Hydraulic drive engine air distributing mechanism

A valve train, engine technology, applied in the direction of engine components, machines/engines, non-mechanically actuated valves, etc., which can solve the inability to control the duration of the opening, it is difficult to achieve the best match of the engine, and the valves cannot be controlled at the same time. Problems such as the duration of the lift valve opening to achieve the effect of soft opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

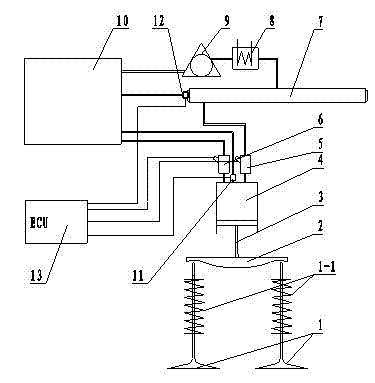

[0013] Referring to the drawings, the present invention includes a drive assembly, an actuator assembly, a hydraulic oil circuit, an oil storage tank 10 and a control system, the drive assembly is connected in the hydraulic oil circuit, and the hydraulic oil circuit is communicated with the oil storage tank 10, and the The actuator assembly includes a valve bridge 2, two valves 1 and a valve return spring 1-1. The upper end face of the valve bridge 2 is fitted with the drive assembly, and the lower end face is connected with the two valves 1. The valve return spring 1- 1 Set on the outside of the valve stem.

[0014] Referring to the drawings, the drive assembly of the present invention includes a high-pressure oil pump 9, a cooler 8, a high-pressure oil pipe 7 and a hydraulic cylinder 4. The inlet of the high-pressure oil pump 9 is connected to the oil storage tank 10, and the outlet of the high-pressure oil pump 9 is connected to the cooler 8. The cooling The outlet of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com