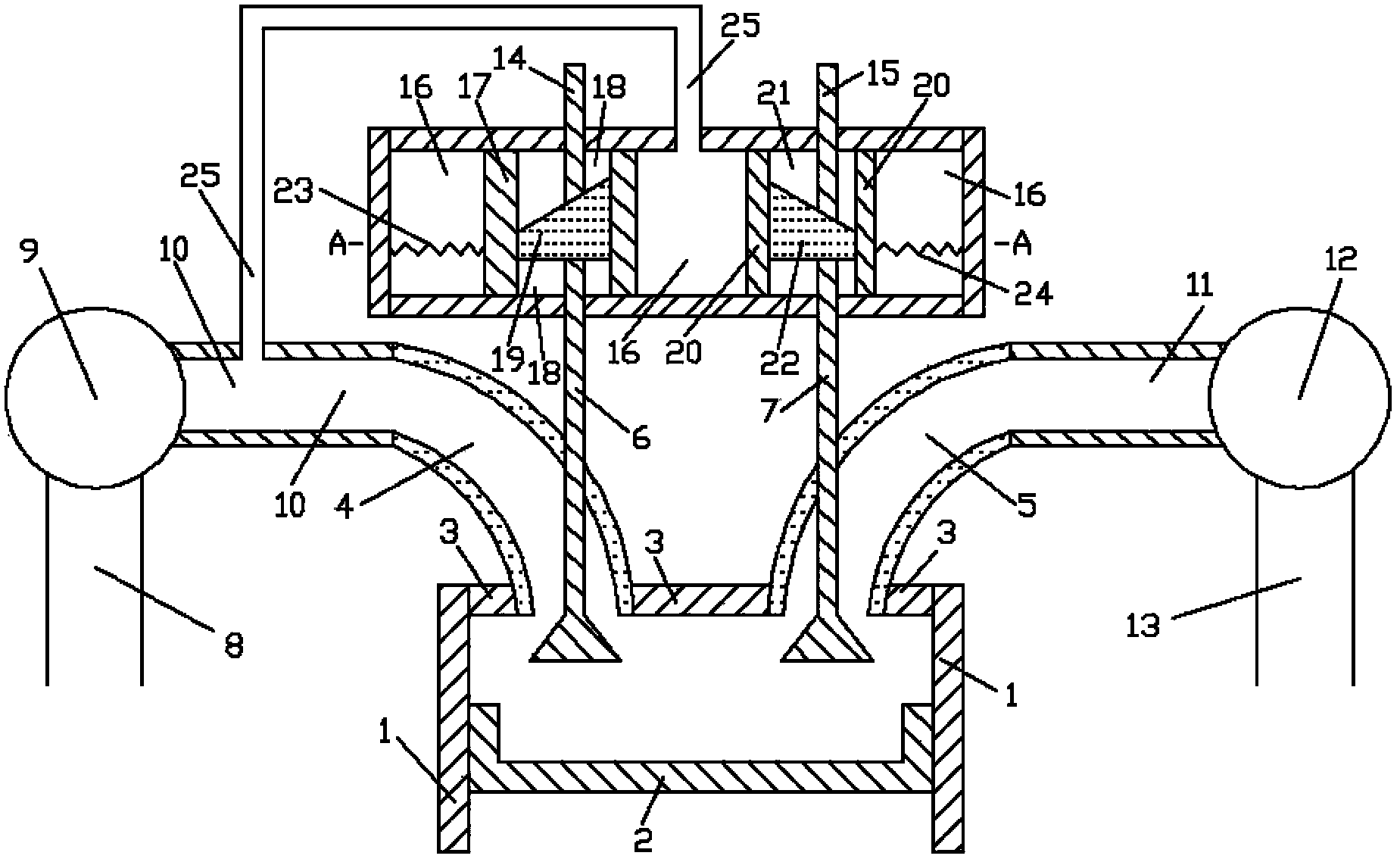

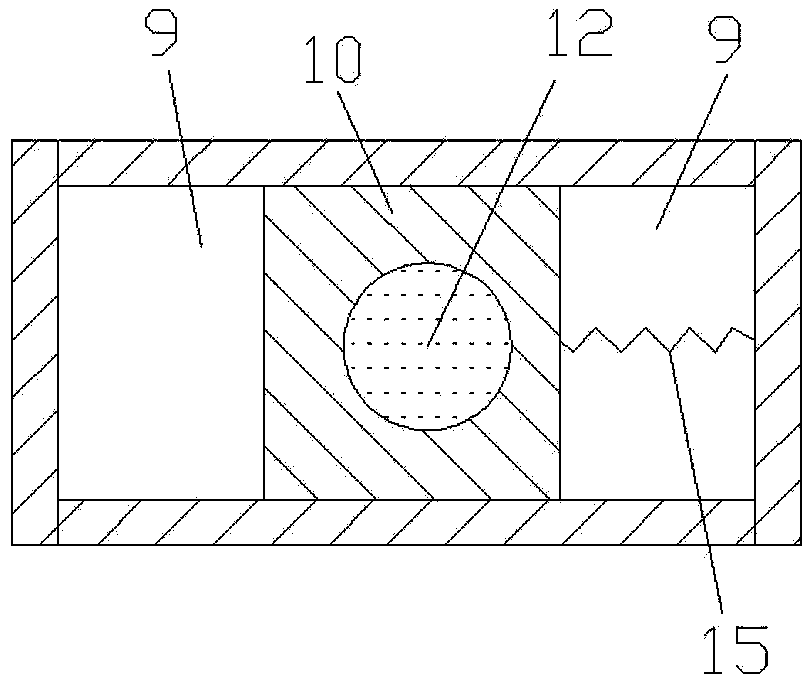

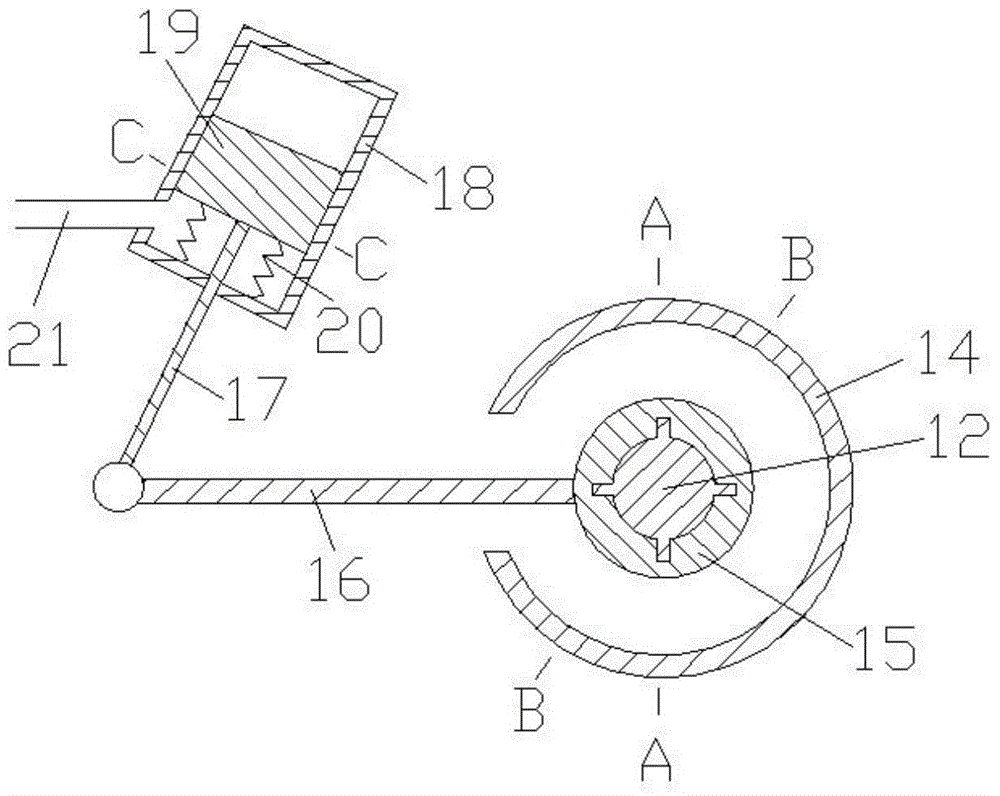

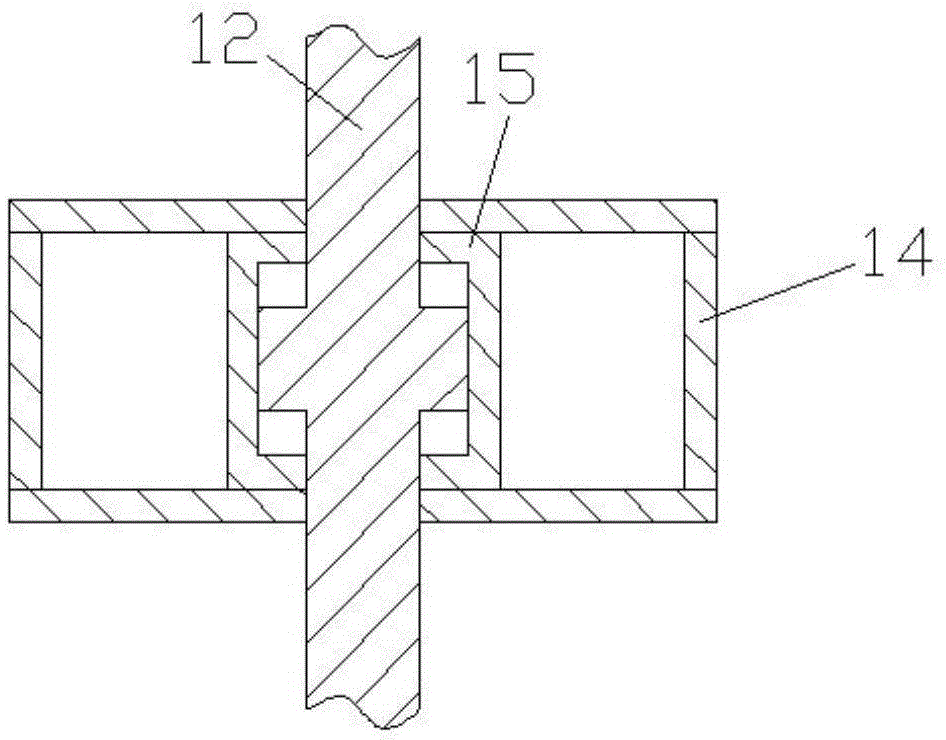

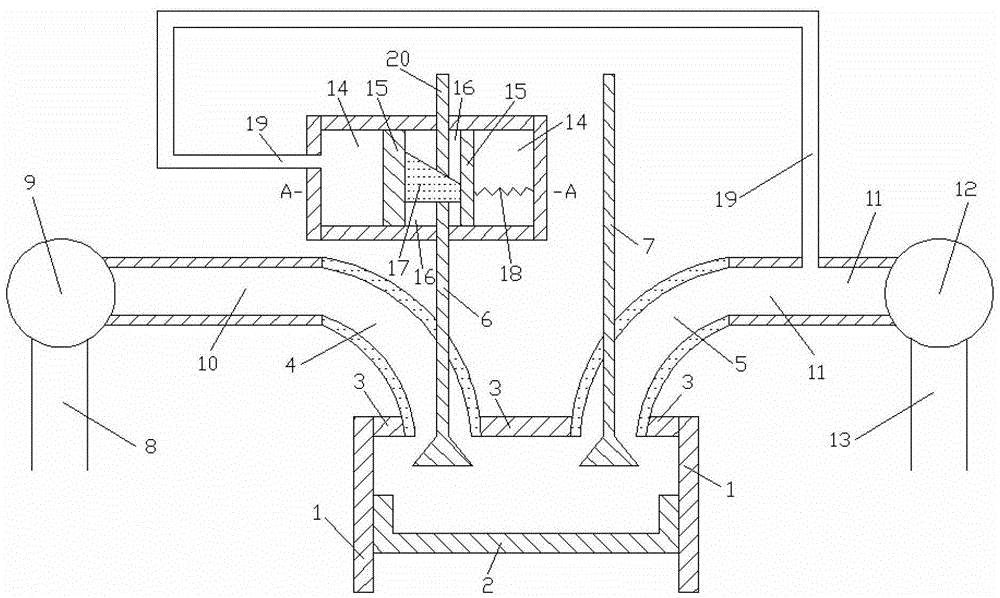

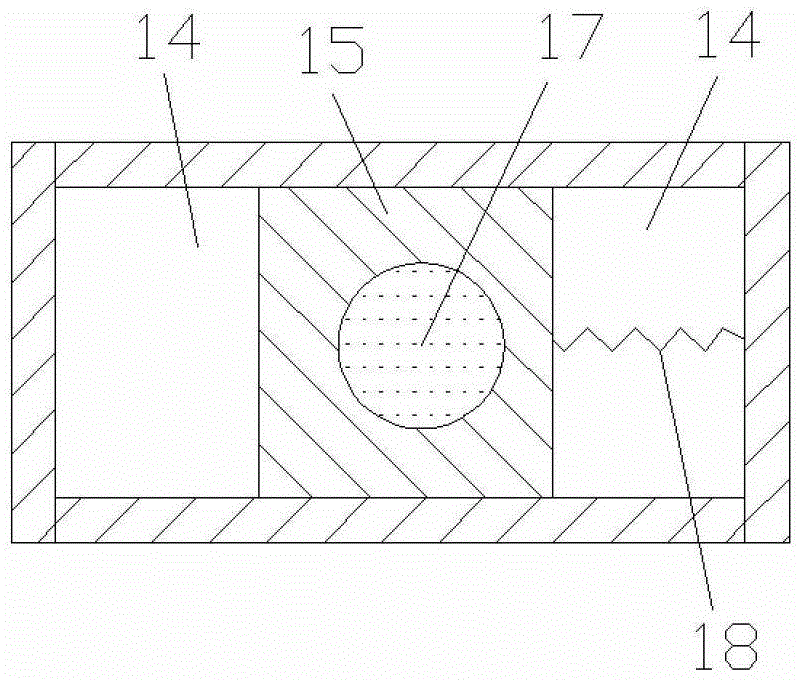

Tappet rod device with transverse moving type moving body

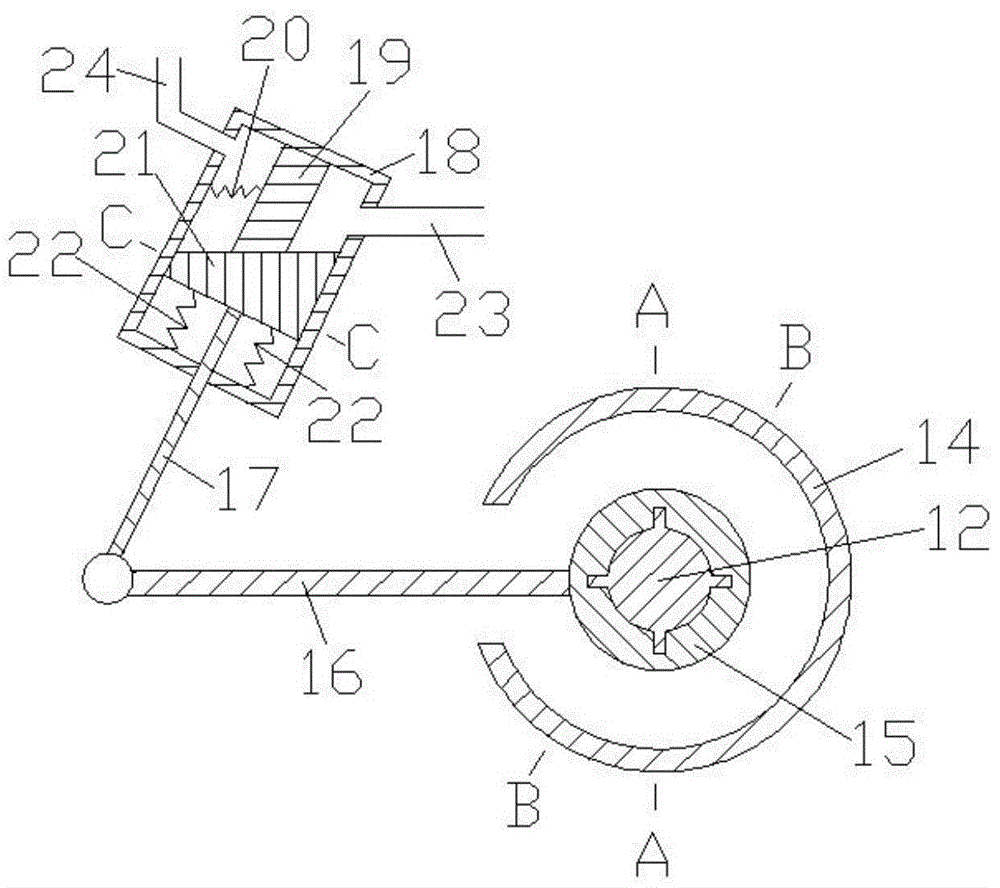

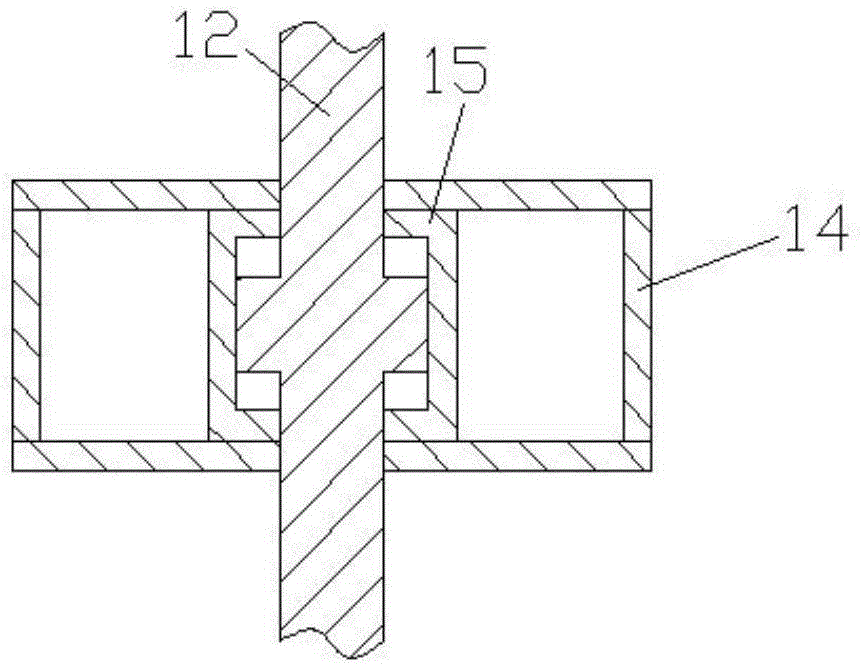

InactiveCN102966399AContinuously variableReasonable designMachines/enginesNon-mechanical valveExhaust valveInlet valve

A tappet rod device with a transverse moving type moving body in the technical field of mechanical design comprises a cylinder, a gas inlet pipe, a gas inlet valve, a gas exhaust valve, a gas exhaust pipe, an upright, a lever, a tappet, a volume chamber, a moving body, a through pipe, a moving block and a connecting pipe, wherein the through pipe penetrates through the upper wall surface and the lower wall surface of the moving body; the moving block is mounted in the through pipe and in sealed contact with the inner wall surface of the through pipe; the lower end surface of the moving block is a plane; the upper end surface of the moving block is an inclined surface; two ends of a first connecting pipe are respectively communicated with the gas inlet pipe and the left wall surface of the volume chamber; and two ends of a second connecting pipe are respectively communicated with the gas exhaust pipe and the right wall surface of the volume chamber. When the pressure in the gas inlet pipe is larger than the pressure in the gas exhaust pipe, the moving body moves to the right and the lift of the gas inlet valve is increased; and when the pressure in the gas inlet pipe is smaller than the pressure in the gas exhaust pipe, the moving body moves to the left and the lift of the gas inlet valve is reduced. The tappet rod device with the transverse moving type moving body, provided by the invention, has the advantages of reasonable design and simple structure and is suitable for systems with variable engine valve lifts.

Owner:SHANGHAI JIAO TONG UNIV

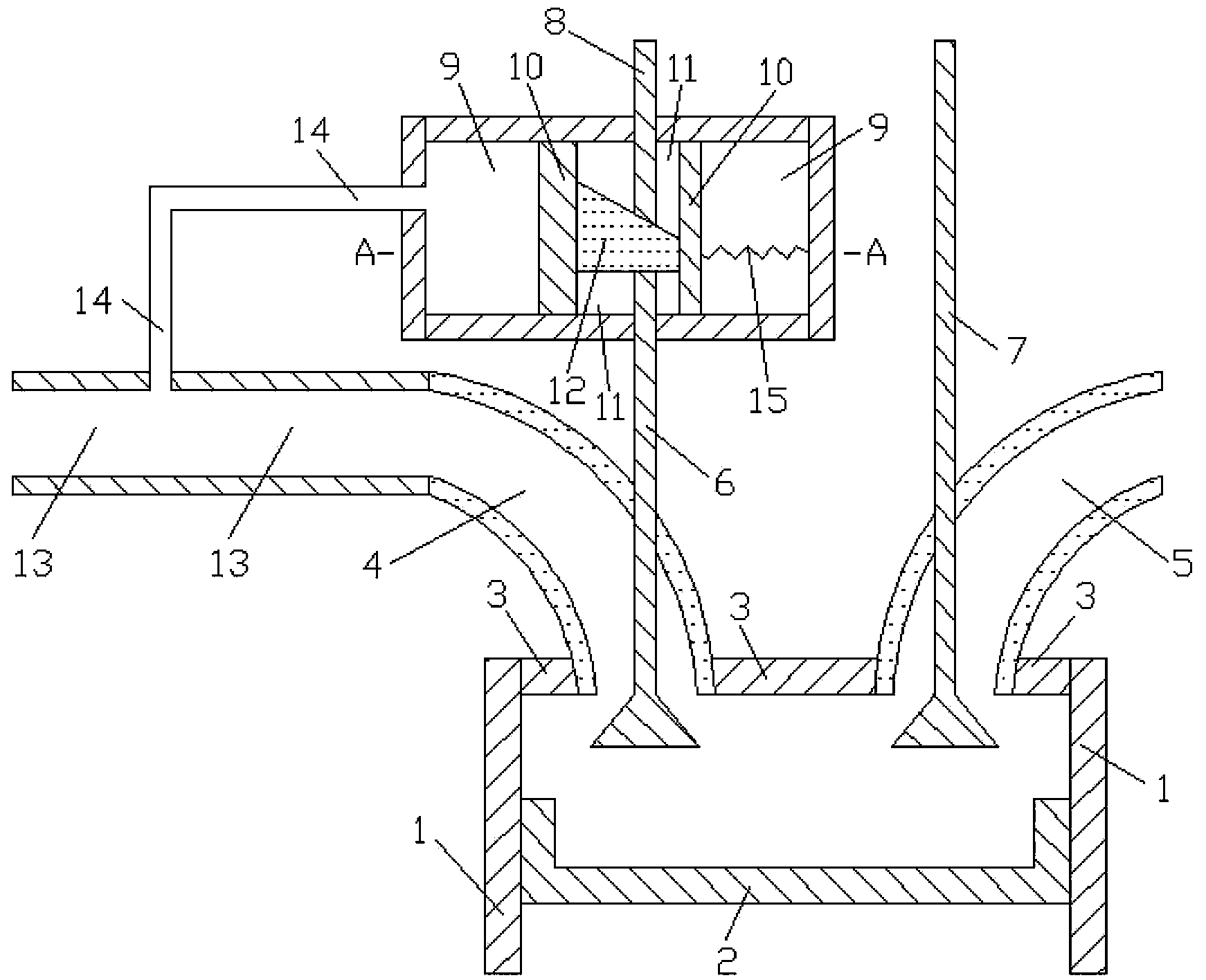

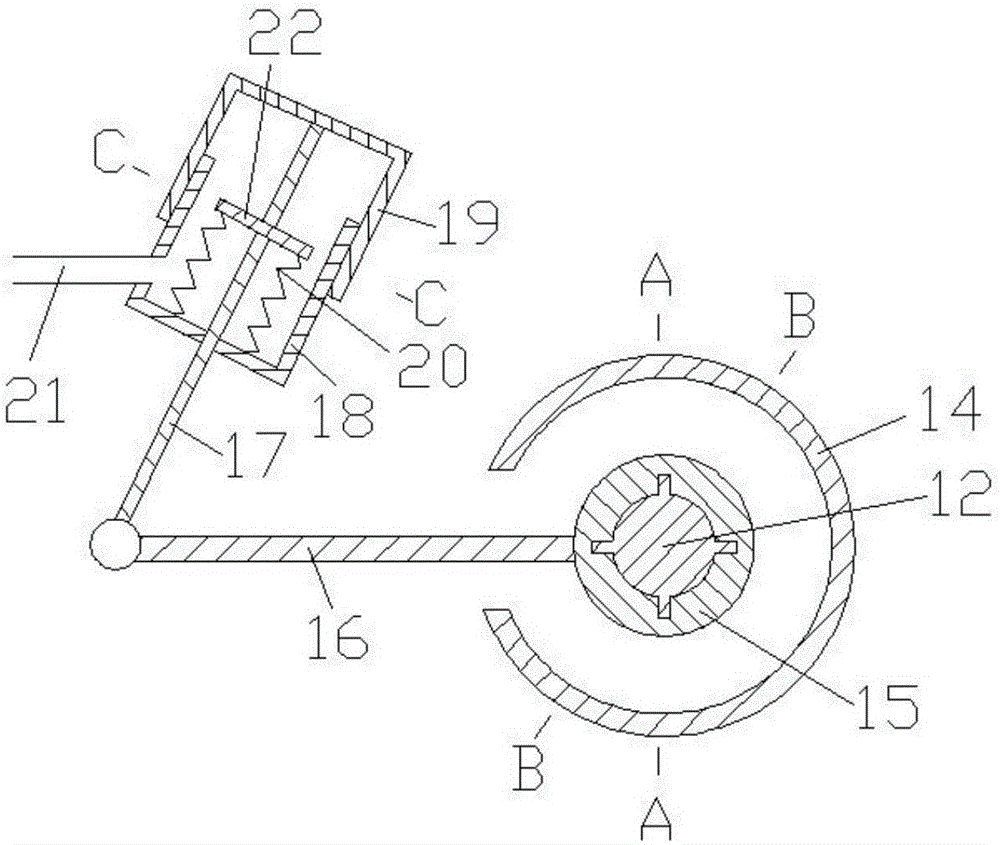

System for adjusting height of moving block type tappet rod

InactiveCN102966400AContinuously variableReasonable designMachines/enginesNon-mechanical valveExhaust valveInlet valve

A system for adjusting height of a moving block type tappet rod in the technical field of mechanical design comprises a cylinder, a gas inlet pipe, a gas inlet valve, a gas exhaust valve, a gas exhaust pipe, an upright, a lever, a tappet, a volume chamber, a moving body, a through pipe, a moving block, a connecting pipe and a spring, wherein the moving body is mounted in the volume chamber and in sealed contact with the inner wall surface of the volume chamber; the through pipe penetrates through the upper wall surface and the lower wall surface of the moving body; the moving block is mounted in the through pipe and in sealed contact with the inner wall surface of the through pipe; the lower end surface of the moving block is a plane; the upper end surface of the moving block is an inclined surface; the right wall surface of the moving body is connected with the right wall surface of the volume chamber through the spring; and two ends of the connecting pipe are respectively communicated with the gas exhaust pipe and the left wall surface of the volume chamber. When the pressure in the gas inlet pipe is larger, the moving body moves to the right and the lift of the gas inlet valve is increased; and when the pressure in the gas inlet pipe is smaller, the moving body moves to the left and the lift of the gas inlet valve is reduced. The system for adjusting the height of the moving block type tappet rod, provided by the invention, has the advantages of reasonable design and simple structure and is suitable for systems with variable engine valve lifts.

Owner:SHANGHAI JIAO TONG UNIV

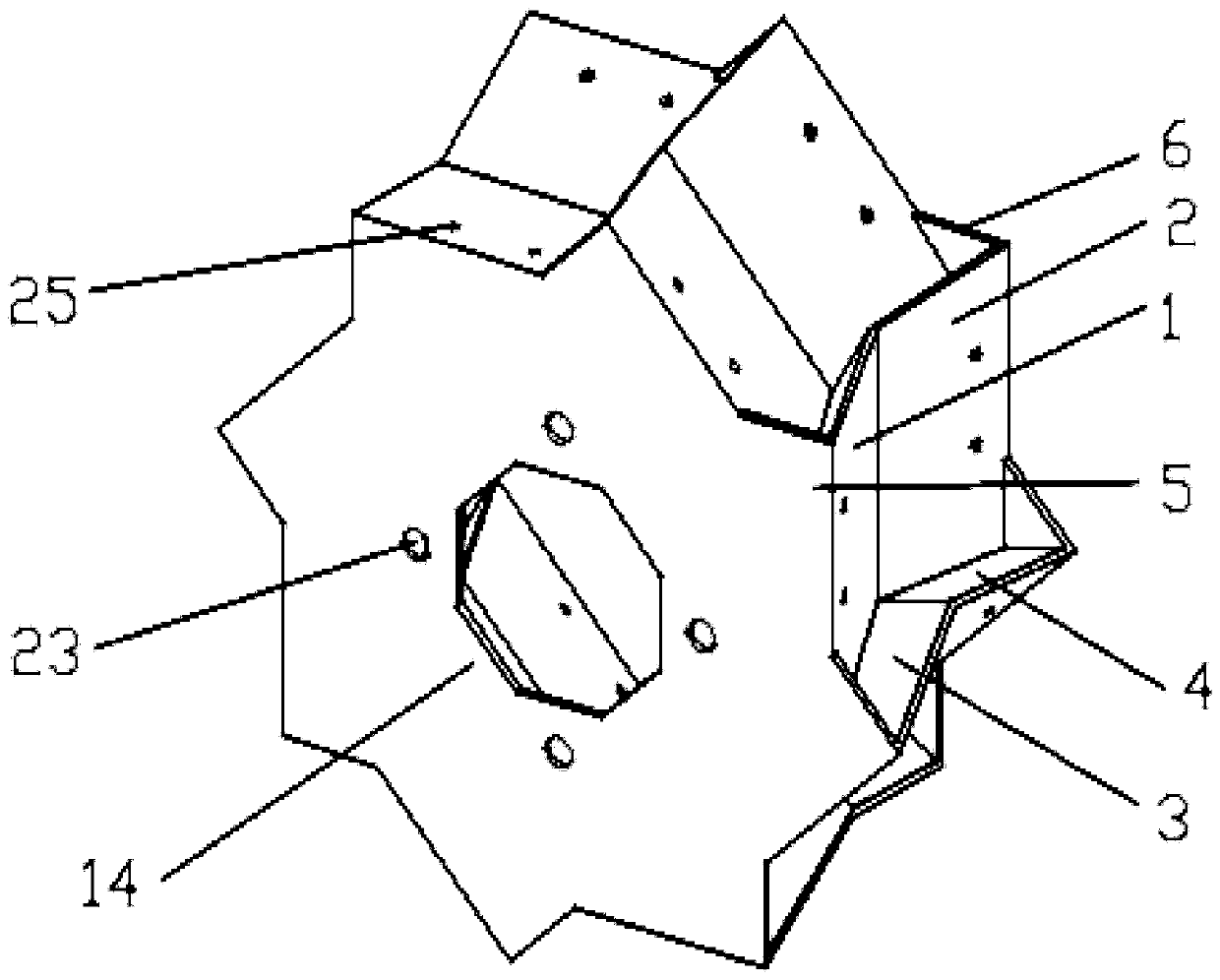

Paper folding type wheel with variable width

PendingCN111391573APreserve collapsibilityExtended production timeWheelsStructural engineeringMechanical engineering

The invention relates to a paper folding type wheel with the variable width. The paper folding type wheel comprises a reducing wheel carrier and a wheel shaft installed on the reducing wheel carrier.The reducing wheel carrier comprises a plurality of folding units sequentially connected end to end to form a ring. Each folding unit is provided with a first plane, a second plane, a third plane, a fourth plane, a fifth plane and a sixth plane; a first valley fold line is arranged between the first plane and the second plane and is symmetrically arranged by taking the first valley fold line as acenter; a first mountain fold line is arranged between the third plane and the fourth plane and is symmetrically arranged by taking the first mountain fold line as the center; a second valley fold line is arranged between the first plane and the third plane, a third valley fold line is arranged between the second plane and the fourth plane, the fifth plane and the sixth plane are symmetrically arranged with the first valley fold line as the center, and the fifth plane and the sixth plane are connected with the first plane and the second plane respectively. The paper folding type wheel with thevariable width can adjust the width of the variable-diameter wheel carrier, and belongs to the technical field of variable-width wheels and variable-diameter wheels.

Owner:GUANGZHOU UNIVERSITY

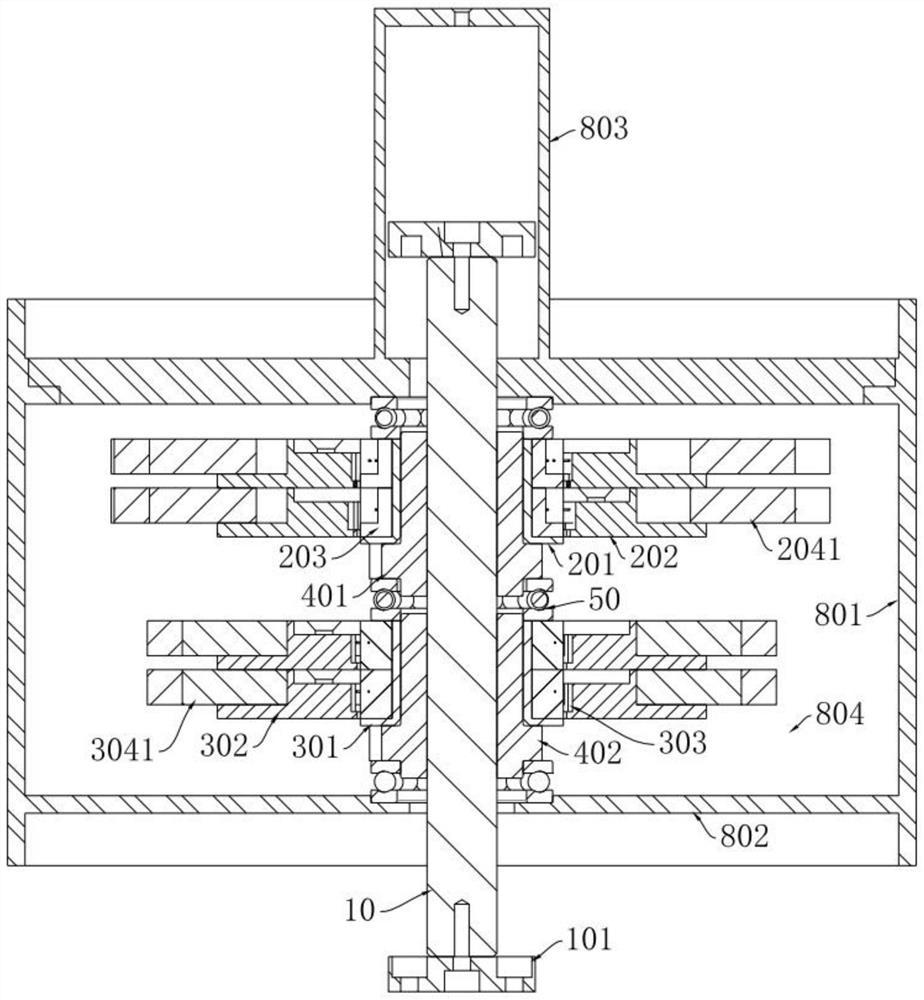

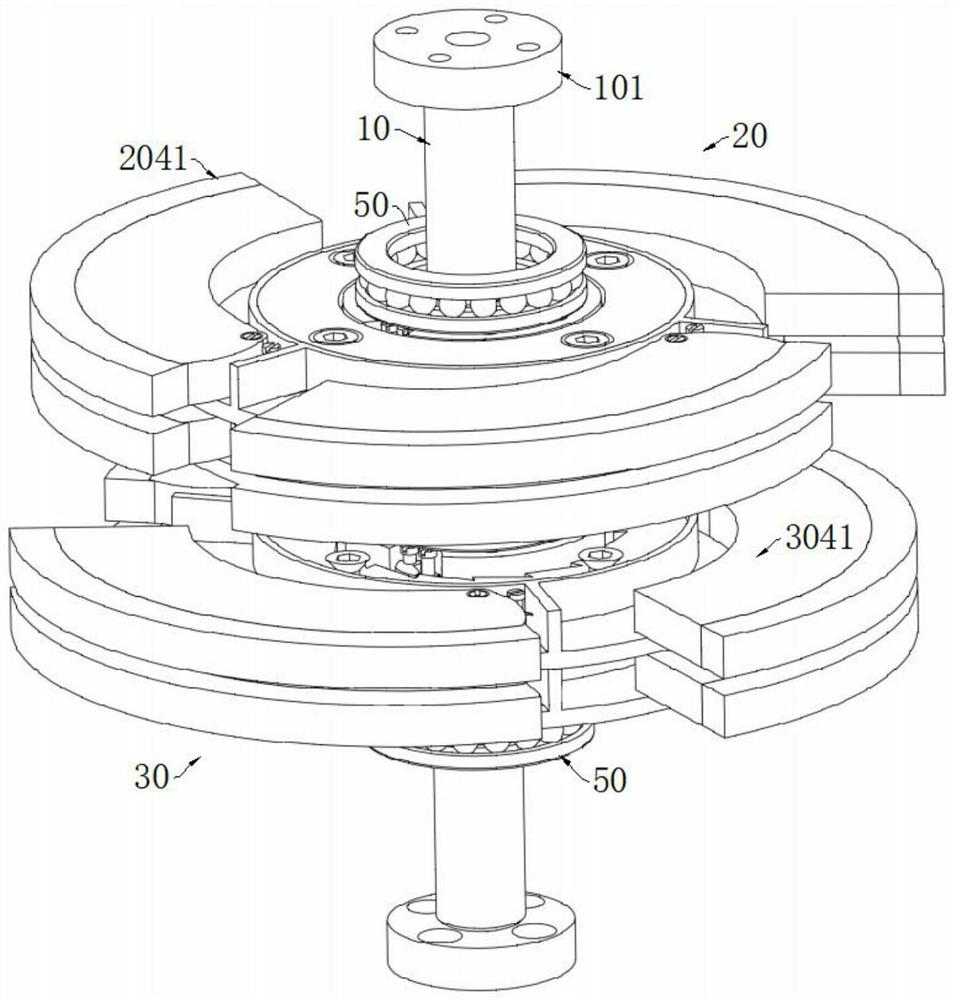

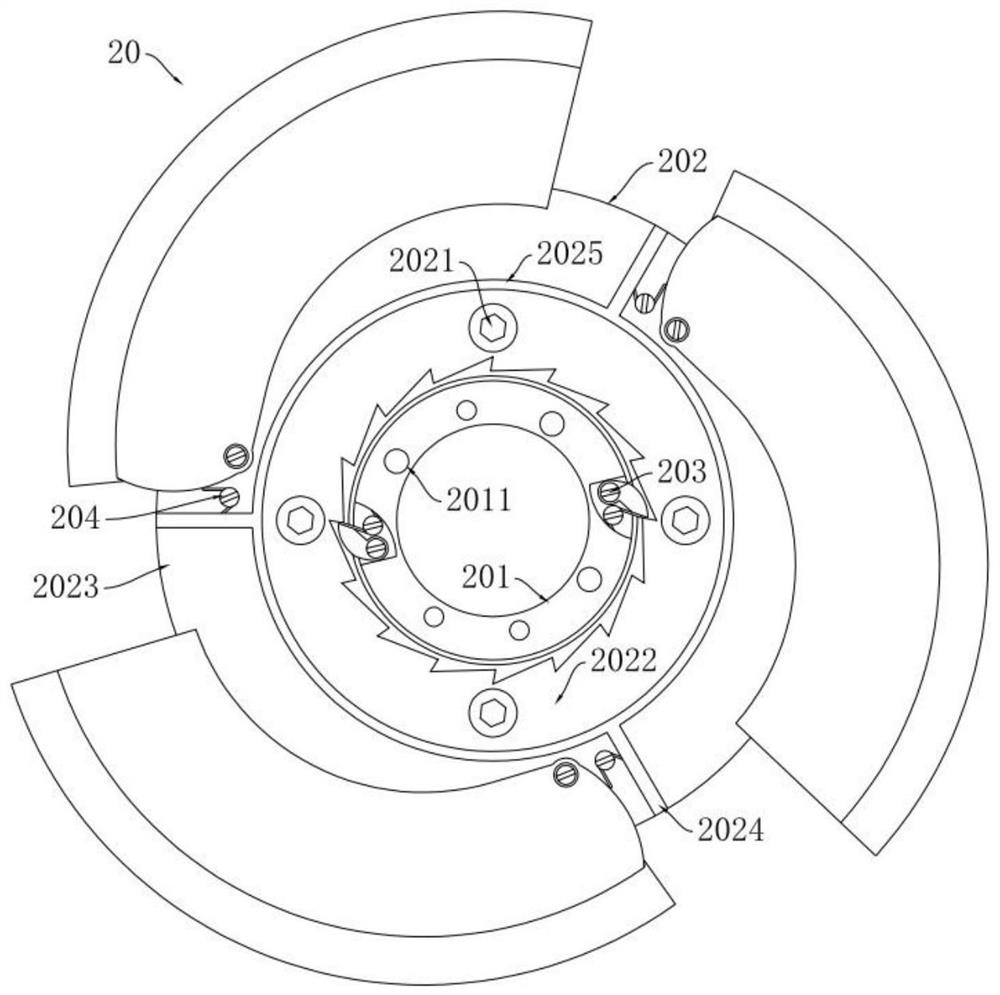

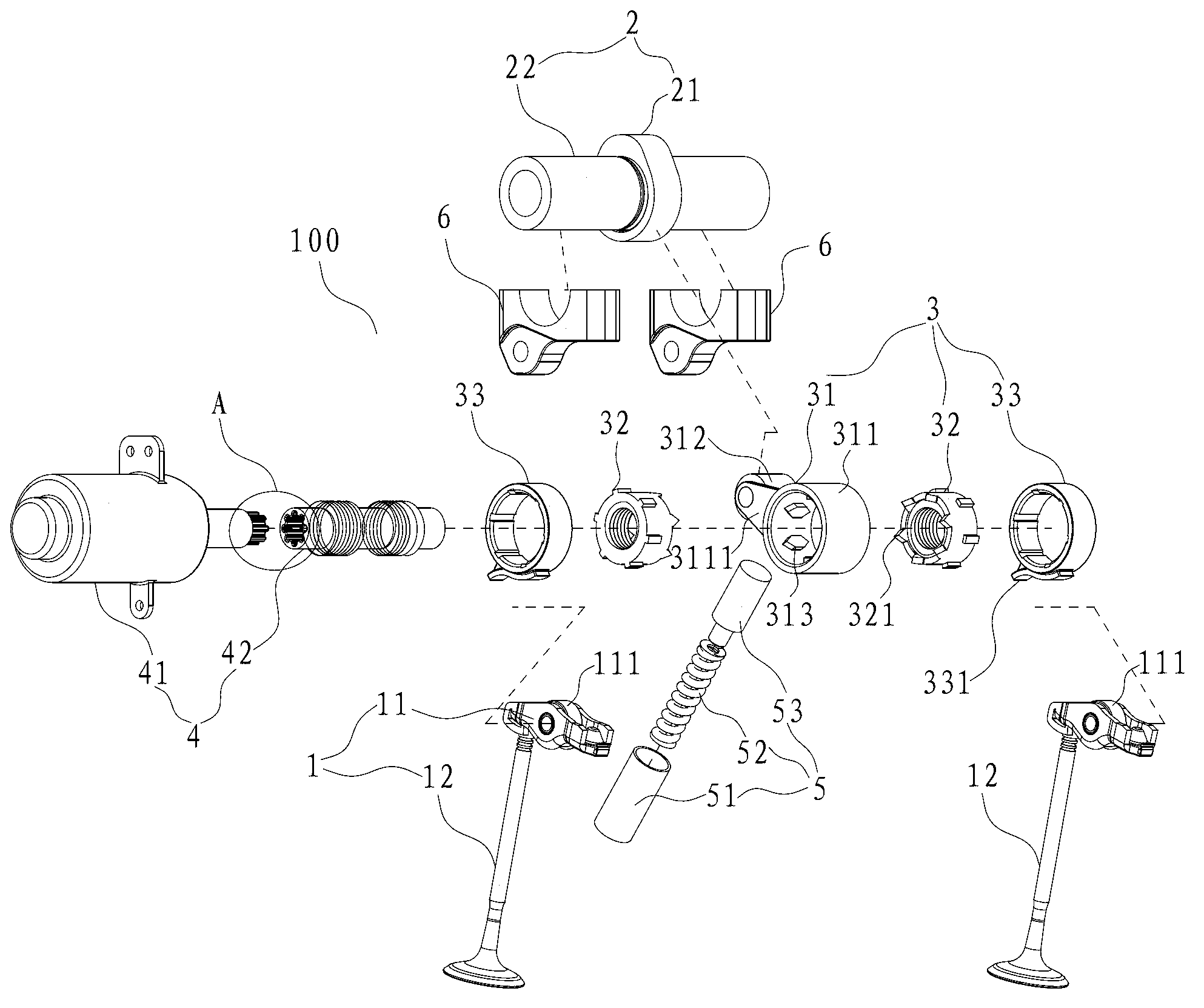

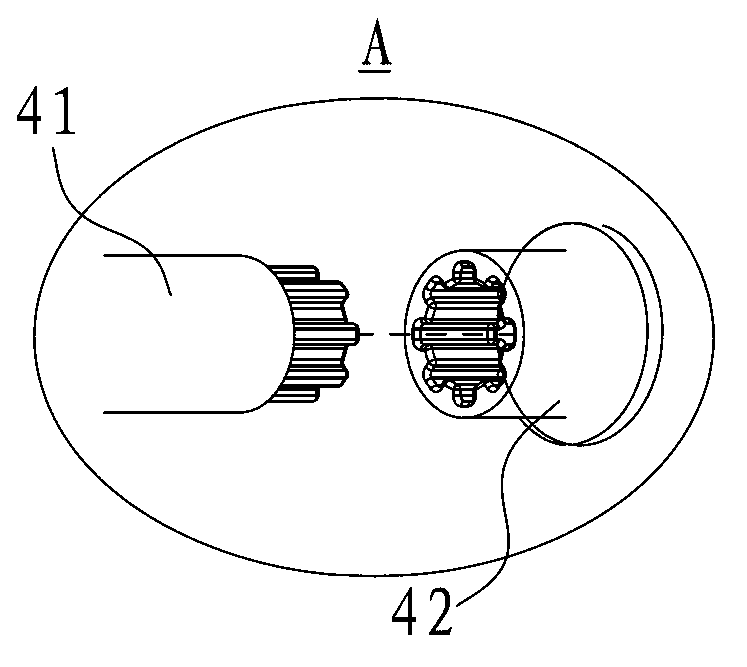

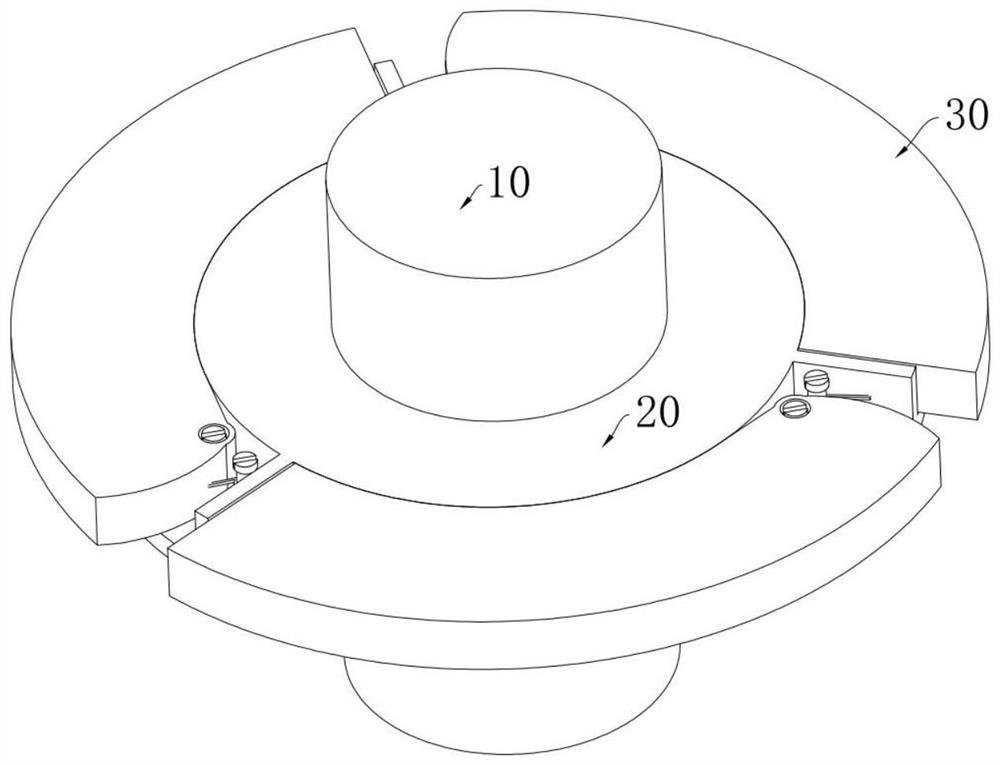

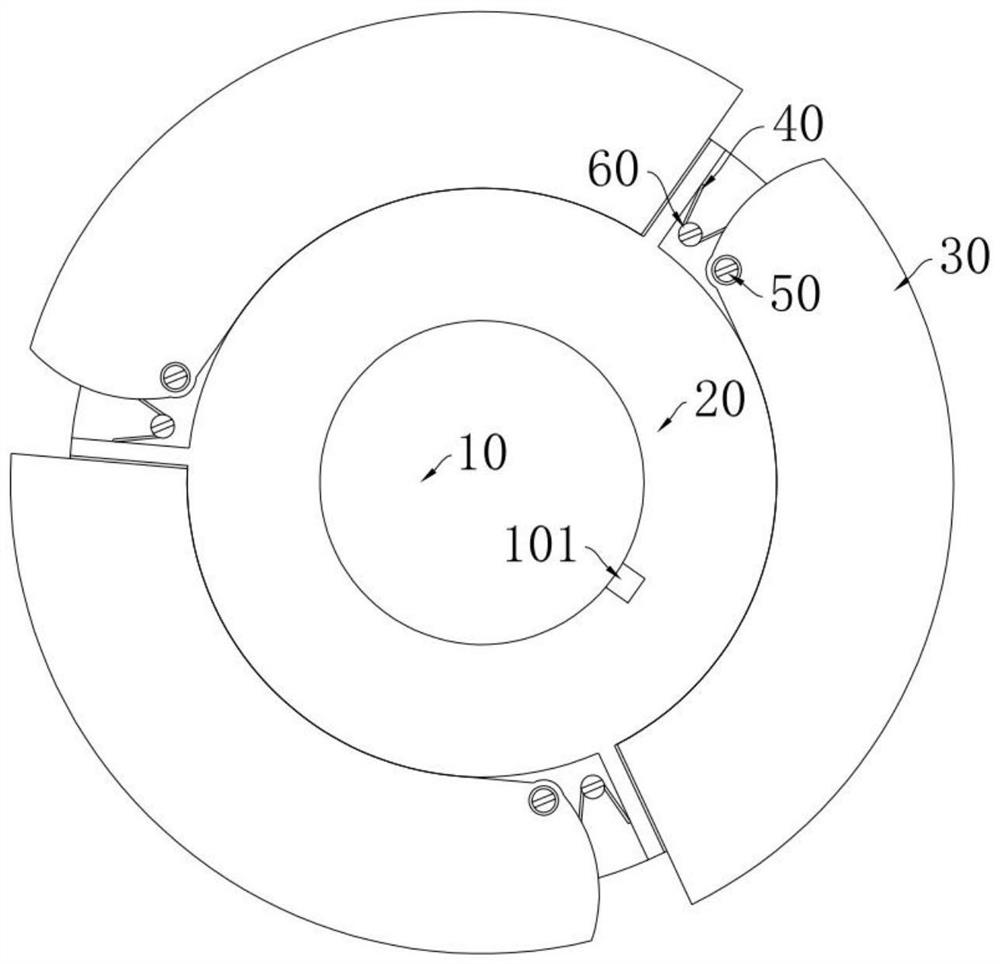

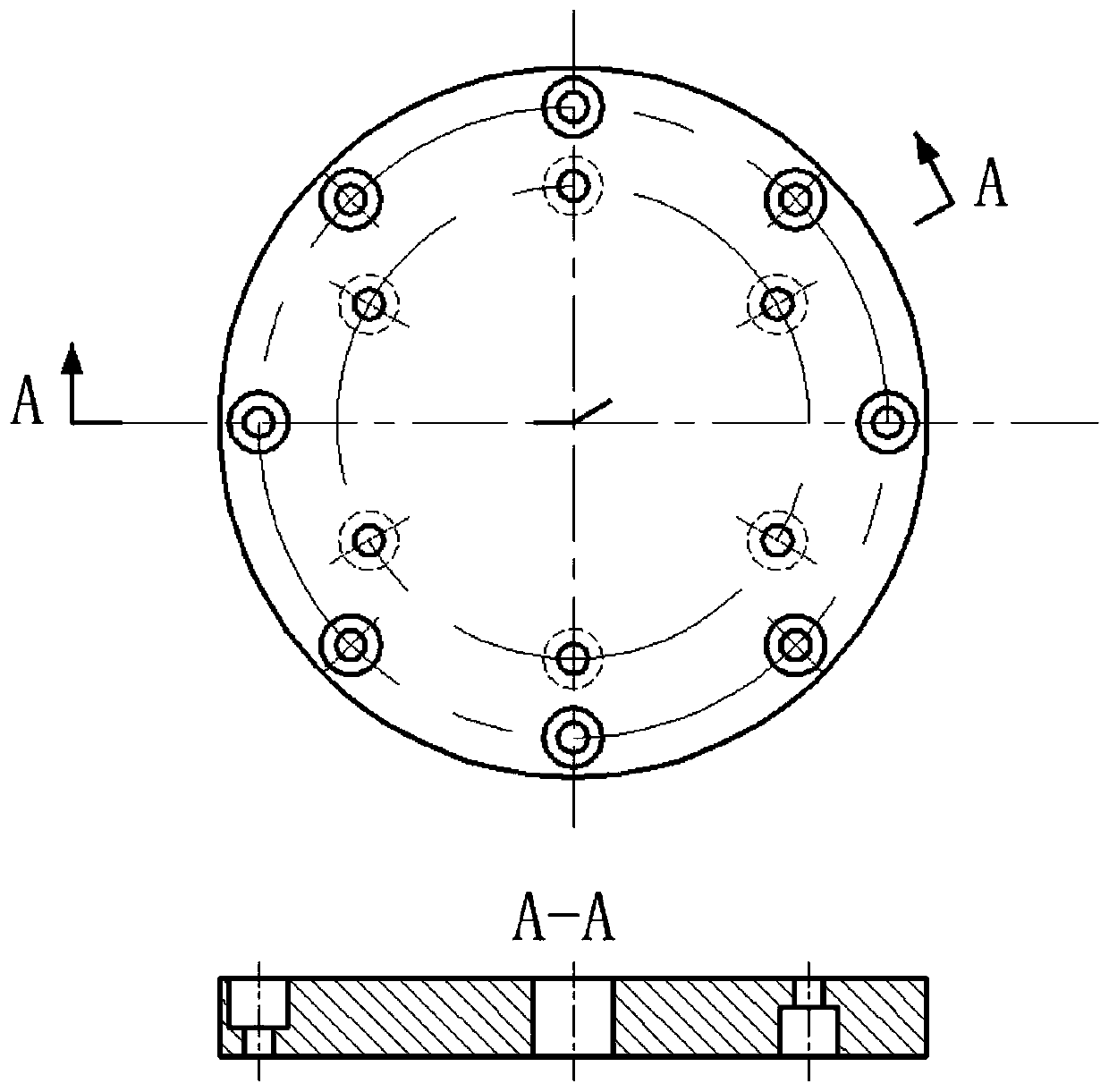

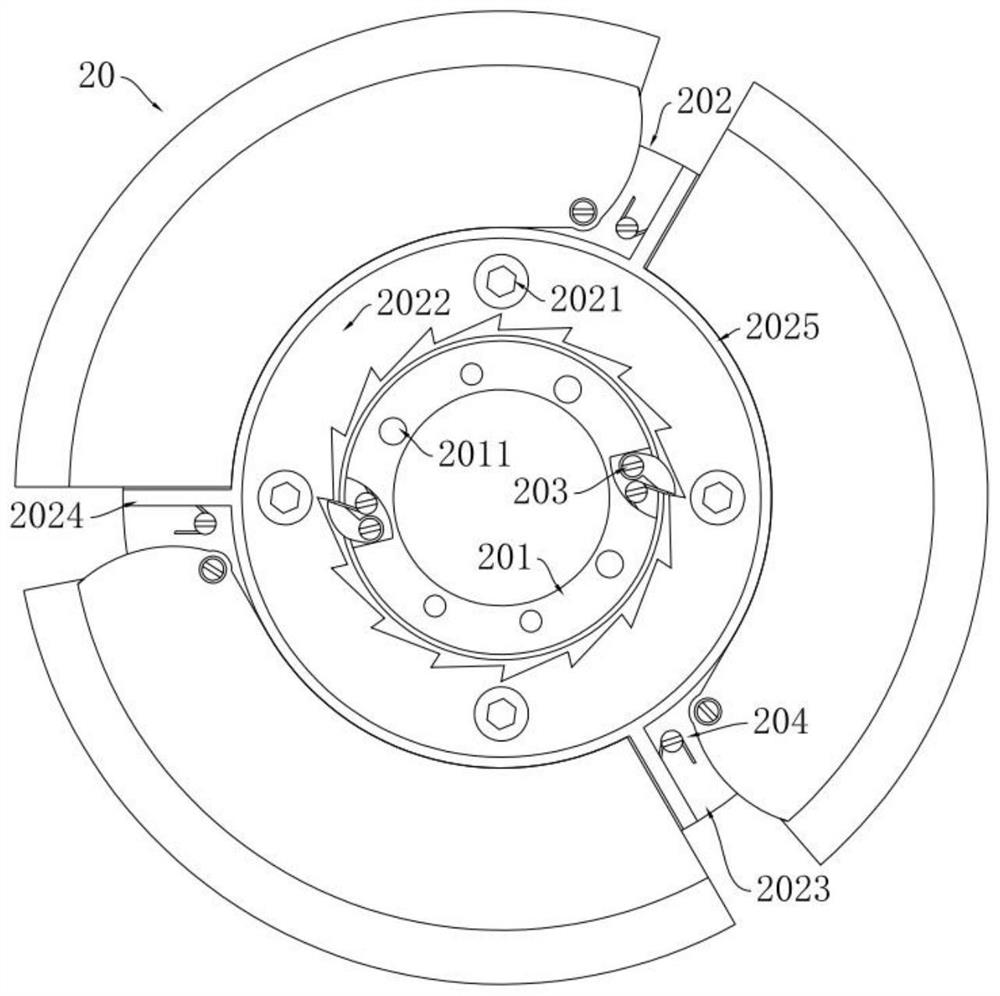

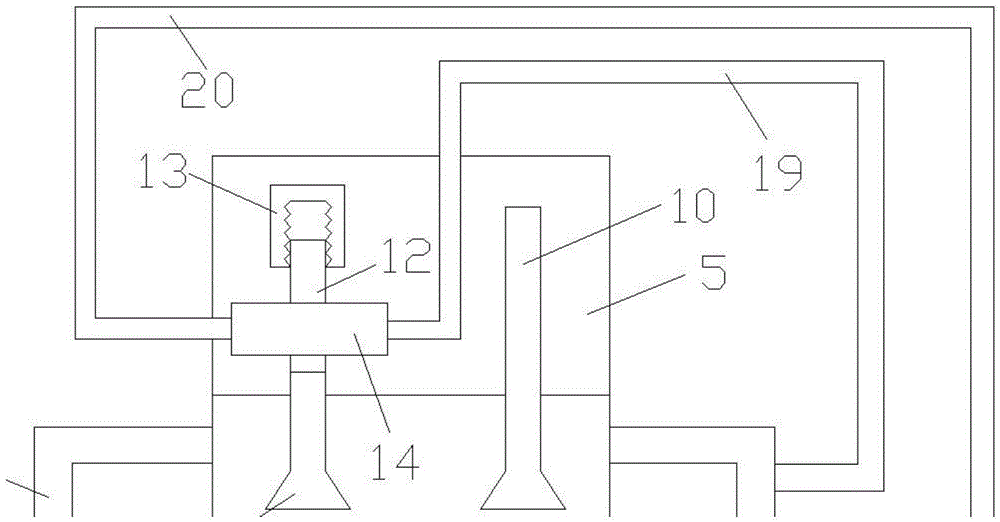

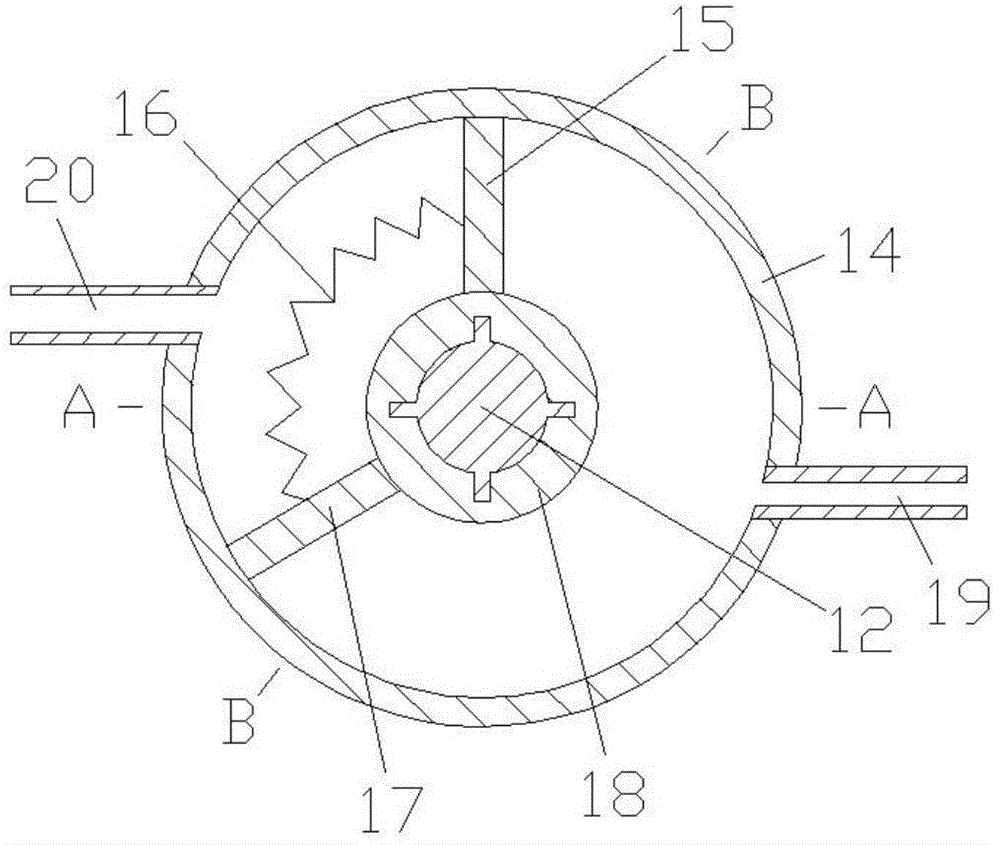

Ratchet wheel type ball screw inerter with variable inertial mass coefficient and capable of rotating bidirectionally

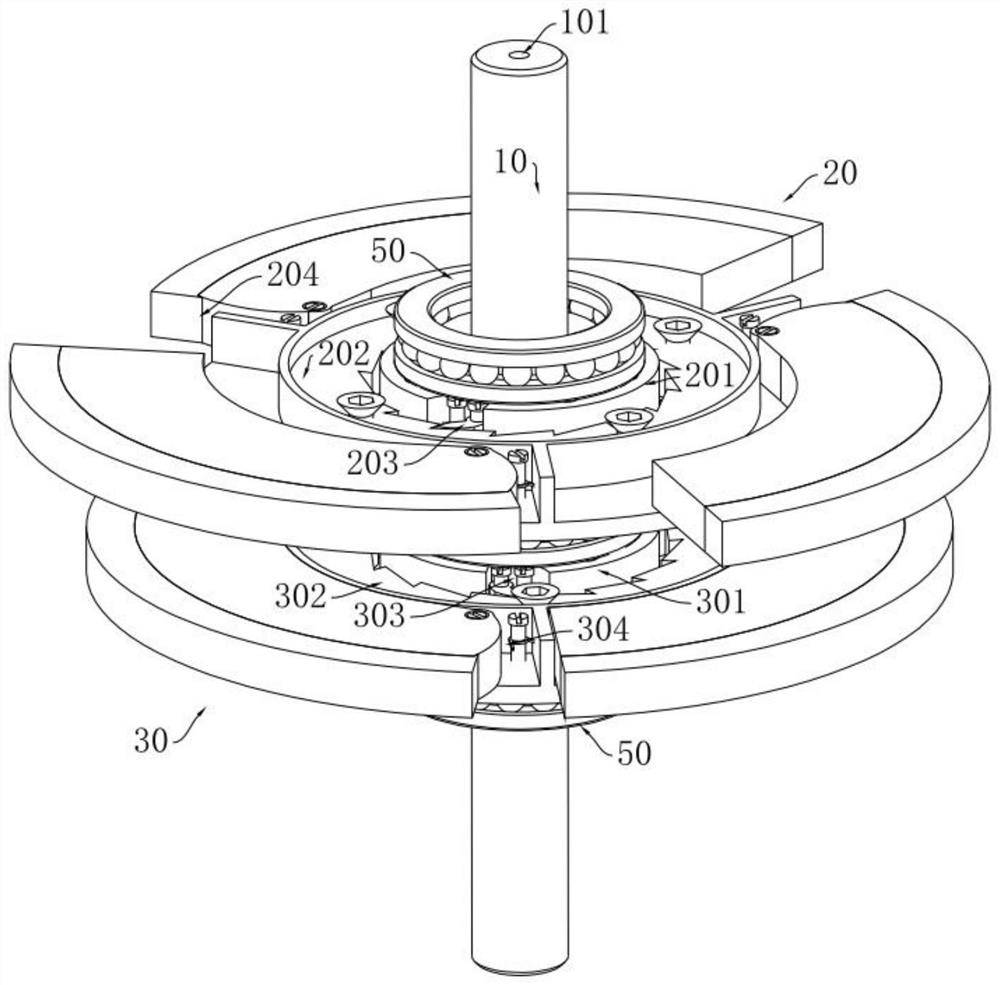

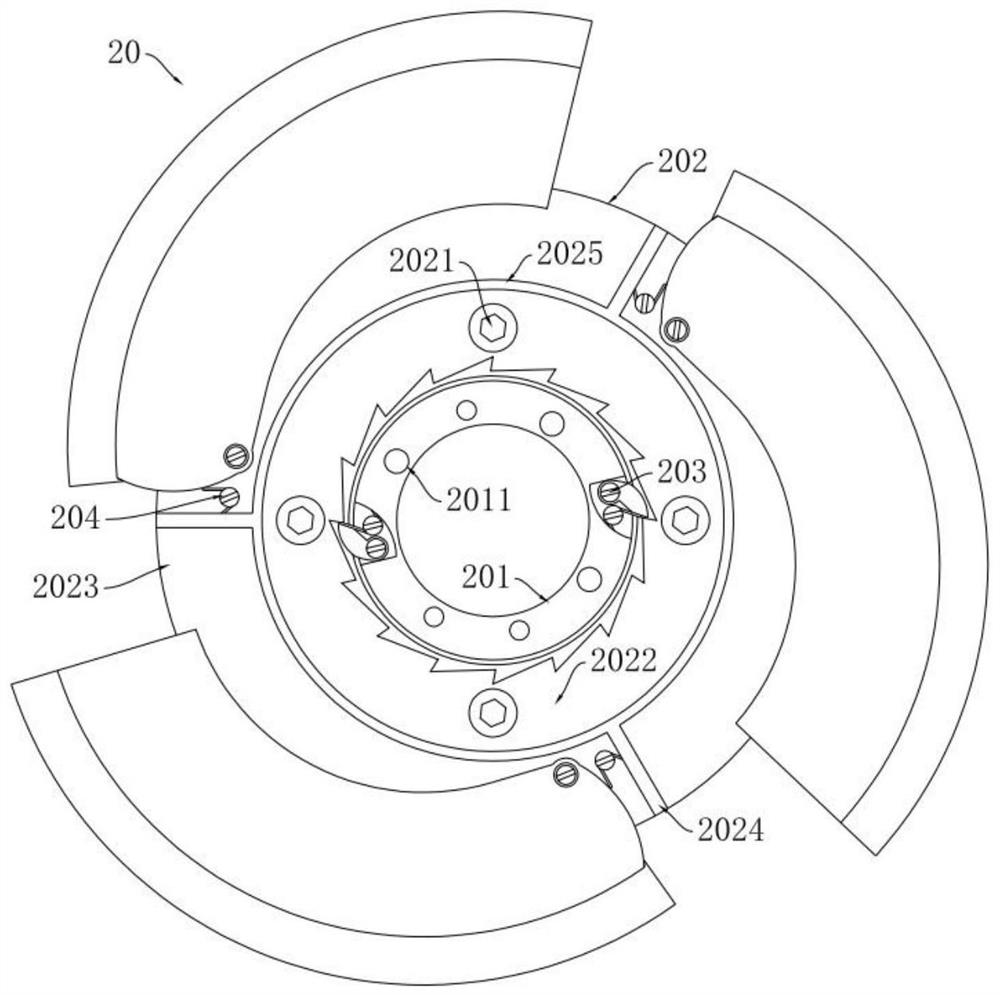

ActiveCN112709785AChange direction of translationReduce shockFlywheelsFreewheel clutchesRatchetBall screw

The invention discloses a ratchet wheel type ball screw inerter with a variable inertial mass coefficient and capable of rotating bidirectionally. The ratchet wheel type ball screw inerter comprises a forward flywheel assembly and a reverse flywheel assembly. The forward flywheel assembly comprises a forward poking wheel, a forward flywheel disc and a forward unfolding mechanism, the forward poking wheel is fixedly arranged on a lead screw nut assembly in a sleeving mode, the forward flywheel disc and the forward poking wheel form a ratchet wheel structure, and the forward unfolding mechanism is arranged on the forward flywheel disc so as to change the turning radius of the forward flywheel disc. The reverse flywheel assembly comprises a reverse poking wheel, a reverse flywheel disc and a reverse unfolding mechanism, the reverse flywheel and the reverse poking wheel form a ratchet wheel structure, and the reverse unfolding mechanism is arranged on the reverse flywheel disc so as to change the turning radius of the reverse flywheel disc. Under the condition that the rotation direction of a flywheel is not changed, the impact caused by the change of the rotation direction of the flywheel when the inertia volume of a ball screw switches the movement direction is reduced. Meanwhile, on the premise that no extra device is added and no extra energy is utilized, continuous variability of the rotational inertia of the flywheel is achieved, and the flywheel is self-adaptive to different working conditions.

Owner:NAT UNIV OF DEFENSE TECH

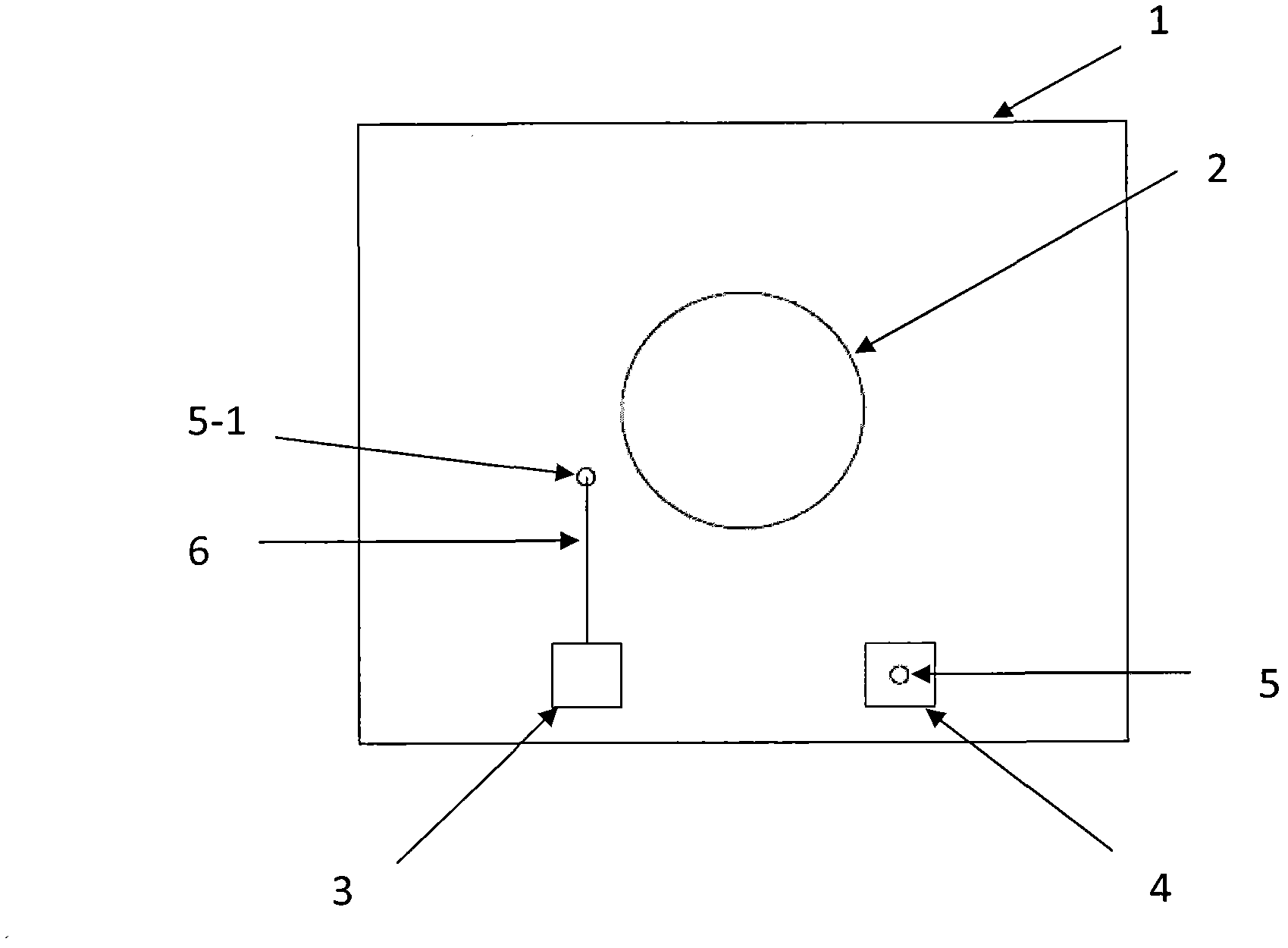

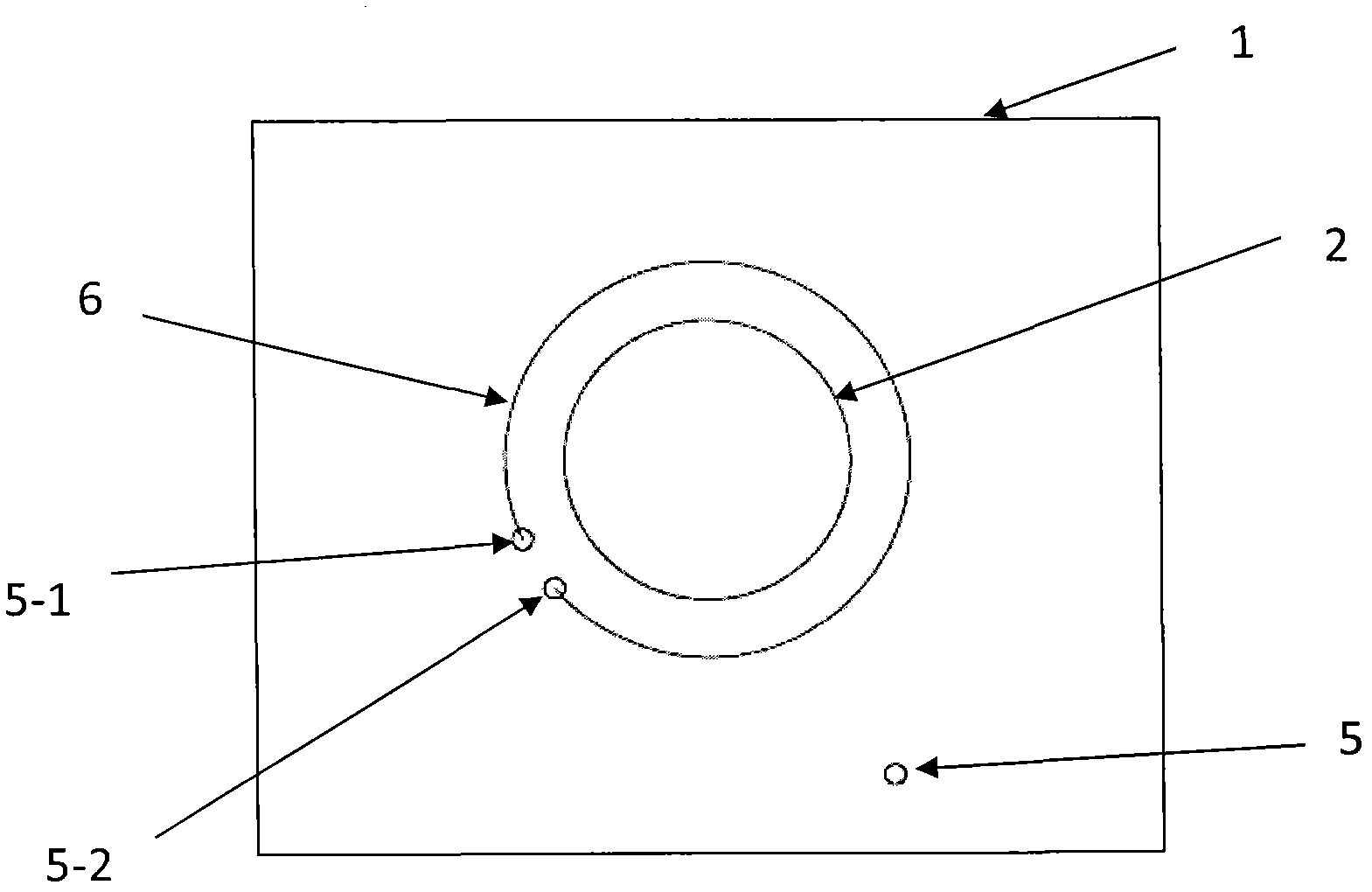

Variable inductor

InactiveCN102610365AContinuously changing inductanceHigh Q valueTransformers/inductances detailsPrinted inductancesMicrowaveInductor

The invention discloses a variable inductor, which comprises a substrate, a core, an inductor body and a pair of electrodes of the inductor body, wherein the inductor body is printed on the substrate, the substrate is provided with a hole, and the core is inserted into the hole and moves along the length direction of the hole. Continuous variability of inductance of high-frequency microwave is realized by changing position of the core.

Owner:YANTEL CORP

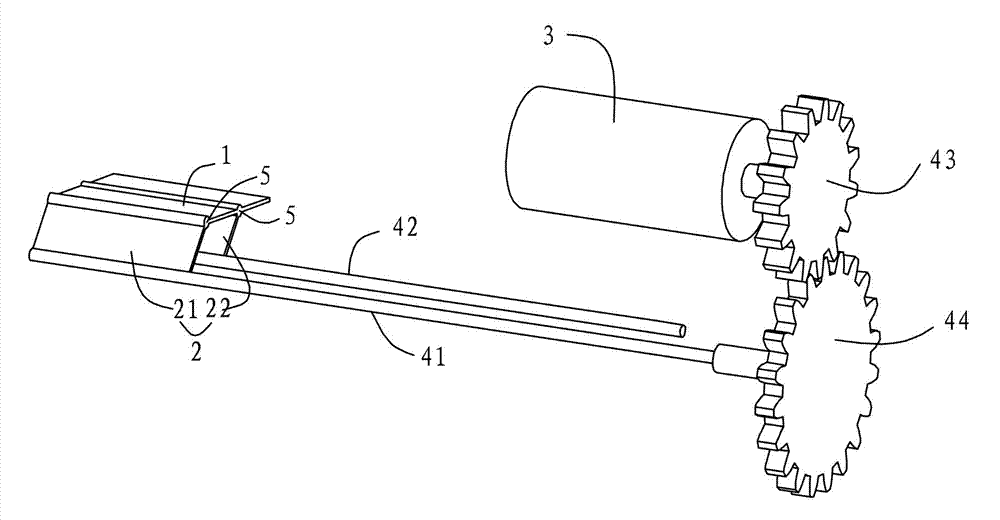

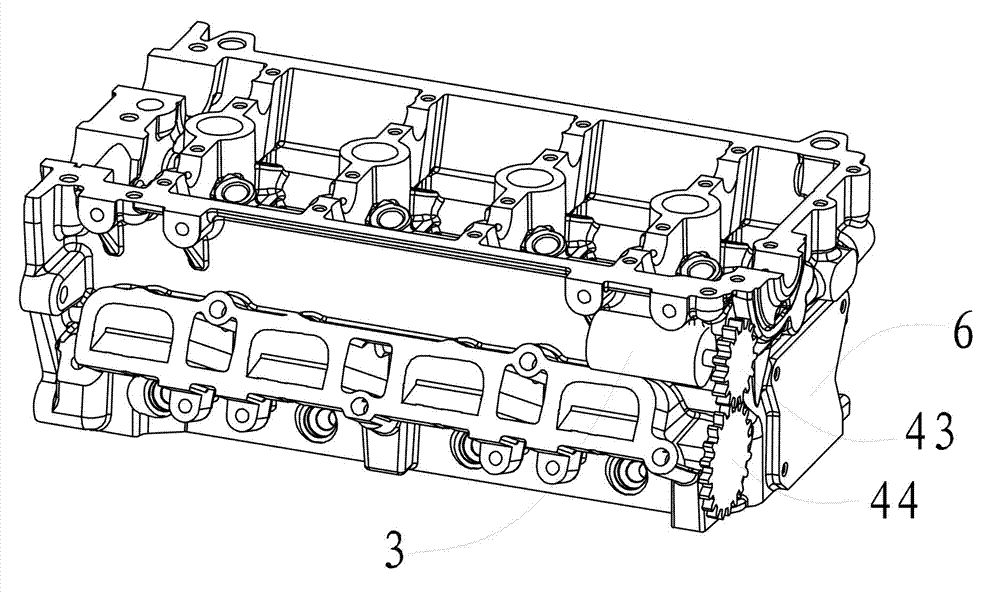

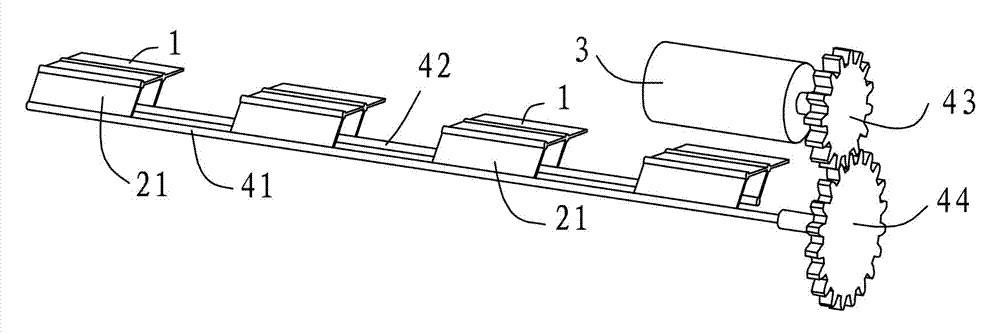

Continuous changeable air inlet tumbling flow control mechanism of engine and engine

ActiveCN103291441APromotes air movementContinuously variableInternal combustion piston enginesEngine controllersControl theoryPower take-off

The invention relates to a device for adjusting air flow in an air inlet pipeline of an engine, in particular to a continuous changeable air inlet tumbling flow control mechanism of the engine. The continuous changeable air inlet tumbling flow control mechanism of the engine comprises a top plate, a supporting stopping device and a power transmission mechanism, wherein the supporting stopping device is used for supporting the top plate and carrying out stopping on the air flow in the air inlet pipeline, and the power transmission mechanism is arranged between the supporting stopping device and a power output device in a connected mode. Meanwhile, the invention further relates to the engine with the continuous changeable air inlet tumbling flow control mechanism. According to the technical scheme, the area of an unblocked channel formed above the top plate can be adjusted at any time, and continuous changeable performance of air inlet tumbling flow can be achieved.

Owner:GREAT WALL MOTOR CO LTD

Air pressure difference value control type dislocation stress device

The invention discloses an air pressure difference value control type dislocation stress device, and belongs to the technical field of mechanical design. The device comprises an air inlet valve, control cavities, a rotating shaft, a rotating rod, a stretching rod, a spring, moving bodies and connecting pipes. Four cavities are formed in the rotating shaft, and four reinforced ribs are arranged on the middle segment of the air inlet valve; the four reinforced ribs on the middle segment of the air inlet valve are arranged in the four cavities of the rotating shaft; the lower wall face of the first moving body and the upper wall face of the second moving body are both provided with slope structures; one end of the first connecting is communicated with an upper cavity body of t he second control cavity, and the other end of the first connecting pipe is communicated with an exhaust pipe of an engine; and one end of the second connecting pipe is communicated with the upper cavity body of the second control cavity, and the other end of the second connecting pipe is communicated with a turbine exhaust pipe. According to the stress device, when the pressure in the control cavities is too high, the middle segment of the air inlet valve are rotated clockwise, the lifting range of the valve is increased, and the air inlet amount of the engine becomes large. The air pressure difference value control type dislocation stress device is reasonable in design, simple in structure and applicable to the design of an air inlet valve lift range variable system.

Owner:聂瑜

Pneumatic engine valve control mechanism

InactiveCN104806318ASmall liftBig liftValve arrangementsMachines/enginesCombustionExternal combustion engine

The invention discloses a pneumatic engine valve control mechanism, and belongs to the technical field of internal combustion engines. The pneumatic engine valve control mechanism comprises a lower intake valve section, a middle intake valve section, an upper intake valve section, a control body, a fixed body, through pipes, an elastic part, a rotating plate, a rotating shaft and a first connecting pipe, wherein the middle intake valve section penetrates through the rotating shaft; four cavities are formed in the rotating shaft; the middle intake valve section is provided with four ribs; the four ribs of the middle intake valve section are arranged in the four cavities of the rotating shaft respectively; a rotating block is connected with the wall surface of the top end of the second through pipe through the elastic part; the two ends of the first connecting pipe are communicated with the first through pipe and an intake pipe of an engine respectively; the two ends of the second through pipe are communicated with the second through pipe and an turbine exhaust pipe. According to the pneumatic engine valve control mechanism, when pressure in the first through pipe is higher, the middle intake valve section rotates clockwise, the valve lift is increased, and the air inflow of the engine is increased; the pneumatic engine valve control mechanism is reasonable in design, simple in structure and applicable to the design of an intake valve lift continuously variable system.

Owner:上海速朗电子科技有限公司

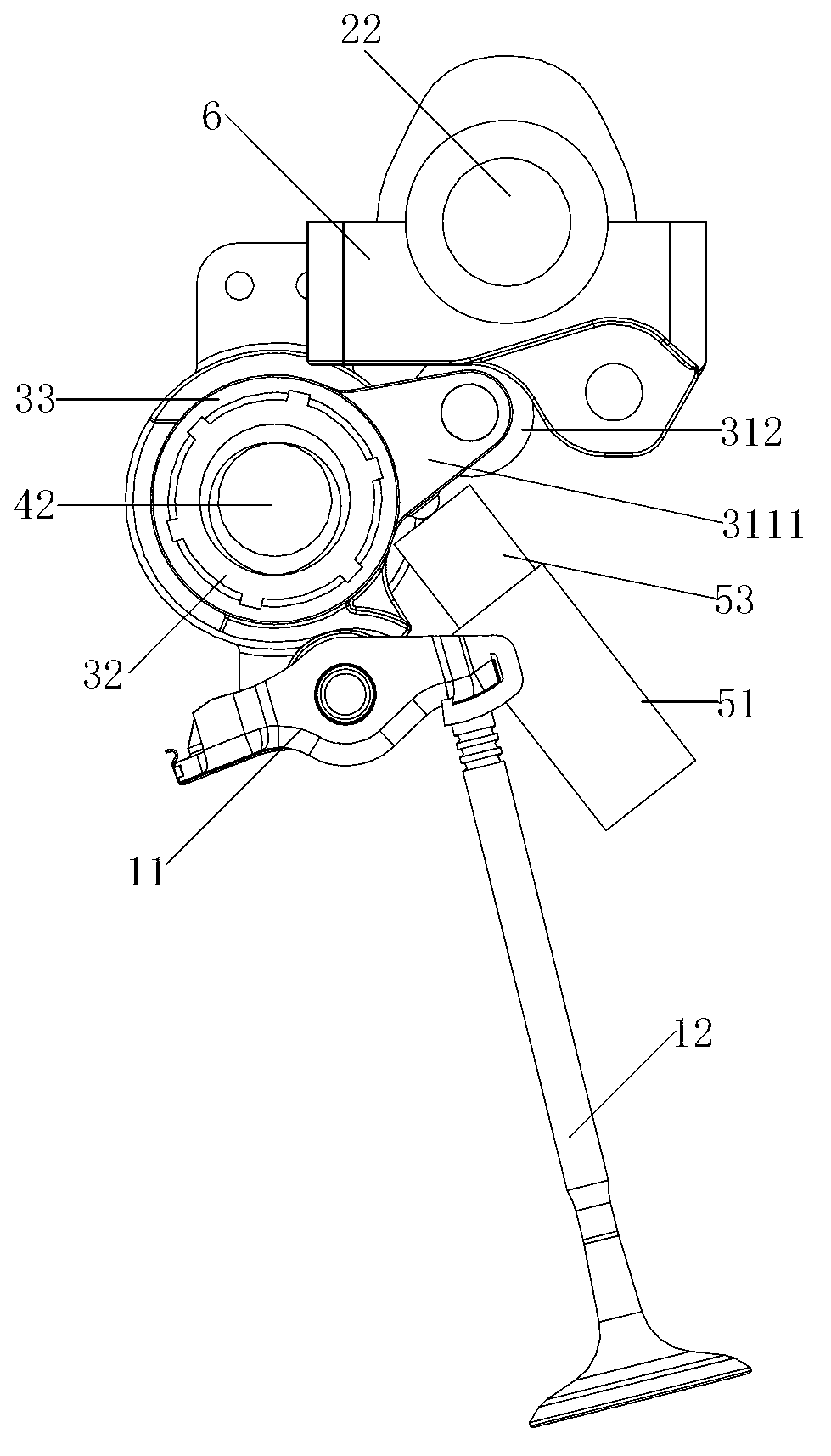

Air valve lifting device for engine, engine comprising same, and automobile comprising same

ActiveCN103216291ASolve the requirements of gas distributionImprove work efficiencyValve arrangementsMachines/enginesLow speedEngineering

The invention discloses an air valve lifting device for an engine, the engine comprising the same, and an automobile comprising the same. The air valve lifting device comprises an air valve mechanism, a cam shaft mechanism, a swing arm mechanism and an actuating mechanism, wherein the top of the air valve mechanism is provided with a roller arm, the cam shaft mechanism is arranged above the air valve mechanism, the cam shaft mechanism comprises a cam, the swing arm mechanism is arranged between the roller arm and the cam shaft mechanism and is driven by the cam to swing around the swing arm rotary axis of the swing arm mechanism, the actuating mechanism is used for driving the swing arm mechanism to rotate around the regulating rotary axis of the actuating mechanism to continuously and changeably regulate the lift of the air valve mechanism, and the swing arm rotary axis is coincident with the regulating rotary axis. According to the air valve lifting device, different air valve lifts can be achieved according to requirements of different working conditions of the engine, and pump gas loss and mechanical loss in the low-speed load working condition are reduced. Meanwhile, continuation and changeability of the air valve lifts are achieved, and work efficiency of the engine is improved.

Owner:GREAT WALL MOTOR CO LTD

Device achieving continuously variable valve lift

The invention belongs to the technical field of internal combustion engines and relates to a device achieving a continuously variable valve lift. The device comprises a lower intake valve section, a middle intake valve section, an upper intake valve section, a control body, a fixing body, penetrating pipes, an elastic component, a rotating plate, a rotating shaft and a connecting pipe, wherein the middle intake valve section penetrates through the rotating shaft, four cavities are formed in the rotating shaft, the middle intake valve section is provided with four ribs, the four ribs of the middle intake valve section are distributed in the four cavities of the rotating shaft respectively, a rotating block is connected with the wall surface of the top end of the second penetrating pipe through the elastic component, one end of the connecting pipe is communicated with the first penetrating pipe, and the other end of the connecting pipe is communicated with an engine exhaust pipe. According to the device, when pressure in the first penetrating pipe is high, the middle intake valve section rotates clockwise, the valve lift becomes larger, and the engine air inflow becomes larger. The device is reasonable in design, simple in structure and suitable for design of an intake valve lift continuous variable system.

Owner:上海速朗电子科技有限公司

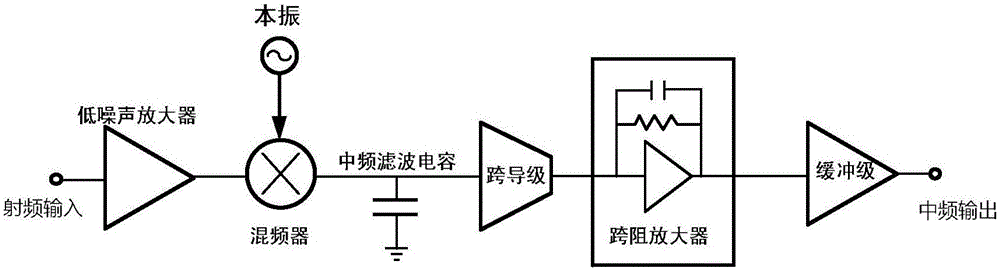

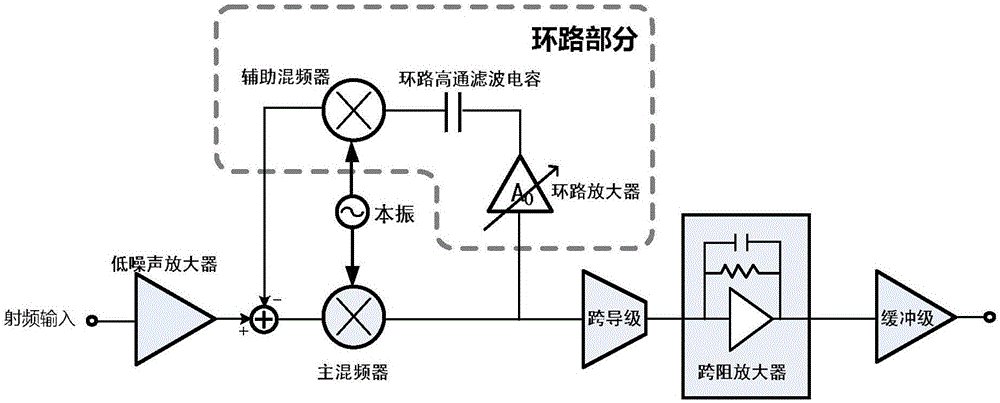

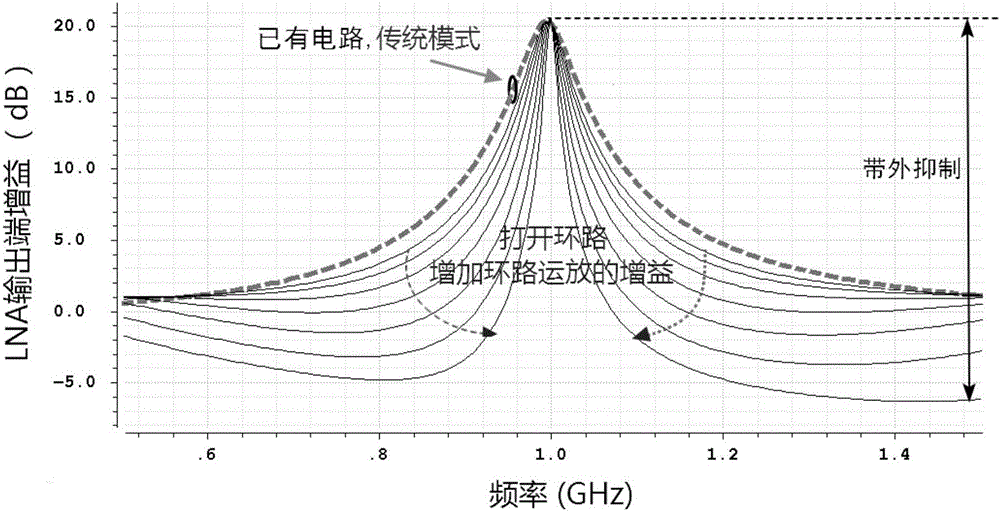

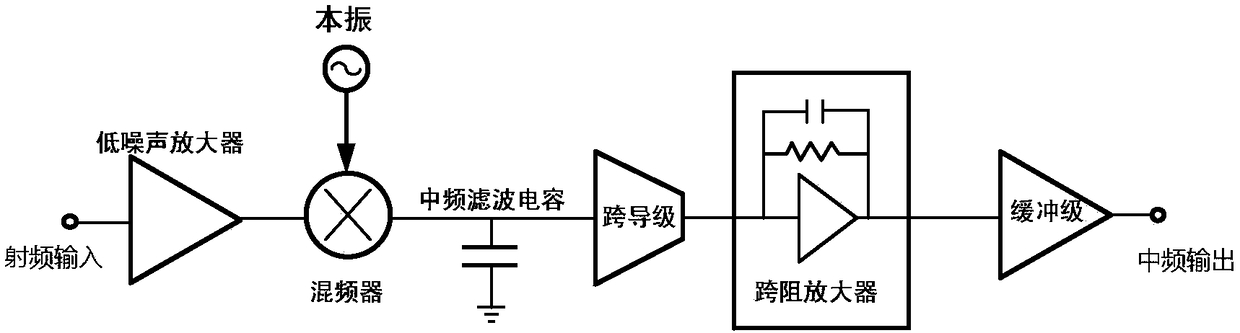

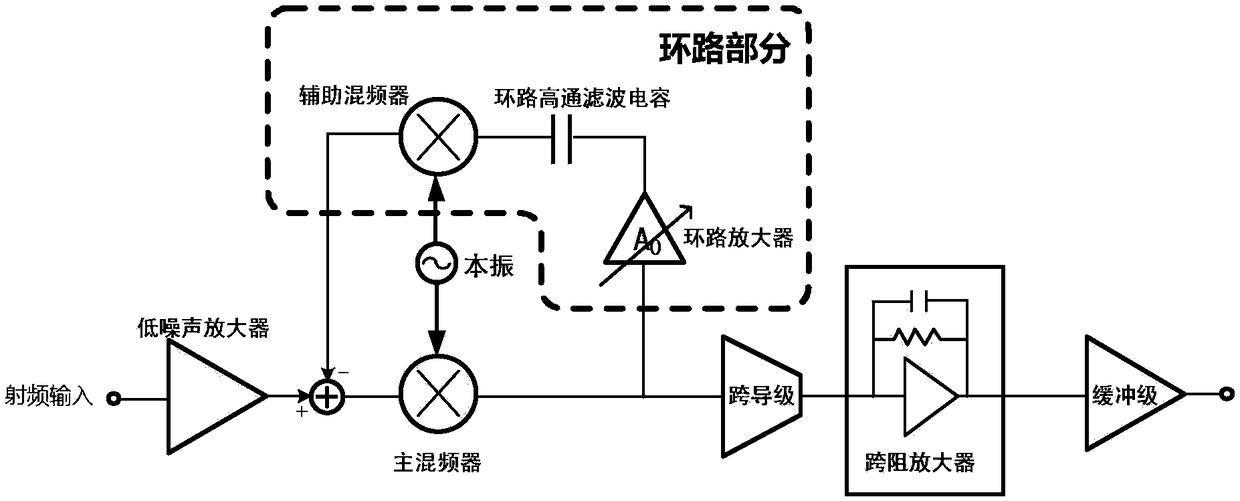

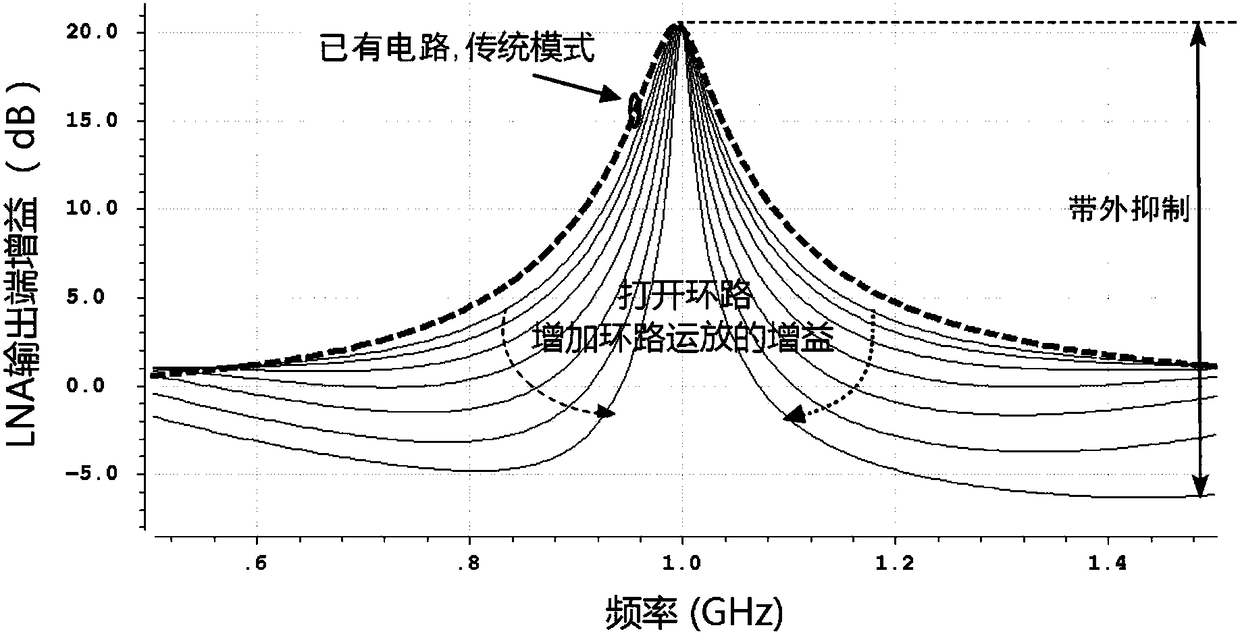

Broadband receiver front-end circuit with continuously adjustable bandwidth

The invention discloses a broadband receiver front-end circuit with a continuously adjustable bandwidth. The circuit comprises a low noise amplifier, a main mixer, a transconductance stage circuit, a transimpedance amplifier and an output buffer stage circuit and a feedback loop, wherein the low noise amplifier amplifies a radio frequency signal, the amplified radio frequency signal is converted by the main mixer into a medium frequency voltage signal, the transconductance stage circuit converts the medium frequency voltage signal into a current signal, the current signal is converted by the transimpedance amplifier into a voltage signal, and the voltage signal is output to an off-chip digital chip through the output buffer stage circuit for processing after being amplified and filtered; and the feedback loop amplifies the value of a high-pass filter capacitor in the feedback loop through the Miller effect of a loop amplifier, thereby not only realizing the clutter filtering of the medium frequency voltage signal, but also omitting a medium frequency filter capacitor. The broadband receiver front-end circuit disclosed by the invention effectively reduces the overall area of the chip, can realize the continuously adjustable bandwidth, and can also further reduce the equivalent on-resistance of the mixer and inhibit out-of-band interference signals.

Owner:SOUTHEAST UNIV

Unidirectional clutch type stepless speed changer

InactiveCN101140025AContinuously variableLarge adjustable speed rangeGearingEngineeringControl theory

The invention relates to a mechanical stepless speed variator having the continuously changed drive ratio, convenient variable speed control and large speed adjusting range; wherein a crankshaft drives a group of rocker arms, a group of rocker arms drive a group of unidirectional clutches, each group of unidirectional clutches drive a middle shaft to rotate in the same rotary direction, the middle shaft transfers the force to a middle shaft crankshaft, and the middle shaft crankshaft drives again a group of unidirectional clutches to drive an output shaft. The drive ratio is changed through changing the distance between the middle shaft and the input and output shafts.

Owner:朱健

Mechanical multidirectional movement mechanism

The invention belongs to the technical field of mechanical design and relates to a mechanical multidirectional movement mechanism comprising an intake valve, control cavities, a rotating shaft, a rotating rod, a stretching rod, springs, a moving body, moving plates and connecting pipes. Four cavities are arranged inside the rotating shaft, four ribs are arranged in the middle section of the intake valve, slope structures of the moving body, the first moving plate and the second moving plate are matched with one another, one end of the rotating rod is hinged to one end of the stretching rod, one end of the first connecting pipe is communicated with a lower cavity of the second control cavity, the other end of the first connecting pipe is communicated with an engine intake pipe, one end of the second connecting pipe is communicated with an upper cavity of the second control cavity, and the other end of the second connecting pipe is communicated with an turbine exhaust pipe. When pressure in the control cavities is high, the middle section of the intake valve rotates clockwise, valve lift is increased, and engine air intake is increased. The mechanism is rational in design, simple in structure and applicable to design of continuously variable intake valve lift systems.

Owner:赵梓涵

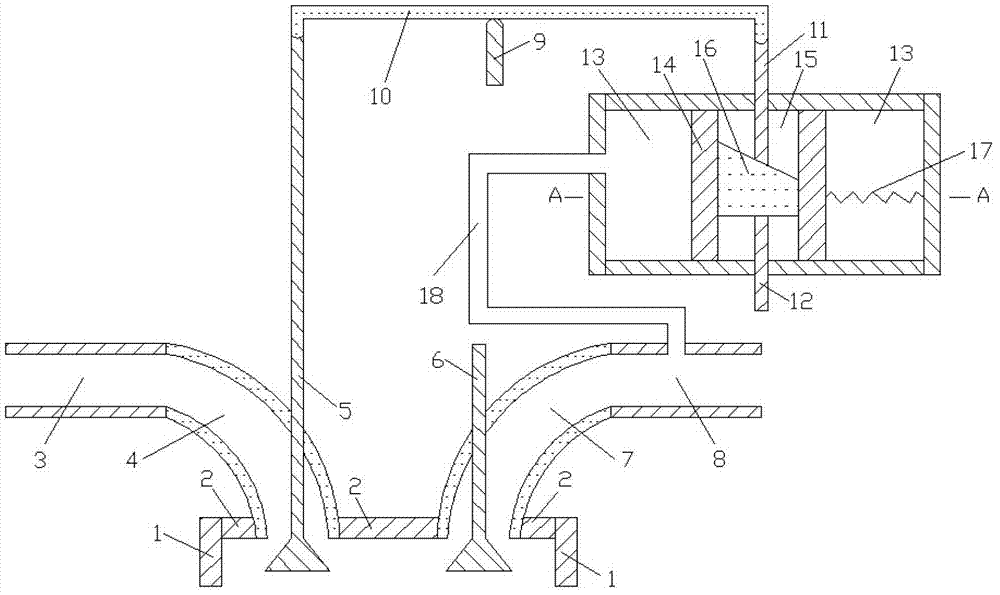

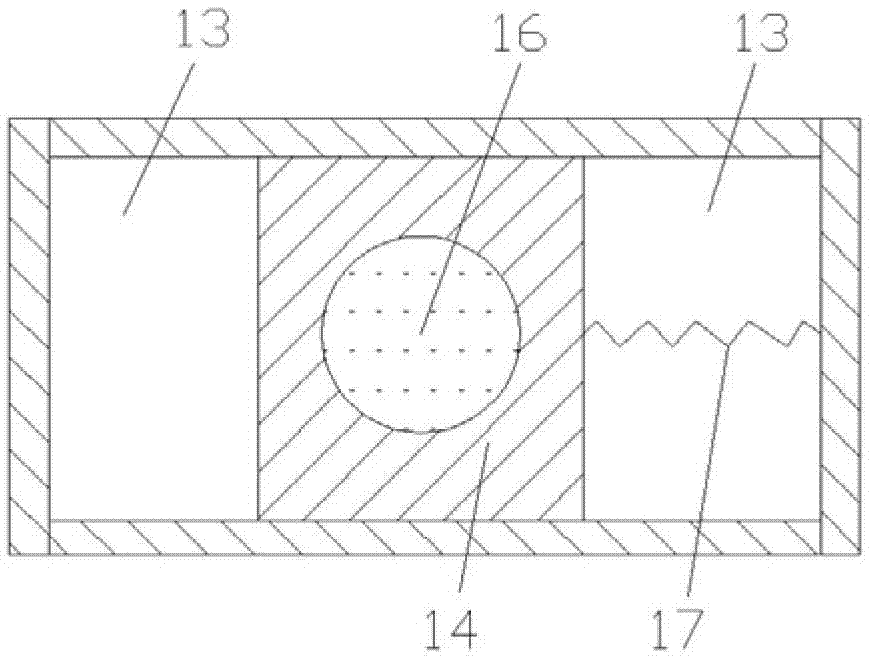

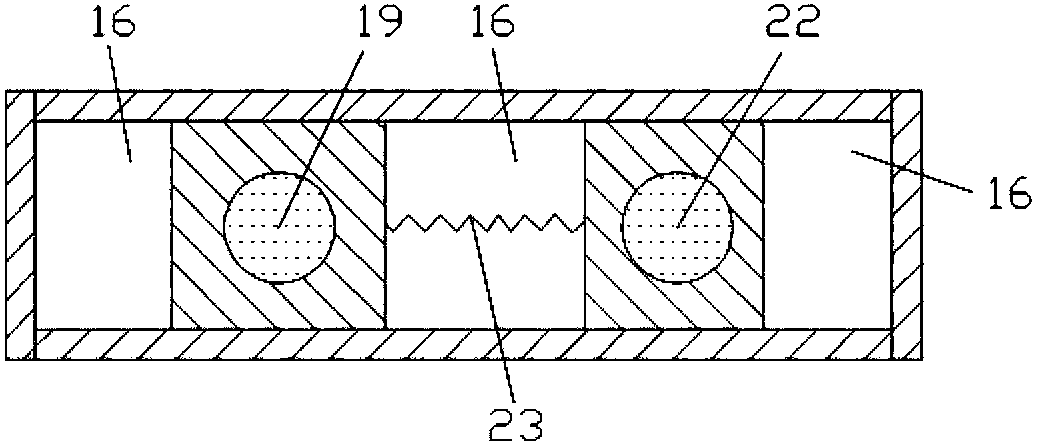

Dual spring synchronous compression type mechanical system

InactiveCN102966401AContinuously variableReasonable designValve arrangementsMachines/enginesExhaust valveInlet valve

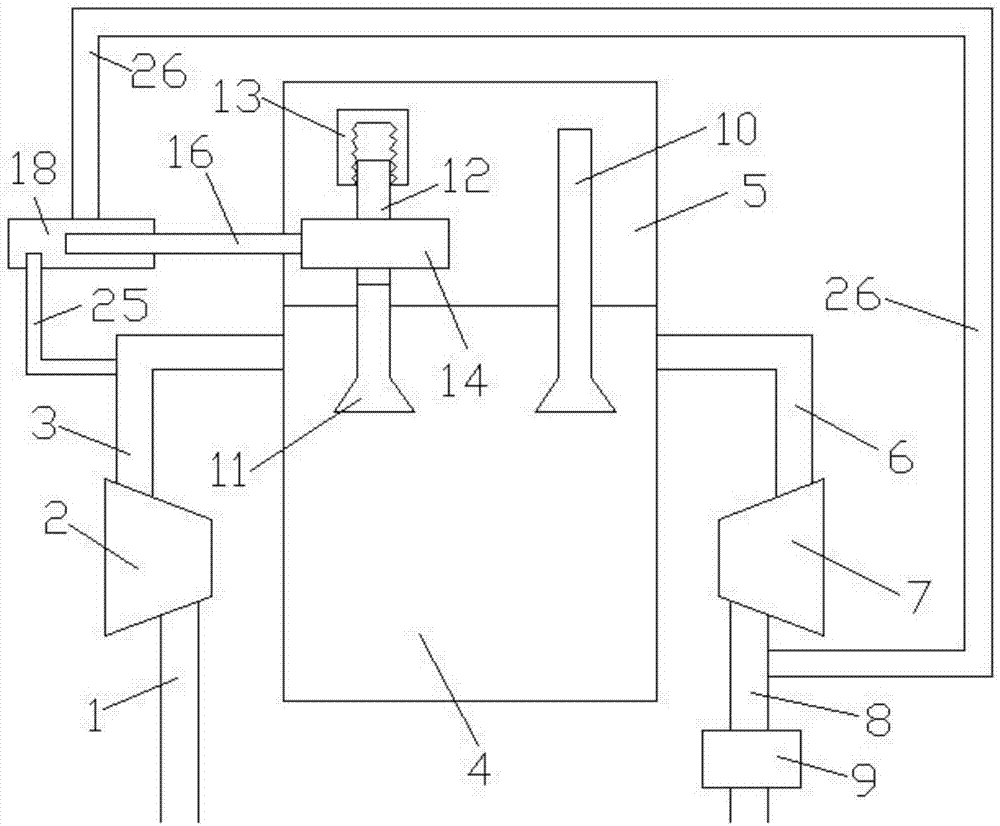

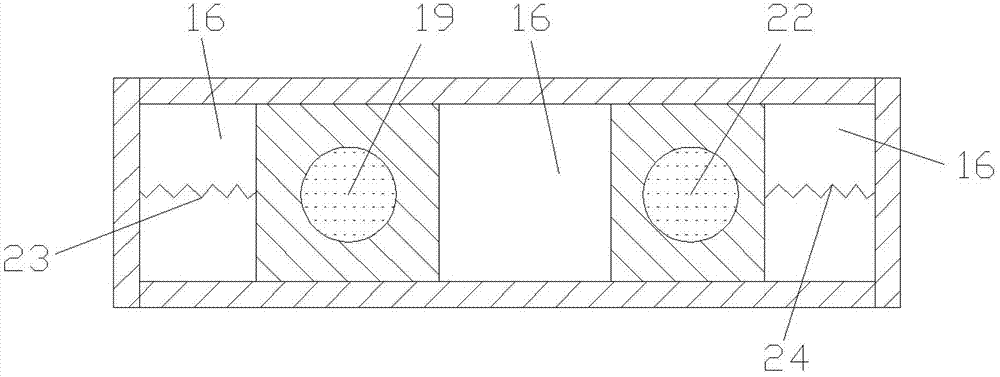

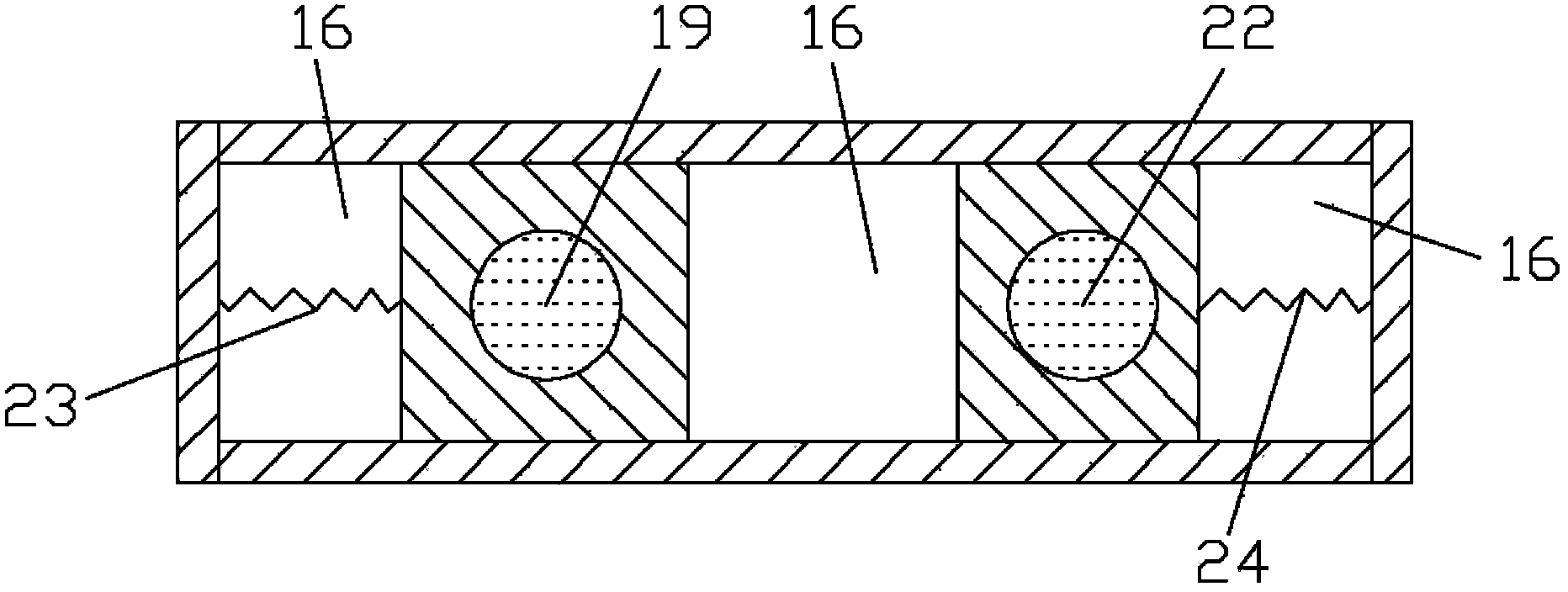

The invention relates to a dual spring synchronous compression type mechanical system, which belongs to the technical field of mechanical design. The dual spring synchronous compression type mechanical system comprises an air inlet, an air outlet, an inlet valve lower section, an exhaust valve, an inlet valve upper section, a containing cavity, moving bodies, a penetrating tube, moving blocks, a connecting tube and springs, wherein the lower end surfaces of the first moving block and the second moving block are flat surfaces, the upper end surfaces of the first moving block and the second moving block are inclined surfaces, the left wall surface of the first moving body is connected with the left wall surface of the containing cavity through the first spring, and the right wall surface of the second moving body is connected with the right wall surface of the containing cavity through the second spring. When pressure in an inlet tube of an engine is higher, the first moving body is moved to the left, the second moving body is moved to the right, and the lift ranges of an inlet valve and the exhaust valve are increased. When the pressure in the inlet tube of the engine is lower, the first moving body is moved to the right, the second moving body is moved to the left, and the lift ranges of the inlet valve and the exhaust valve are reduced. The dual spring synchronous compression type mechanical system has the advantages of reasonable design and simple structure, and is suitable for an engine variable valve lift system.

Owner:SHANGHAI JIAO TONG UNIV

Dual spring synchronous compression type mechanical system

InactiveCN102966401BContinuously variableReasonable designValve arrangementsMachines/enginesExhaust valveInlet valve

The invention relates to a dual spring synchronous compression type mechanical system, which belongs to the technical field of mechanical design. The dual spring synchronous compression type mechanical system comprises an air inlet, an air outlet, an inlet valve lower section, an exhaust valve, an inlet valve upper section, a containing cavity, moving bodies, a penetrating tube, moving blocks, a connecting tube and springs, wherein the lower end surfaces of the first moving block and the second moving block are flat surfaces, the upper end surfaces of the first moving block and the second moving block are inclined surfaces, the left wall surface of the first moving body is connected with the left wall surface of the containing cavity through the first spring, and the right wall surface of the second moving body is connected with the right wall surface of the containing cavity through the second spring. When pressure in an inlet tube of an engine is higher, the first moving body is moved to the left, the second moving body is moved to the right, and the lift ranges of an inlet valve and the exhaust valve are increased. When the pressure in the inlet tube of the engine is lower, the first moving body is moved to the right, the second moving body is moved to the left, and the lift ranges of the inlet valve and the exhaust valve are reduced. The dual spring synchronous compression type mechanical system has the advantages of reasonable design and simple structure, and is suitable for an engine variable valve lift system.

Owner:SHANGHAI JIAO TONG UNIV

Air intake valve lift-variable system in air intake pressure regulating type

The invention discloses an air intake valve lift-variable system in an air intake pressure regulating type, belonging to the technical field of internal combustion engines. The system comprises an air intake channel, an air exhaust channel, an air intake valve lower section, an air exhaust valve, an air intake valve upper section, a capacity cavity, a movable body, a perforation pipe, a movable block, an air inlet pipe, a connecting pipe and a spring, wherein the movable body is mounted in the capacity cavity and is contacted with the inner wall face of the capacity cavity in a sealing manner; the perforation pipe perforates the upper wall face and the lower wall face of the movable body; the movable block is mounted in the perforation pipe and is contacted with the inner wall face of the perforation pipe in a sealing manner; the lower end face of the movable block is a plane; the upper end face of the movable block is an inclined face; two ends of the connecting pipe are communicated with the left wall faces of the air intake pipe and the capacity cavity; the right wall face of the movable body is connected with the right wall face of the capacity cavity through the spring; when pressure in the air intake pipe is relatively large, the movable body is moved to right; the air intake valve lift is increased; when the pressure in the air intake pipe is relatively small, the movable body is moved to left; the air intake valve lift is reduced; and the intake valve variable-lift system is characterized by reasonable design and simple structure and is suitable for engine valve lift-variable systems.

Owner:SHANGHAI JIAOTONG UNIV

Upper-section sliding device for mechanical valve

InactiveCN102966393BContinuously variableReasonable designMachines/enginesNon-mechanical valveExhaust valveInlet channel

The invention discloses an upper-section sliding device for a mechanical valve in the technical field of the mechanical design. The upper-section sliding device for the mechanical air valve comprises an inlet channel, an outlet channel, a lower section of an inlet valve, an exhaust valve, an upper section of the inlet valve, a volume cavity, moving bodies, a through tube, moving blocks, a connecting tube and a spring, wherein the lower end surface of the first moving block and the lower end surface of the second moving block are both planes; the upper end surface of the first moving block and the upper end surface of the second moving block are both slopes; and the right wall surface of the first moving body is connected with the left wall surface of the second moving body via the spring. When pressure in the exhaust tube of the an engine is bigger, the first moving body moves leftwards, the second moving body moves rightwards, and the lifts of the inlet valve and the exhaust valve are largenedned; and when the pressure in the exhaust tube of the engine is smaller, the first moving body moves rightwards, the second moving body moves leftwards, and the lifts of the inlet valve and the exhaust valve are reduced. The upper-section sliding device disclosed by the invention has the advantages of reasonability in design and simple structure and is suitable for the lift variable system of the engine.

Owner:SHANGHAI JIAOTONG UNIV

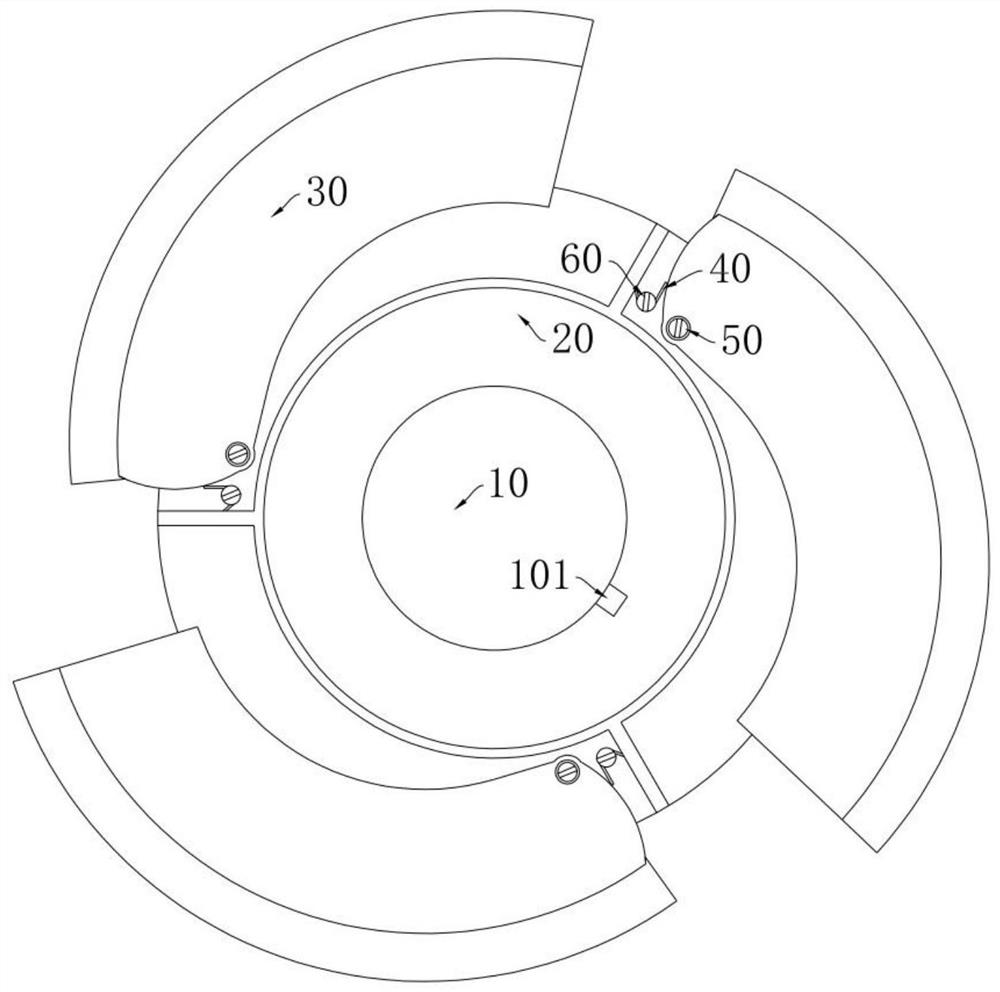

An Adaptive Expandable Flywheel With Continuously Variable Moment of Inertia

The invention discloses an self-adaptive unfolding flywheel with continuously variable moment of inertia, which includes a flywheel mounting plate and a plurality of unfolding flywheels; the edge position of the flywheel mounting plate is provided with a number of flywheels and unfolding flywheels at intervals along the circumference of the flywheel mounting plate. The corresponding flywheel connection part; the head end of the unfolded flywheel is rotatably connected to the position close to its head end on the corresponding flywheel connection part; end stroke, and then realize the continuous variable moment of inertia of the flywheel. It realizes the continuously variable moment of inertia of the flywheel and adapts to different working conditions without adding additional devices and using additional energy; not only can the maximum moment of inertia and minimum moment of inertia be designed according to the conditions of use, but also has a wider range of The utility model has a wide range of applications, and has a compact structure without excessively increasing the occupied space of the flywheel. At the same time, the manufacturing and assembly are simple, the cost is low, and it has good engineering application value.

Owner:NAT UNIV OF DEFENSE TECH

Mechanical valve stroke regulating system

The invention discloses a mechanical valve stroke regulating system and belongs to the technical field of mechanical design. The mechanical valve stroke regulating system comprises an intake valve, control cavities, a rotary shaft, a rotary rod, a stretching rod, a spring, a mobile object and a connection pipe. Four cavities are formed in the rotary shaft. Four ribs are arranged in the middle section of the intake valve and distributed in the four cavities of the rotary shaft respectively. One end of the rotary rod is hinged to one end of the stretching rod, and the other end of the stretching rod penetrates through the lower wall of the second control cavity and then is fixedly connected with the lower wall of the mobile object. One end of the connection pipe is communicated with a lower cavity of the second control cavity, and the other end of the connection pipe is communicated with an intake pipe of an engine. According to the mechanical valve stroke regulating system, when pressure in the lower cavity of the second control cavity is high, the middle section of the intake valve rotates clockwise, valve stroke is increased, and air inflow of the engine is increased. The mechanical valve stroke regulating system is reasonable in design, simple in structure and suitable for design of an intake valve stroke continuously variable system.

Owner:李学营

Switching mechanism for translation system and rotating system

The invention belongs to a switching mechanism for a translation system and a rotating system, belonging to the technical field of mechanical design. The switching mechanism comprises an air inlet door, control cavities, a rotating shaft, a rotating rod, a tension bar, a spring, a mobile object, a connecting pipe and a fixed plate, wherein four cavities are arranged in the rotating shaft, the middle section of the air inlet door is provided with four reinforcing ribs, and the four reinforcing ribs in the middle section of the air inlet door are respectively arranged in the four cavities of the rotating shaft; the second control cavity consists of a second control cavity lower body and a second control cavity upper body, the fixed plate is arranged in the second control cavity and is fixedly connected with the tension bar, and the lower wall surface of the second control cavity lower body is connected with the fixed plate through the spring; one end of the connecting pipe is communicated with the second control cavity, and the other end of the connecting pipe is communicated with an engine exhaust pipe. According to the switching mechanism provided by the invention, when pressure in the second control cavity is higher, the middle section of the air inlet door rotates clockwise, so that the valve stroke can be increased, and the air inflow of an engine can be increased; furthermore, the switching mechanism is reasonable in design and simple in structure, and is applicable to the design of a lift-continuously-variable system of the air inlet door.

Owner:鲁斯嘉

An electro-hydraulic fully variable gas distribution device and its control method

ActiveCN107327329BSimple structureReduce processing difficultyMachines/enginesNon-mechanical valveFuel tankEngineering

The invention discloses an electro-hydraulic fully variable gas distribution device and a control method, which belong to the technical field of engine valves. The electro-hydraulic fully variable gas distribution device includes a buffer control valve, a lift control valve, a low-pressure fuel tank, a filter, a hydraulic Motor, accumulator, overflow valve, electromagnetic reversing valve, electro-hydraulic fully variable air distribution actuator, electronic control system and oil pipe and other auxiliary components; on the fully variable air distribution actuator, there are high pressure oil port, lift The stroke control oil port, the buffer control oil port, the cylinder throttle port and the five hydraulic chambers A, B, C, D, and E. By controlling the pressure of the hydraulic oil in these five chambers, the opening and closing of the engine air valve can be realized. Seating and other actions; by changing the power-on and power-off times of the two-position three-way valve, lift control valve, and buffer control valve, the opening phase and lift of the engine valve can be changed, and the flexible adjustment of the lift and phase of the valve and the adjustment of the valve can be realized. The duration of opening, so as to realize the fully variable movement of the valve.

Owner:HARBIN ENG UNIV

A Wideband Receiver Front-End Circuit With Continuously Adjustable Bandwidth

The invention discloses a broadband receiver front-end circuit with a continuously adjustable bandwidth. The circuit comprises a low noise amplifier, a main mixer, a transconductance stage circuit, a transimpedance amplifier and an output buffer stage circuit and a feedback loop, wherein the low noise amplifier amplifies a radio frequency signal, the amplified radio frequency signal is converted by the main mixer into a medium frequency voltage signal, the transconductance stage circuit converts the medium frequency voltage signal into a current signal, the current signal is converted by the transimpedance amplifier into a voltage signal, and the voltage signal is output to an off-chip digital chip through the output buffer stage circuit for processing after being amplified and filtered; and the feedback loop amplifies the value of a high-pass filter capacitor in the feedback loop through the Miller effect of a loop amplifier, thereby not only realizing the clutter filtering of the medium frequency voltage signal, but also omitting a medium frequency filter capacitor. The broadband receiver front-end circuit disclosed by the invention effectively reduces the overall area of the chip, can realize the continuously adjustable bandwidth, and can also further reduce the equivalent on-resistance of the mixer and inhibit out-of-band interference signals.

Owner:SOUTHEAST UNIV

Device for adjusting lift of intake valve of supercharged engine

Owner:SHANGHAI JIAOTONG UNIV

Single valve height pneumatic control system

InactiveCN102966395BContinuously variableReasonable designMachines/enginesNon-mechanical valveExhaust valveControl system

A single-valve height pneumatic control system in the technical field of mechanical design, including: intake port, exhaust port, intake valve lower section, exhaust valve, intake valve upper section, volume cavity, moving body, through pipe, moving block, The connecting pipe and the spring, the moving body is installed in the volume chamber and is in sealing contact with the inner wall of the volume chamber, the penetrating pipe runs through the upper and lower walls of the moving body, the moving block is installed in the penetrating pipe and is in sealing contact with the inner wall of the penetrating pipe, the moving block The lower end surface of the moving body is a plane, the upper end surface of the moving block is an inclined plane, the two ends of the connecting pipe are respectively connected with the intake pipe and the left wall of the volume cavity, and the left wall of the moving body is connected with the left wall of the volume cavity through a spring. When the pressure in the exhaust pipe of the engine is high, the moving body moves to the right, and the lift of the intake valve becomes larger; when the pressure in the exhaust pipe of the engine is low, the moving body moves to the left, and the lift of the intake valve becomes small. The invention has reasonable design and simple structure, and is suitable for a variable valve lift system of a supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

A bidirectionally rotatable ratchet unfolding flywheel for ball screw inertial capacity

The invention discloses a bidirectionally rotatable ratchet-deployable flywheel for ball screw inertial capacity, which includes a forward flywheel assembly and a reverse flywheel assembly; the forward flywheel assembly includes a forward dial, a forward flywheel disc and a forward expansion Mechanism, the forward dial is fixedly set on the screw nut assembly, the forward flywheel sleeve and the forward dial form a ratchet structure, and the forward expansion mechanism is set on the forward flywheel to change the rotation of the forward flywheel Radius; the reverse flywheel assembly includes a reverse dial, a reverse flywheel disc and a reverse expansion mechanism, the reverse flywheel and the reverse dial form a ratchet structure, and the reverse expansion mechanism is set on the reverse flywheel disc to change the reverse direction The radius of gyration of the flywheel. The impact caused by the change of the rotation direction of the flywheel when the inertial capacity of the ball screw switches the movement direction is realized without changing the rotation direction of the flywheel. At the same time, under the premise of not adding additional devices and using additional energy, the flywheel moment of inertia can be continuously variable and adaptive to different working conditions.

Owner:NAT UNIV OF DEFENSE TECH

Tappet rod device with transverse moving type moving body

InactiveCN102966399BContinuously variableReasonable designMachines/enginesNon-mechanical valveExhaust valveInlet valve

A tappet rod device with a transverse moving type moving body in the technical field of mechanical design comprises a cylinder, a gas inlet pipe, a gas inlet valve, a gas exhaust valve, a gas exhaust pipe, an upright, a lever, a tappet, a volume chamber, a moving body, a through pipe, a moving block and a connecting pipe, wherein the through pipe penetrates through the upper wall surface and the lower wall surface of the moving body; the moving block is mounted in the through pipe and in sealed contact with the inner wall surface of the through pipe; the lower end surface of the moving block is a plane; the upper end surface of the moving block is an inclined surface; two ends of a first connecting pipe are respectively communicated with the gas inlet pipe and the left wall surface of the volume chamber; and two ends of a second connecting pipe are respectively communicated with the gas exhaust pipe and the right wall surface of the volume chamber. When the pressure in the gas inlet pipe is larger than the pressure in the gas exhaust pipe, the moving body moves to the right and the lift of the gas inlet valve is increased; and when the pressure in the gas inlet pipe is smaller than the pressure in the gas exhaust pipe, the moving body moves to the left and the lift of the gas inlet valve is reduced. The tappet rod device with the transverse moving type moving body, provided by the invention, has the advantages of reasonable design and simple structure and is suitable for systems with variable engine valve lifts.

Owner:SHANGHAI JIAO TONG UNIV

Mechanical force-balancing device

Provided is a mechanical force-balancing device, pertaining to the technical field of internal combustion engines. The mechanical force-balancing device comprises a lower segment of an intake valve, a middle segment of the intake valve, an upper segment of the intake valve, a control body, a fixing plate, an elastic part, a rotary plate, a rotary shaft and connecting pipes. The middle segment of the intake valve penetrates through the rotary shaft, the interior of which is provided with four cavities. The middle segment of the intake valve is provided with four ribbed bars which are respectively arranged in the four cavities of the rotary shaft. One end of a first connecting pipe is communicated with a right-side cavity of the control body. The other end of the first connecting pipe is communicated with an engine exhaust pipe. One end of a second connecting pipe is communicated with a left-side cavity of the control body. The other end of the second connecting pipe is communicated with a turbine exhaust pipe. In the mechanical force-balancing device, the middle segment of the intake valve rotates clockwise at high internal pressure of the control body so that the valve lift and air inflow of an engine increase. The mechanical force-balancing device is reasonable in design and simple in structure and is suitable for design of a continuous variable system of the lift of the intake valve.

Owner:昆山市易泰汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com