Patents

Literature

98results about How to "Small lift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

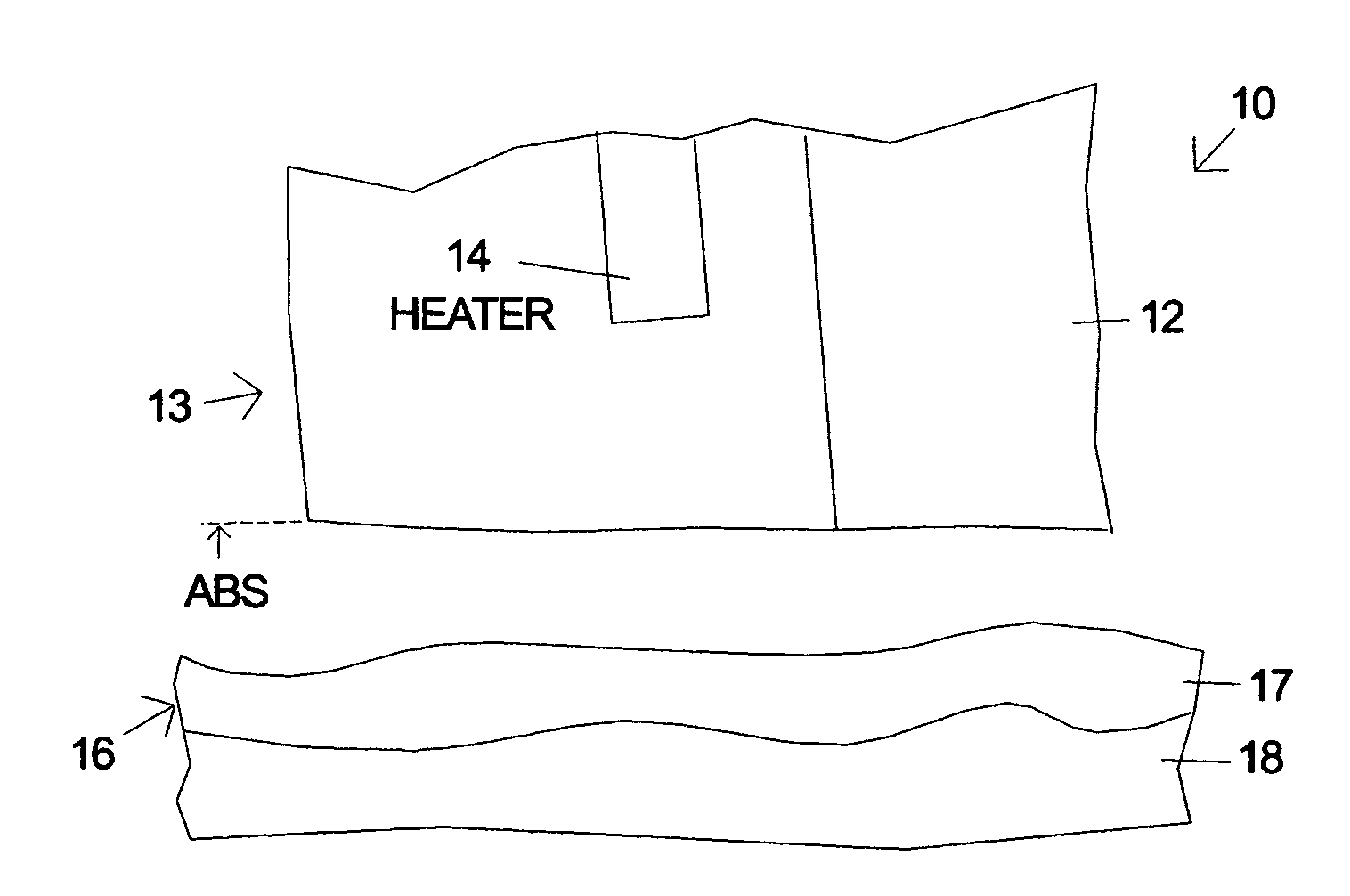

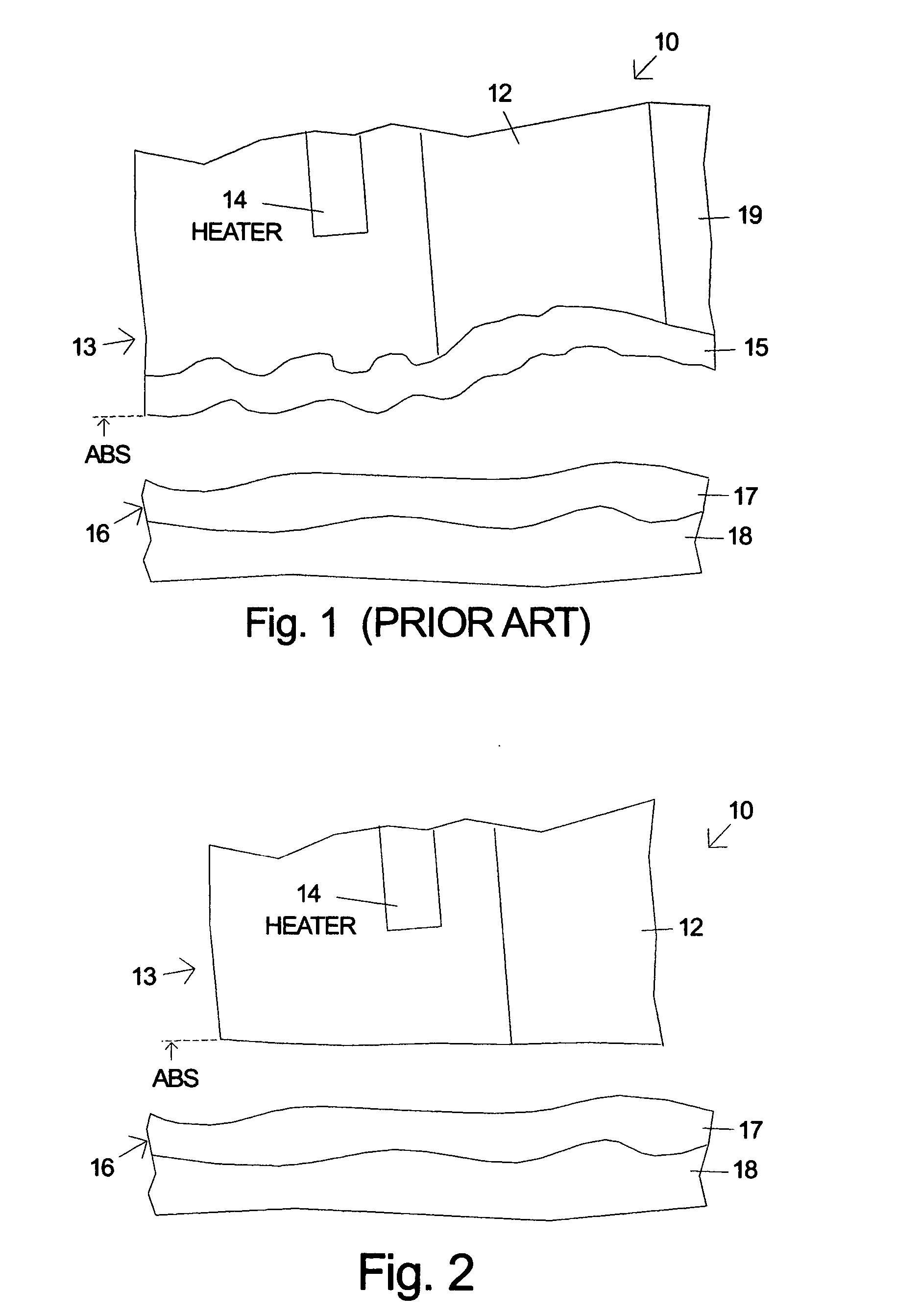

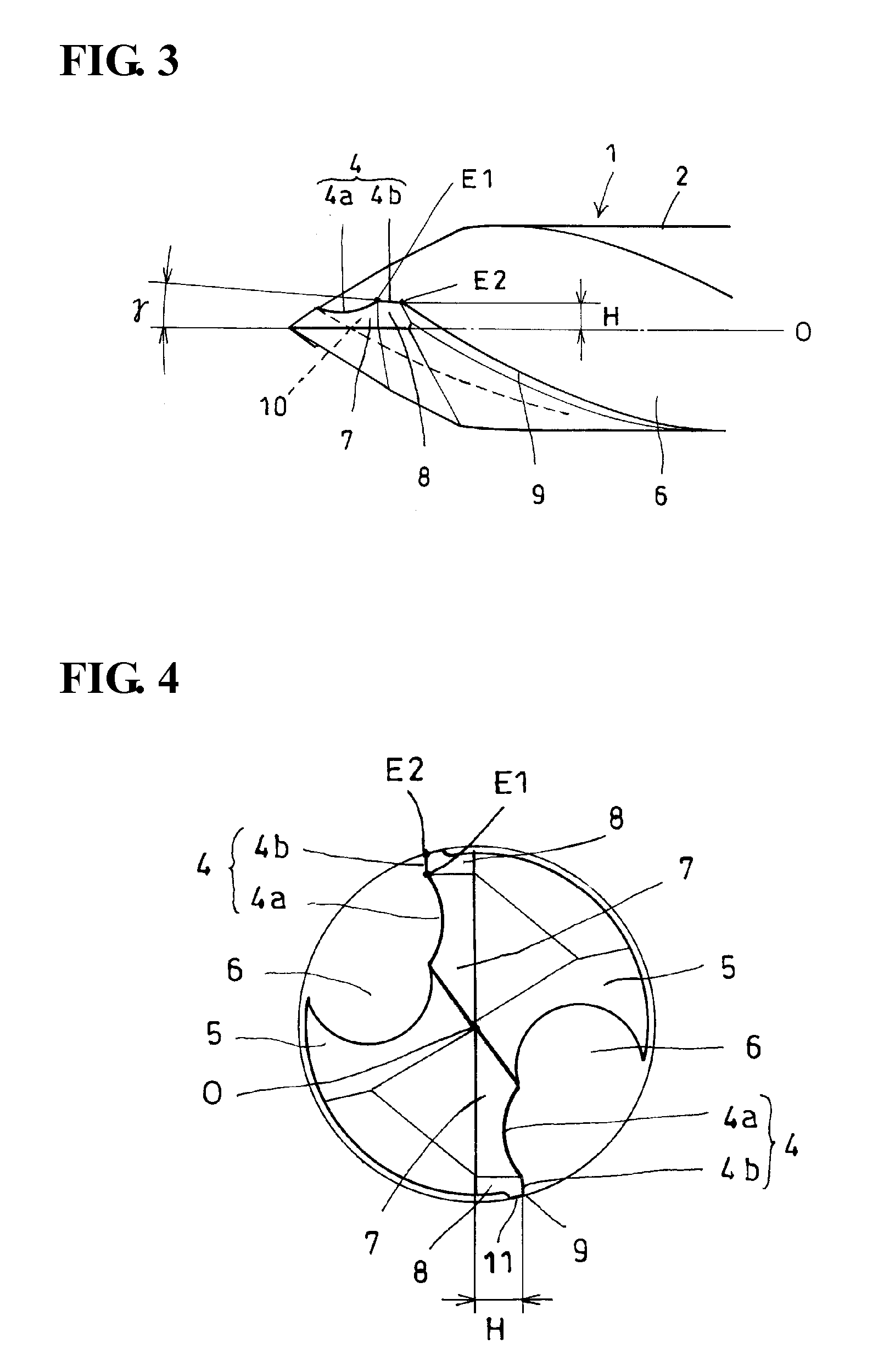

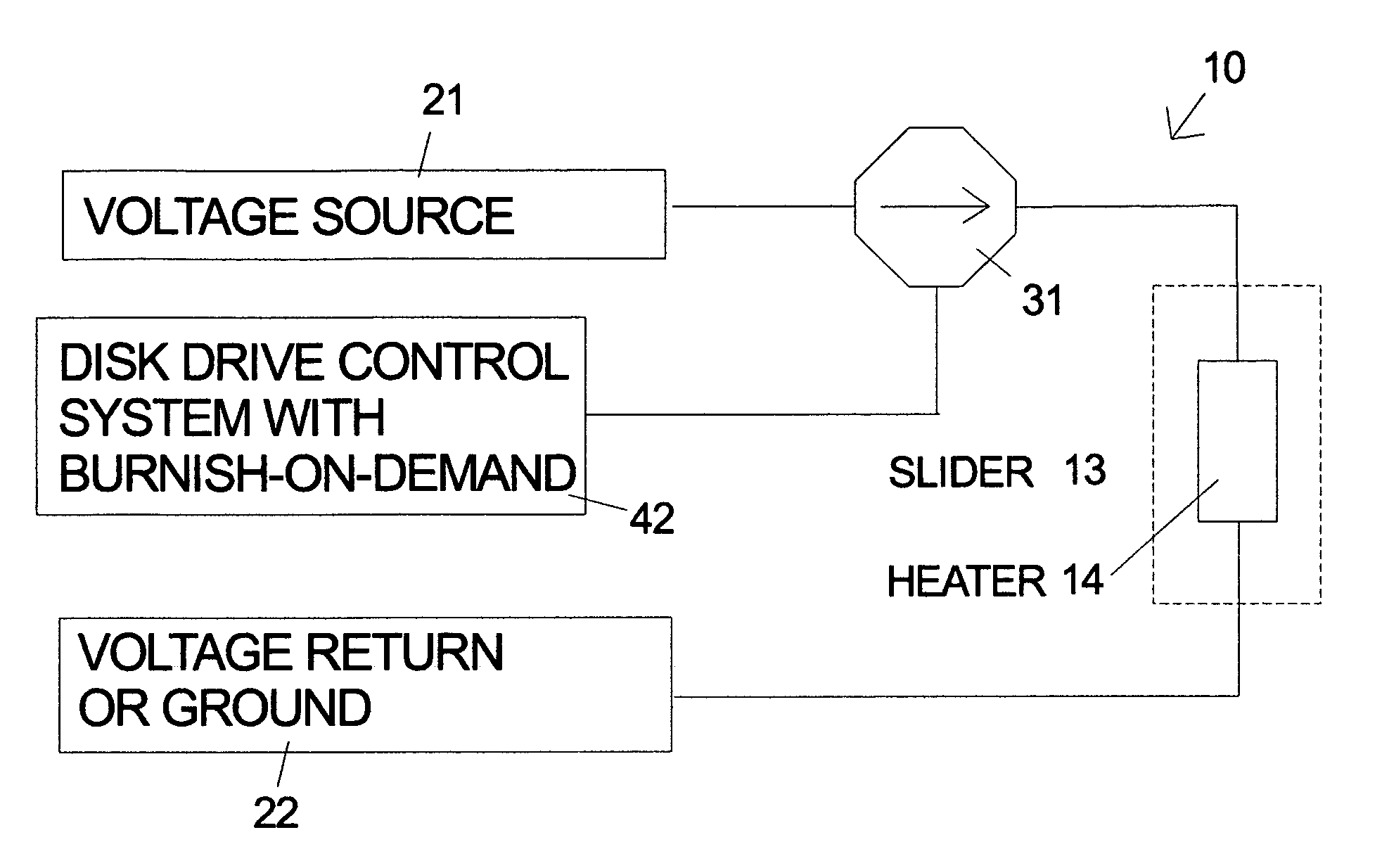

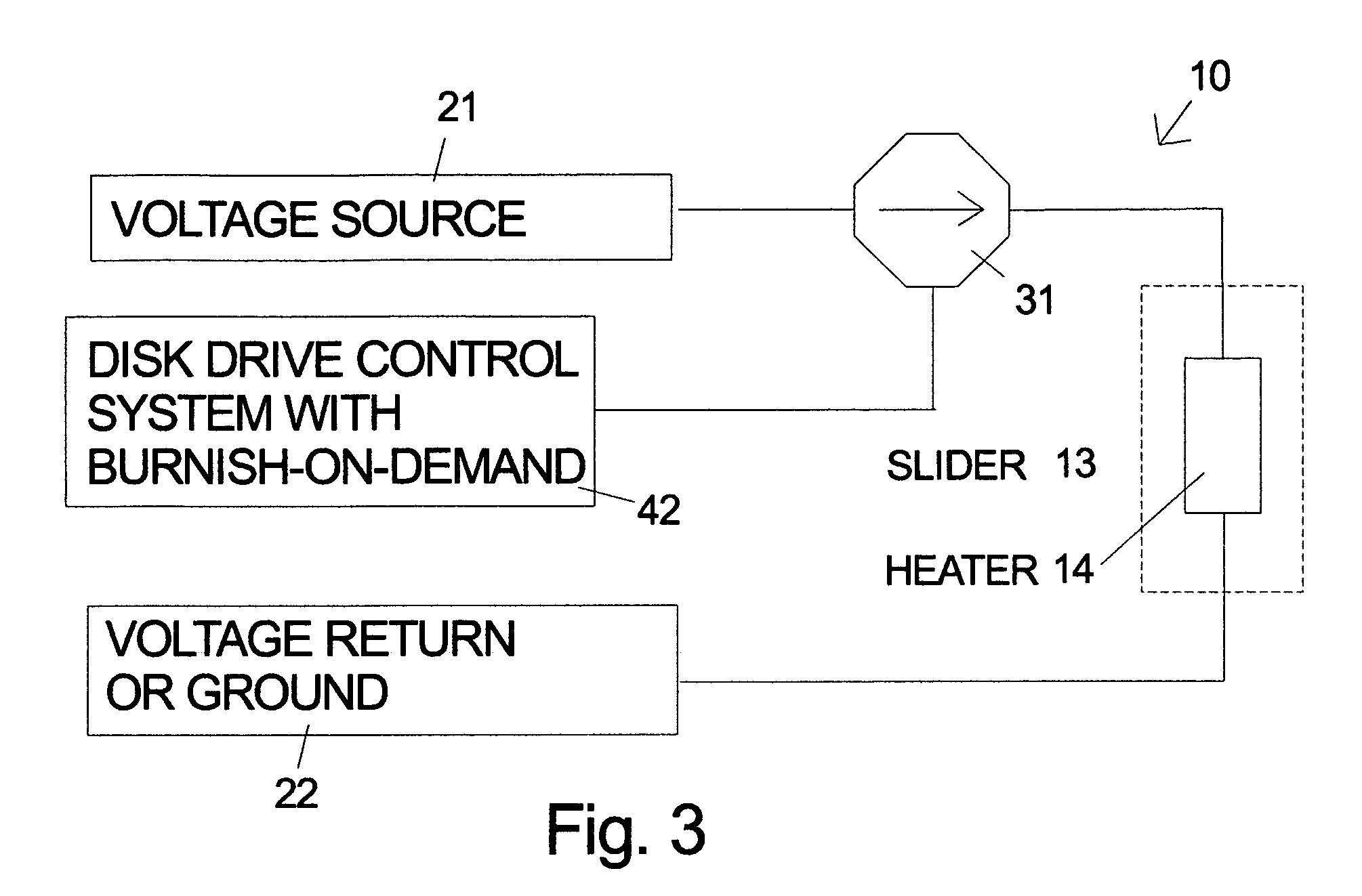

Disk drive slider design for thermal fly-height control and burnishing-on-demand

InactiveUS20060092570A1Reduced risk of corrosionAvoid corrosionElectrical transducersDriving/moving recording headsEngineeringFlying height

Owner:WESTERN DIGITAL TECH INC

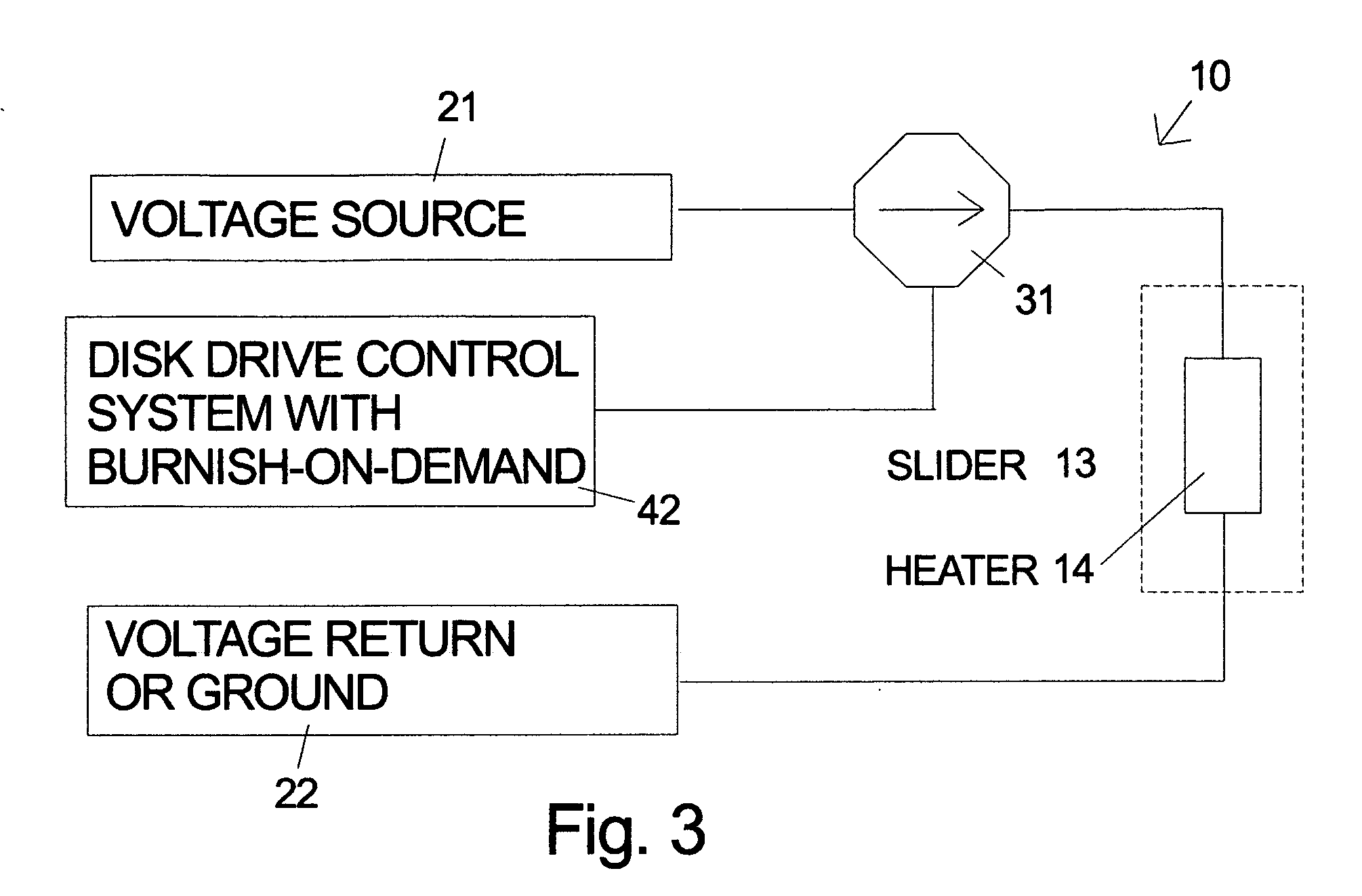

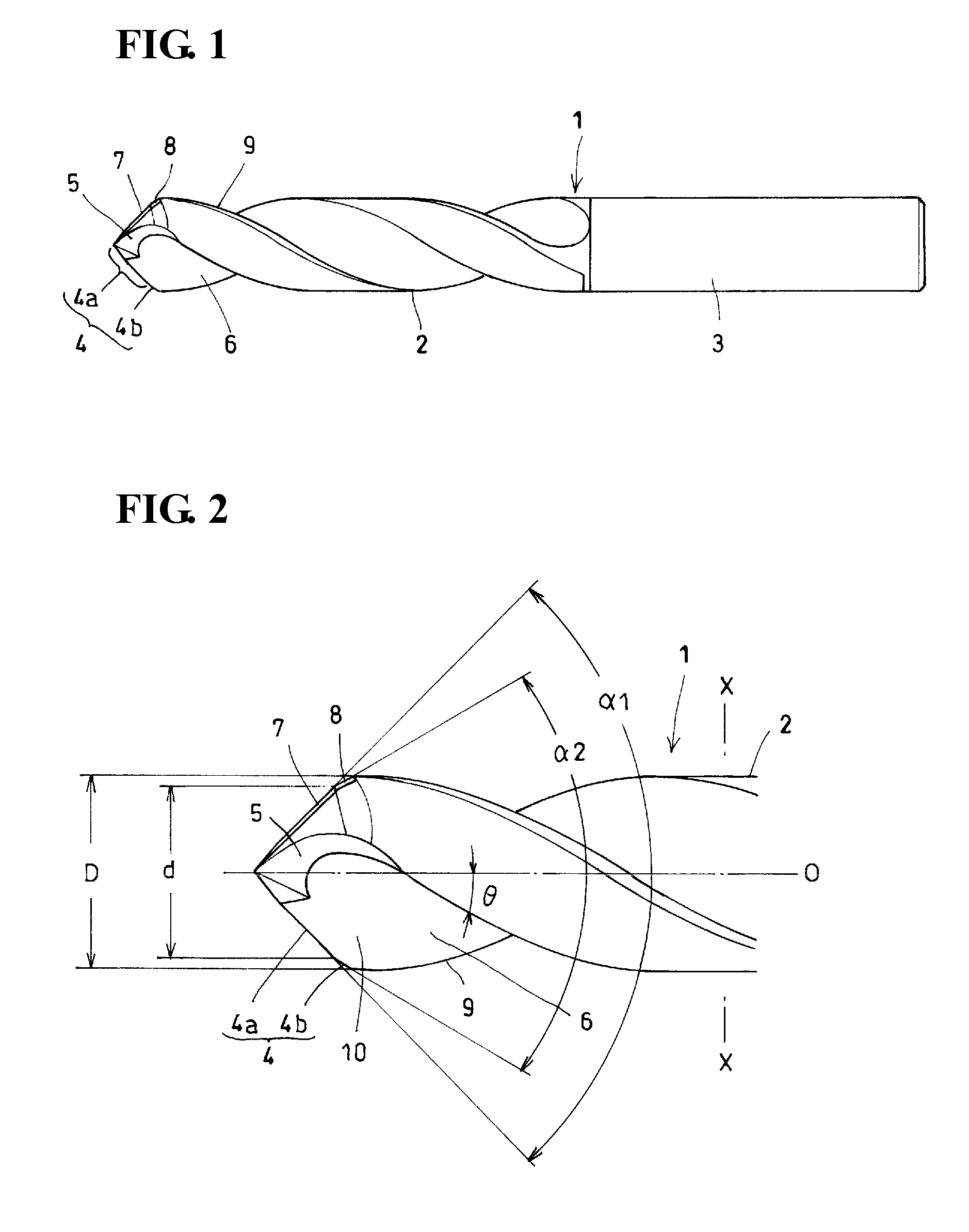

Twist drill

InactiveUS20110081215A1High quality drillingSmall liftWood turning toolsTransportation and packagingFluteLeading edge

Provided is a double-angle twist drill that increases the quality of drilling without increasing the amount of manufacturing work or the like. A secondary cutting edge 4b is substantially parallel to the rotation axis O of the drill, and at least a rake face 10 of the secondary cutting edge is included in the flute face of a helical flute 6. A part of the flute face of the helical flute that is located along a leading edge 9 is convexly curved with respect to the normal direction of rotation of the drill, so that the secondary cutting edge 4b having a small skew angle with respect to the rotation axis can be formed as a ridge at which the flute face intersects a second flank face.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Disk drive slider design for thermal fly-height control and burnishing-on-demand

InactiveUS7495856B2Small liftLow experience requirementElectrical transducersDriving/moving recording headsEngineeringFlying height

Owner:WESTERN DIGITAL TECH INC

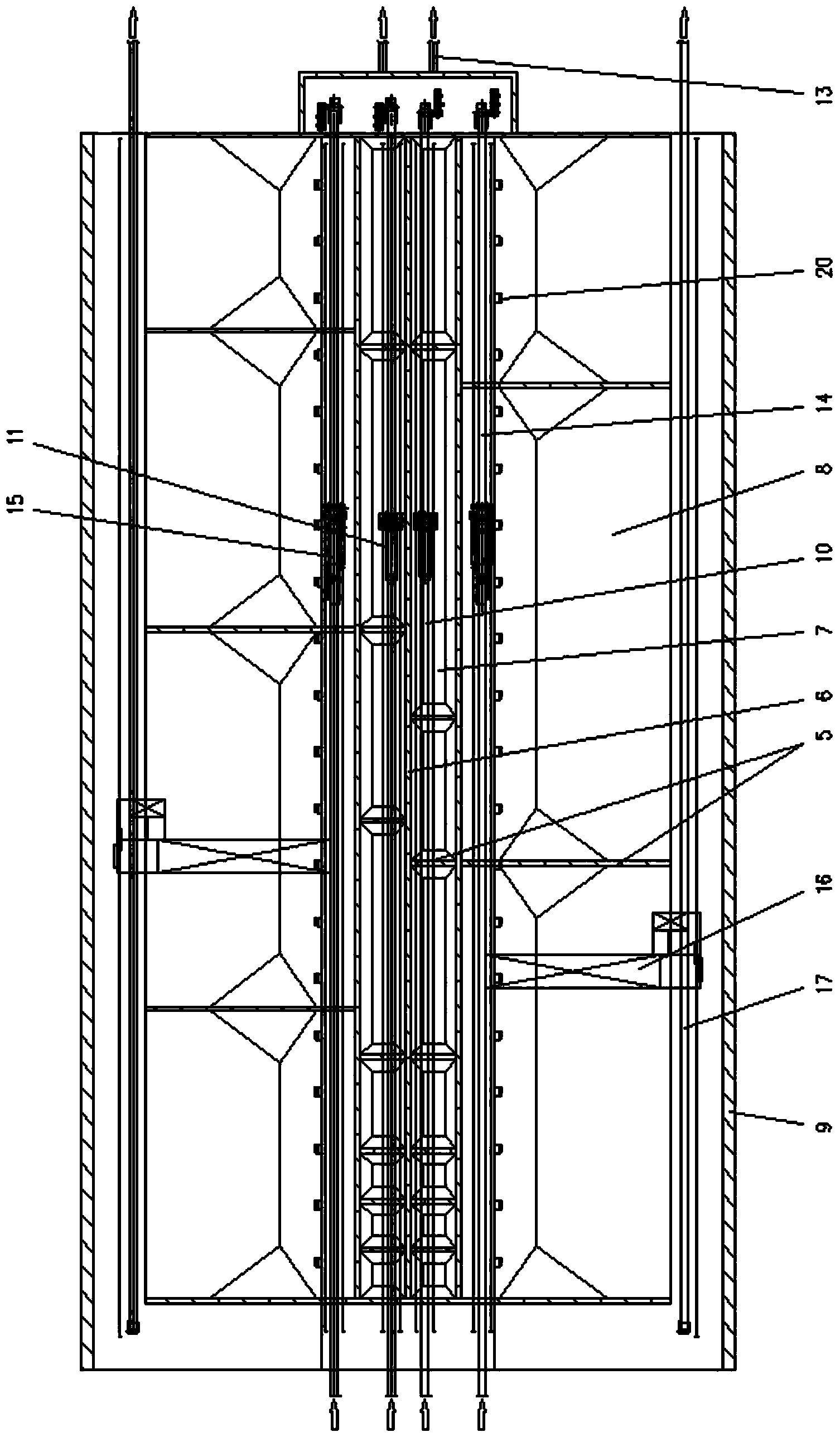

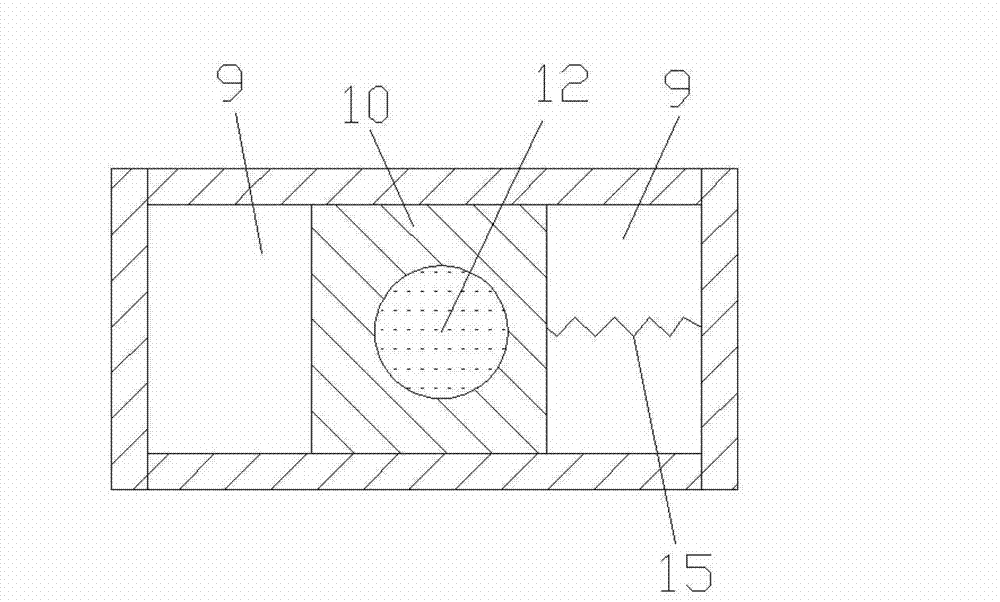

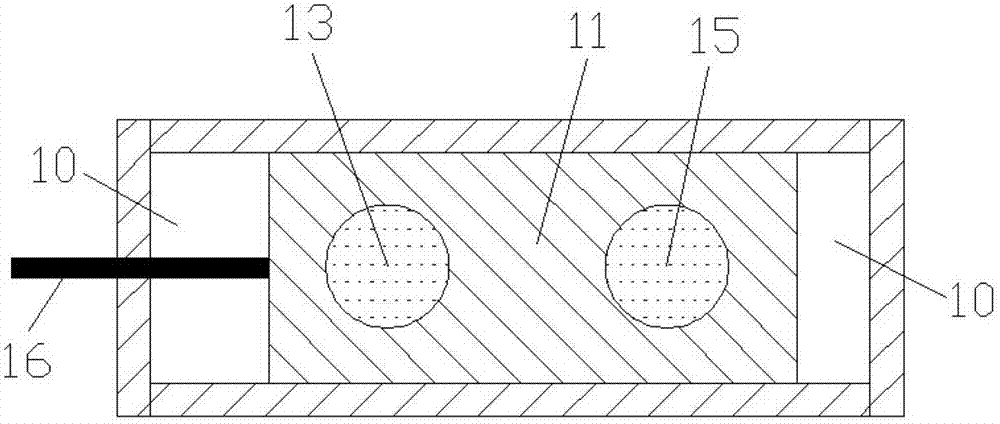

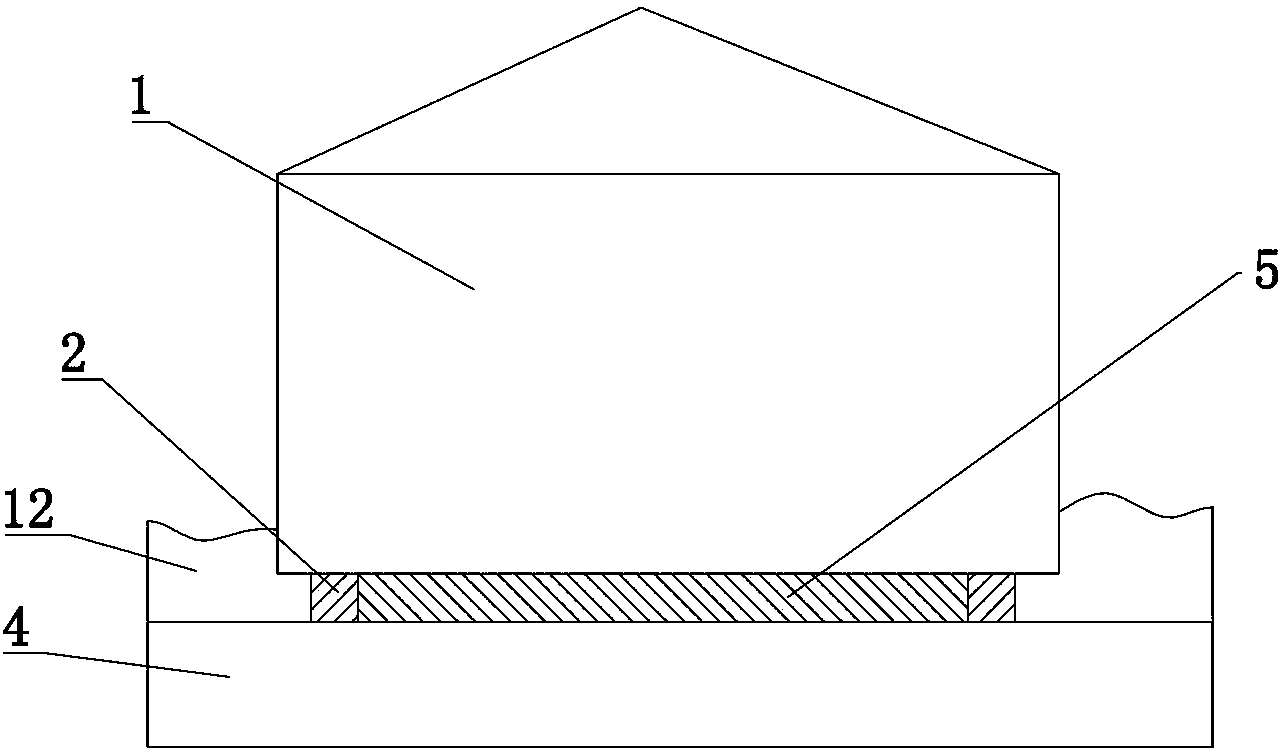

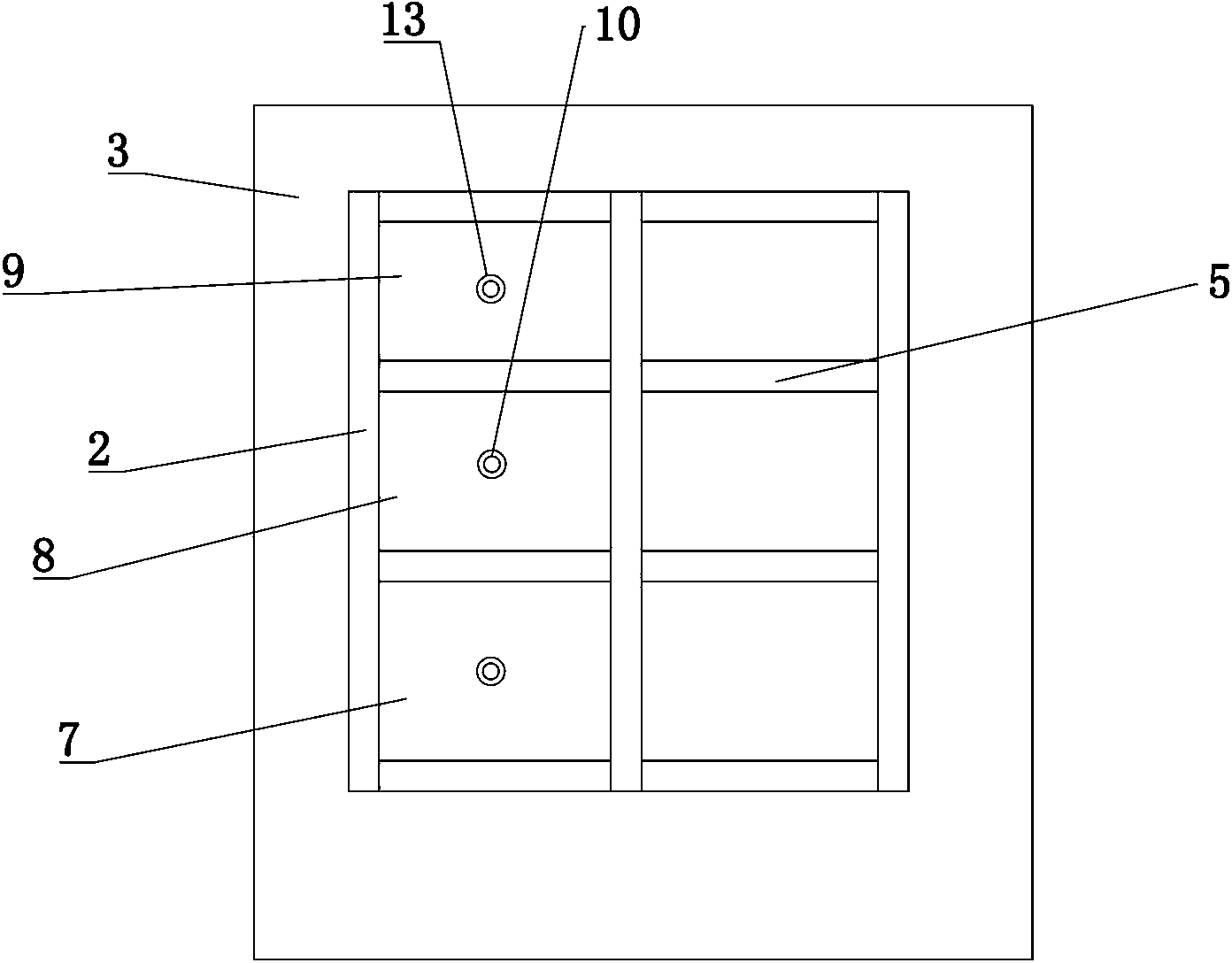

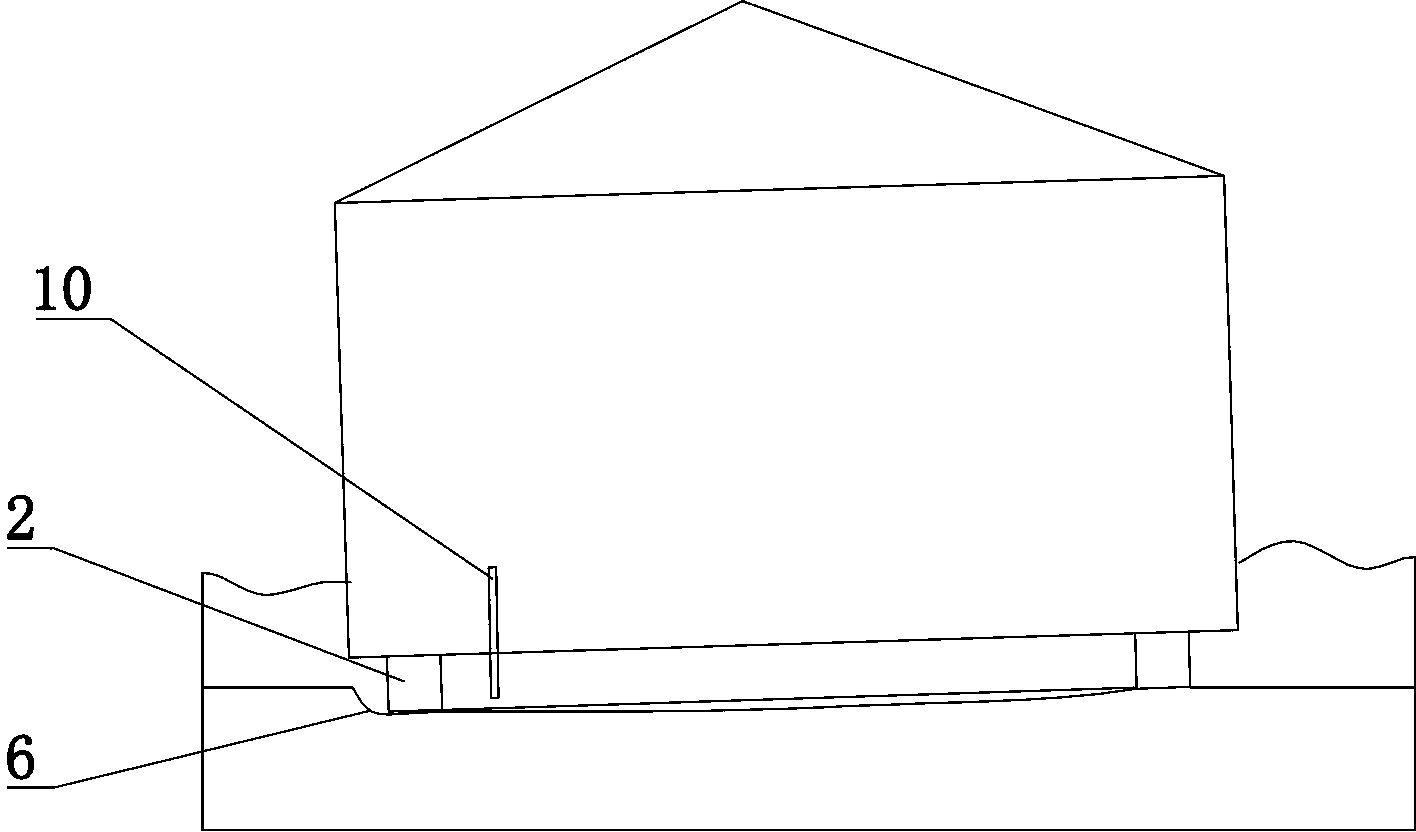

Material storage device of storage yard and closed storage yard

ActiveCN103640832AIncrease storage capacityImprove space utilizationLoading/unloadingStorage devicesEngineeringYard

The invention discloses a material storage device of a storage yard. The material storage device comprises a material storage bearing bottom plate and two retaining walls, wherein a material storage bin is formed between the two retaining walls, and material storage lattices are arranged on two longitudinal sides or one side of the material storage bin. The invention further discloses a closed storage yard which comprises a material storage shed and the material storage device arranged in the material storage shed. According to the invention, the material storage bin can eliminate V-shaped space at the top of the material, then the space utilization rate is increased, and the occupied area as well as energy consumption for ventilation, heating, lighting and the like of the storage yard are reduced; more independent unit storage bins and unit material lattices are provided, and the variety adaptability of the storage yard is higher; an across bulkhead can support the retaining walls, the rigidity and pressure bearing performance of the retaining walls can be improved greatly, the thickness of each retaining wall is smaller, and the construction investment cost is lower; size of the material exposed in the air in the material storage bin is smaller, raising amount of dust in feeding and discharging processes is smaller, so that the material with high environmental protection requirement can be stored in the material storage bin, and the environmental protection performance is better.

Owner:CISDI ENG CO LTD

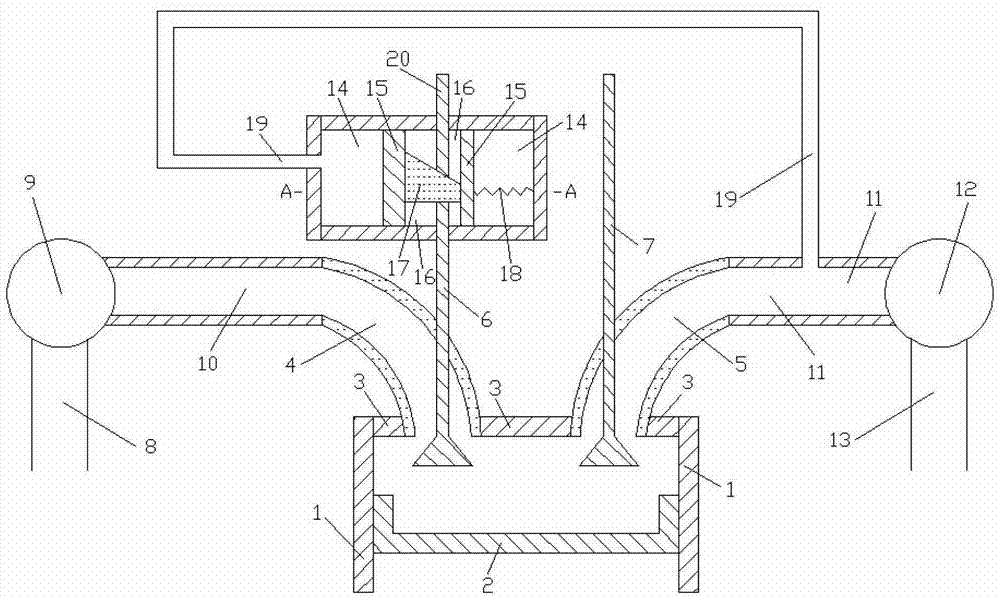

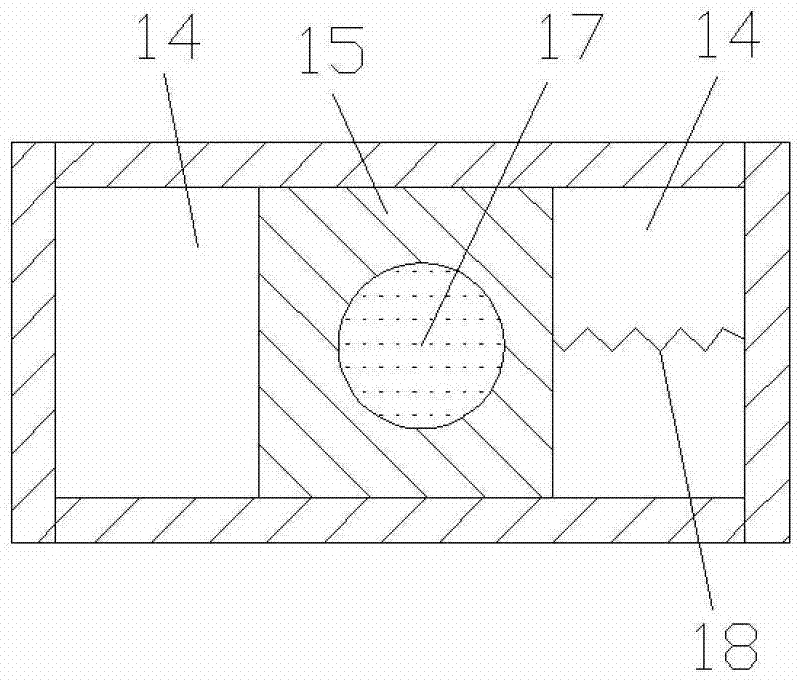

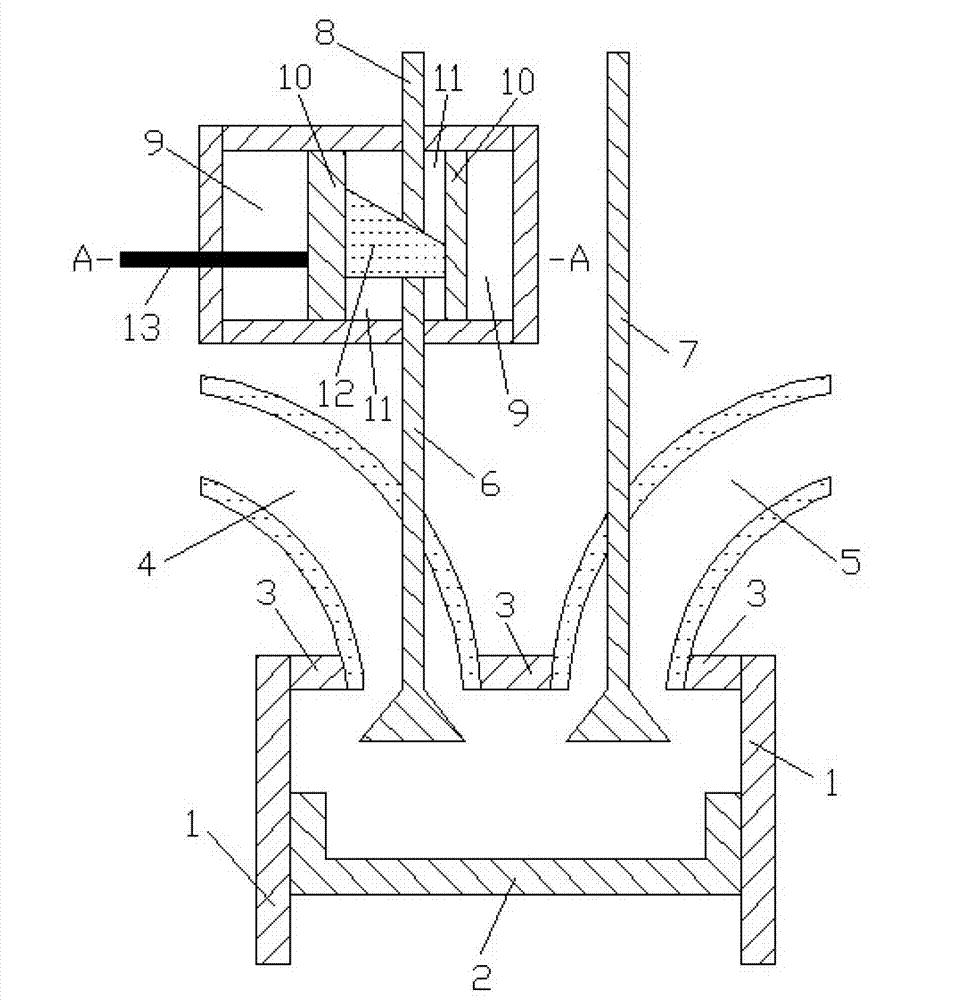

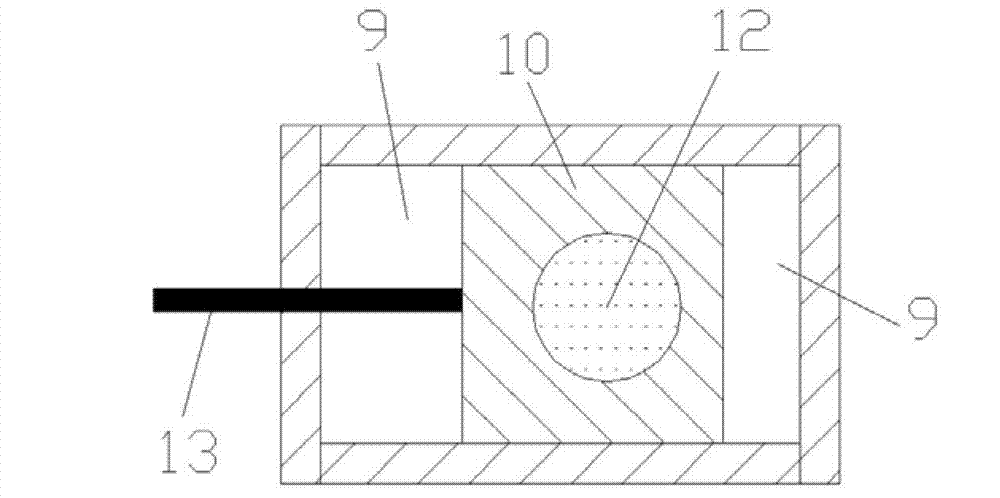

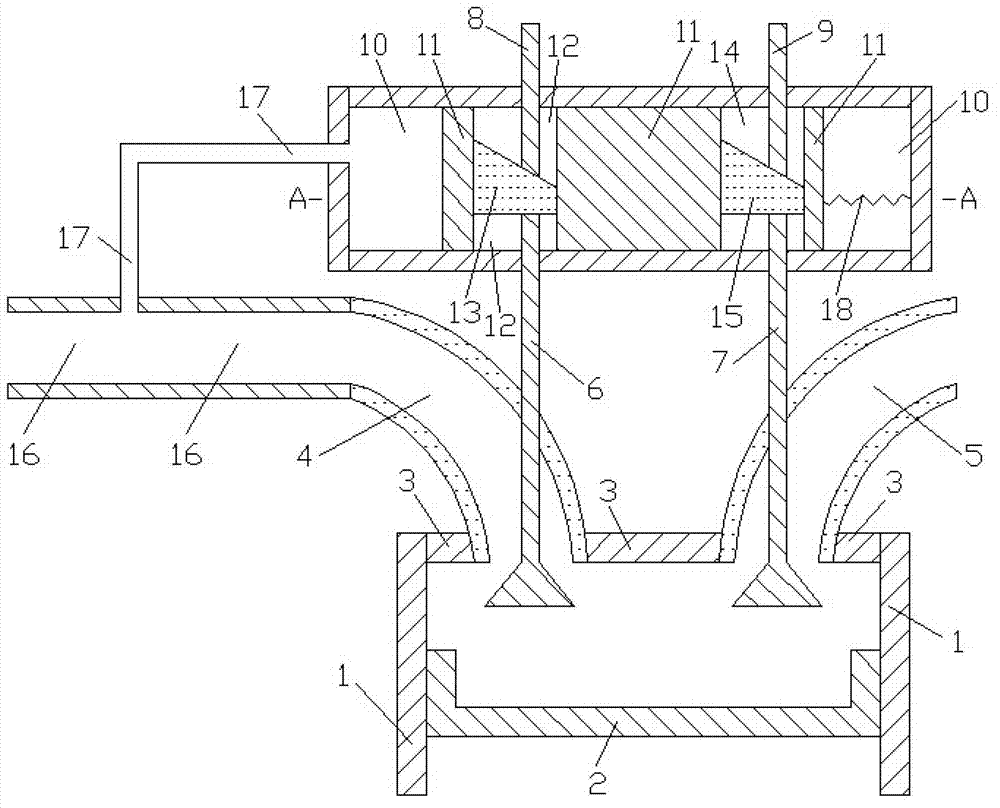

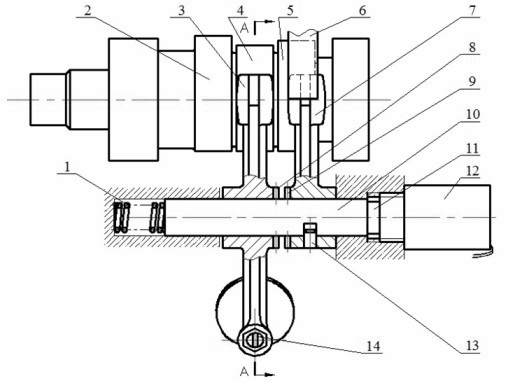

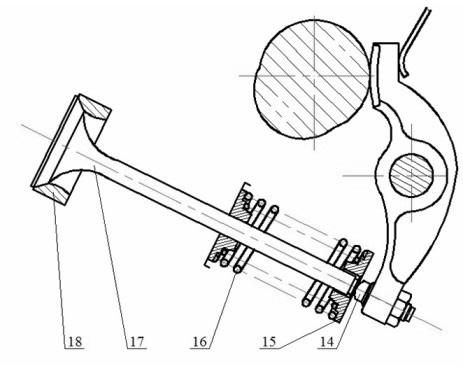

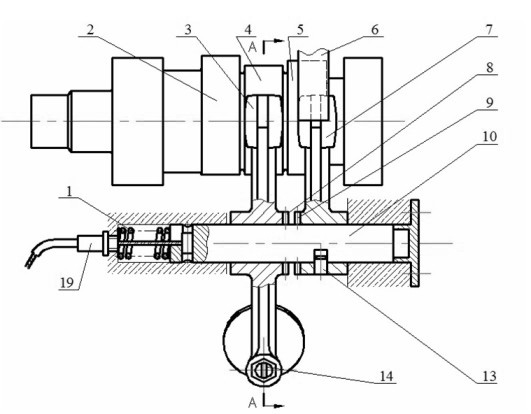

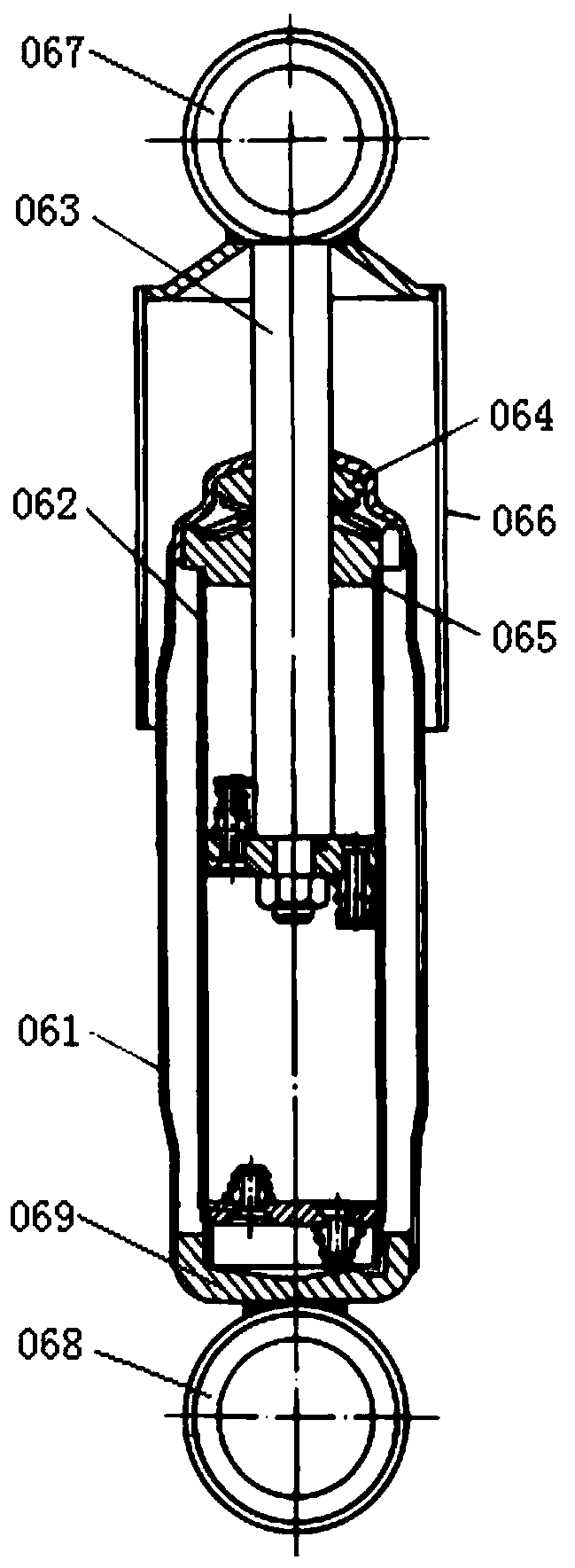

Device for adjusting lift of intake valve of supercharged engine

InactiveCN102966403AReasonable designSimple structureMachines/enginesNon-mechanical valveEngineeringExhaust valve

The invention relates to the technical field of an internal combustion engine, in particular to a device for adjusting a lift of an intake valve of a supercharged engine. The device comprises an intake channel, an exhaust channel, a lower intake valve section, an exhaust valve, an upper intake valve section, a volumetric cavity, a moving body, a penetrating tube, a moving block, a connecting tube and a spring, wherein the moving body is arranged in the volumetric cavity and is contacted with the inner wall surface of the volumetric cavity in a sealing way, the penetrating tube is arranged in a way of penetrating the upper wall surface and the lower wall surface of the moving body, the moving block is arranged in the penetrating tube and is contacted with the inner wall surface of the penetrating tube in a sealing way, a plane is adopted by the lower end face of the moving block, a slope is adopted by the upper end face of the moving block, two ends of the connecting tube are respectively communicated with the left wall surfaces of an intake tube and the volumetric cavity, and the right wall surface of the moving body is connected with the right wall surface of the volumetric cavity through the spring. When the pressure in an exhaust tube of the engine is relatively high, the moving body can move rightwards, and the lift of the intake valve can be increased; and when the pressure in the exhaust tube of the engine is relatively low, the moving body can move leftwards, and the lift of the intake valve can be decreased. The device has the advantages of reasonable design and simple structure and is suitable for a variable valve lift system of the supercharged engine.

Owner:SHANGHAI JIAO TONG UNIV

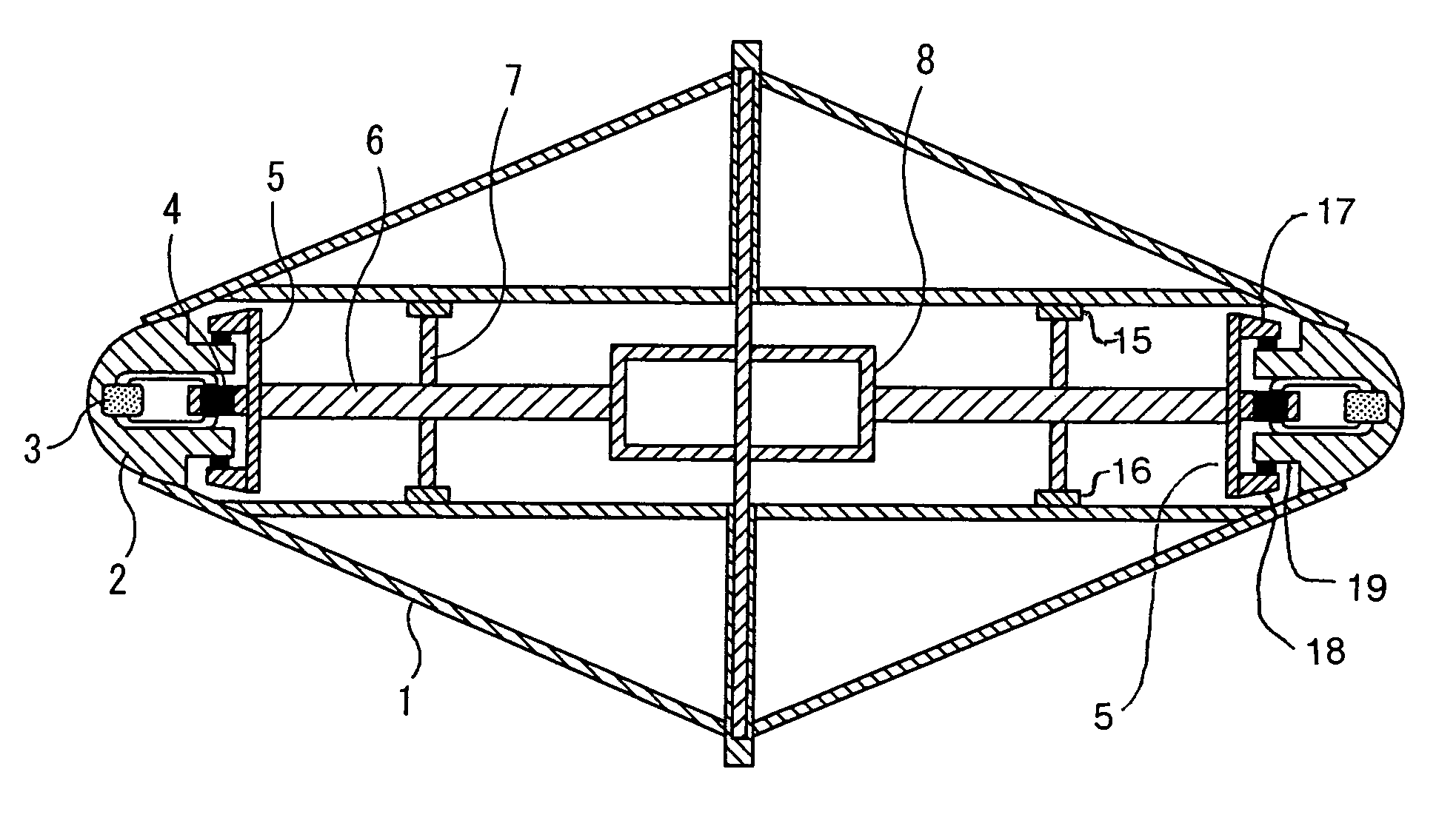

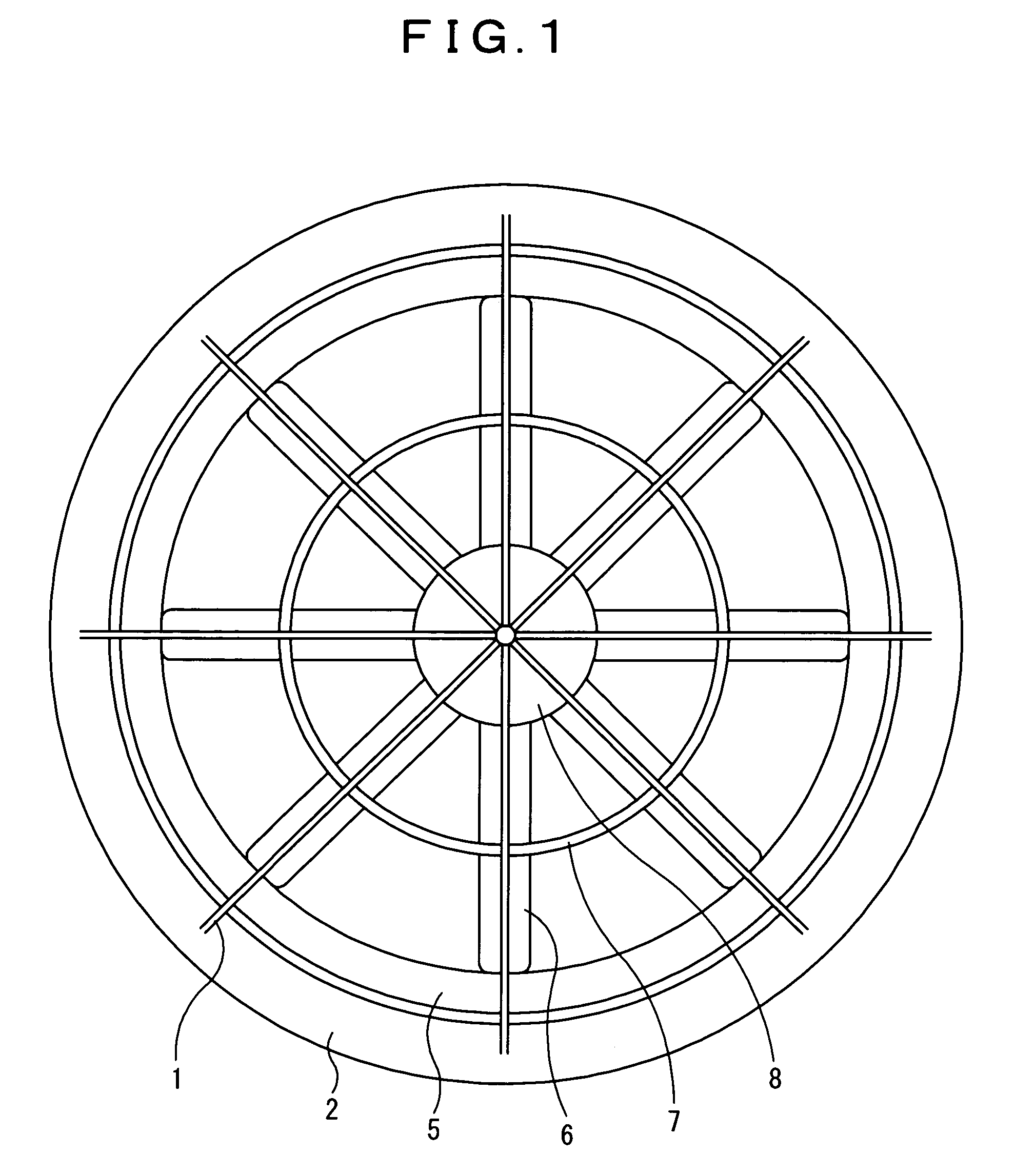

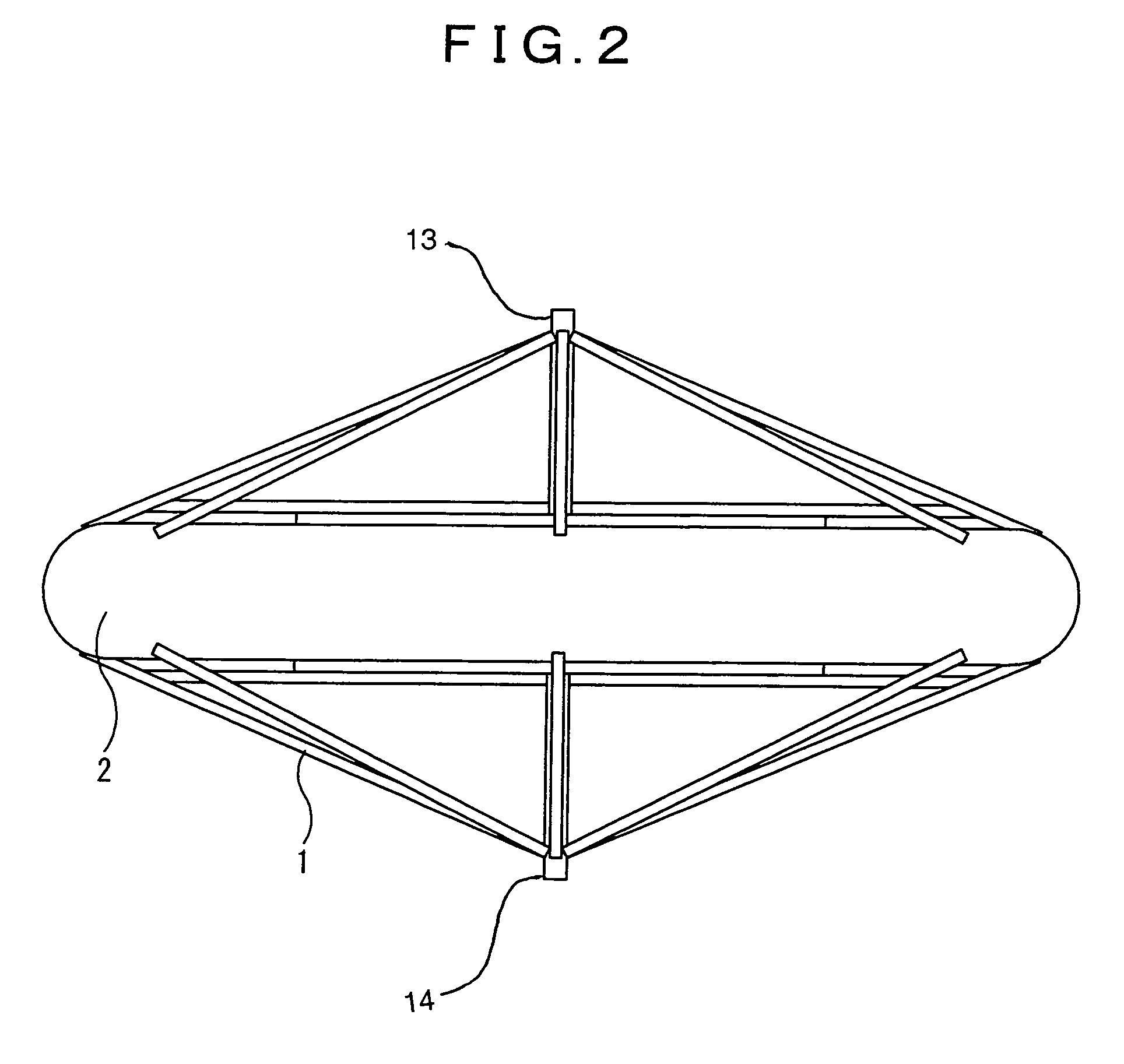

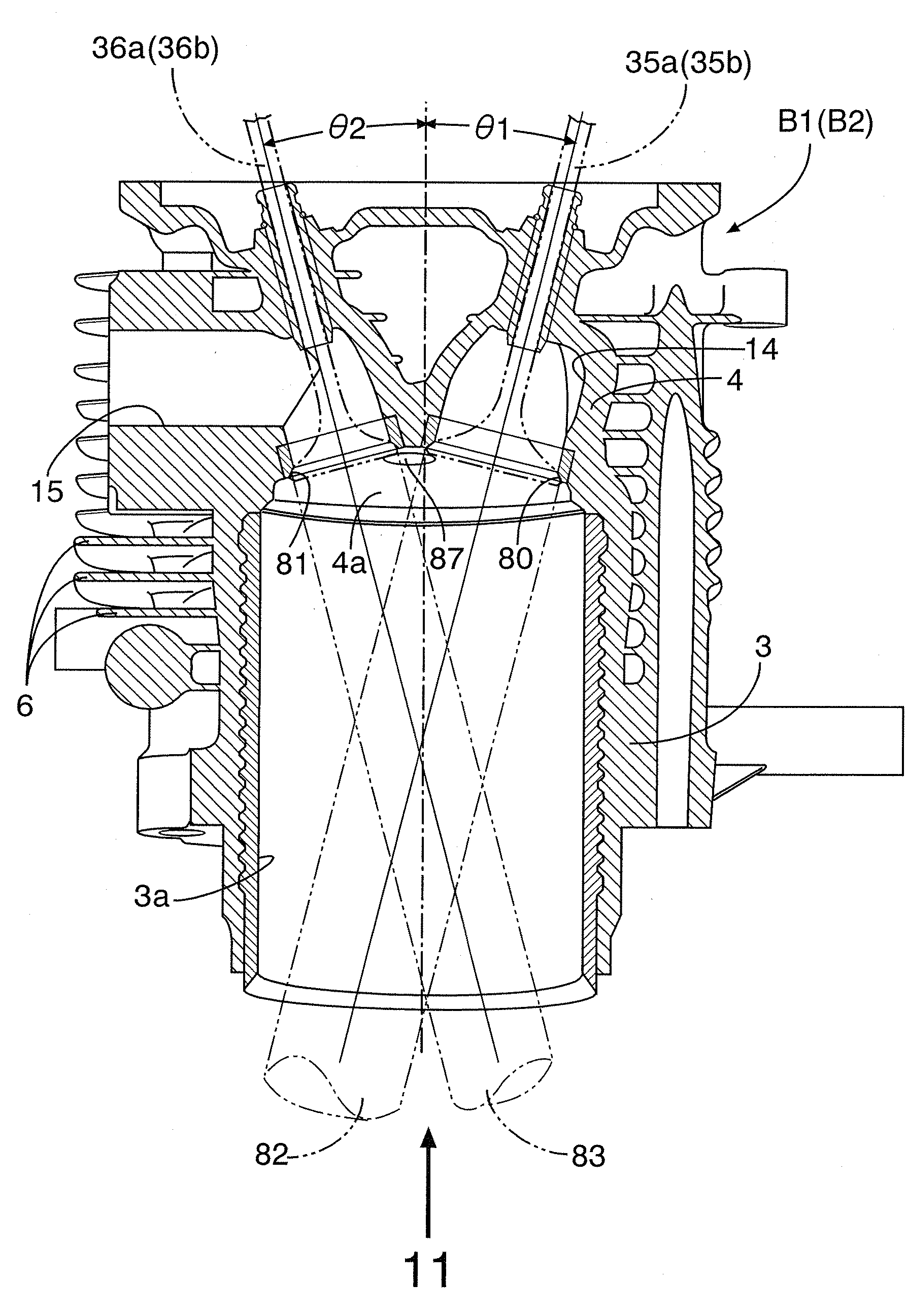

Rotatable duct type shrouded rotating wing

InactiveUS7503747B2Avoid deflectionAvoid distortionPropellersReaction enginesHorizontal orientationDistortion

In a rotatable duct type shrouded rotating wing, permanent magnets are arranged in the outer periphery of a rotatable duct, rotor blades are connected to the inner periphery of the rotatable duct, the rotor blades having a rotatable support portion at about every 2.5 m to prevent deflection or distortion. The shroud and the rotatable duct are constantly in vertical contact with each other, and an appropriate horizontal spacing is provided between the inner periphery of the shroud and the outer periphery of the rotatable duct to permit expansion and contraction of the rotatable duct and the rotor blades. Accordingly, even if the shrouded rotating wing is of a large radius, is used in a horizontal orientation and undergoes a rapid change of direction mounted to a turntable, it always rotates stably to generate lift and thrust.

Owner:IKEDA KAIDOU

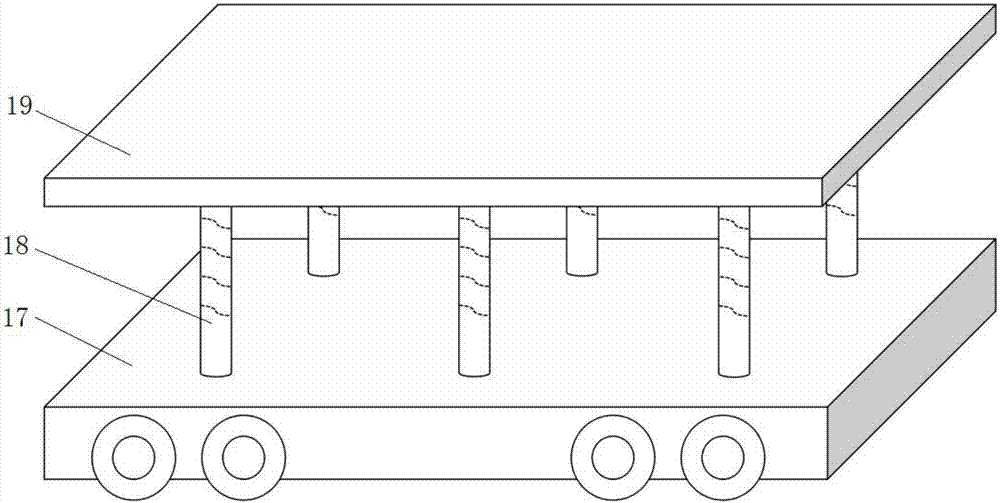

Lifting robot car

PendingCN107381428ASolve the technical problems of occupying a large space sizeSmall space sizeLifting framesMachineControl theory

The invention relates to a lifting robot car. The lifting robot car comprises a car body with wheels, multiple lifting devices arranged at the upper end of the car body side by side, objective tables mounted on the one or more lifting devices and a controller for controlling the lifting devices to do lifting motion. The car body is an AGV or OMV car. According to the lifting robot car, the lifting motion of the objective tables is achieved by the adoption of the spiral lifting manner, after the spiral lifting machines are completely contracted, the whole space size is small, the structure is compact, and the technical problem that a traditional lifting mechanism occupies a large space is solved; and besides, the lifting force cannot become small suddenly when the lifting height is increased, the stability is higher, and the safety performance is high.

Owner:WUHU C&K AUTOMATION TECH CO LTD

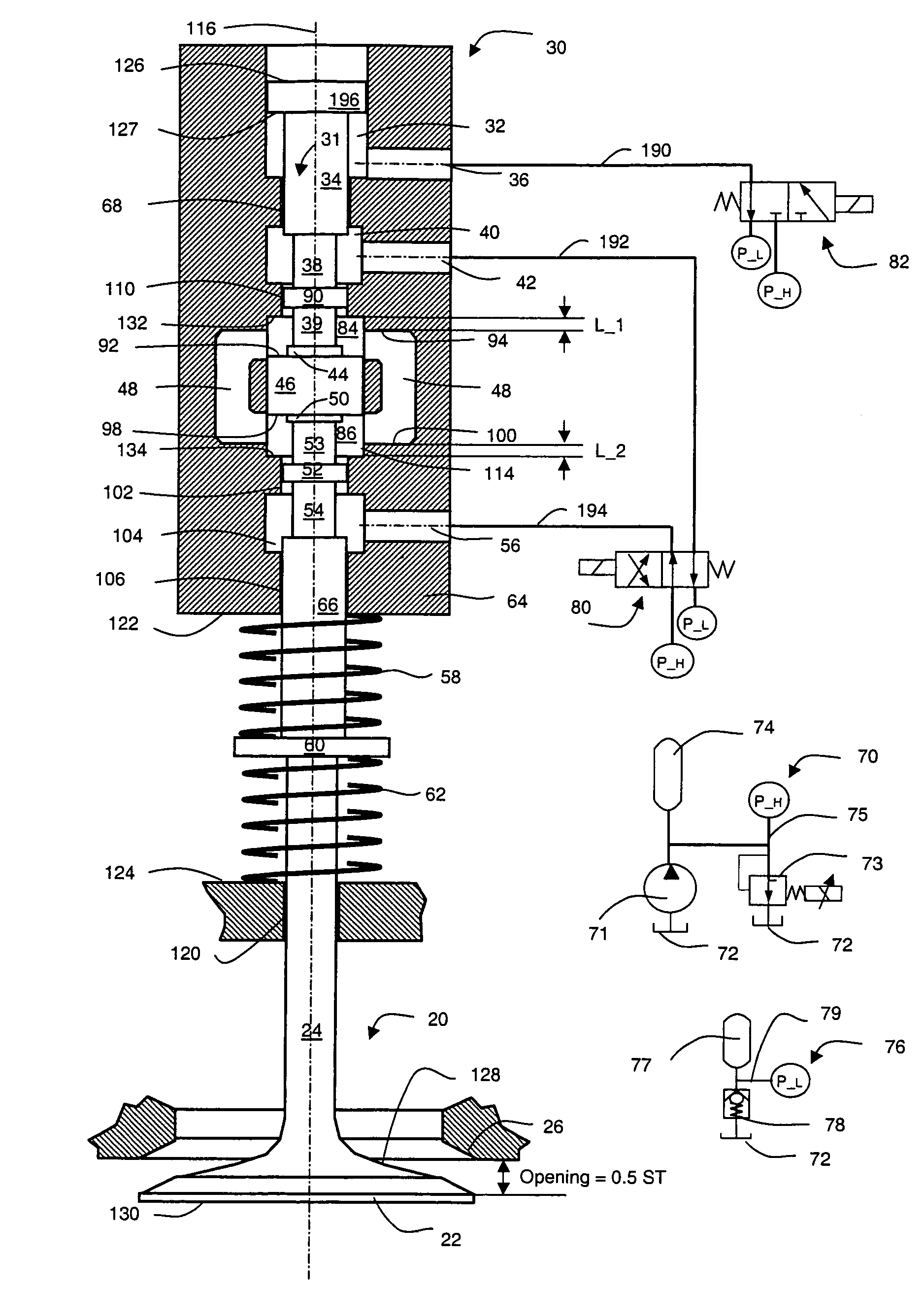

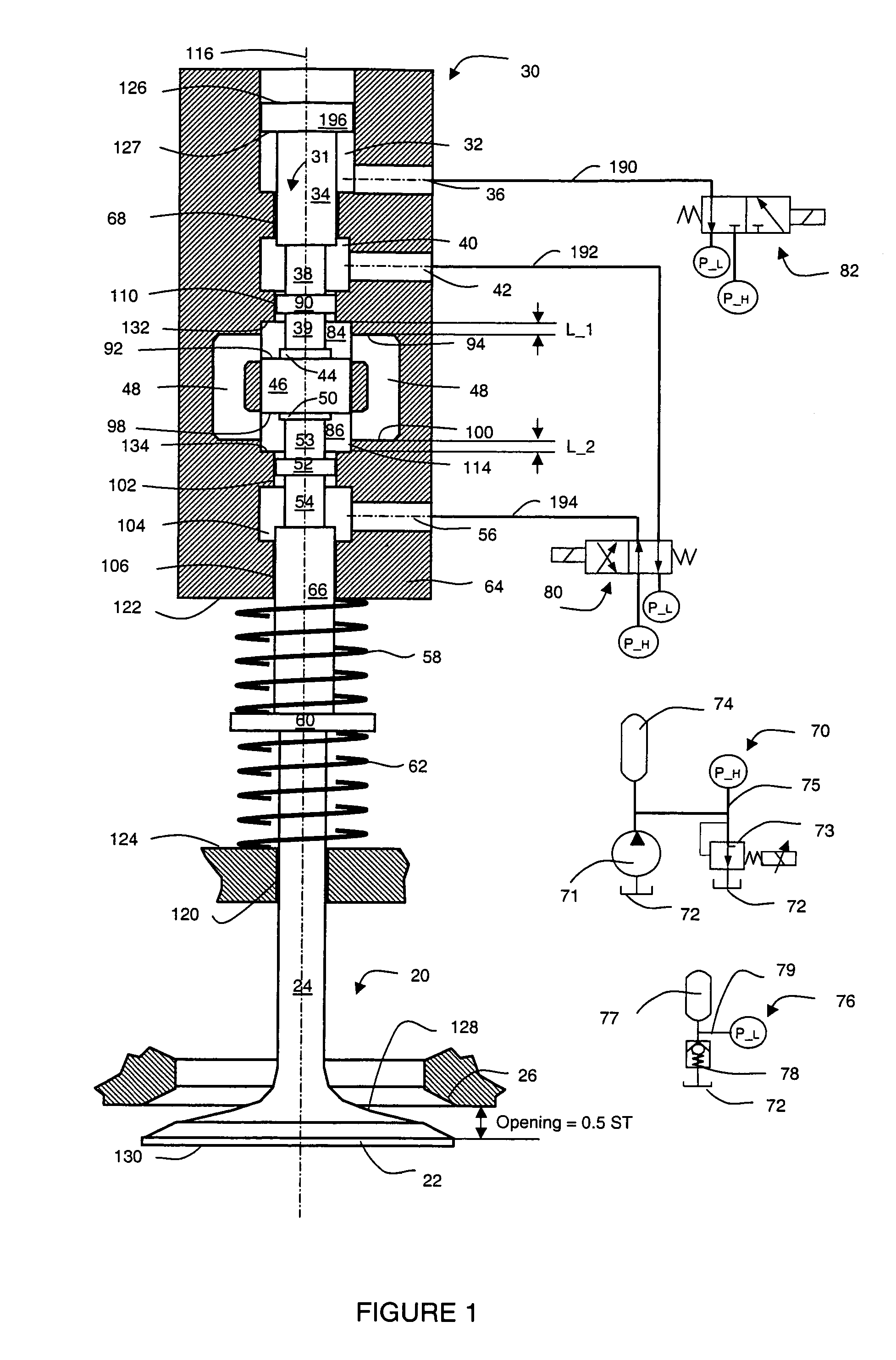

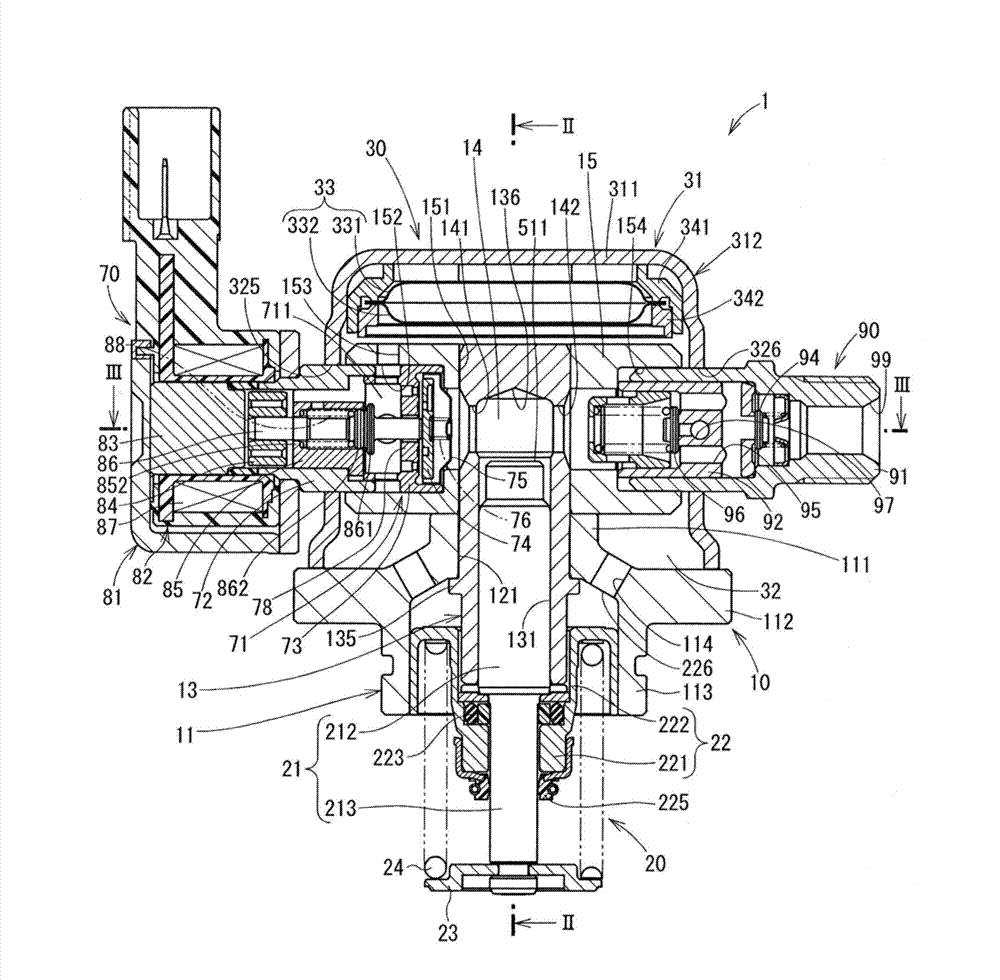

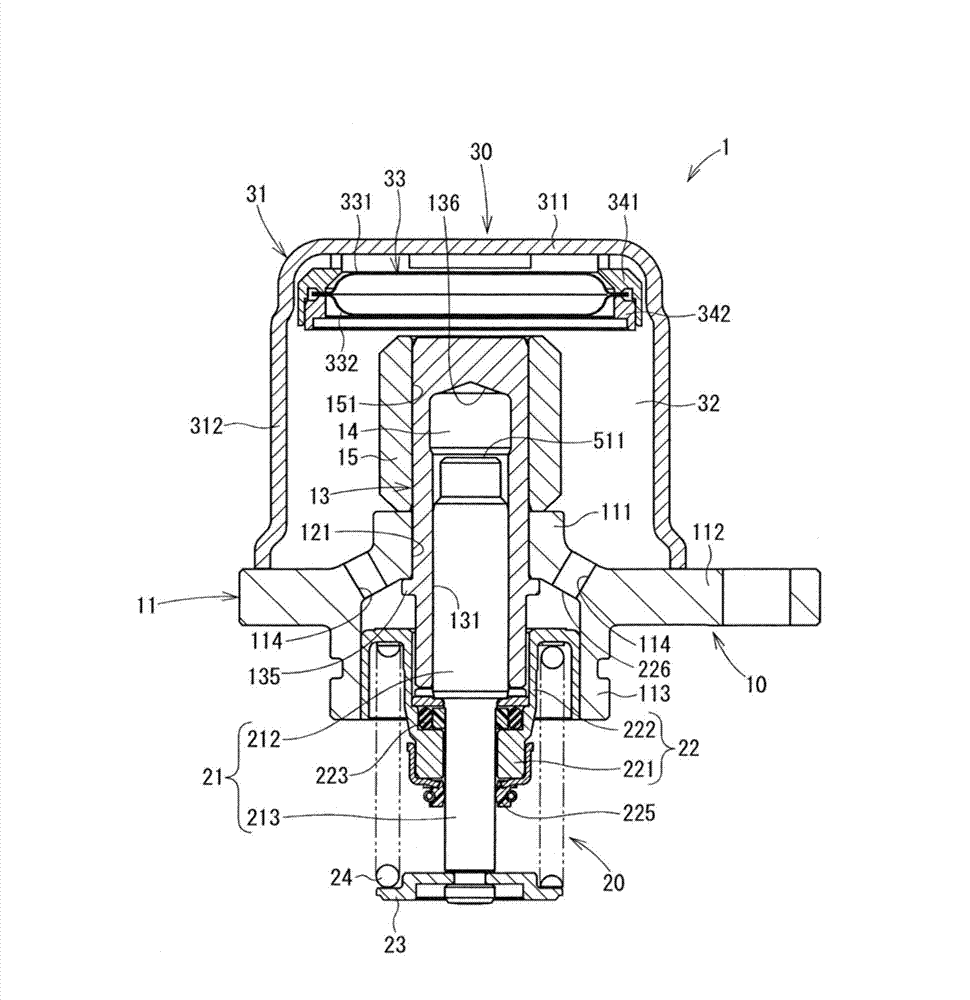

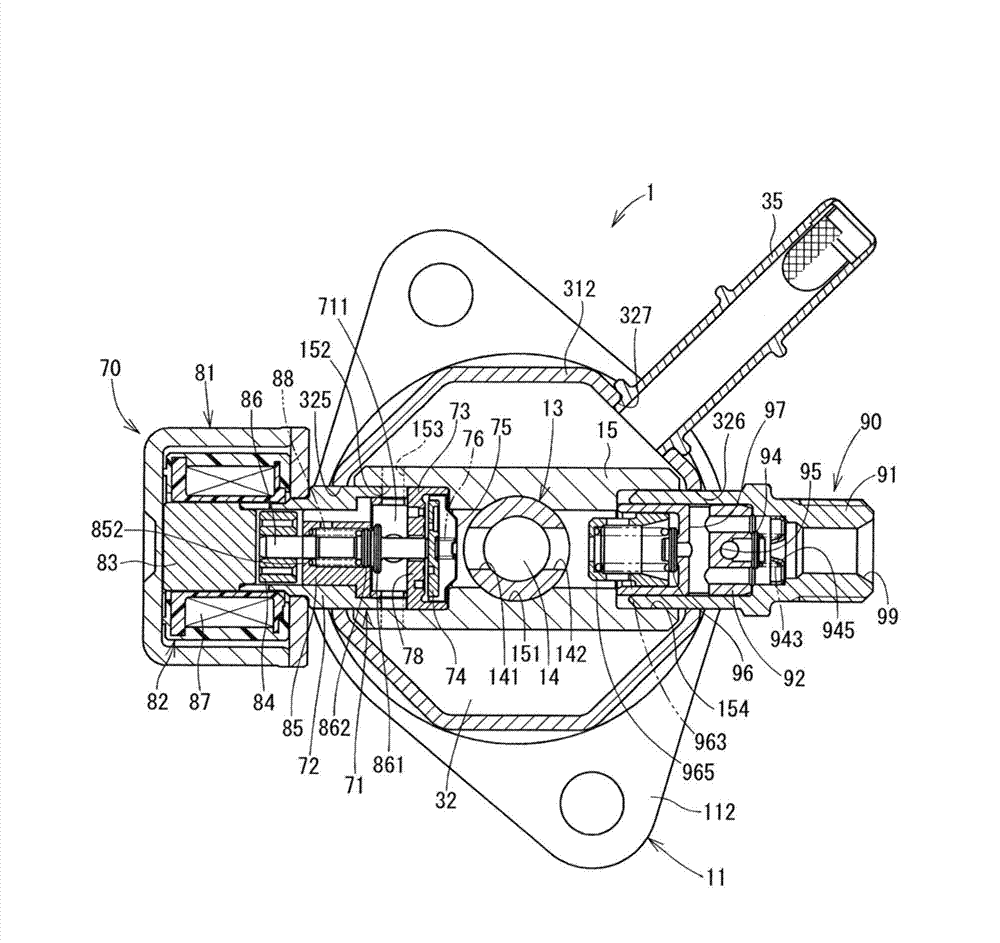

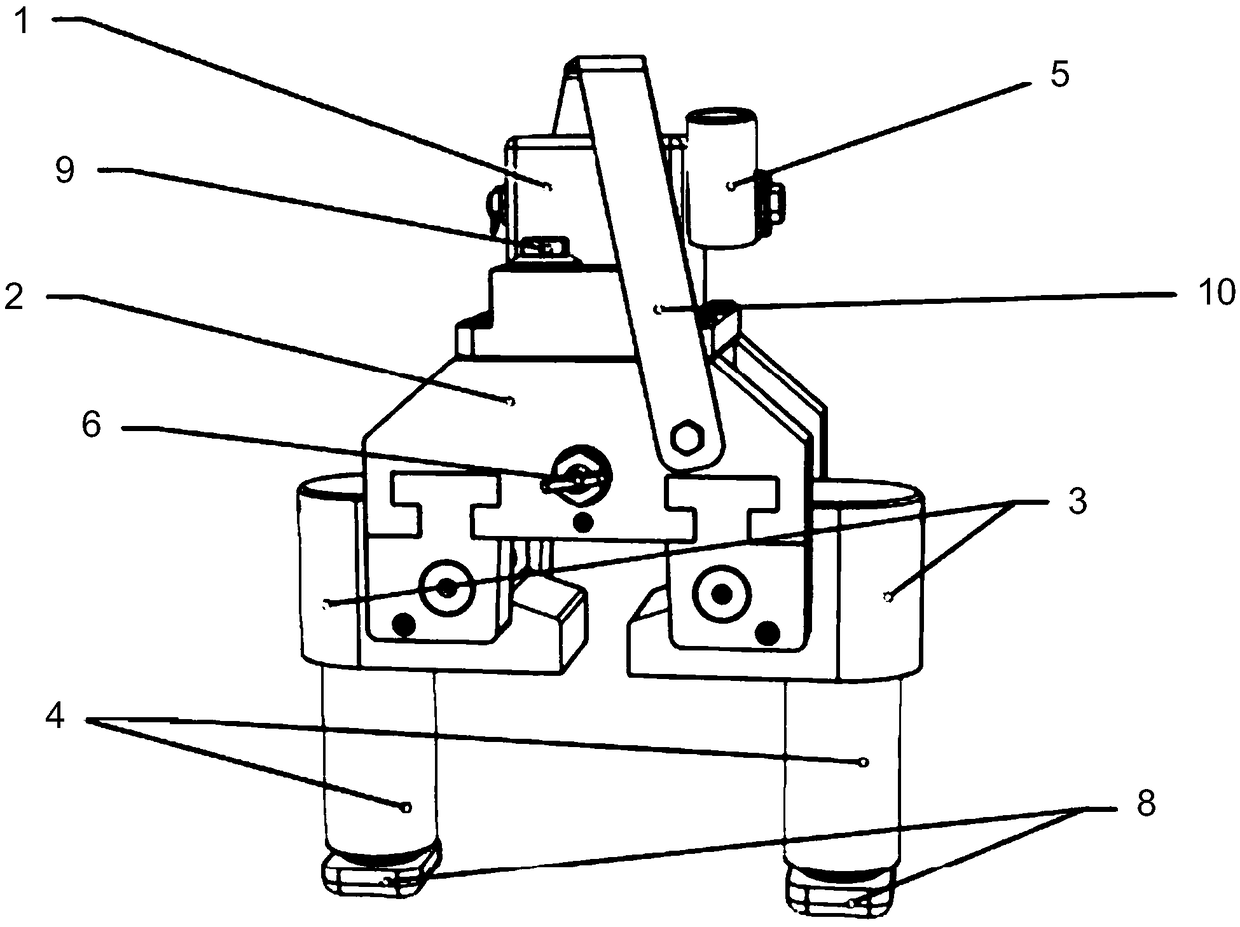

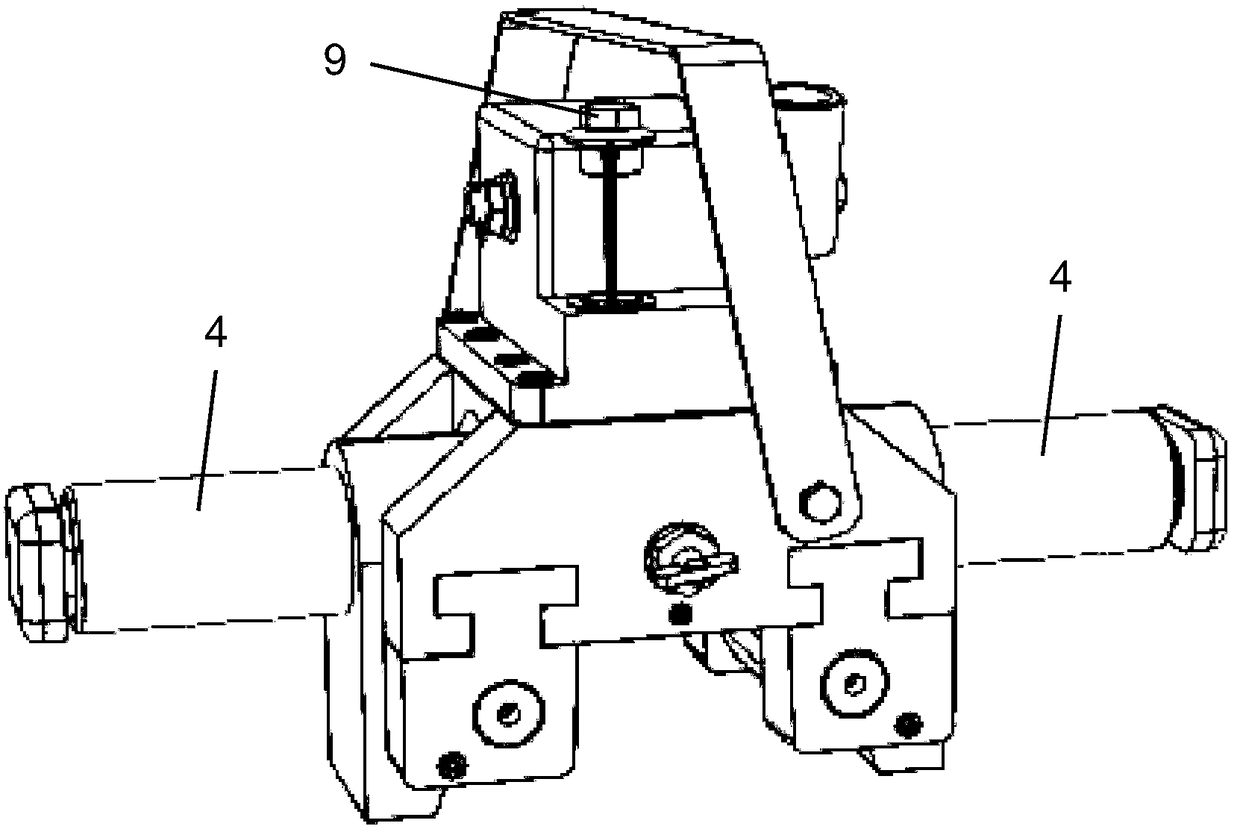

Variable valve actuator

InactiveUS7302920B2Small liftSelective operationMachines/enginesNon-mechanical valveValve actuatorInternal combustion engine

Owner:LGD TECH LLC

Air intake valve lift-variable system in air intake pressure regulating type

InactiveCN102808671AContinuously variableReasonable designValve arrangementsMachines/enginesExhaust valveCombustion

The invention discloses an air intake valve lift-variable system in an air intake pressure regulating type, belonging to the technical field of internal combustion engines. The system comprises an air intake channel, an air exhaust channel, an air intake valve lower section, an air exhaust valve, an air intake valve upper section, a capacity cavity, a movable body, a perforation pipe, a movable block, an air inlet pipe, a connecting pipe and a spring, wherein the movable body is mounted in the capacity cavity and is contacted with the inner wall face of the capacity cavity in a sealing manner; the perforation pipe perforates the upper wall face and the lower wall face of the movable body; the movable block is mounted in the perforation pipe and is contacted with the inner wall face of the perforation pipe in a sealing manner; the lower end face of the movable block is a plane; the upper end face of the movable block is an inclined face; two ends of the connecting pipe are communicated with the left wall faces of the air intake pipe and the capacity cavity; the right wall face of the movable body is connected with the right wall face of the capacity cavity through the spring; when pressure in the air intake pipe is relatively large, the movable body is moved to right; the air intake valve lift is increased; when the pressure in the air intake pipe is relatively small, the movable body is moved to left; the air intake valve lift is reduced; and the intake valve variable-lift system is characterized by reasonable design and simple structure and is suitable for engine valve lift-variable systems.

Owner:SHANGHAI JIAO TONG UNIV

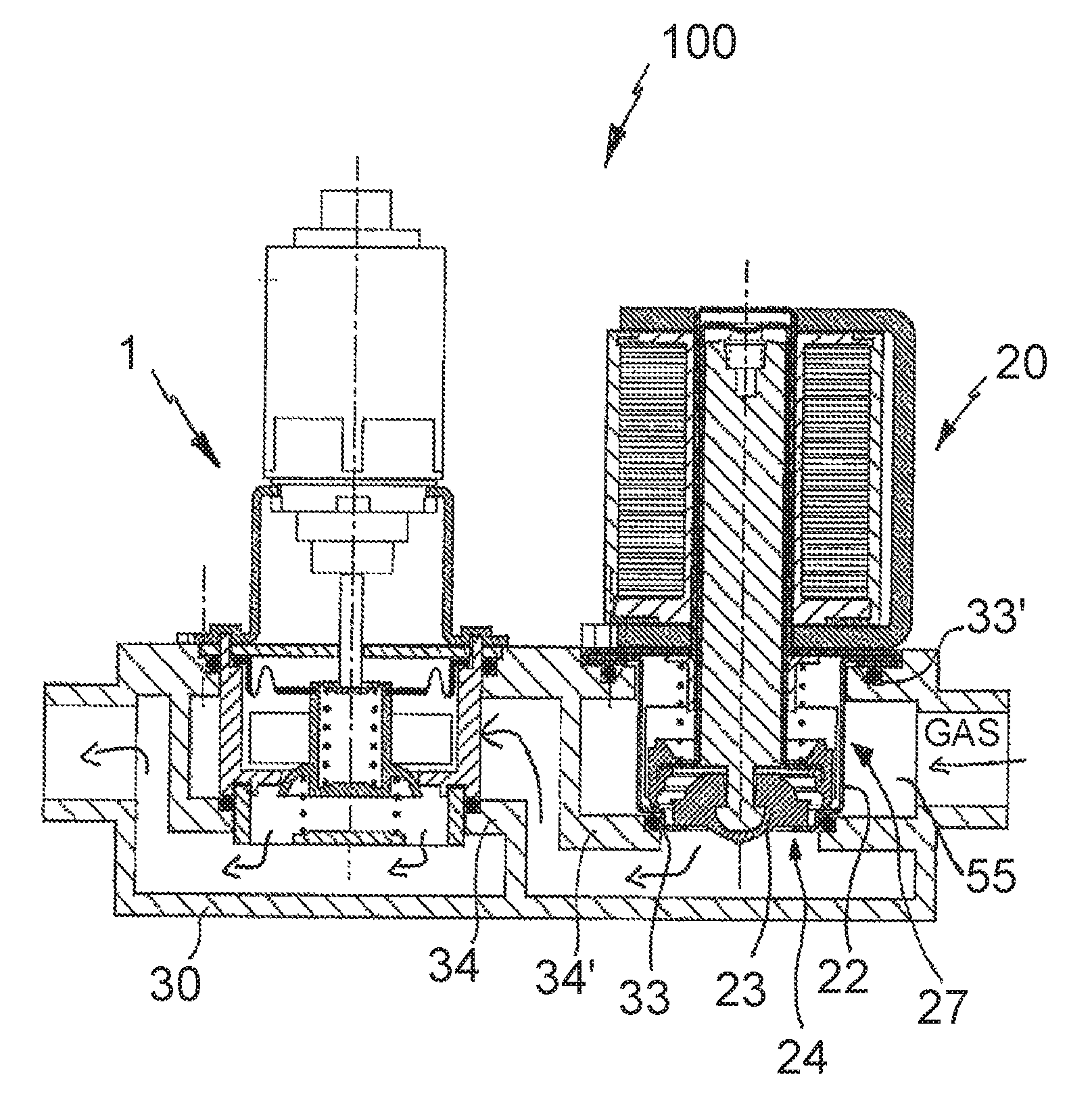

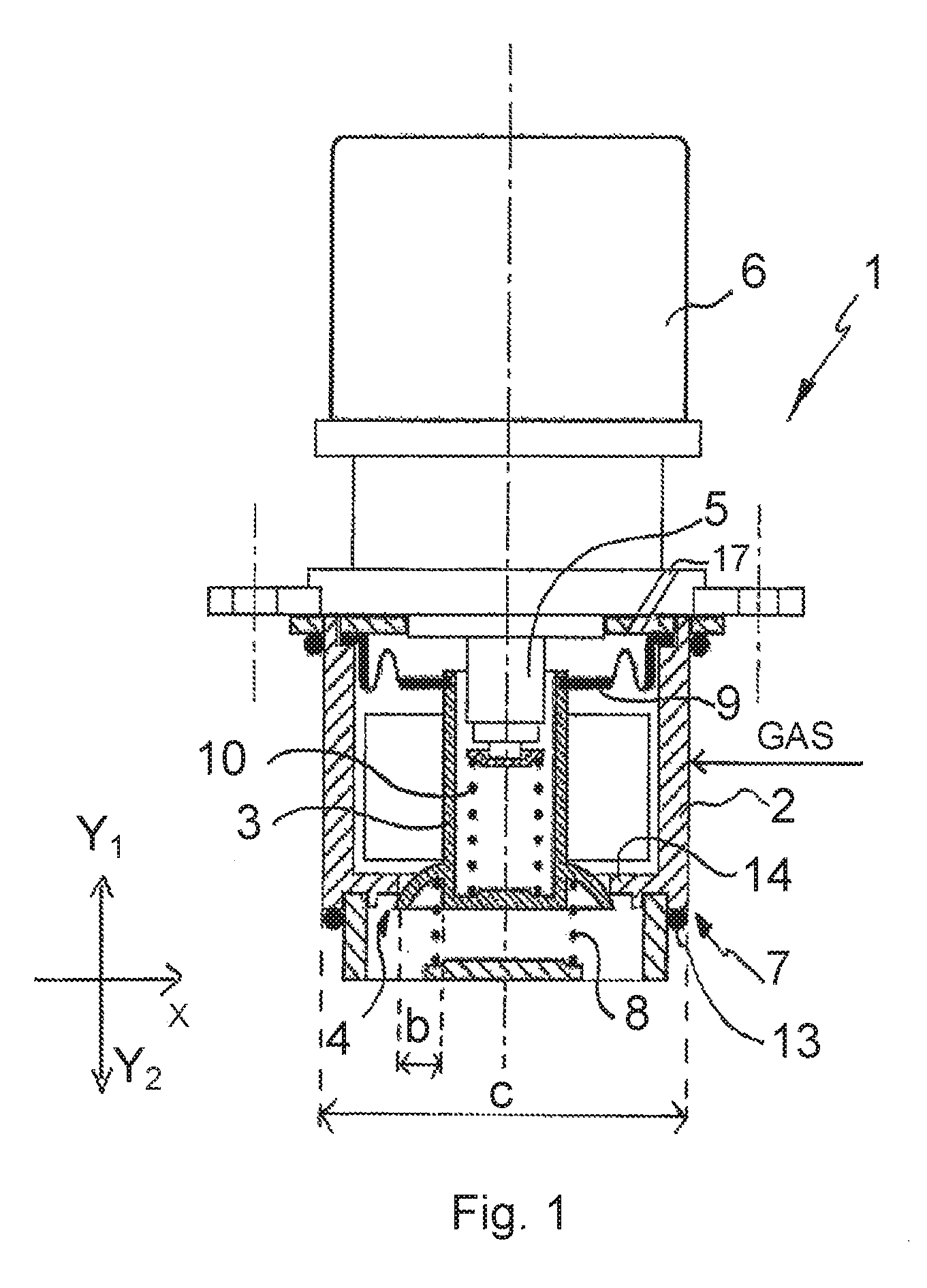

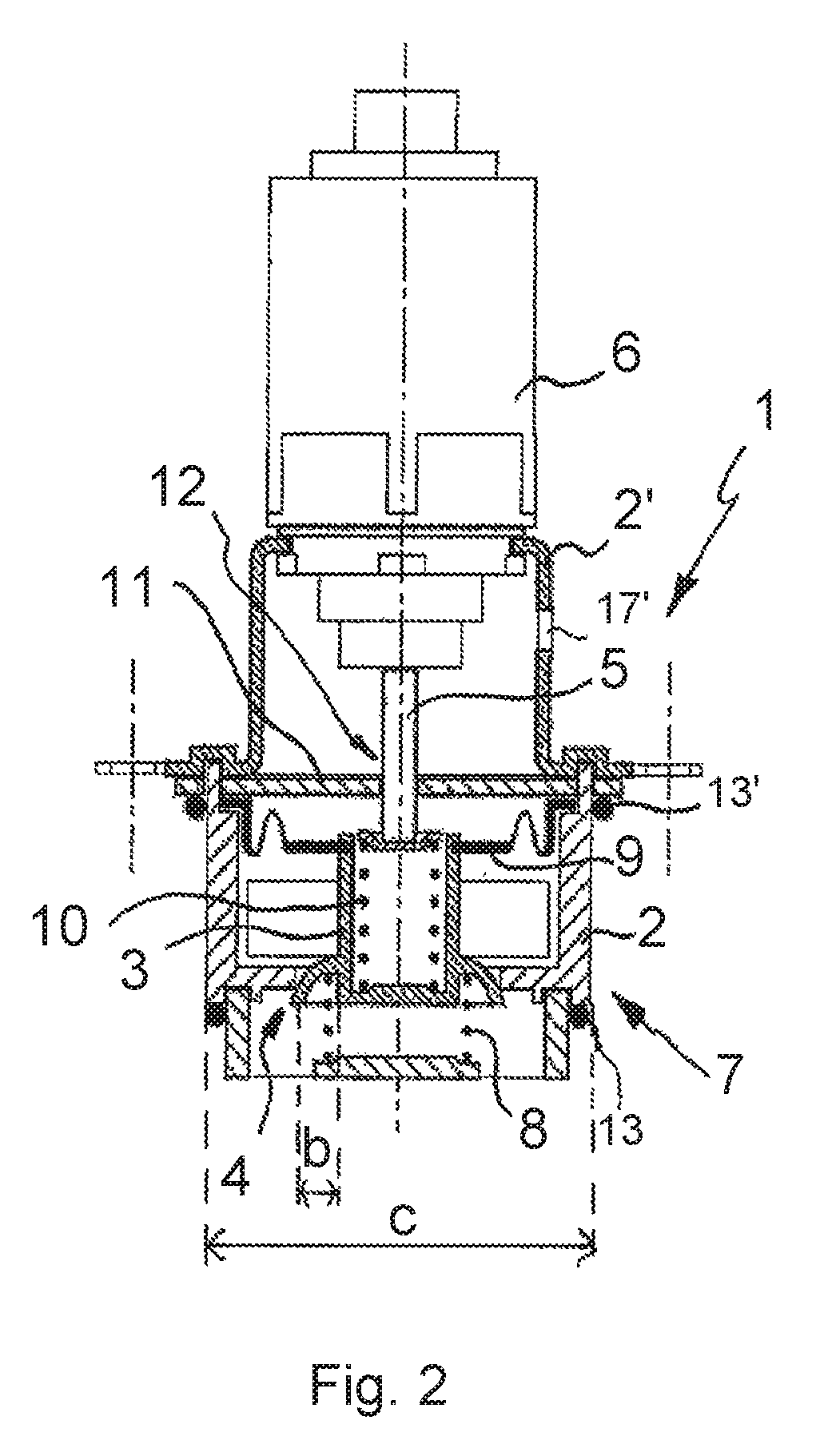

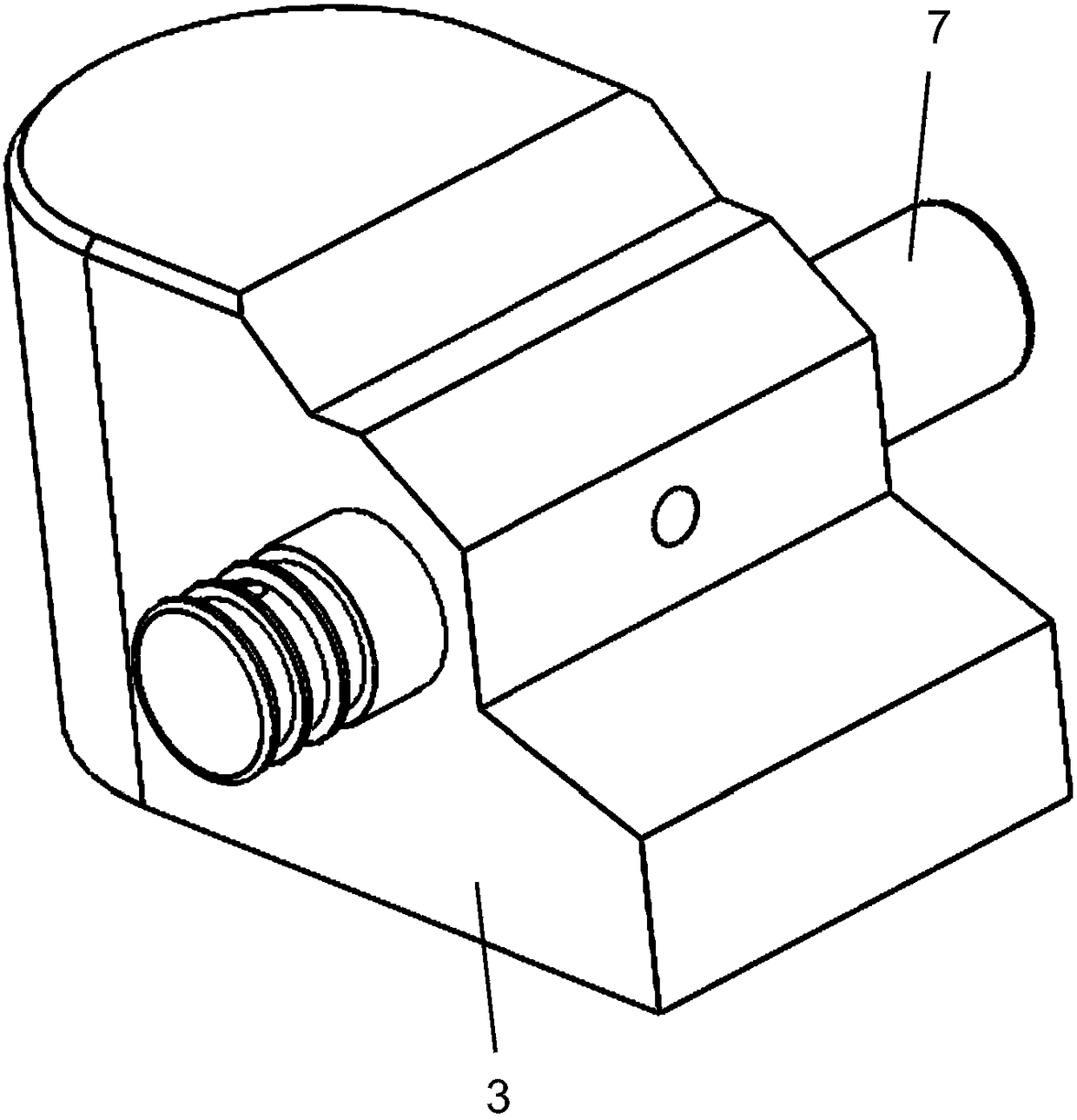

Gas regulating unit of modular construction and gas regulating valve

ActiveUS9416888B2Small liftSimple and comparatively cost-effective configurationFuel supply regulationOperating means/releasing devices for valvesProduct gasGas burner

The invention relates to a gas regulating unit of modular construction, in particular for regulating the amount of gas to be supplied to a gas burner, and to a gas regulating valve which, as a whole, is in the form of a module and which can be used in an aforementioned gas regulating unit of modular construction.

Owner:EBM PAPST LANDSHUT

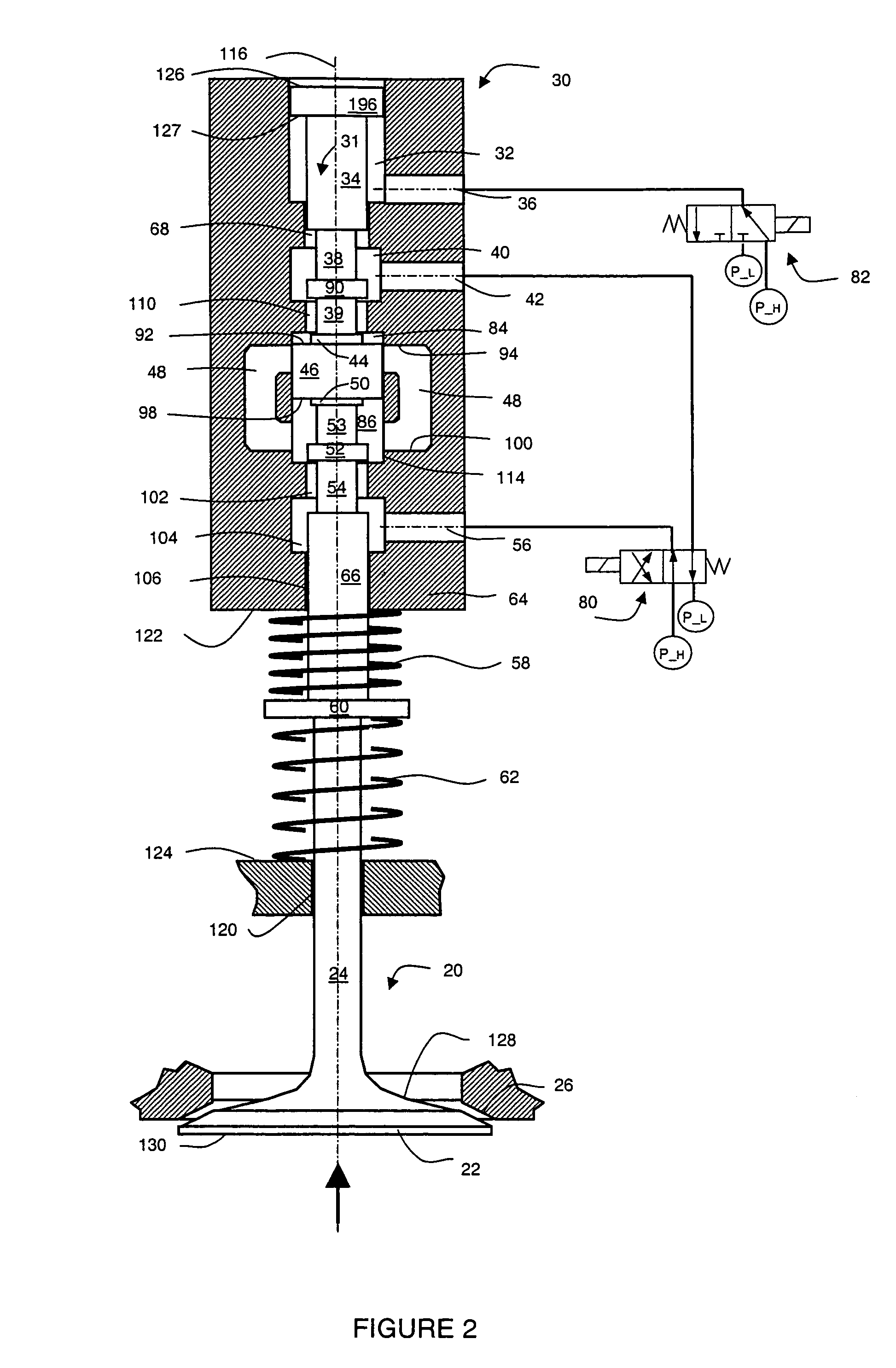

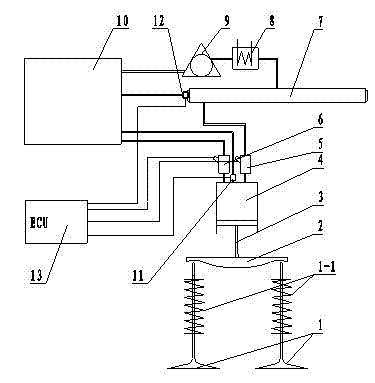

Hydraulic drive engine air distributing mechanism

ActiveCN102787878ASmall liftOpen time adjustmentMachines/enginesNon-mechanical valveControl systemIdle speed

A hydraulic drive engine air distributing mechanism is used for improving the dynamic property, fuel economy and emission performance of vehicles, and includes a driving assembly, an actuating assembly, a hydraulic oil circuit, an oil storage tank and a control system, wherein the driving assembly is connected with the hydraulic oil circuit; the hydraulic oil circuit is communicated with the oil storage tank; the actuating assembly includes an air valve bridge, two air valves and an air valve return spring; the upper end face of the air valve bridge is assembled with the driving assembly, and the lower end face thereof is connected with the two air valves; and the air valve return spring is mounted outside an air valve stem in a sleeving manner. The engine air distributing mechanism realizes the fully variable air valve technology, can simultaneously control the opening / closing time, the opening continuity and the valve lift of the air valves, thereby being more suitable for the requirements of engine frequent variable working condition, reducing the engine oil consumption, ensuring the power output of the engine under high load, endowing the engine with the satisfactory idling characteristic, and providing technical support for the cylinder deactivation technology.

Owner:GREAT WALL MOTOR CO LTD

Fork comb type automobile handling device

The invention relates to a fork comb type automobile handling device, and belongs to the technical field of parking equipment. The fork comb type automobile handling device is characterized in that achassis is supported by a group of walking wheels, and is driven by a walking mechanism to move along the horizontal direction; the chassis is of a combined structure, and comprises a fixed frame anda movable frame; a lifting mechanism is arranged between the fixed frame and the movable frame; lifting frames are respectively arranged at the front end and back end of the movable frame; the liftingmechanism is used for driving the movable frame to move corresponding to the fixed frame; the lifting mechanism is used for driving the lifting frame to ascend and lift an automobile to leave off theground; then, the walking mechanism is used for driving the chassis, so as to realize the purpose of horizontal conveying of the automobile. The fork comb type automobile handling device has the advantages that the structure is simple, the thickness is small, and the lifting force is large.

Owner:SHANDONG JIANZHU UNIV

Valve device and high pressure pump using the same

ActiveCN102777300AInhibit automatic closingMaximum output reducedOperating means/releasing devices for valvesPositive displacement pump componentsEqualizationHigh pressure

The present invention provides a valve device and a high pressure pump using the same. A valve seat (78) has an inner passage (781) and outer passages (782). A suction valve member (74) has first passages (743) and a first projection portion (744) that guides, to the first passages (743), the fuel that flows from a pressure chamber at the time of valve opening. Therefore, an action force by the dynamic pressure applied to the suction valve member (74) in the valve closing direction is reduced. An action force by the pressure of fuel that flows into pressure equalization grooves (746, 784, 785) counterbalances the action force by the dynamic pressure of the suction valve member (74). Therefore, self-closing by the dynamic pressure can be inhibited, and the maximum output of an electromagnetic driving unit can be reduced. Fuel flows through a passage radially outside the suction valve member (74) and the first passages (743). A fluid passage area is securable even when a lift amount of the suction valve member (74) is small. The maximum output of an electromagnetic drive unit also can be reduced.

Owner:DENSO CORP

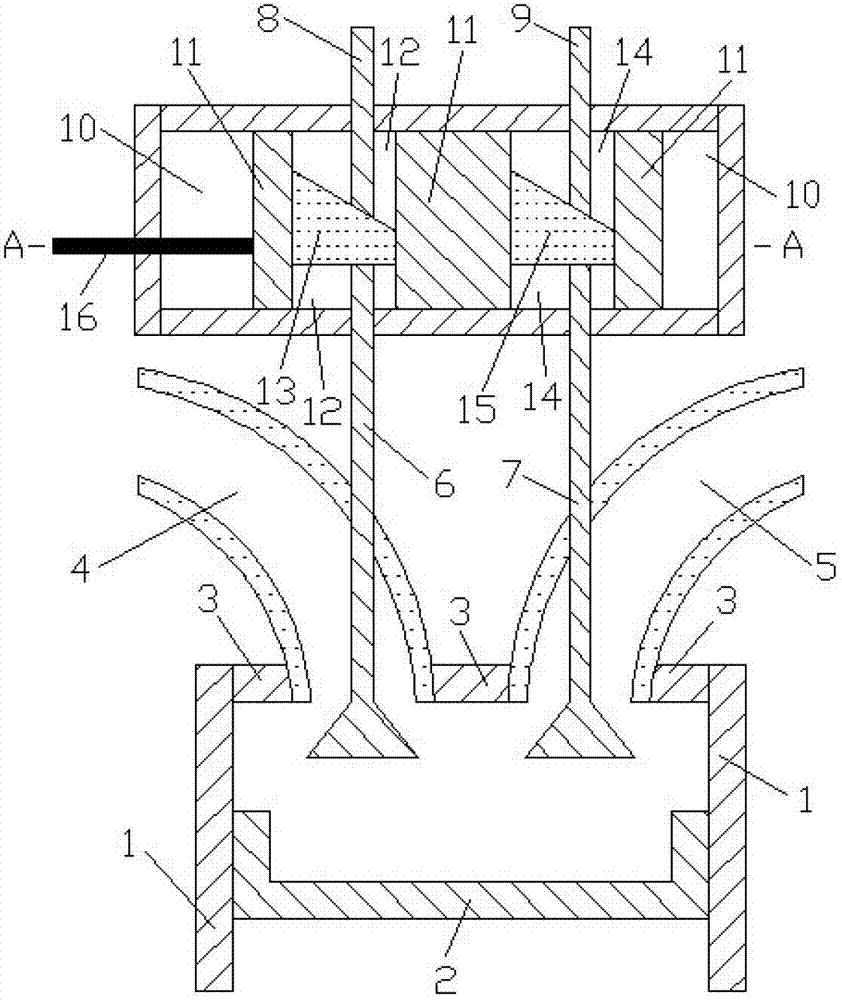

Two-valve stroke synchronously-variable device

ActiveCN102926835AReasonable designSimple structureValve arrangementsMachines/enginesMechanical designEngineering

The invention relates to a two-valve stroke synchronously-variable device which belongs to the technical field of mechanical design. The two-valve stroke synchronously-variable device comprises an inlet channel, an exhaust channel, an inlet valve lower segment, an exhaust valve, an inlet valve upper segment, a volume cavity, a movable body, a through tube, a movable block and a movable rod, wherein the movable body is arranged in the volume cavity and is hermetically contact with the inner wall surface of the volume cavity; the through tube penetrates through the upper wall surface and the lower wall surface of the movable body; the movable block is arranged in the through tube and is hermetically contact with the inner wall surface of the through tube; the lower end surface of the movable block forms a plane, and the upper end surface of the movable block forms a slope; the inlet valve upper segment penetrates through the upper wall surface of the volume cavity and extends into the through tube, and the lower end surface of the inlet valve upper segment is hermetically contact with the upper end surface of the movable block. When the movable body moves towards right, the strokes of inlet and exhaust valves are lengthened, when the movable body moves towards left, the strokes of the inlet and exhaust valves are shortened, and the continuous variation of the strokes of the inlet and exhaust valves can be realized. The two-valve stroke synchronously-variable device disclosed by the invention is reasonable in design, simple in structure and suitable for the inlet and exhaust valve stroke variable system of an engine.

Owner:SHANGHAI JIAO TONG UNIV

Mechanical type valve stroke continuously-variable device

ActiveCN102926834AConsidering both high and low speed conditionsQuick responseValve arrangementsMachines/enginesExhaust valveInlet channel

The invention relates to a mechanical type valve stroke continuously-variable device which belongs to the technical field of mechanical design. The mechanical type valve stroke continuously-variable device comprises an inlet channel, an exhaust channel, an inlet valve lower segment, an exhaust valve, an inlet valve upper segment, a volume cavity, a movable body, a through tube, a movable block and a movable rod, wherein the movable body is arranged in the volume cavity and hermetically is contact with the inner wall surface of the volume cavity; the through tube penetrates through the upper wall surface and the lower wall surface of the movable body; the movable block is arranged in the through tube and hermetically is contact with the inner wall surface of the through tube; the lower end surface of the movable block forms a plane, and the upper end surface of the movable block forms a slope; the inlet valve upper segment penetrates through the upper wall surface of the volume cavity and extends into the through tube, and the lower end surface of the inlet valve upper segment hermetically is contact with the upper end surface of the movable block. When the movable body moves towards right, the stroke of an inlet valve is lengthened, when the movable body moves towards left, the stroke of the inlet valve is shortened, and the continuous variation of the stroke of the inlet valve can be realized. The mechanical type valve stroke continuously-variable device disclosed by the invention is reasonable in design, simple in structure and suitable for the inlet valve stroke variable system of an engine.

Owner:SHANGHAI JIAO TONG UNIV

Air intake/exhaust valve lift-variable system in air intake pressure regulating type

InactiveCN102808670AContinuously variableReasonable designValve arrangementsMachines/enginesCombustionExhaust valve

The invention discloses an air intake / exhaust valve lift-variable system in an air intake pressure regulating type, belonging to the technical field of internal combustion engines. The system comprises an air intake channel, an air exhaust channel, an air intake valve lower section, an air exhaust valve, an air intake valve upper section, a capacity cavity, a movable body, a perforation pipe, a movable block, an air inlet pipe, a connecting pipe and a spring, wherein the movable body is mounted in the capacity cavity and is contacted with the inner wall face of the capacity cavity in a sealing manner; the perforation pipe perforates the upper wall face and the lower wall face of the movable body; the movable block is mounted in the perforation pipe and is contacted with the inner wall face of the perforation pipe in a sealing manner; the lower end face of the movable block is a plane; the upper end face of the movable block is an inclined face; the air intake valve upper section passes through the upper wall face of the capacity cavity and is extended into the perforation pipe; the lower end face of the air intake door upper section is contacted with the upper end face of the movable block in a sealing manner; when pressure in the air intake pipe is relatively large, the movable body is moved to right; the air intake valve lift is increased; when the pressure in the air intake pipe is relatively small, the movable body is moved to left; the air intake valve lift is reduced; and the intake / exhaust valve variable-lift system is characterized by reasonable design and simple structure and is suitable for engine valve lift-variable systems.

Owner:SHANGHAI JIAO TONG UNIV

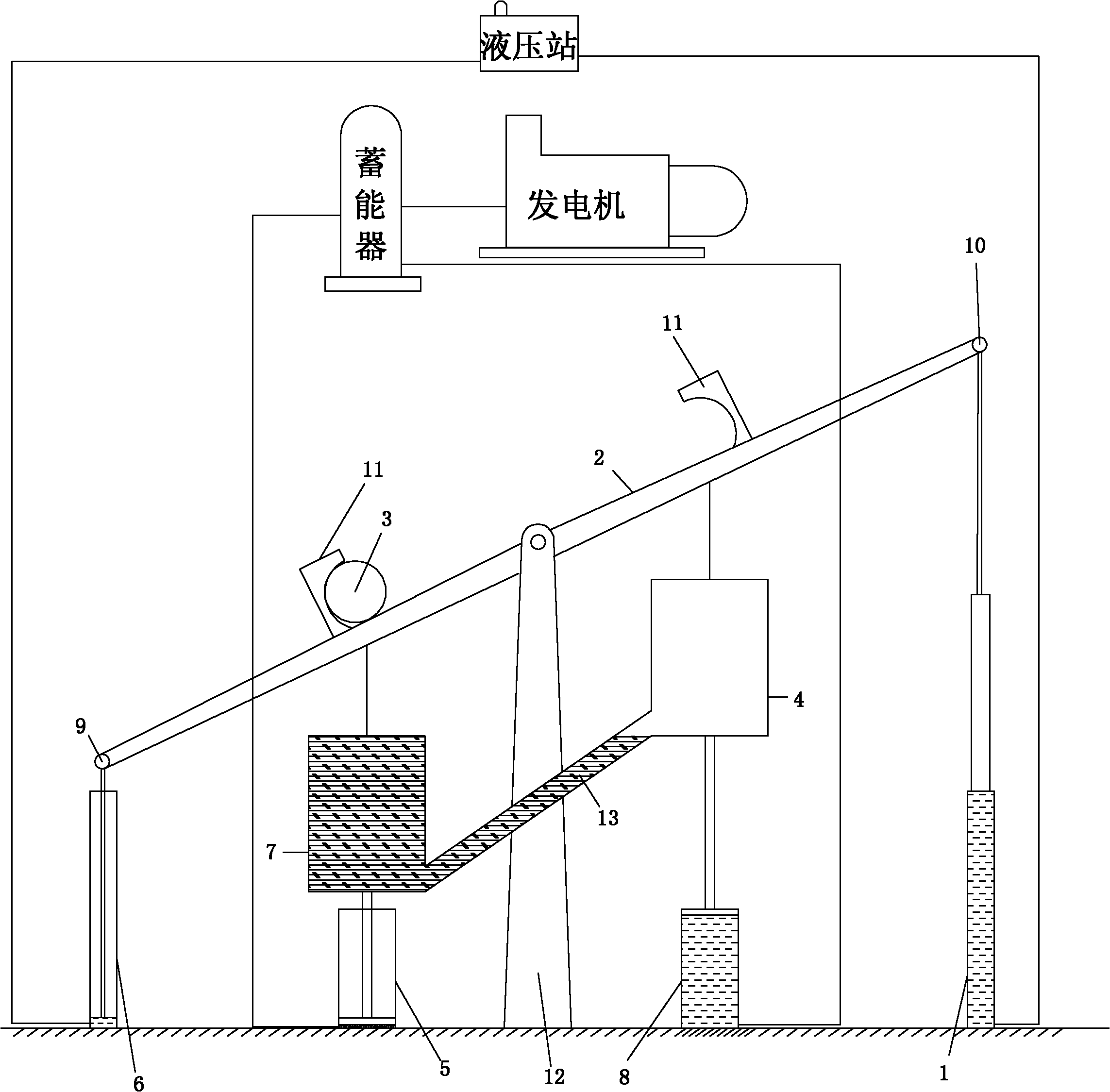

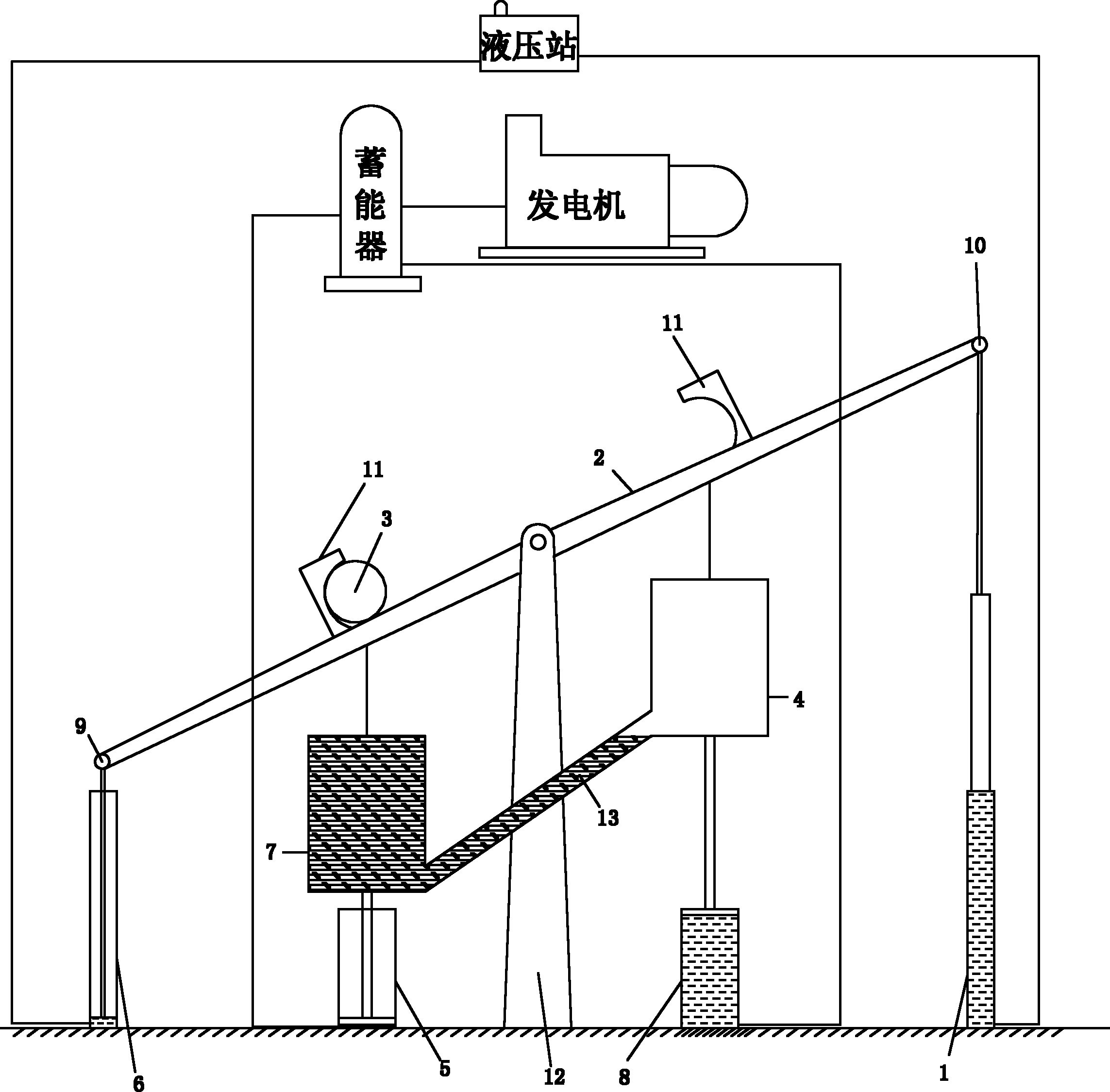

Lever-type energy-storage power generation method and device

InactiveCN102022293AIngenious designReduce manufacturing costMachines/enginesMechanical power devicesEngineeringPower apparatus

The invention discloses a lever-type energy-storage power generation method, which comprises the following steps: a power unit applies an upward hydraulic pressure to a tail end of a lever so as to rotate the lever; and according to the lever arm principle, a downward pressure larger than the hydraulic pressure is applied to a short lever arm at the other side of the lever, and the energy-storage power generation is performed by the downward pressure. The invention also discloses a lever-type energy-storage power generation device. The device disclosed by the invention is clever in structure, and can generate power by using the lever principle.

Owner:陈达强

Method for lifting and centralizing sinking house

The invention relates to a method for lifting and centralizing a sinking house. The method comprises the steps that a detecting radar is used for detecting the sinking position of the sinking house and the positions of a vertical foundation beam and a horizontal foundation beam, the positions of first blank space, second blank space and third blank space are marked on the ground surface, close to the sinking position, in the house, the positions of injected holes are marked and drilled, injected pipes are arranged, the injected pipes extend into the first blank space, the second blank space and the third blank space, level gauges are arranged on the left side and in front of the house, grouting is performed on the injected pipes, the level gauges are used for detecting the vertical and horizontal inclining conditions of the house in time, the grouting volumes to the first blank space, the second blank space and the third blank space are respectively adjusted in time according to the vertical and horizontal inclining volumes of the house, and the whole grouting process is divided into several times until the house is centralized; the injected holes are sealed after the grouting is finished and the slurry is completely solidified; the sinking house is lifted through the grouting, and the grouting volumes to the first blank space, the second blank space and the third blank space are respectively adjusted to centralize the house.

Owner:JIANGSU DINGTAI ENG MATERIAL

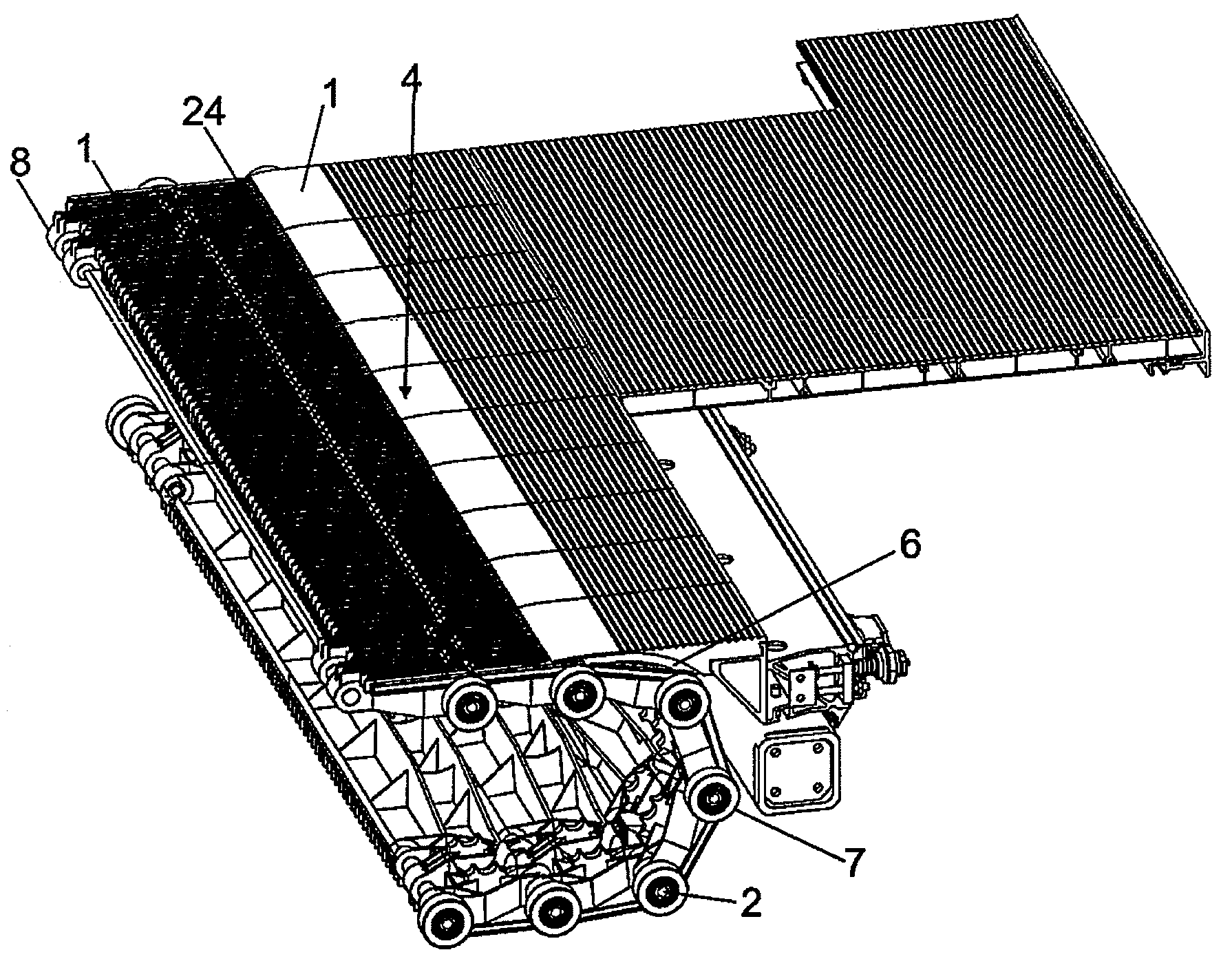

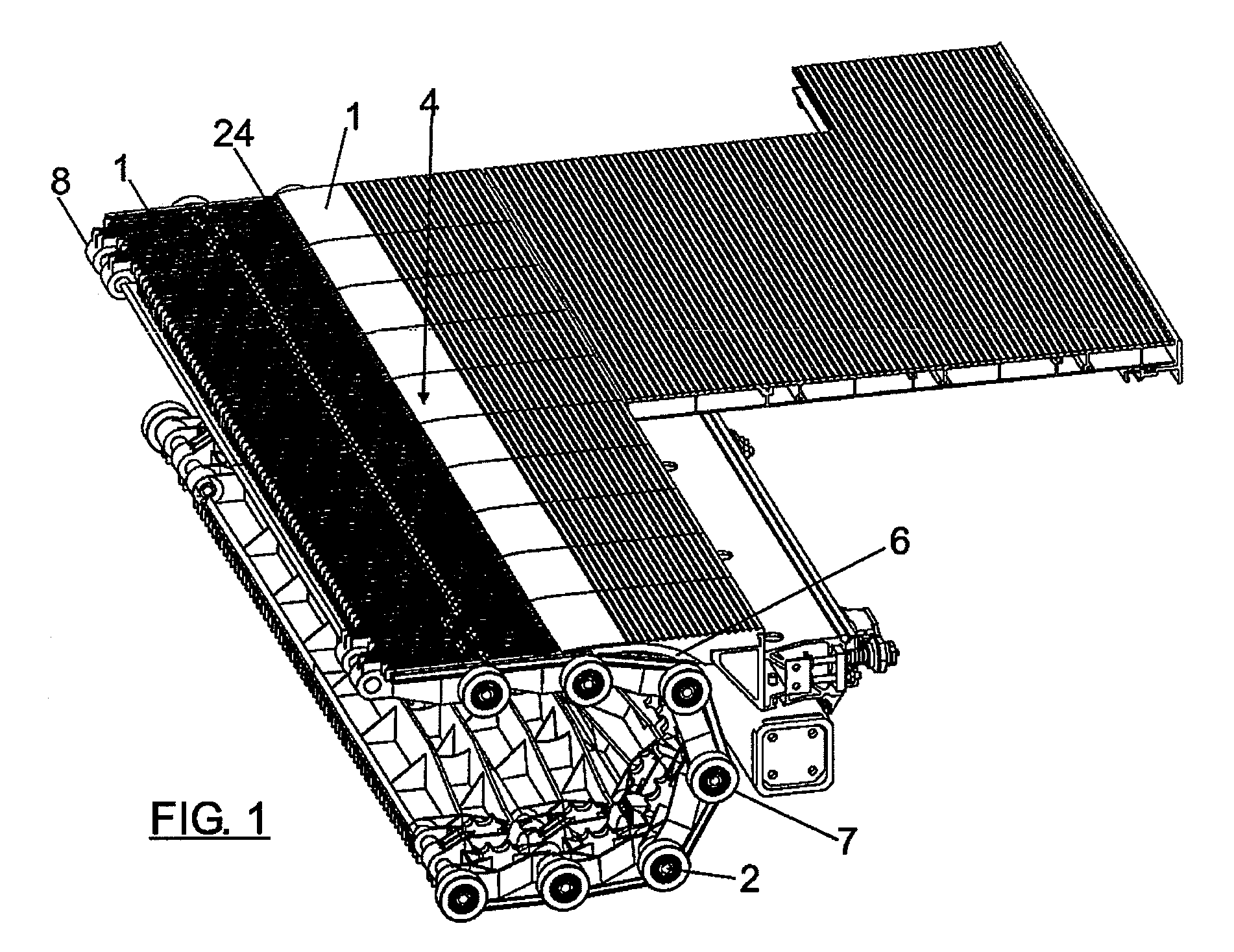

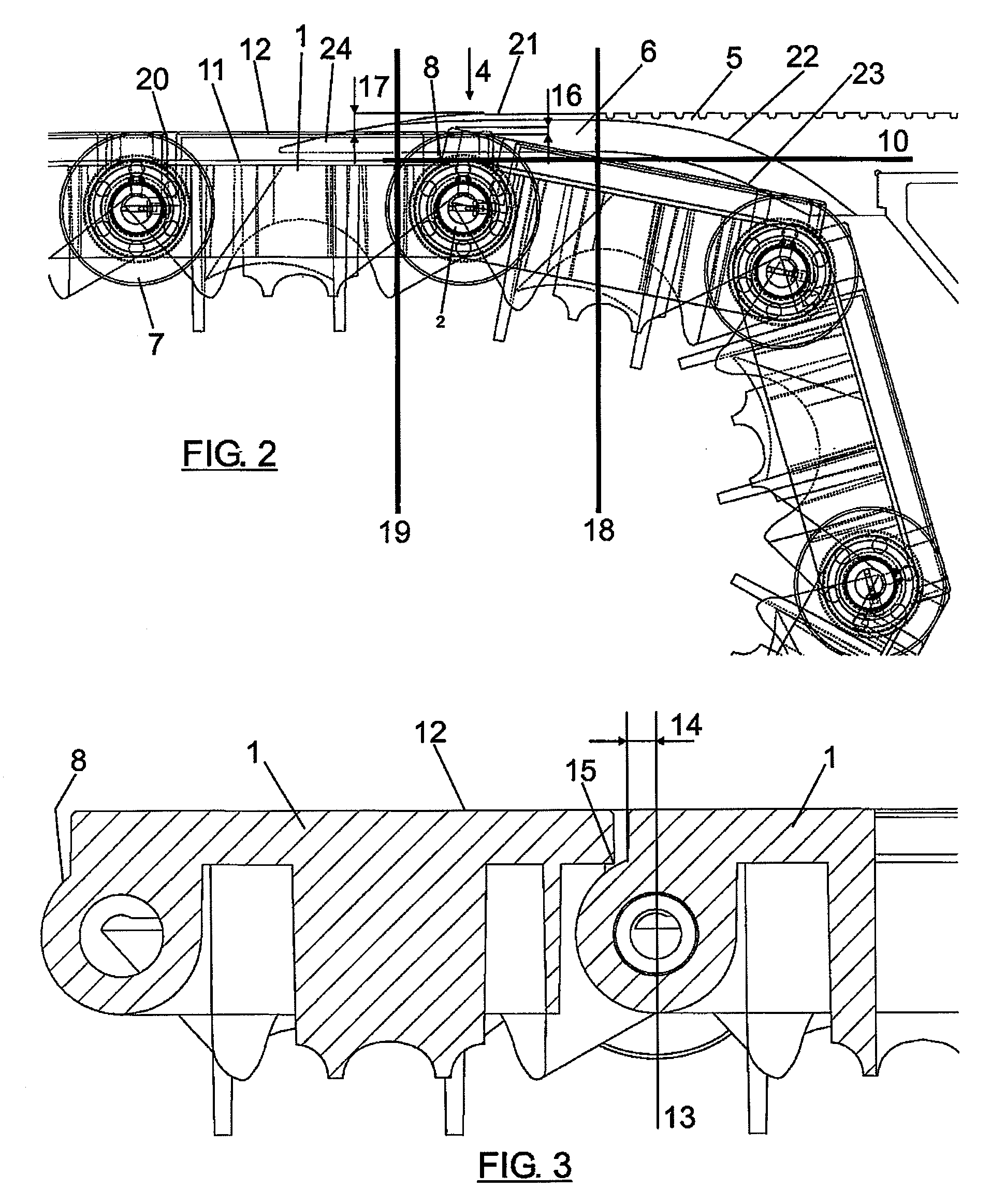

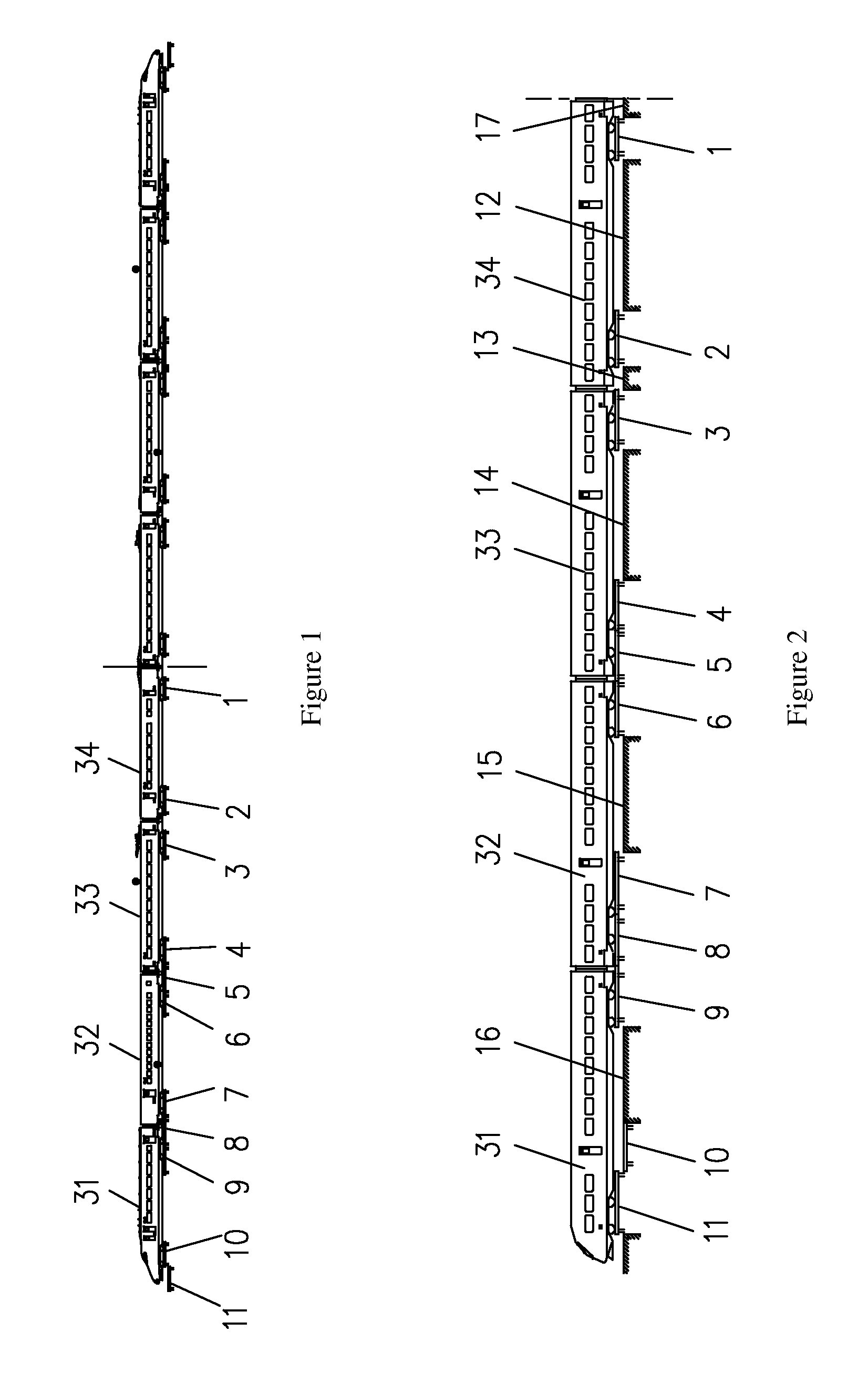

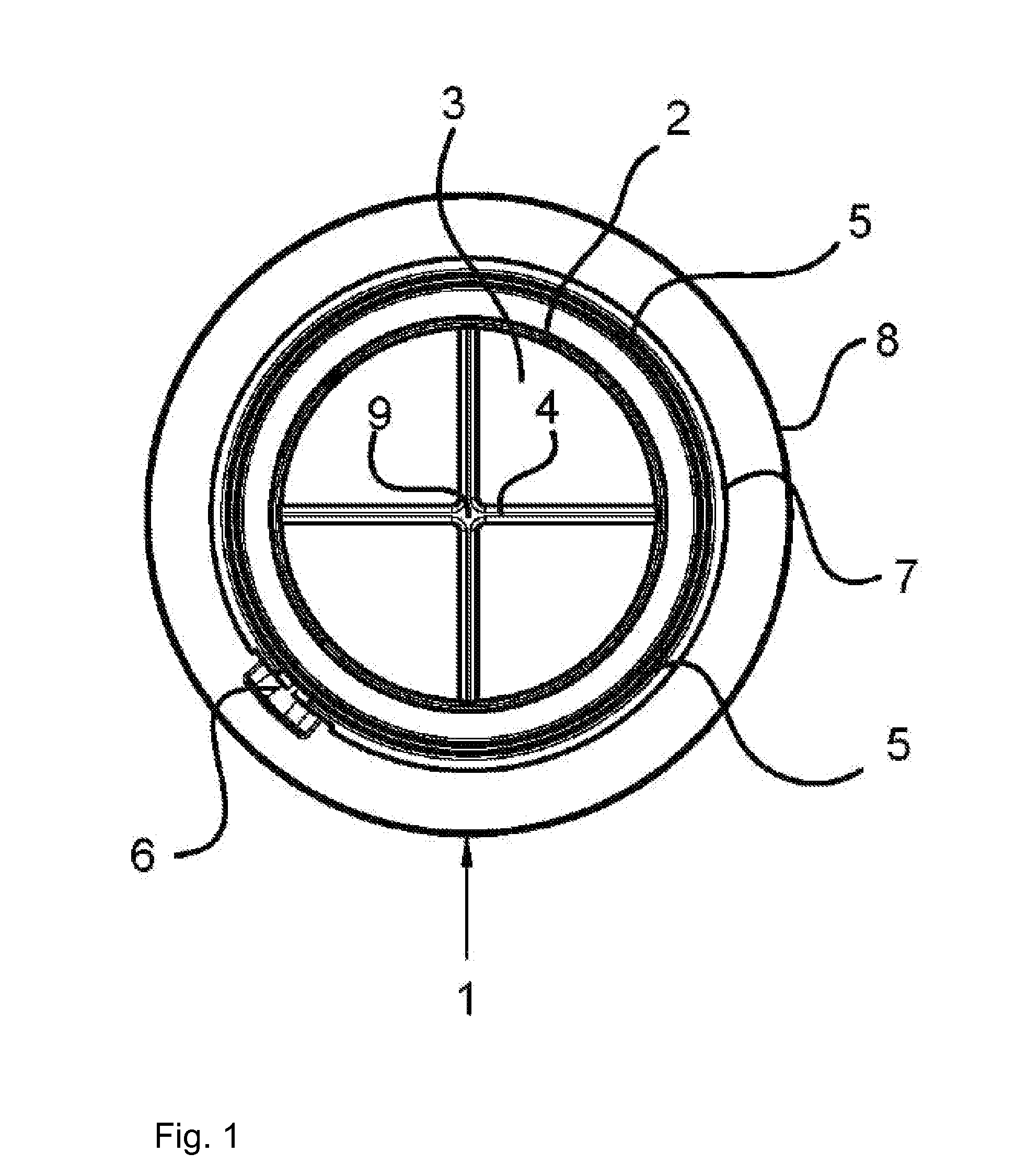

Moving walkway

The invention relates to a moving walkway transporting people on a grooved surface included in pallets (1) having the same pitch as the traction chain, all of them being able to be attached by means of pins (2) forming the actual traction chain between them, in which the pallets (1) are overturned by means of a guide (3) in which only three pallets are located, causing a quick overturning allowing the comb (5) to have sufficient inertia in its ribs (6) so as to support the loads which the users will apply to it in the direction (4).

Owner:THYSSENKRUPP ELEVATOR INNOVATION CENT SA +1

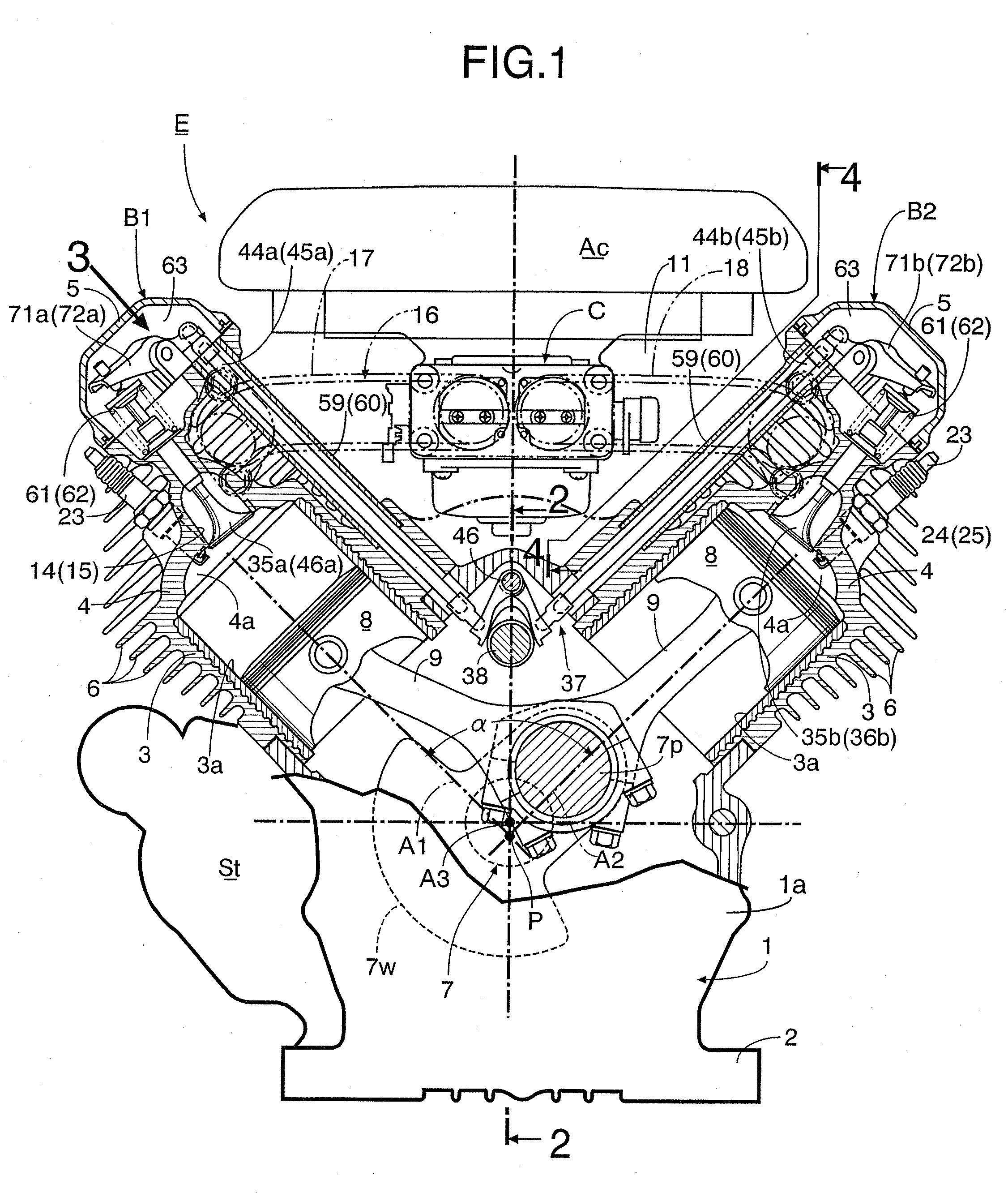

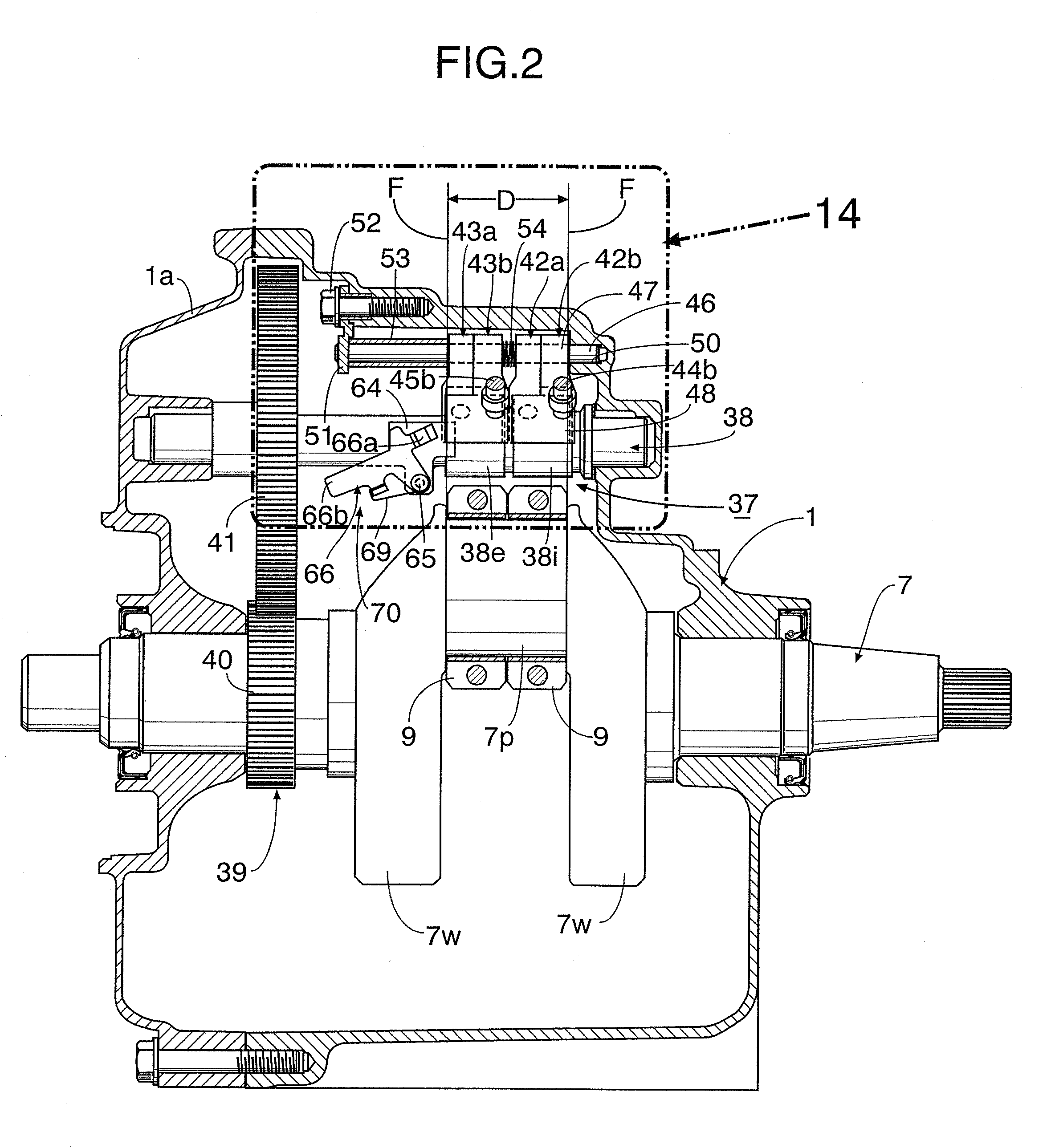

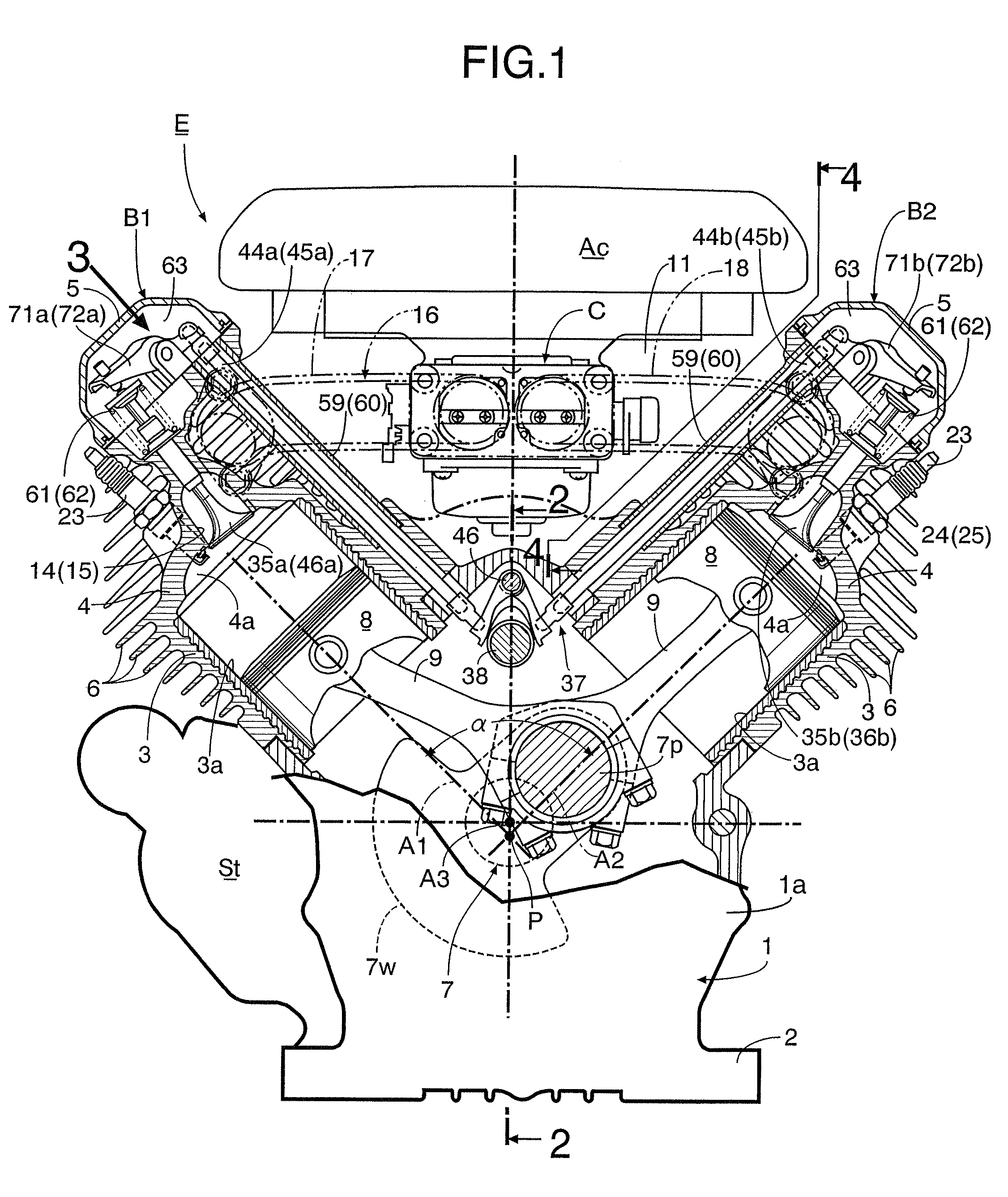

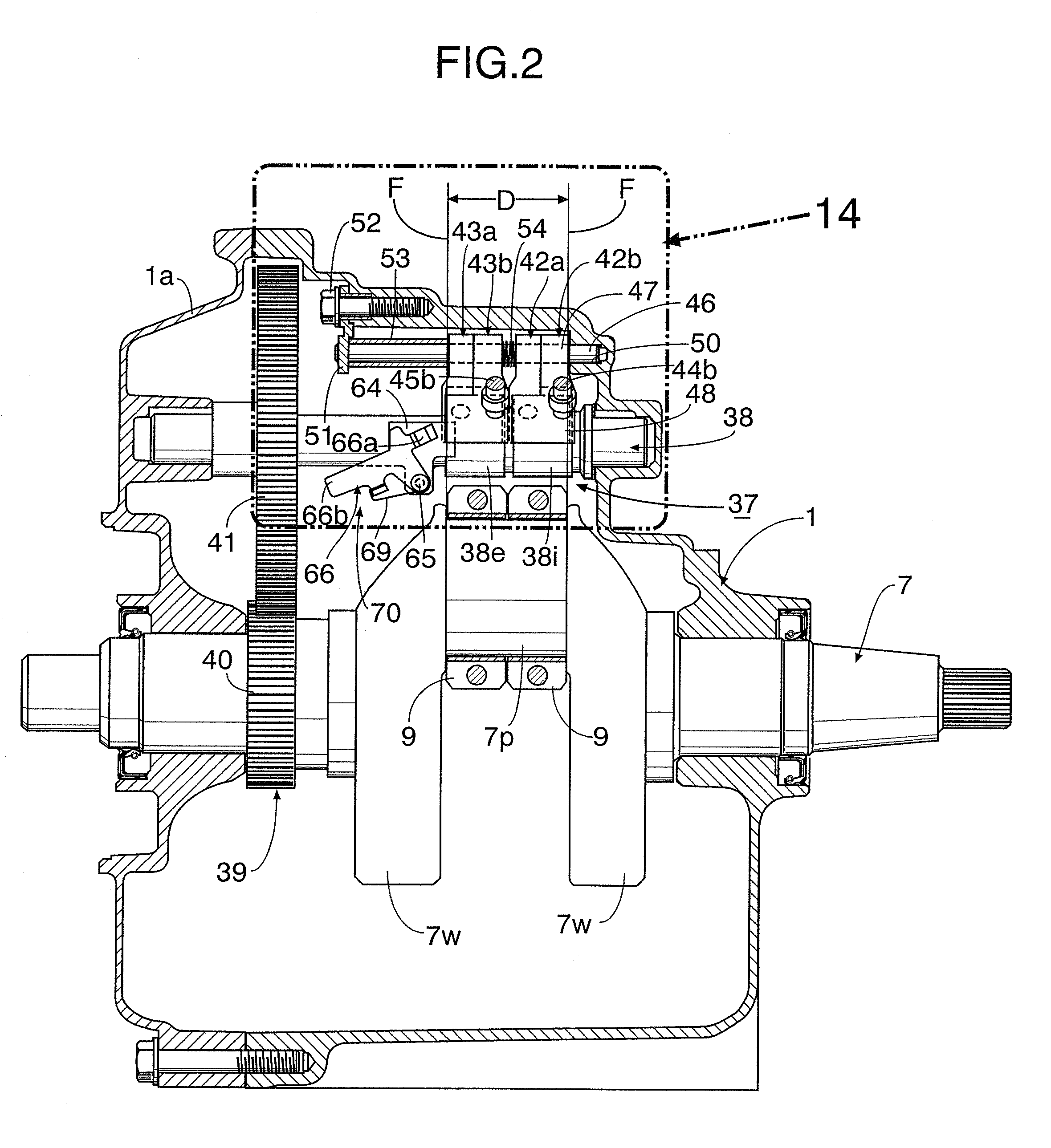

V-type engine

In a V-type engine, intake and exhaust rocker arms in each bank are arranged in a substantially inverted-V-shape in a plan view, so that side end portions of corresponding intake and exhaust push rods are positioned adjacent to each other. Slipper portions of first and second intake cam followers have end portions at one end along the axial direction of a camshaft protrude respectively in opposite directions to each other so that they face each other across an intake cam therebetween. Slipper portions of first and second exhaust cam followers have end portions at one end along the axial direction of the camshaft protrude respectively in opposite directions to each other so that they face each other across an exhaust cam therebetween. This reduces the distance between the push rods in each bank to provide a compact valve-operating device.

Owner:HONDA MOTOR CO LTD

Mobile rocker arm shaft type variable valve timing mechanism

ActiveCN102071982AImprove power performanceReduce pumping lossValve arrangementsInternal combustion piston enginesRocker armWheel drive

The invention relates to a mobile rocker arm shaft type variable valve timing mechanism of a single-cylinder internal combustion engine. The mechanism is structurally characterized in that: a rocker arm shaft and a high-speed rocker arm can move together along the axis of the rocker arm shaft; and the high-speed rocker arm and a low-speed rocker arm are combined or separated. When the high-speed rocker arm and the low-speed rocker arm are in a combination state, a high-speed cam drives the high-speed rocker arm and drives the low-speed rocker arm to swing together, and the high-speed cam drives a valve to open and close, so the mechanism is suitable for the high-speed and large-load working conditions of the internal combustion engine; and when the high-speed rocker arm and the low-speed rocker arm are in a separation state, a low-speed cam drives the low-speed rocker arm and the valve to open and close, so the mechanism is suitable for the low-speed working conditions and small-load working conditions of a gasoline engine. The variable valve timing mechanism has simple structure, can obviously enhance the dynamic property and economy of the internal combustion engine, and is particularly suitable for a single overhead camshaft type single-cylinder four-stroke internal combustion engine.

Owner:SHANDONG UNIV

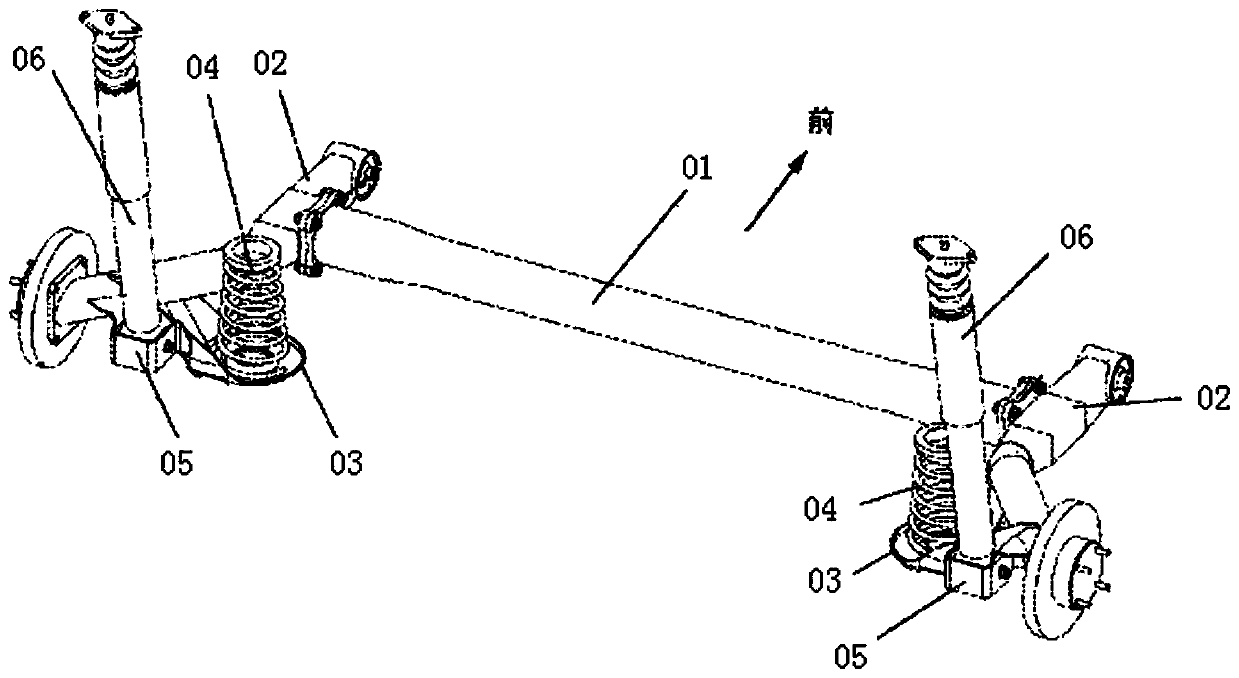

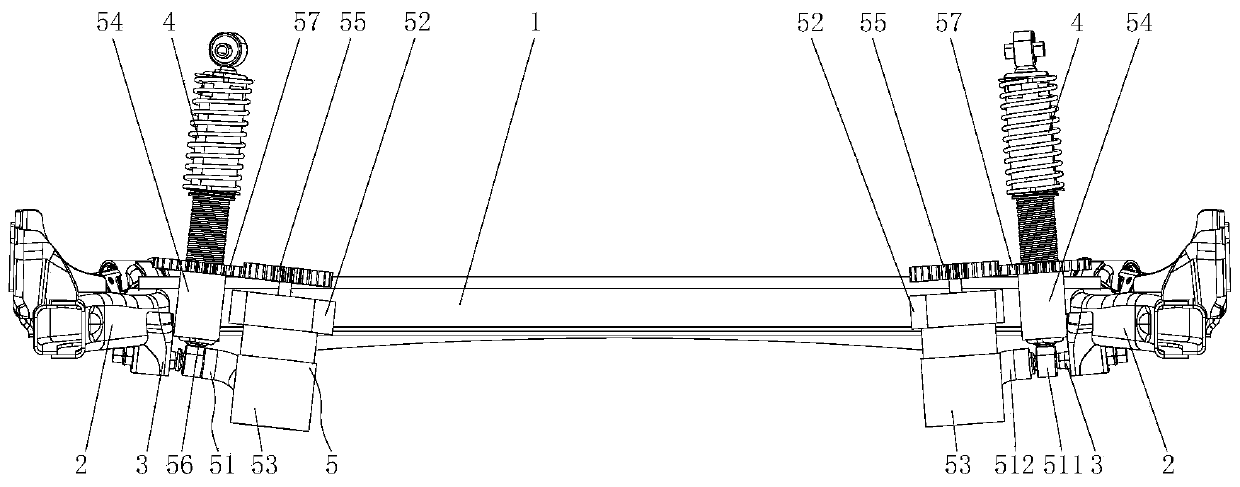

Torsion beam suspension structure capable of active lifting

PendingCN110001344ACompact structureStable center of gravityInterconnection systemsResilient suspensionsEngineeringDrive motor

The invention relates to a torsion beam suspension structure capable of active lifting. The torsion beam suspension structure comprises a torsion beam, two suspension longitudinal arms, two shock absorber mounting support frames, two shock absorbers and a lifting and lowering driving mechanism for driving the two shock absorbers to perform synchronous opposite lifting and lowering movement, wherein the lifting and lowering driving mechanism comprises two sleeves, two driving motors, two motor bushings and two shock absorber bushings; the two sleeves are separately arranged on the two shock absorber mounting support frames in a movable and sleeving manner; one end of each of the two sleeves is fixed to the side wall of the corresponding motor bushing; the two driving motors are separately mounted in the two motor bushings in an erect manner; output shafts of the two driving motors are separately and fixedly sleeved with two first external gears; the lower ends of the two shock absorberbushings are separately and rotationally connected to the outer walls of the two sleeves; the upper ends of the two shock absorber bushings are separately and fixedly sleeved with two second externalgears which mesh with the two first external gears; the lower ends of the two shock absorbers are separately arranged in the two shock absorber bushings in a lifting and lowering manner; and the lowerends of the two shock absorbers are separately in threaded connection with the two second external gears.

Owner:FUJIAN UNIV OF TECH

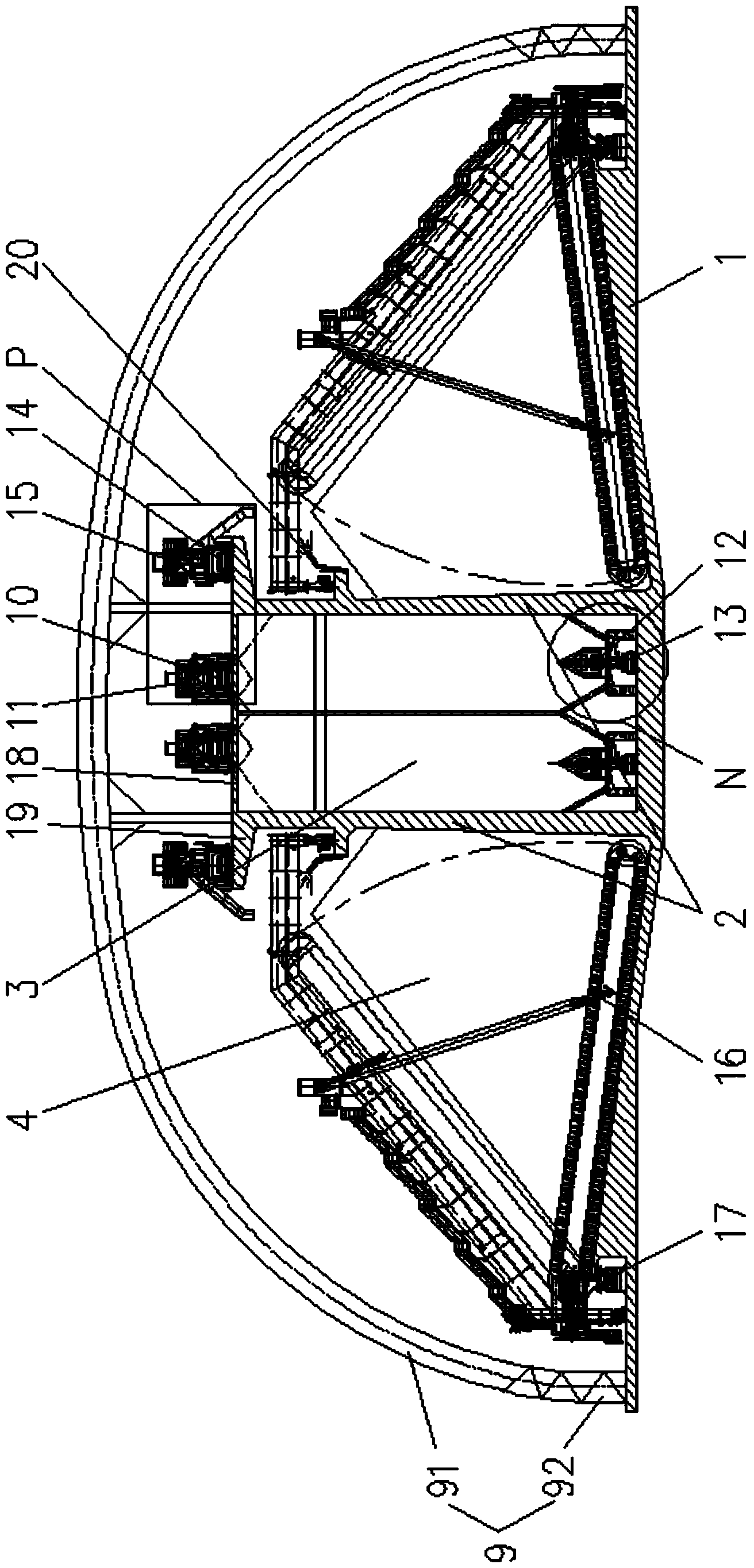

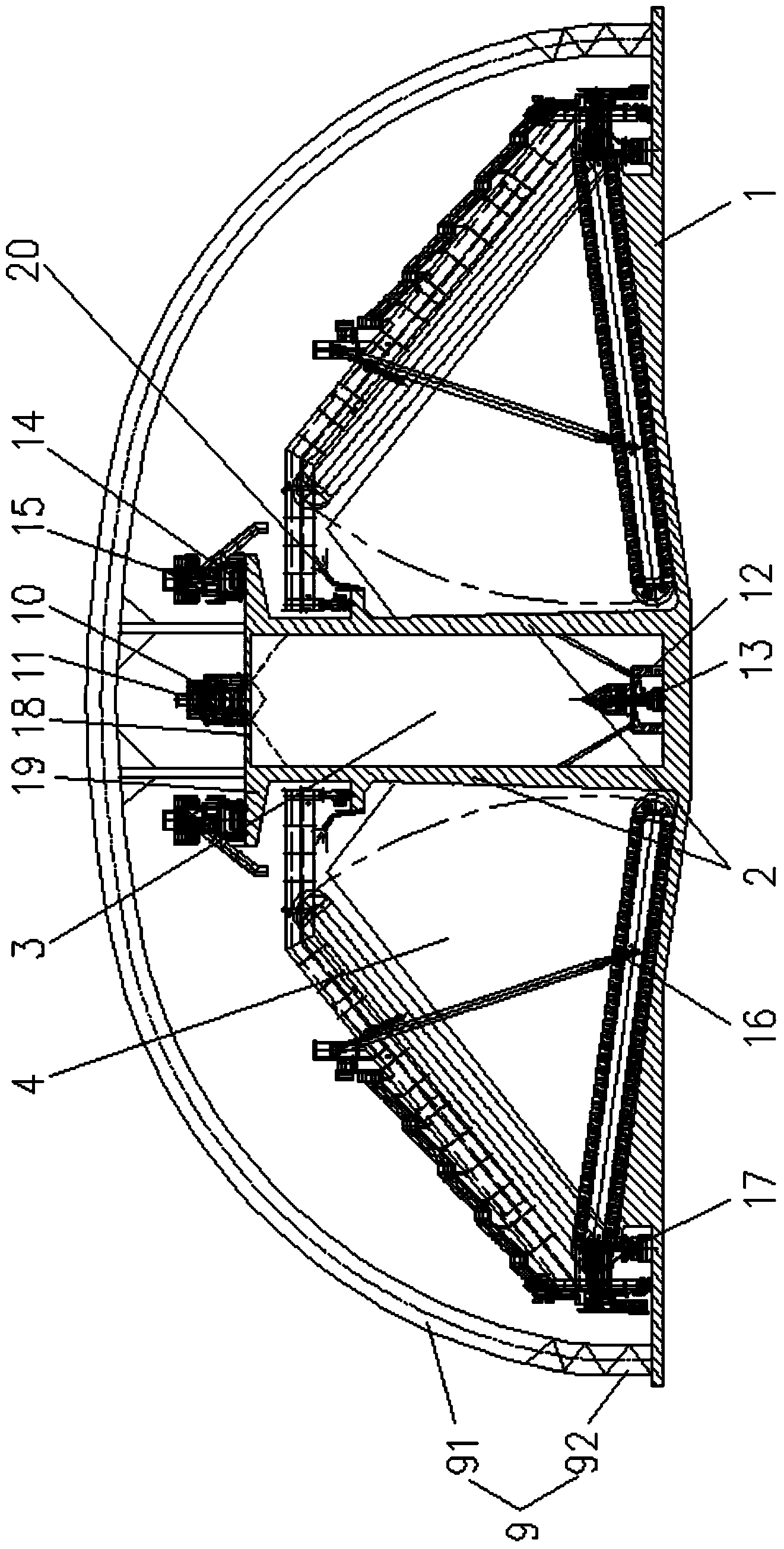

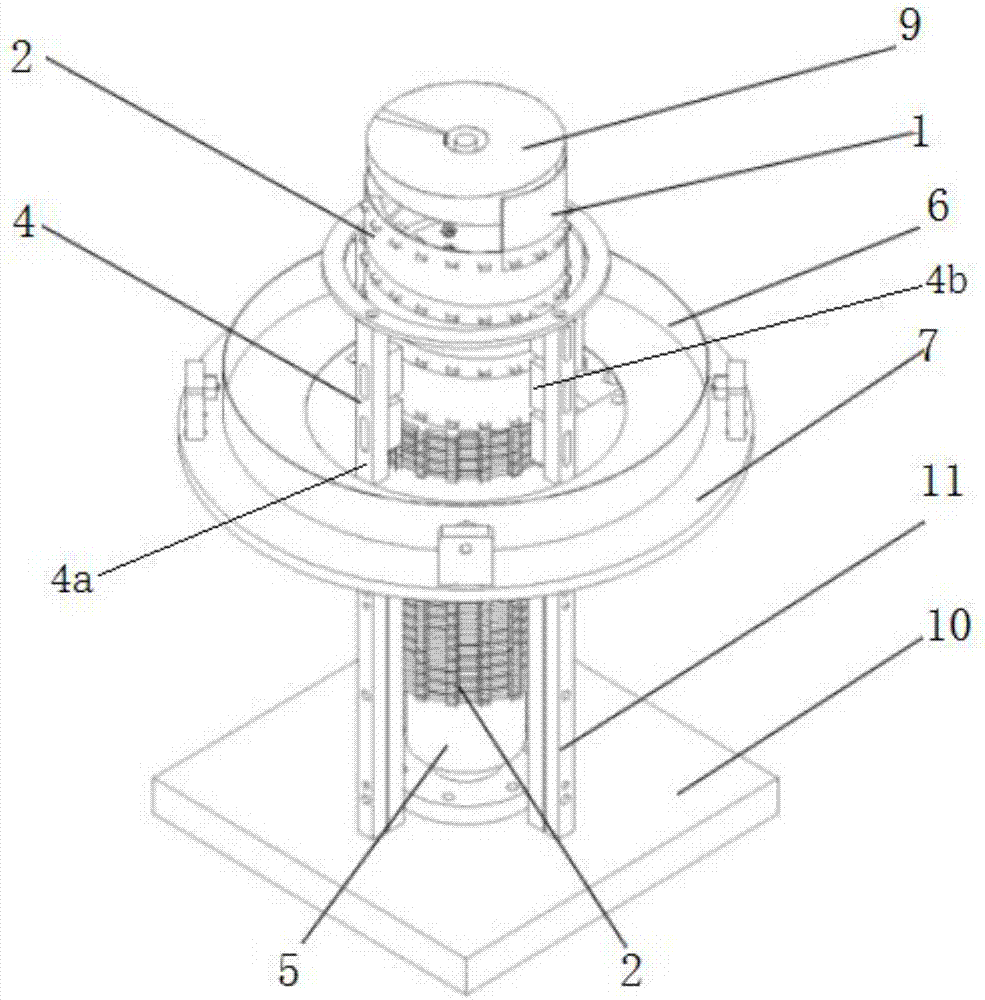

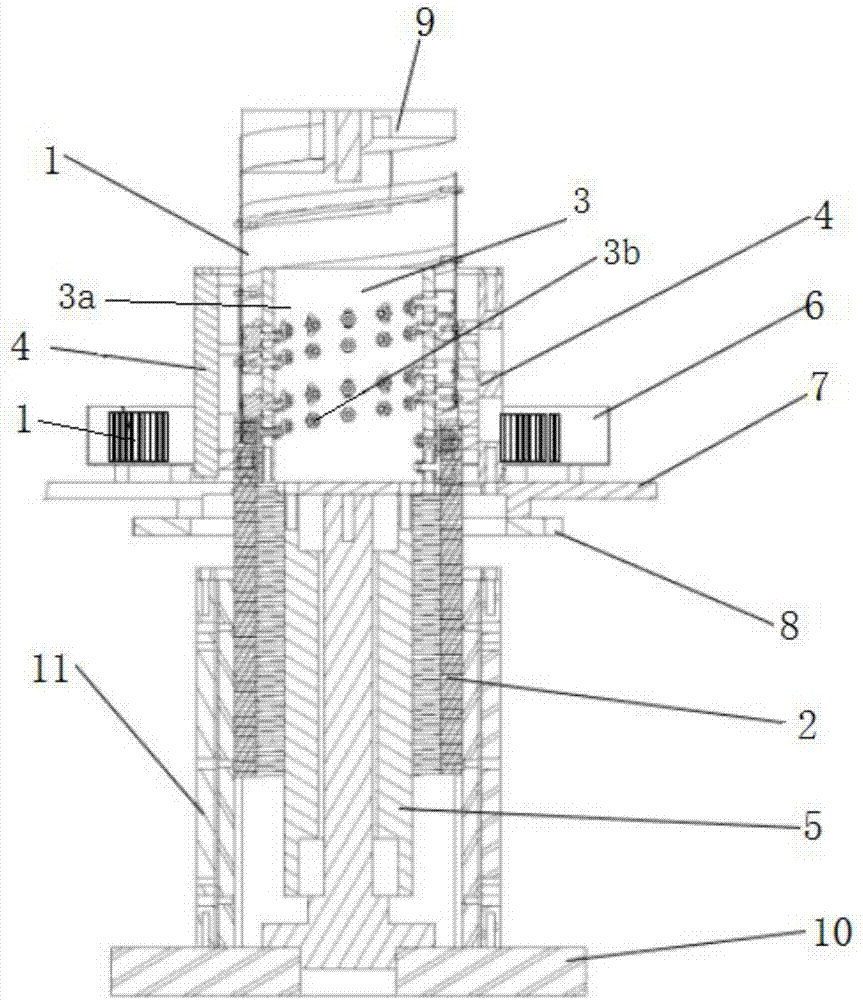

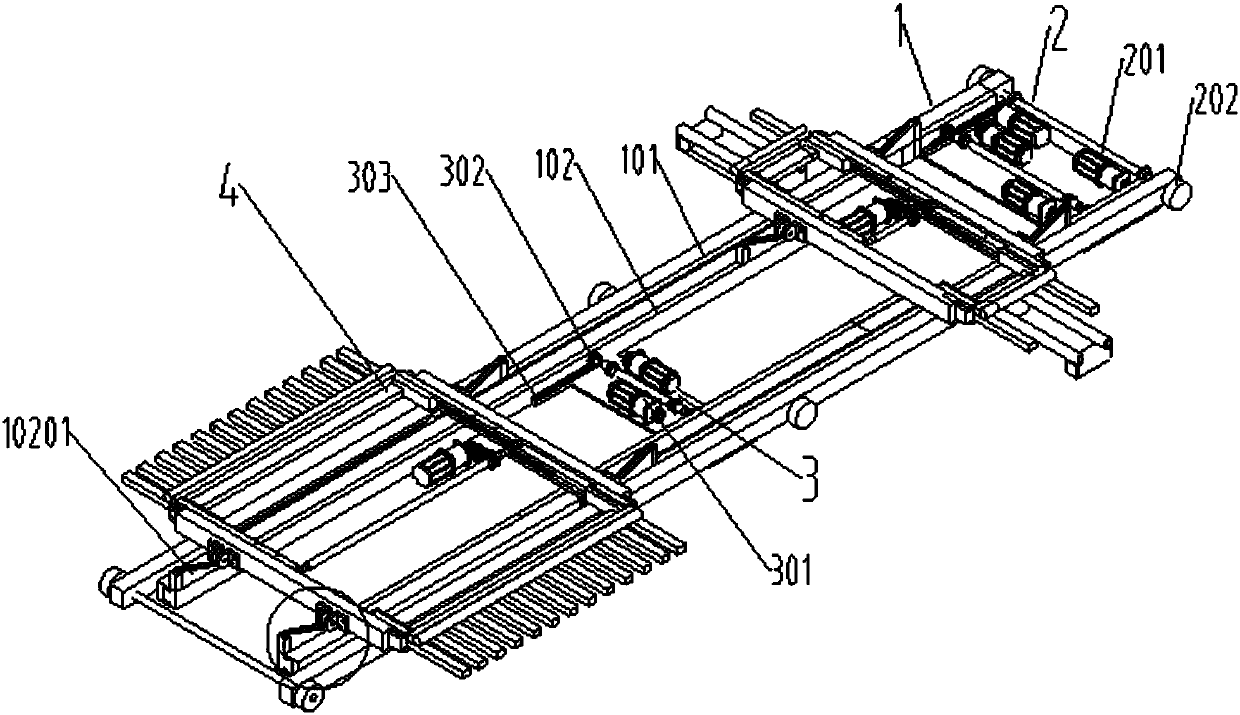

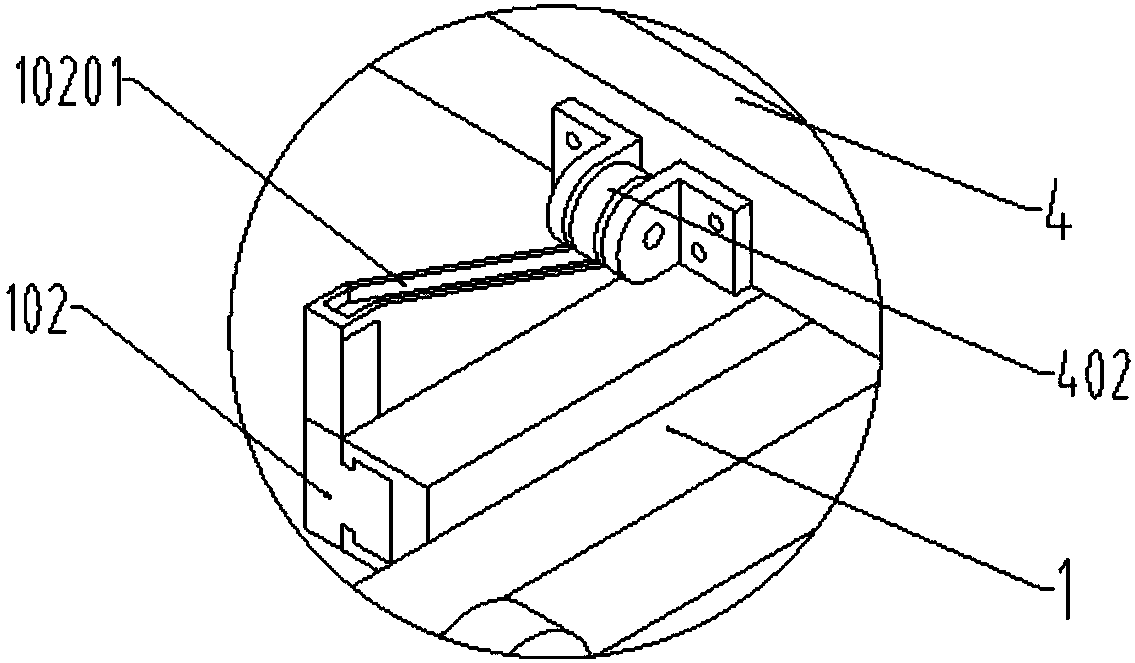

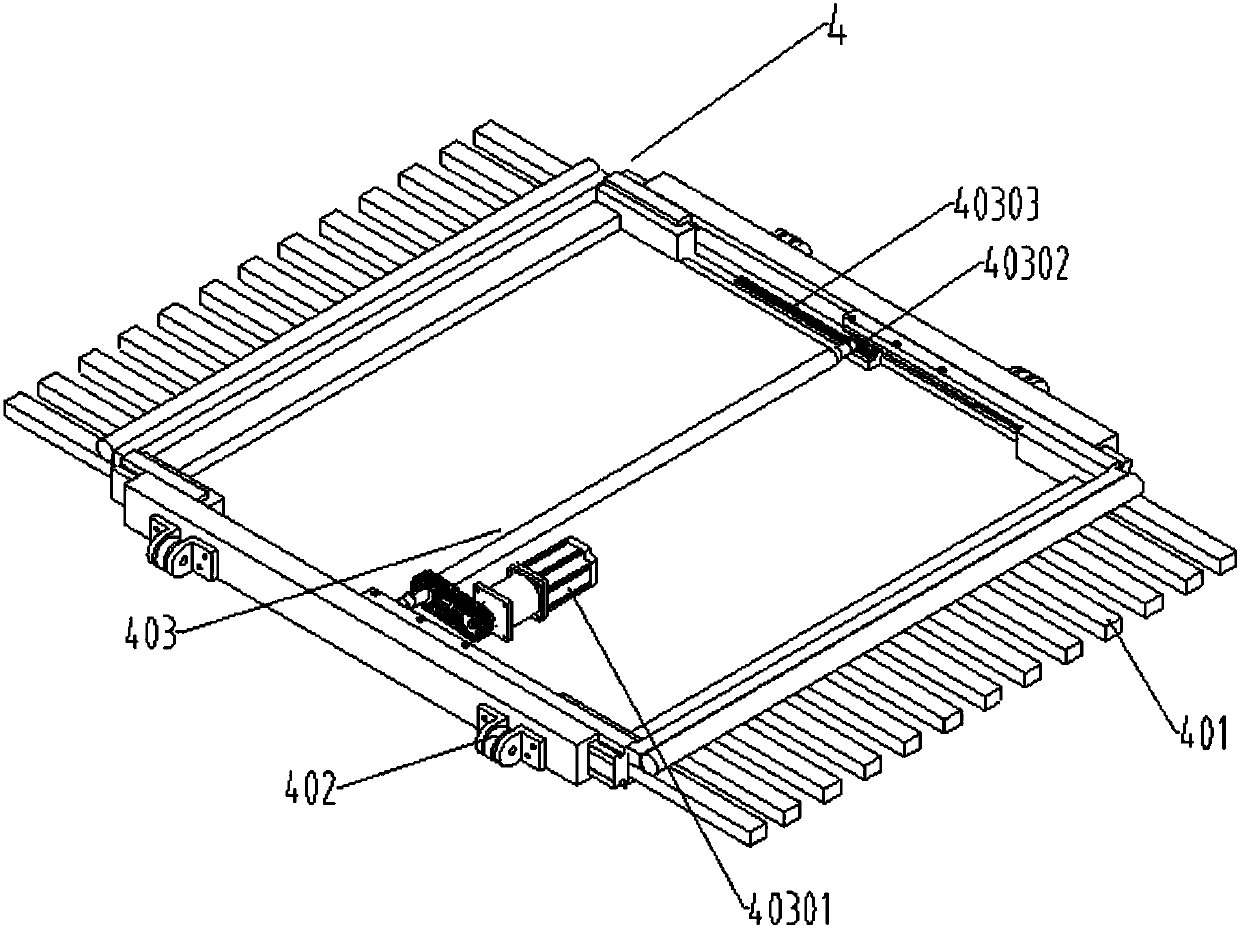

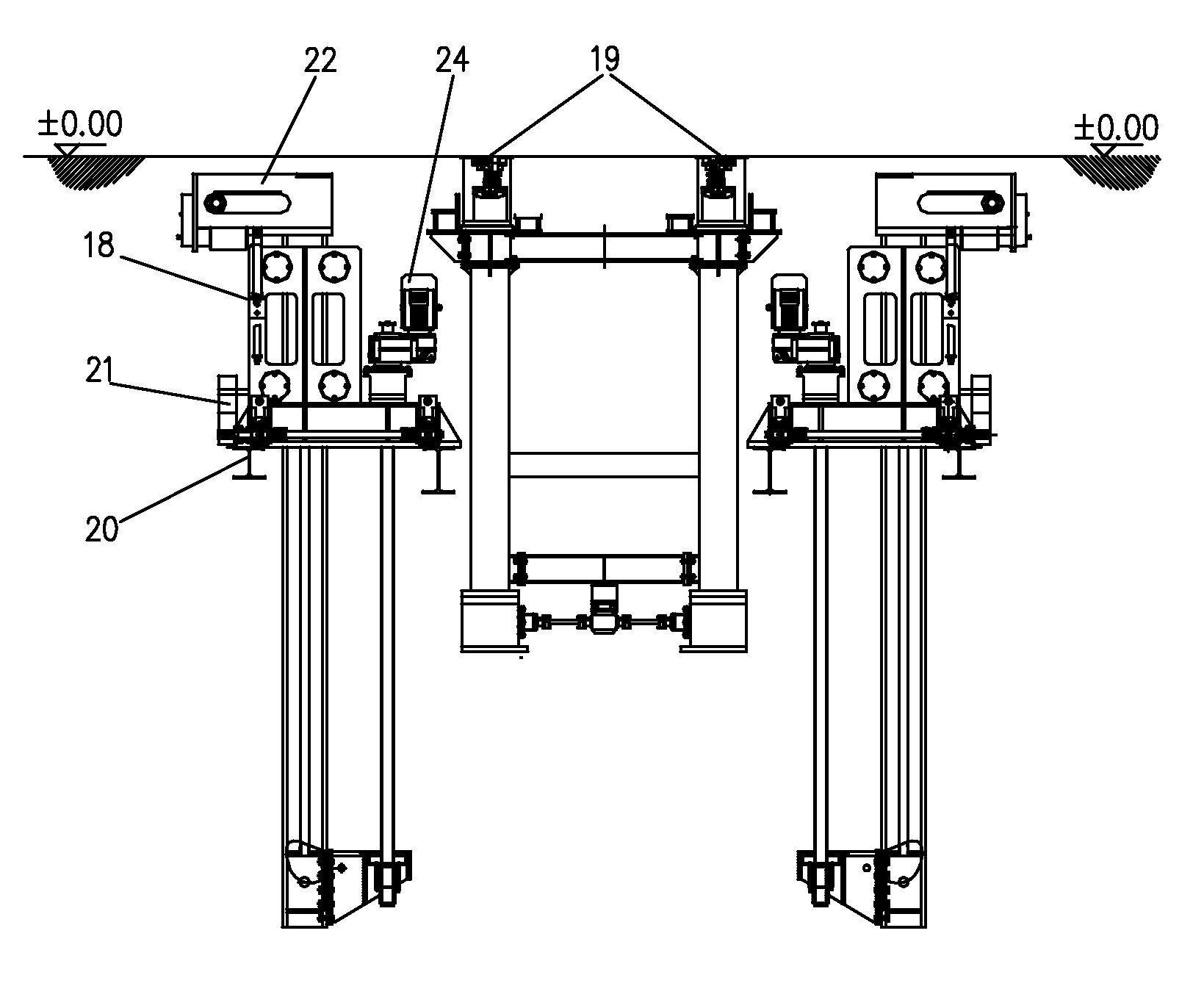

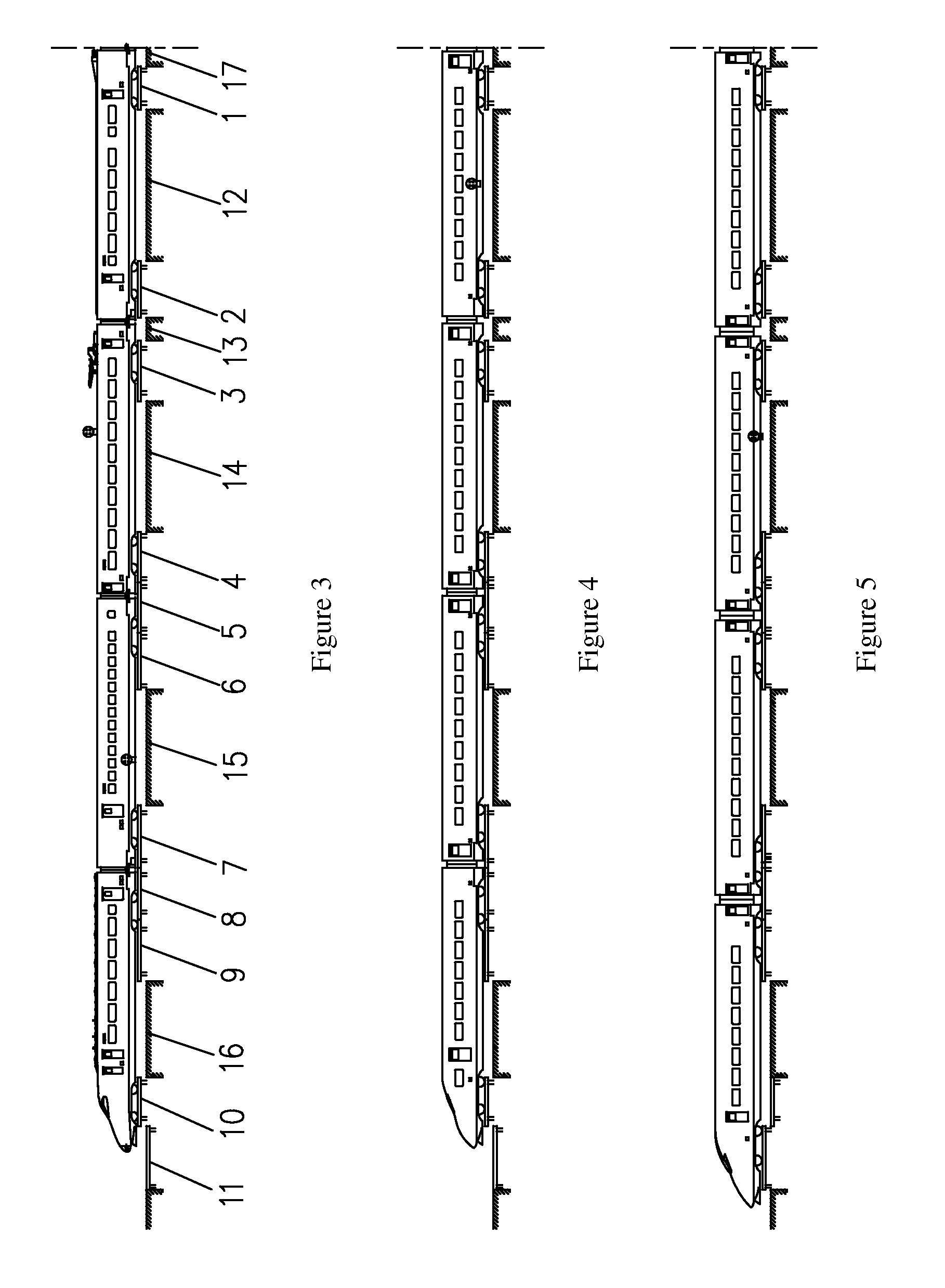

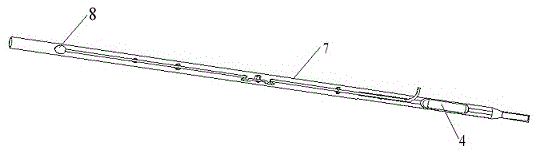

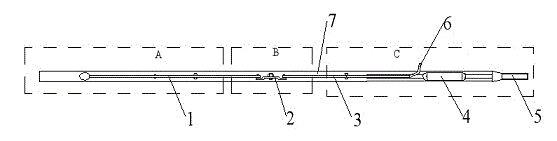

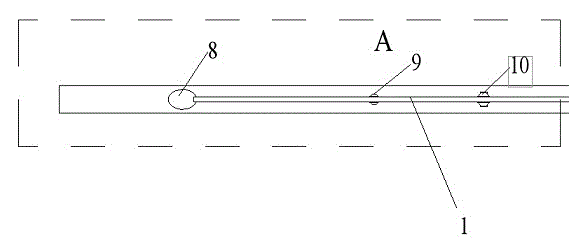

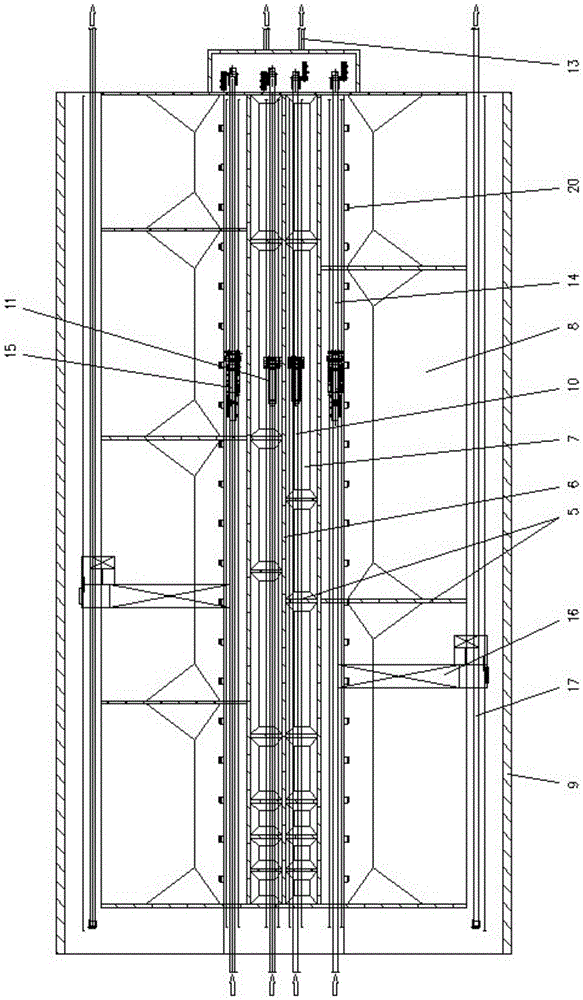

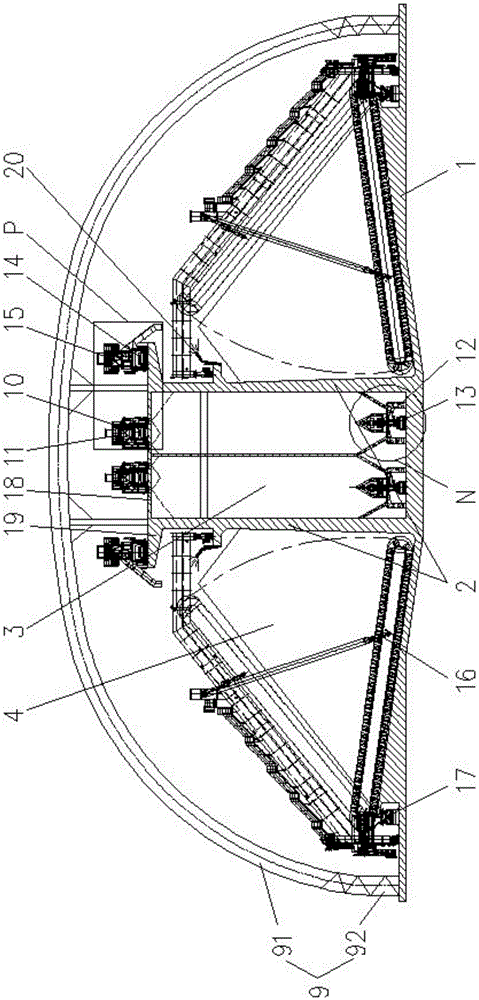

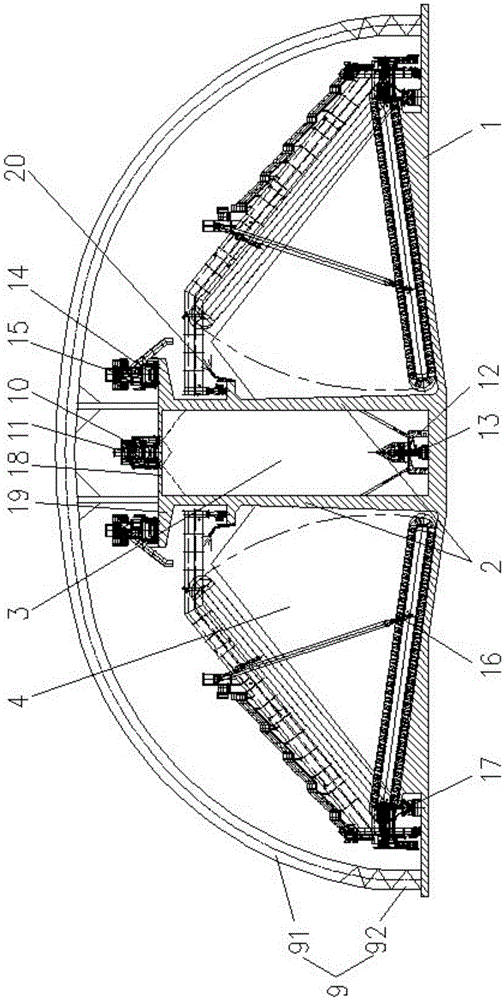

Under-floor lifting jack for high-speed electric multiple unit trainset

ActiveUS9045150B2Reduce positioning errorsIncrease the number ofArtificial islandsLifting framesBogieUnit train

The invention discloses an under-floor lifting jack for high-speed EMU train, comprising: a main control electric part for controlling the jack, multiple bogie lifting means arranged in pits, fixed rails on the ground between adjacent pits, and body hoists movable along dedicated rails on both sides of the bogie lifting means, wherein lifting rails of the bogie lifting means and the fixed rails form continuous rails, and one or more of the bogie lifting means are set in each pit and adapted for lifting individually or synchronously in combination according to the wheel positions of different types of electric multiple unit trains under the control of the main control electric part. The invention is compatible with the maintenance of various EMU trains, thus the same lifting jack can satisfy maintenance requirements of various EMU trains, resulting in high compatibility and construction cost-reduction of the maintenance base for the EMU train.

Owner:BEIJING RAILWAY INST OF MECHANICAL & ELECTRICAL ENG

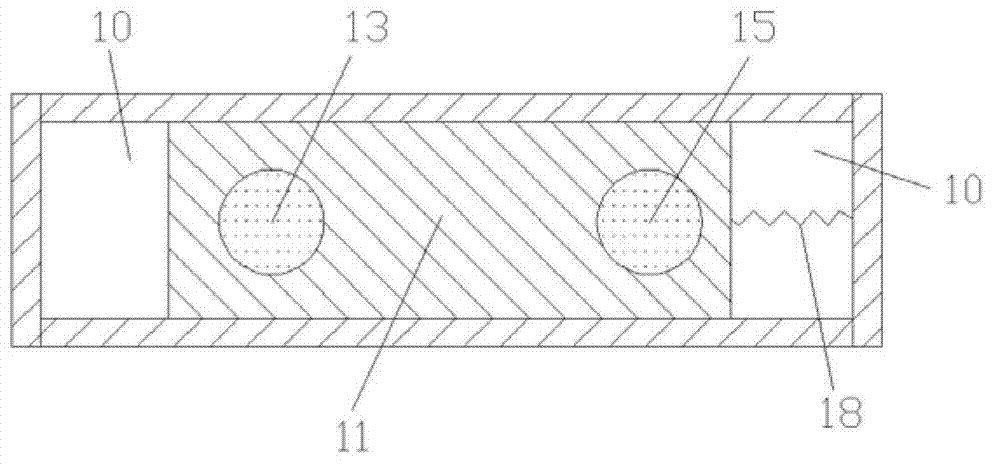

Button-relay-type sheng pipe

ActiveCN105304070ASmall liftShow emotion effectivelyAgriculture gas emission reductionWind musical instrumentsEngineeringRelay

The invention discloses a button-relay-type sheng pipe. A button of the sheng pipe is formed by combining three sections, and action for triggering the button is transmitted in a relay manner through the sections, so that action delay caused by material tenacity can be eliminated effectively, sounding is timely, and colliding noise generated by a sound window hole cover can be lowered remarkably. By using a Sheng made by using the sheng pipe, a player can better present own playing talent incisively and vividly, and both the player and audience can acquire satisfactory effect.

Owner:涿州市赵家笙乐器销售有限公司

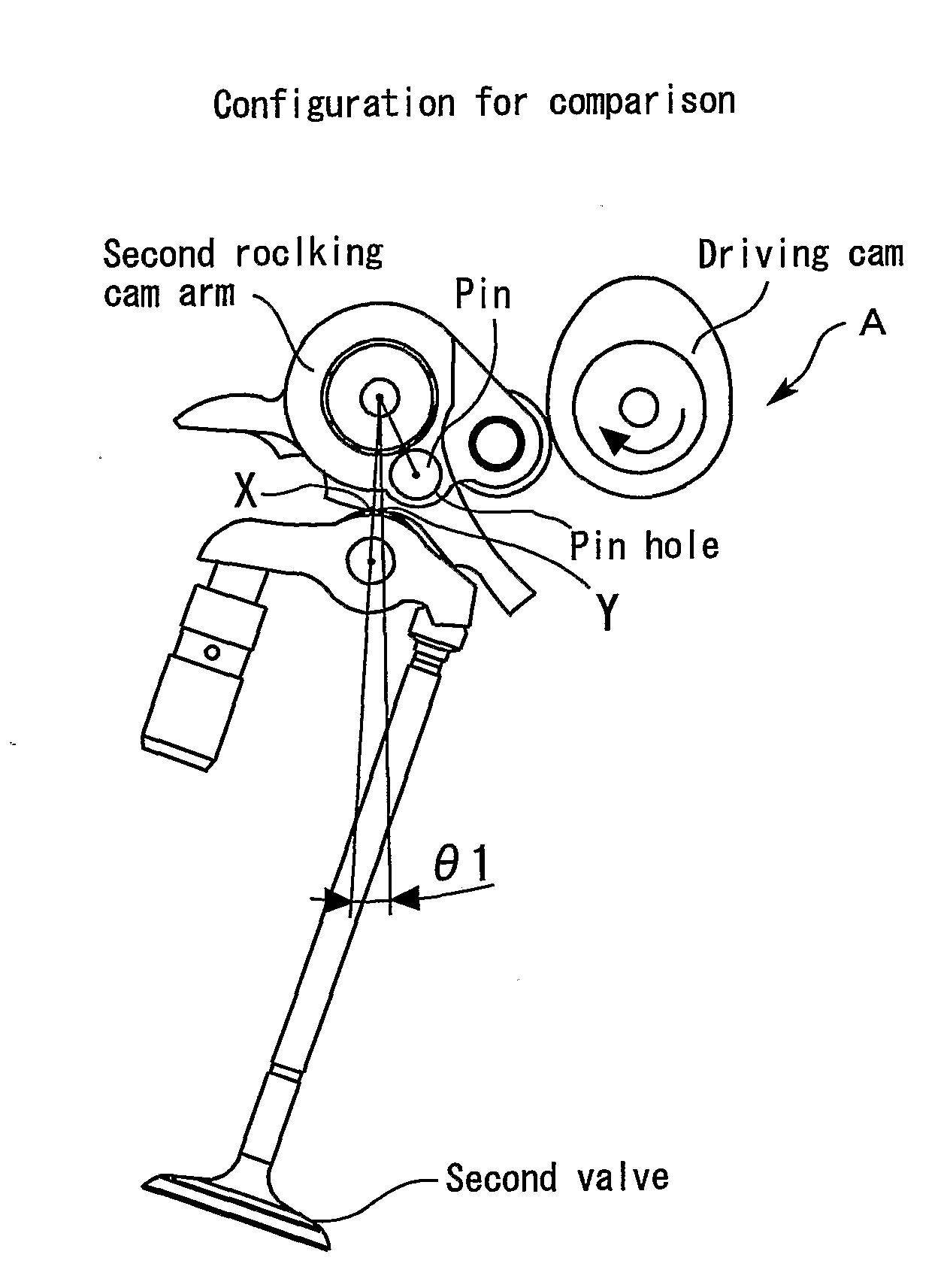

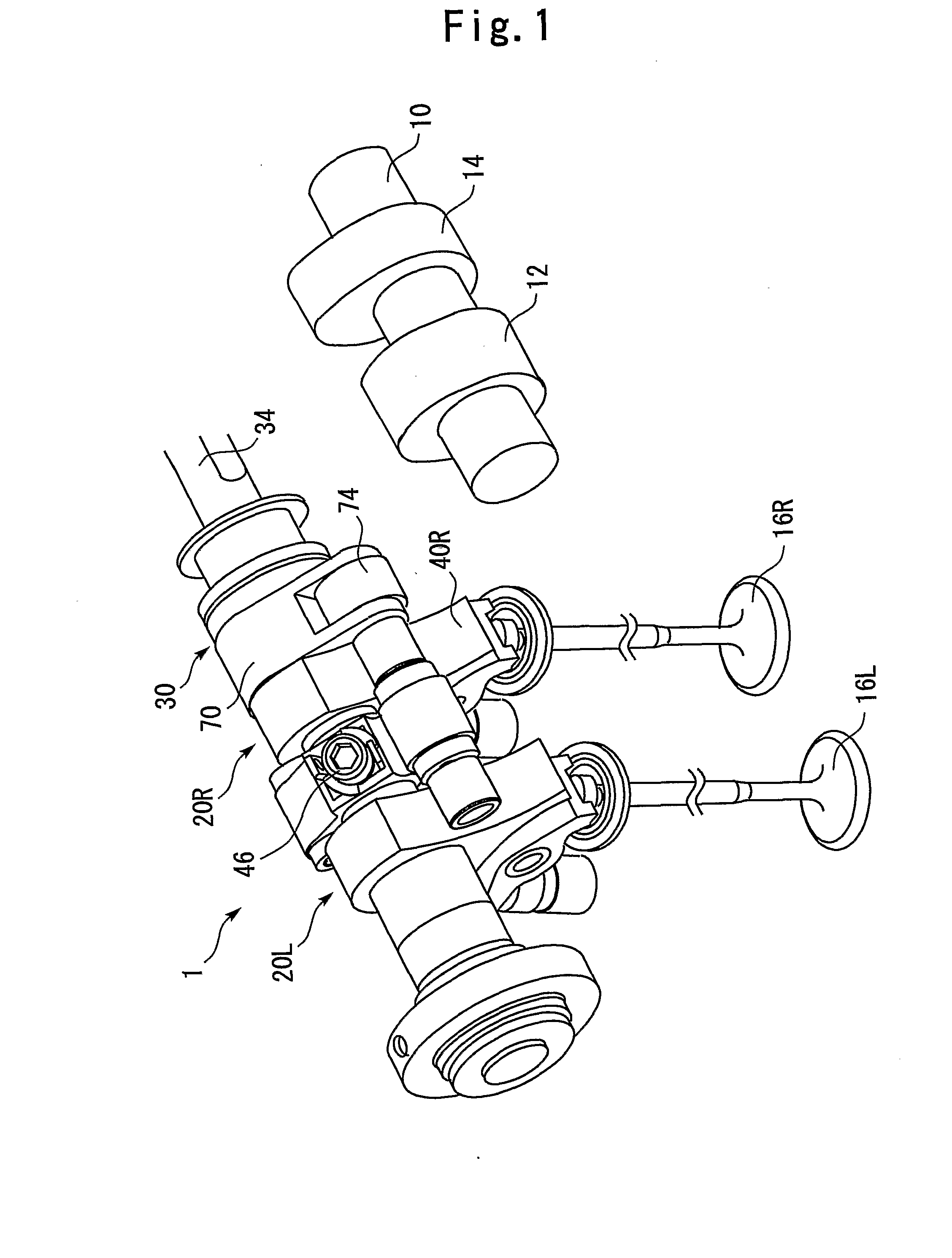

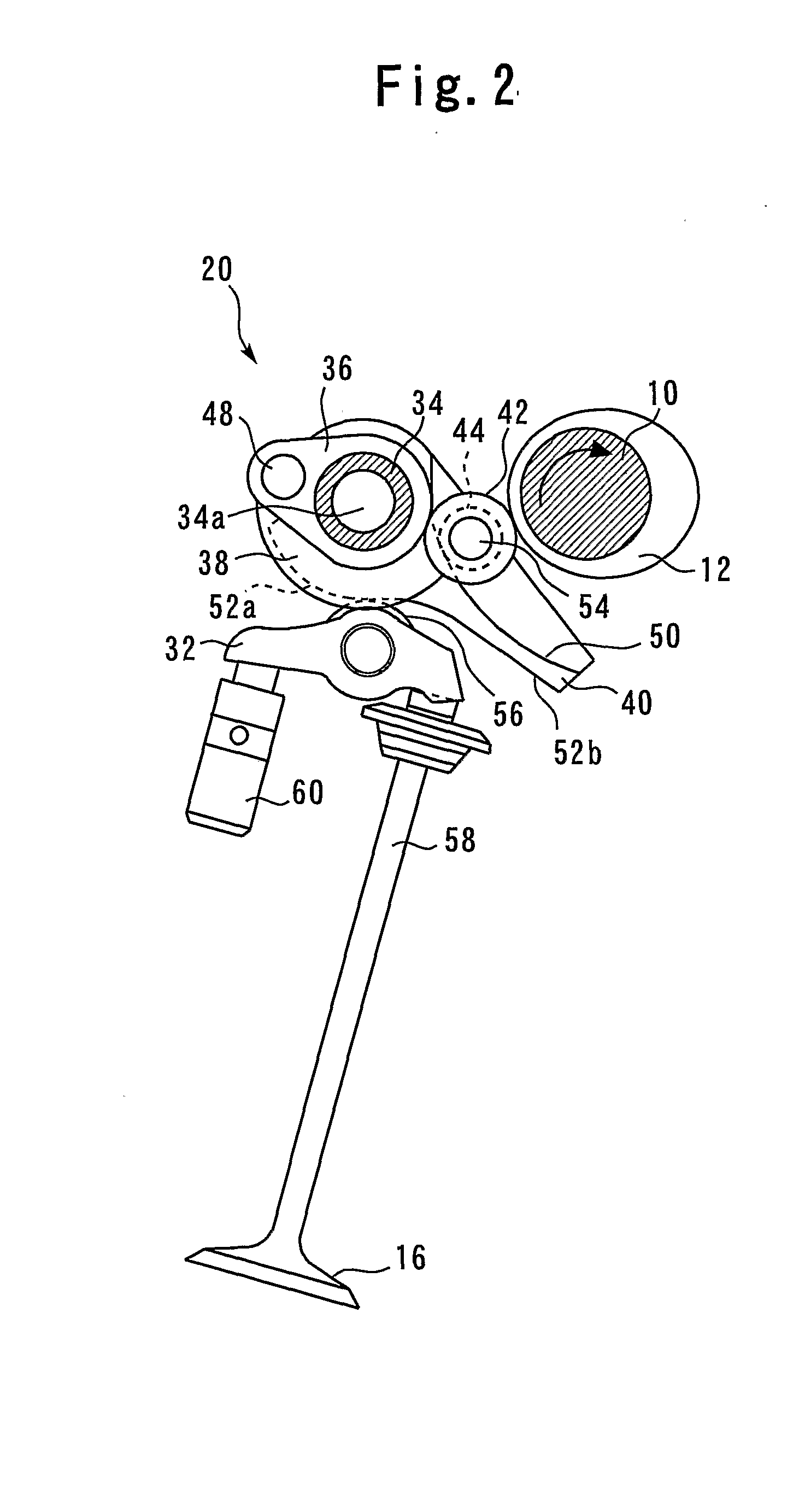

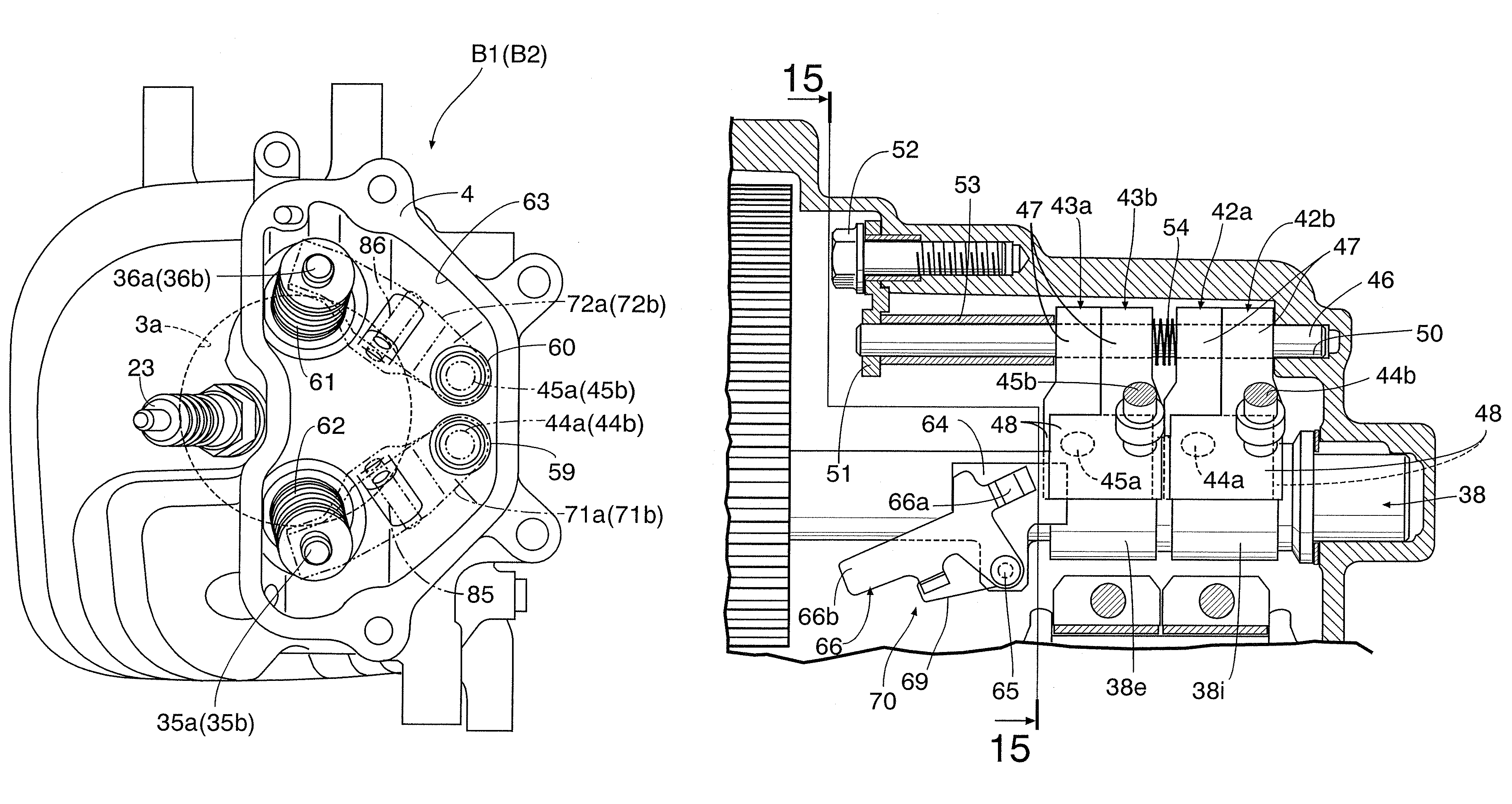

Variable valve apparatus

InactiveUS20090044771A1Limited operating timeSmall liftValve arrangementsMachines/enginesEngineeringCam

An arm coupling mechanism for selectively switching a double valve variable control and single valve variable control. The single valve variable control is achieved in a condition in which a large lift arm and a second rocking cam arm are coupled together with a pin. The second rocking cam arm for moving a second valve includes a pin hole, in which the pin is inserted, formed therein. The position of the pin hole is set so that a pin switching operation can be executed when control is provided to achieve an operating angle, at which the single valve variable control is to be started for reduced NOx. A second driving cam is adapted to have a cam height greater than a cam height of a first driving cam.

Owner:TOYOTA JIDOSHA KK

V-type engine

In a V-type engine, intake and exhaust rocker arms in each bank are arranged in a substantially inverted-V-shape in a plan view, so that side end portions of corresponding intake and exhaust push rods are positioned adjacent to each other. Slipper portions of first and second intake cam followers have end portions at one end along the axial direction of a camshaft protrude respectively in opposite directions to each other so that they face each other across an intake cam therebetween. Slipper portions of first and second exhaust cam followers have end portions at one end along the axial direction of the camshaft protrude respectively in opposite directions to each other so that they face each other across an exhaust cam therebetween. This reduces the distance between the push rods in each bank to provide a compact valve-operating device.

Owner:HONDA MOTOR CO LTD

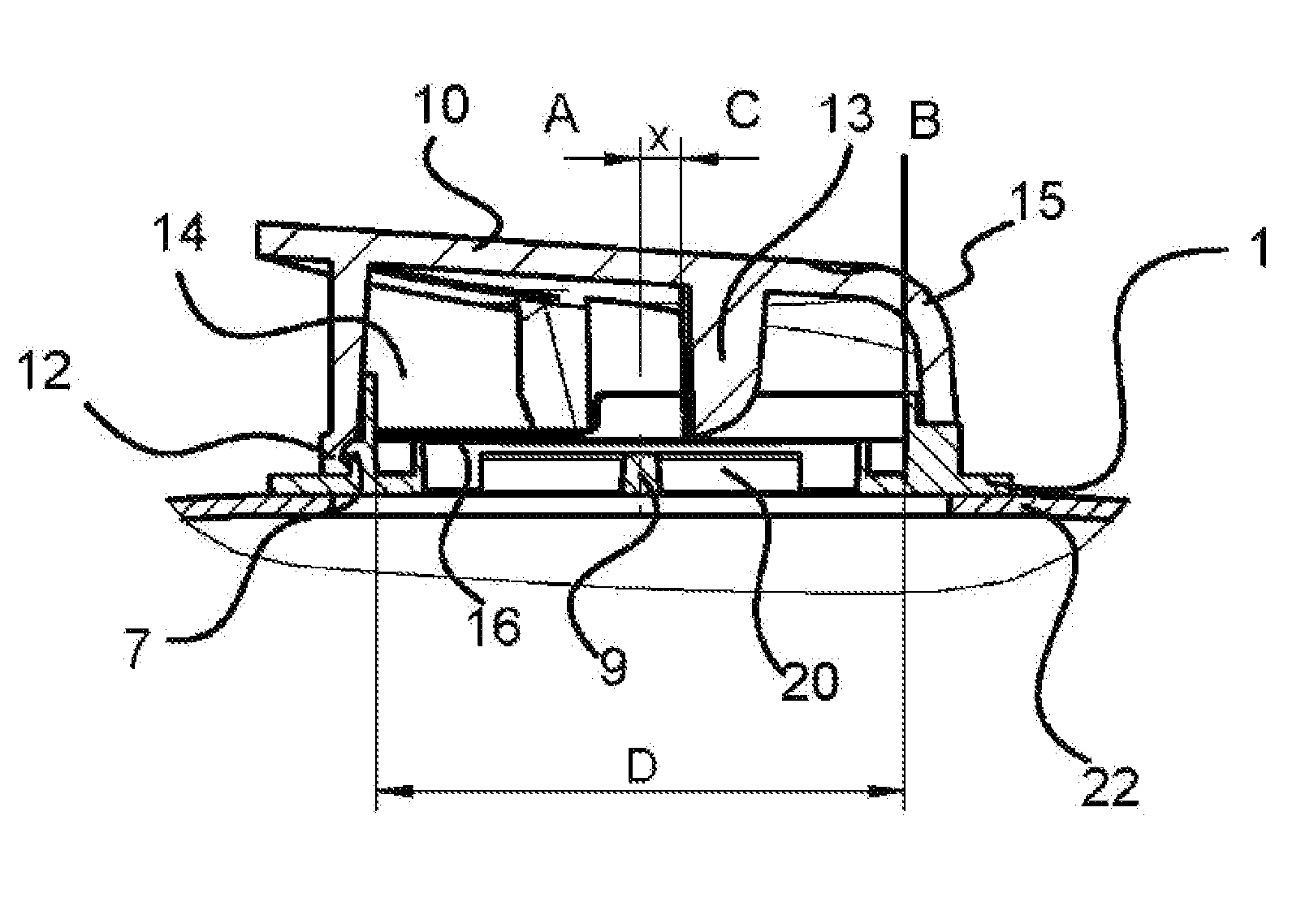

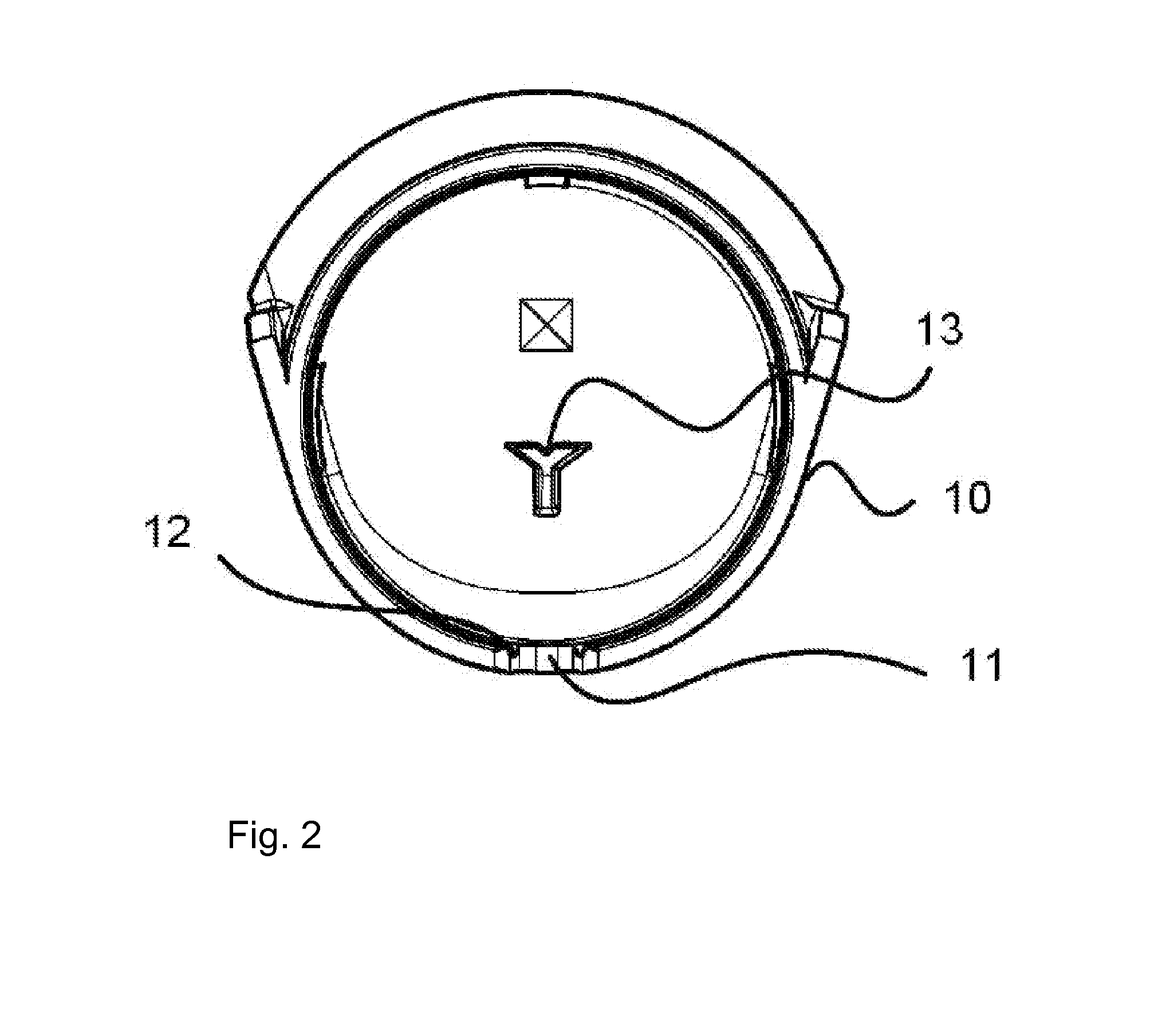

Directional valve and breathing mask with a directional valve

ActiveUS20130068232A1Low flow resistanceStable fastening of the valve membraneBreathing masksVALVE PORTBreathing

A directional valve includes a fixing lug (13), which is arranged eccentrically to a valve membrane (16) and is arranged at a valve housing (15). The dimensions of the fixing lug (13) are selected for fixing the valve membrane (16) relative to the sealing surface (2) of valve seat (1). The size of the eccentric offset (x) is in a range between 8% and 15% of the axis length (D) of the greatest longitudinal extension of valve membrane (16).

Owner:DRAGER SAFETY

Storage device for storage yard and closed storage yard

ActiveCN103640832BIncrease storage capacityImprove space utilizationStorage devicesLoading/unloadingEngineeringYard

Owner:CISDI ENG CO LTD

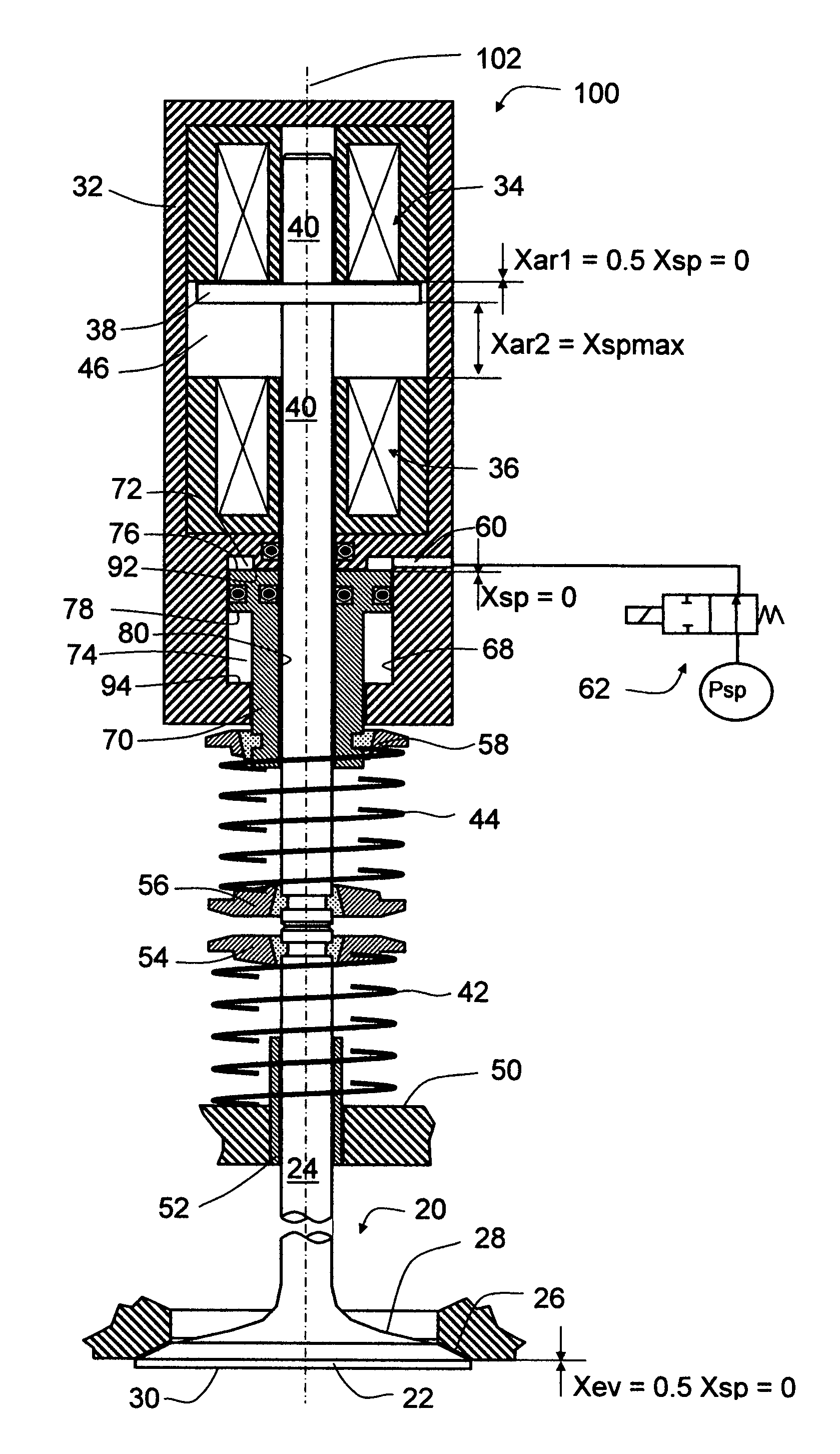

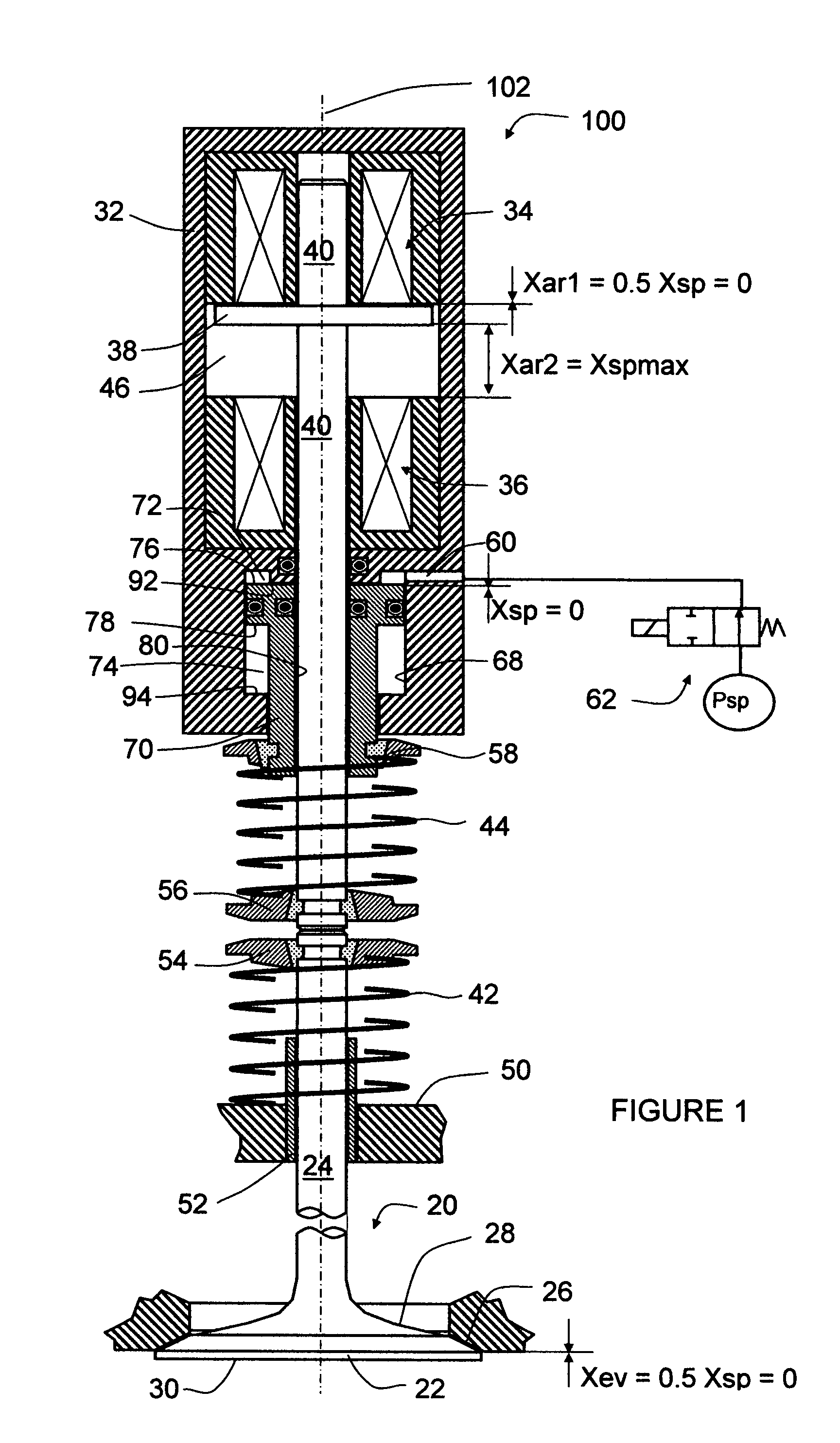

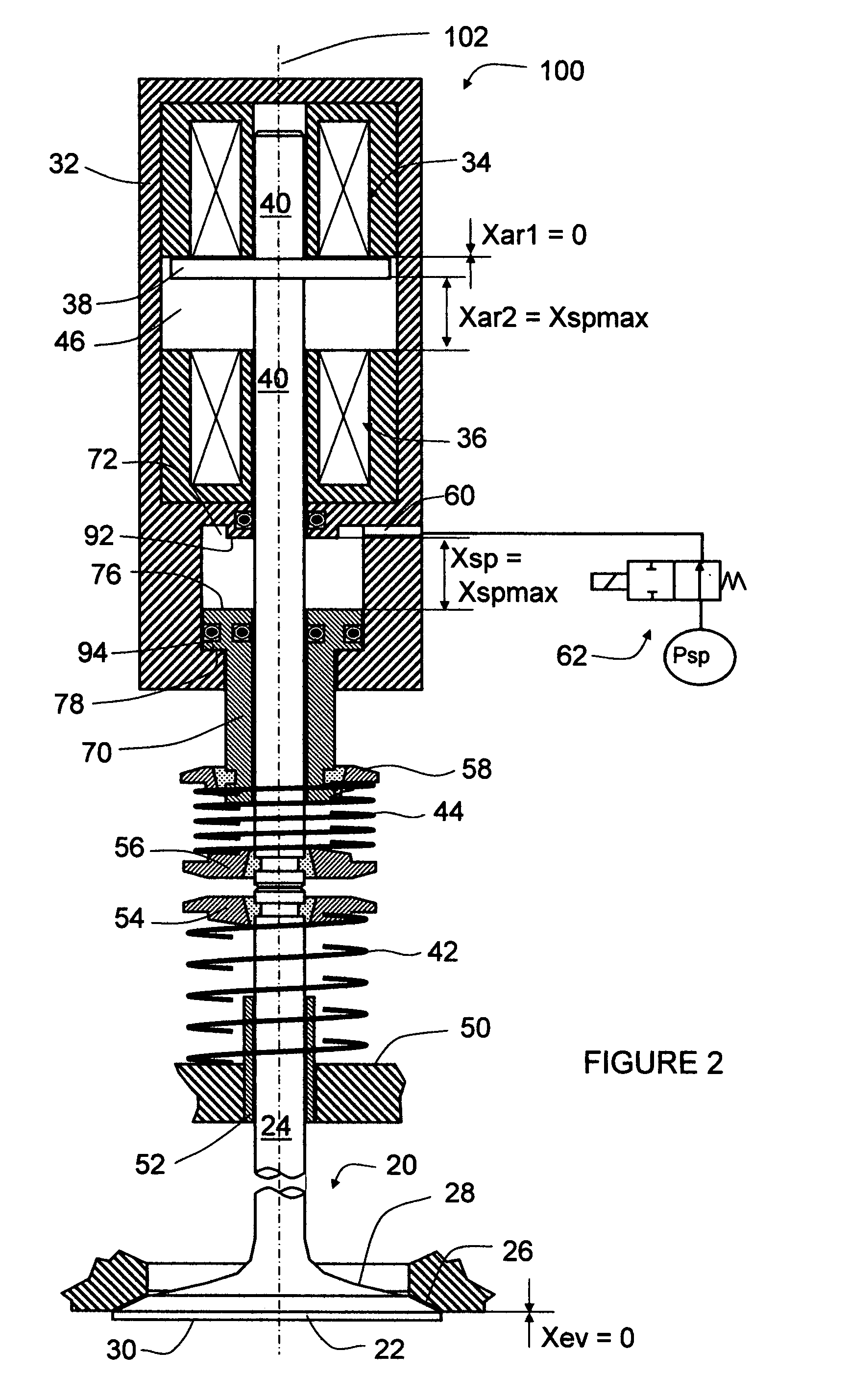

Electromechanical variable valve actuator with a spring controller

InactiveUS7591237B2Guaranteed uptimeEfficiently and effectively operateMachines/enginesNon-mechanical valveValve actuatorEngineering

Actuators, and corresponding methods and systems for controlling such actuators, provide independent lift and timing control with minimum energy consumption. In an exemplary embodiment, an electromechanical actuator comprises a housing, first and second electromagnets rigidly disposed in the housing and separated from each other by an armature chamber, an armature disposed in the armature chamber and movable between the first and second electromagnets, an armature rod rigidly connected with the armature and operably connected with a load, at least one first actuation spring biasing the armature in a first direction, at least one second actuation spring biasing the armature in a second direction, and one fluid-operated spring controller capable of controlling the position of the first-direction end of the at least one second actuation spring. The spring controller allows the actuation springs at their least compressed state and the engine valve closed when engine power is off. The spring controller may also be adjusted, with a low or moderate control fluid pressure, to allow the engine valve to operate with a partial lift.

Owner:LGD TECH LLC

Hydraulic railhead track jack and use method thereof

The invention discloses a hydraulic railhead track jack and a use method thereof. The hydraulic railhead track jack comprises an oil tank and a base; the oil tank is arranged at the top of the base; alifting handle is connected to the oil tank; a manual oil return valve is also arranged on the base; a track lifting structure is arranged at the bottom of the base; the track lifting structure comprises a pair of track lifting hooks symmetrically arranged; hook heads of the two track lifting hooks are also oppositely arranged; rotating shafts are arranged on the track lifting hooks; the interiors of the rotating shafts are in communication with the oil tank; the track lifting hooks are connected to the bottom of the base through rotating shafts so that the track lifting hooks turn over to the external sides for 90 degrees to rotate around the rotating shafts; a hydraulic oil cylinder is connected to each track lifting hook; the two hydraulic oil cylinders are also symmetrically arranged;and rotatable feet are connected to piston ends of the hydraulic oil cylinders. The hydraulic railhead track jack can be applicable to but not limited to the track lifting operations of broad-gauge sleeper slabs under a situation of a small space.

Owner:上海瑞纽机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com