Variable valve apparatus

a valve apparatus and variable valve technology, applied in mechanical equipment, valve arrangements, machines/engines, etc., can solve the problems of requiring a certain amount of time for switching from the double valve variable control to the single valve variable control, and no consideration is made in terms of shortening the switching operation time, etc., to achieve the operation time of controlling the variably controlled other valves, small lift, and small operating angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[Configuration of a Variable Valve Apparatus]

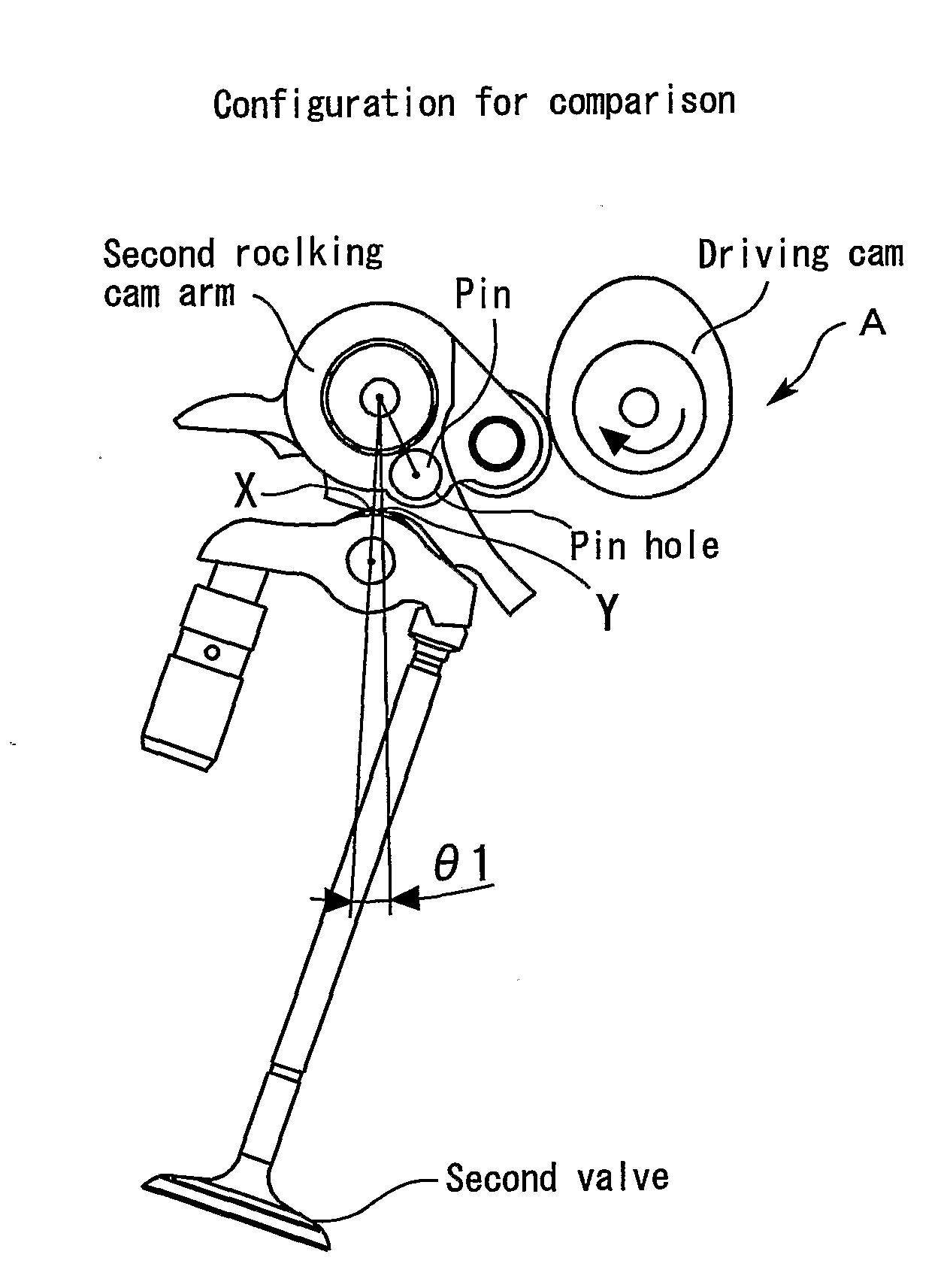

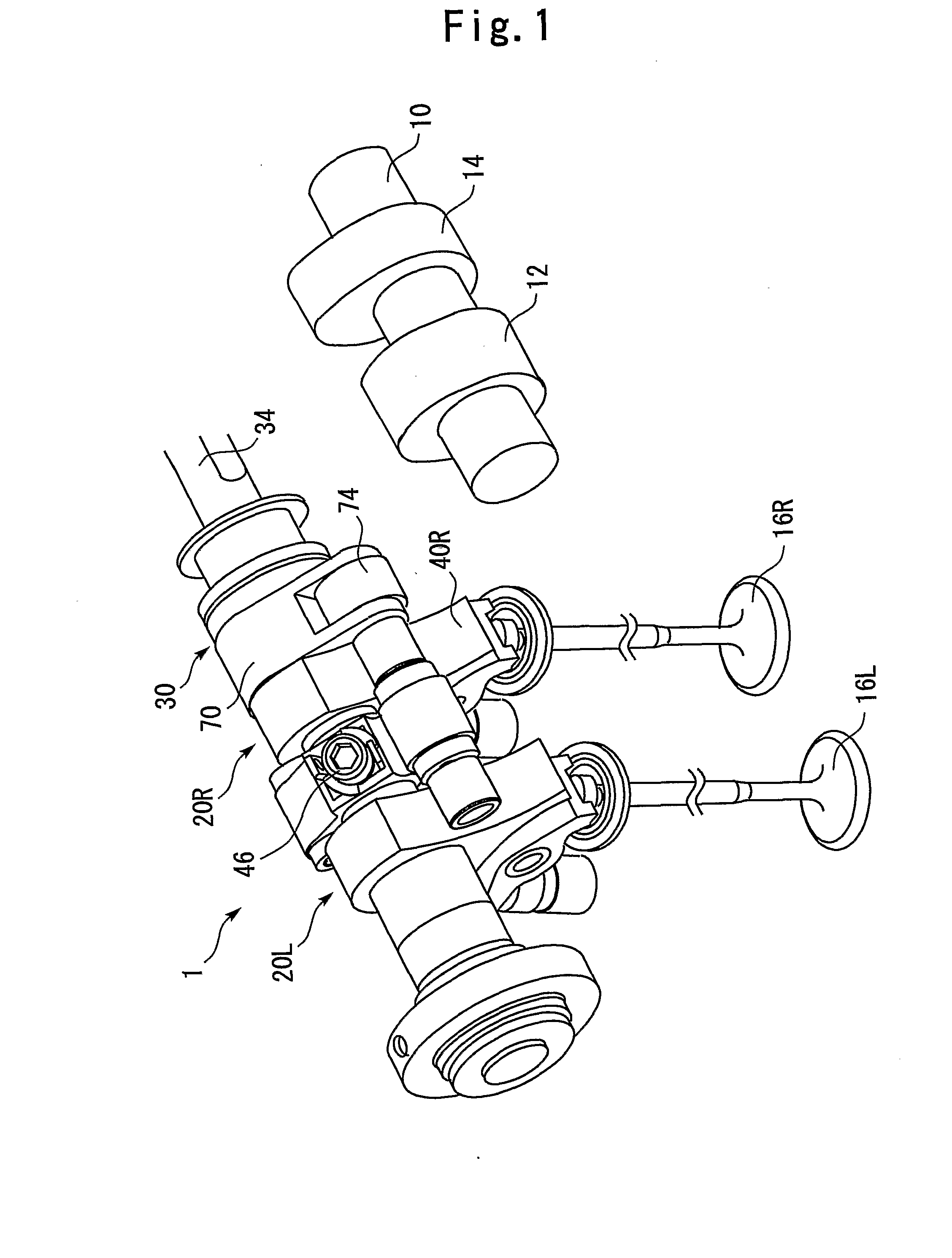

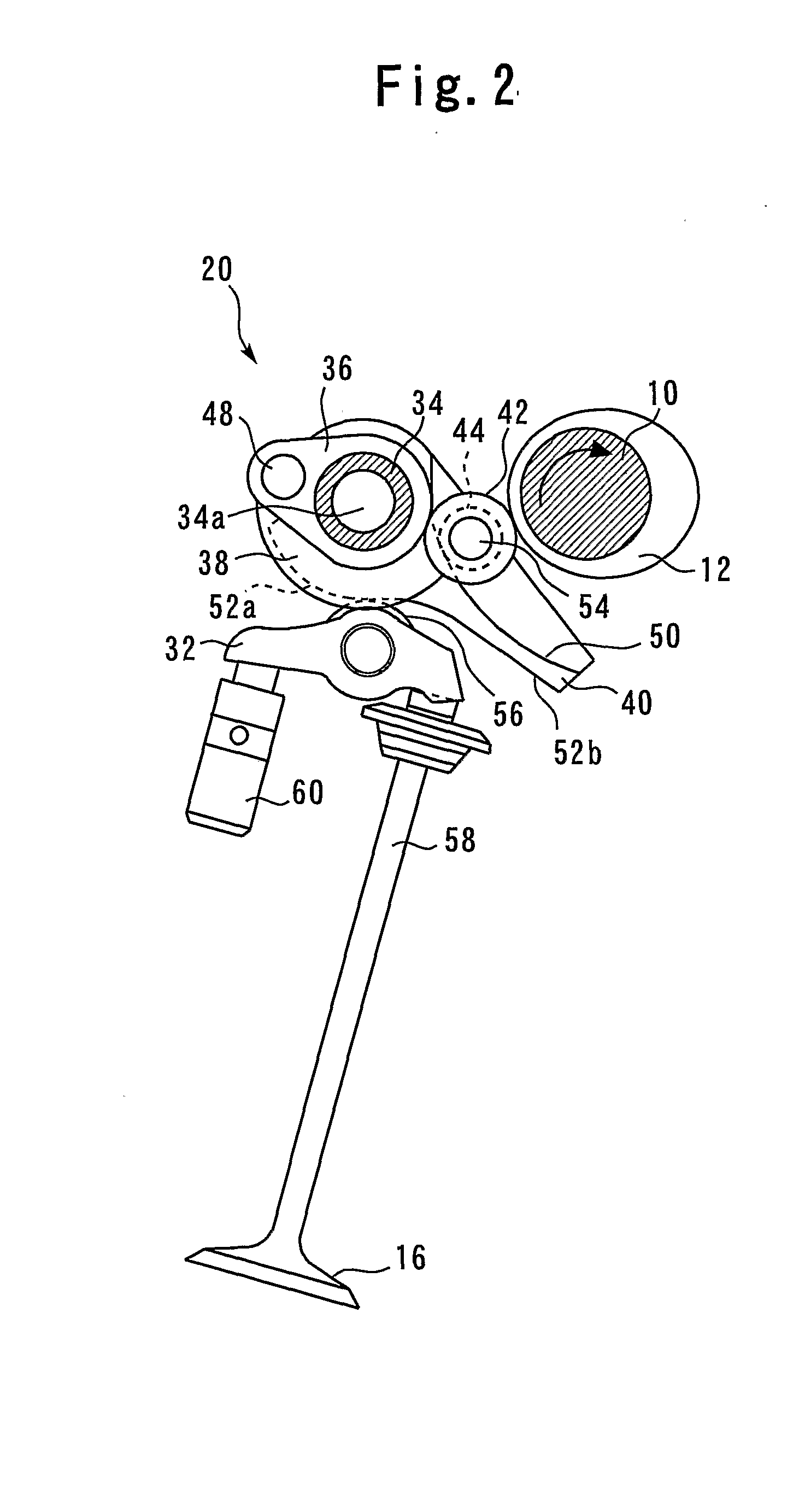

[0046]FIG. 1 is a view for illustrating a mechanism interposed between a driving cam and a valve in a variable valve apparatus 1 according to a first embodiment of the present invention. It is assumed herein that each of the cylinders of the internal combustion engine has two intake valves and two exhaust valves. The arrangement shown in FIG. 1 functions as a mechanism for driving two intake valves or two exhaust valves disposed in a single cylinder.

[0047]Referring to FIG. 1, a camshaft 10 of the variable valve apparatus 1 is provided with two driving cams 12, 14 per cylinder. Two valves—a first valve 16L and a second valve 16R—are symmetrically disposed with respect to one of the two driving cams (a first driving cam) 12. Each of variable valve mechanism 20L, 20R is disposed between the first driving cam 12 and each of the valves 16L, 16R. The variable valve mechanism 20L, 20R operatively couple a lifting movement of each of the valves 1...

second embodiment

[0083]A second embodiment of the present invention will be described below with reference to FIGS. 5 through 8.

[0084]FIG. 5 is a view for illustrating the arrangement of a variable valve apparatus 90 according to the second embodiment of the present invention. The variable valve apparatus 90 according to the second embodiment of the present invention has the same arrangements as those of the variable valve apparatus 1 according to the first embodiment of the present invention, except for the arrangement of a camshaft 92. Specifically, in the variable valve apparatus 90, too, the position of a pin hole 80 is set so that the pin switching operation can be executed when a second rocking cam arm 40R is in a posture for achieving an operating angle for the operating range required for the switching operation (pin switching operation) from the double valve variable control to the single valve variable control.

[0085]Referring to FIG. 5, the variable valve apparatus 90 has the same arrangem...

third embodiment

[0089]A third embodiment of the present invention will be described below with reference to FIGS. 9 through 11(A) and 11(B).

[0090]A variable valve apparatus 110 according to the third embodiment of the present invention has the same arrangements as those of the variable valve apparatus 1 according to the first embodiment of the present invention, except for the following two points. Specifically, the posture is different of a second rocking cam arm 40R when the switching operation (pin switching operation) from the double valve variable control to the single valve variable control is performed. Further, a second driving cam 114 differs in height from a first driving cam 112.

[0091]FIG. 9 shows a torque curve diagram for illustrating the operating range, in which the single valve variable control is executed, in the variable valve apparatus 110 according to the third embodiment of the present invention. Referring to FIG. 9, the double valve variable control, in which both valves are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com