Fork comb type automobile handling device

A car carrier and fork-comb type technology, which is applied in the field of parking equipment, can solve the problems of complex structure, affecting efficiency, and large thickness of the carrier structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below in conjunction with the above-mentioned drawings.

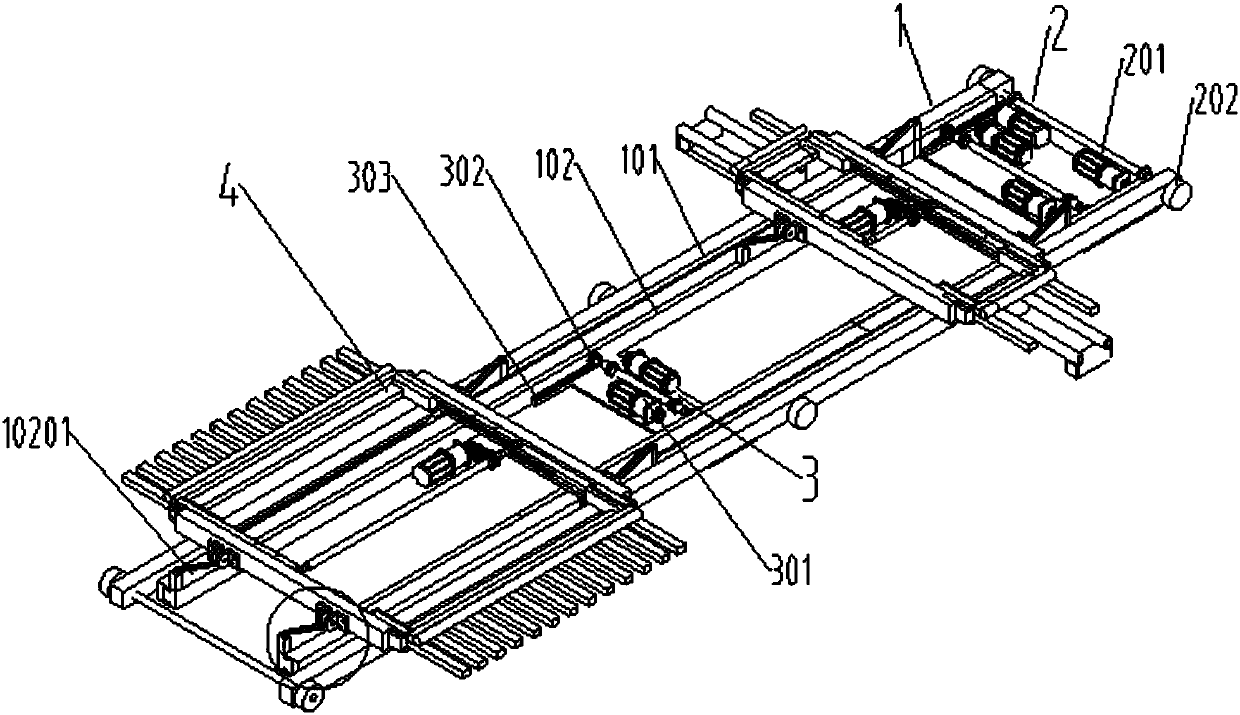

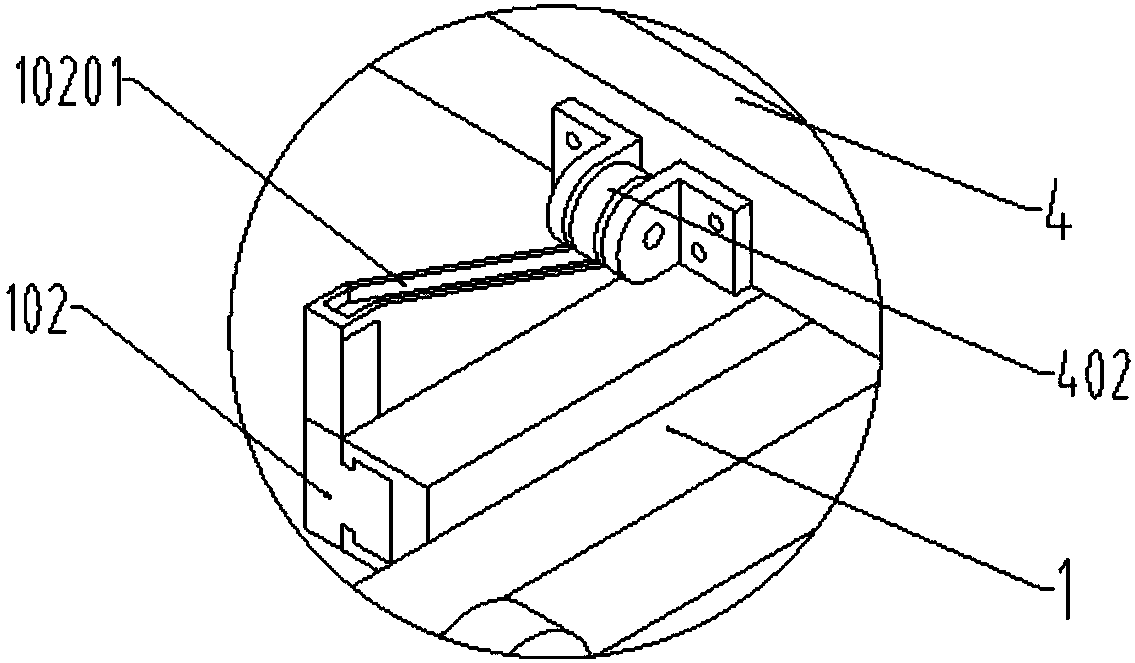

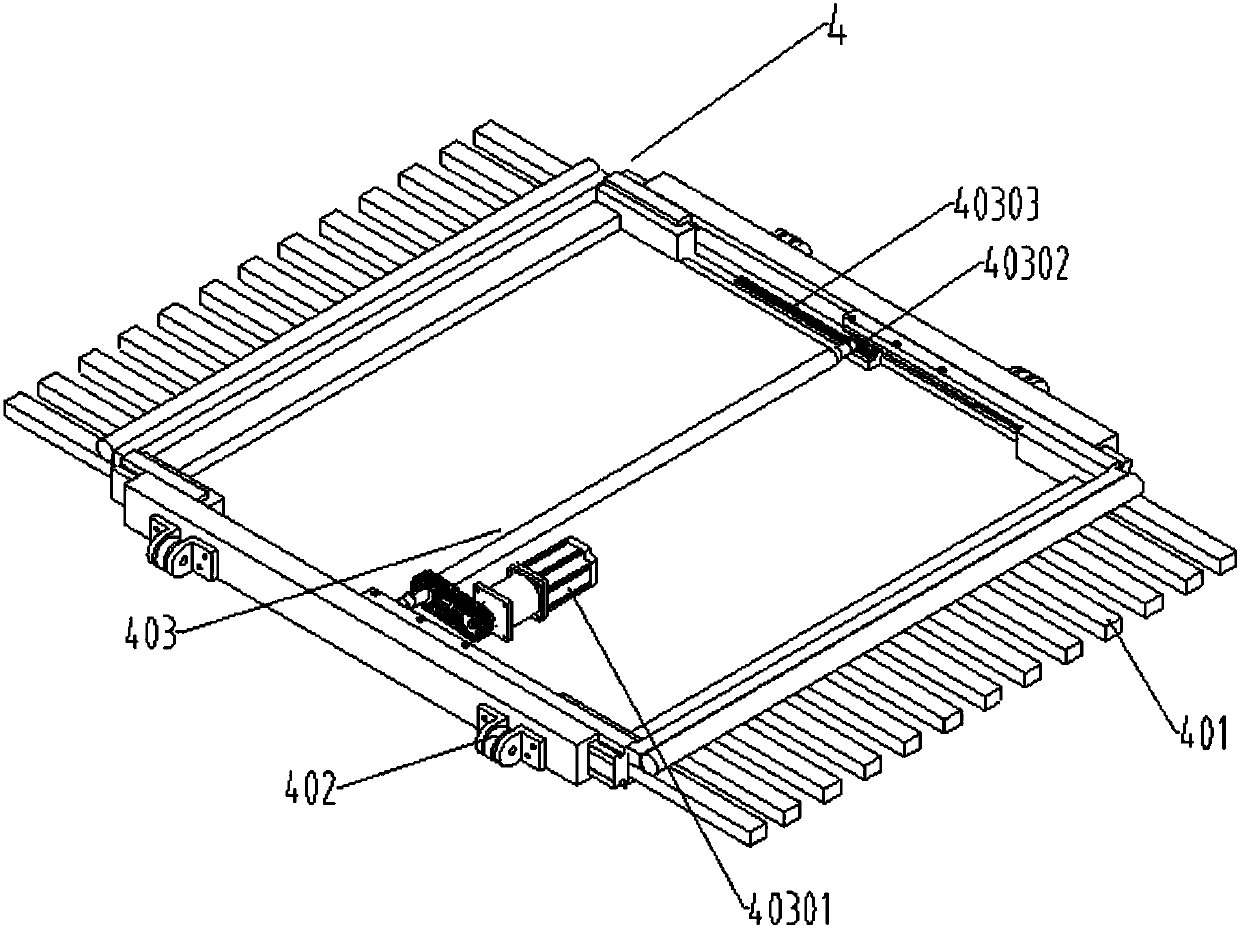

[0022] Such as Figure 1 to Figure 4 As shown, the fork-comb type vehicle carrier of the present invention supports the underframe 1 by a group of road wheels 202, and the underframe 1 is driven to move horizontally by the running mechanism 2. The underframe 1 includes a fixed frame 101 and a movable frame 102, and the fixed frame 101 A lifting mechanism 3 is arranged between the moving frame 102, and a lifting frame 4 is installed on the moving frame 102. The lifting mechanism 3 drives the moving frame 102 to move relative to the fixed frame 101, and drives the lifting frame 4 to rise to lift the car off the ground. Then the traveling mechanism 2 drives the underframe 1 to realize the horizontal transmission of the automobile. The above-mentioned traveling mechanism 2 has been disclosed in the prior art, and is only briefly described here.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com