Mobile rocker arm shaft type variable valve timing mechanism

A valve timing and rocker shaft technology, applied in combustion engines, engine control, engine components, etc., can solve the problems of increased manufacturing costs, complex and bulky variable valve drive mechanisms and control mechanisms, etc., to improve power performance, improve Fuel economy and emissions performance, the effect of reducing pumping losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

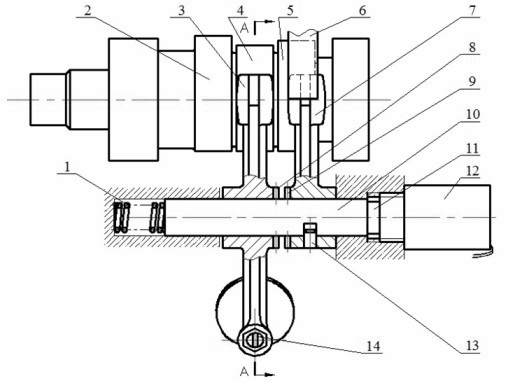

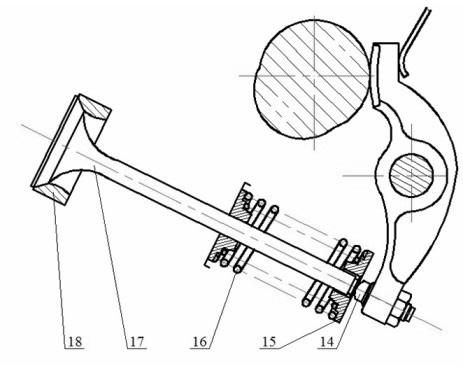

[0018] exist figure 1 and figure 2 The interrelationships among the components are as follows: the low-speed intake cam 4 drives the low-speed rocker arm 3, the high-speed intake cam 5 drives the high-speed rocker arm 7, and the leaf spring 6 exerts a certain elastic force on the high-speed rocker arm 7, so that the high-speed rocker arm 7 is always in contact with the high-speed intake cam 5; the low-speed rocker arm 3 and the high-speed rocker arm 7 can swing around the intake rocker shaft 10 driven by their respective cams, and the high-speed rocker arm 7 is on the shaft of the intake rocker shaft 10 The direction position is determined by the axial positioning pin 13; the electromagnet 12 is the rocker shaft driving mechanism, and the electromagnetic force generated by it pushes the armature 11 to drive the intake rocker shaft 10 to move to the left; the return spring 1 is in a compressed state; the low-speed rocker The axial position of 3 is fixed, its upper end is in c...

Embodiment 2

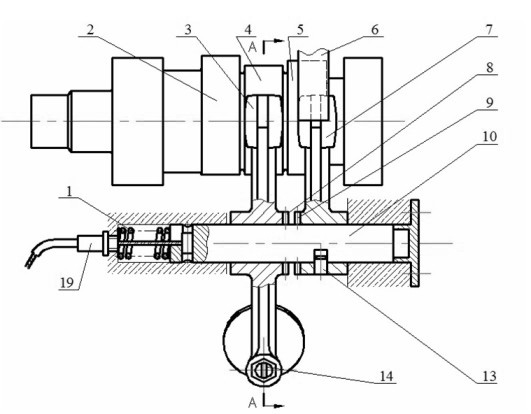

[0024] exist image 3 Among them, the tension cable system 19 is a rocker shaft drive mechanism. By manually applying a certain force, the ropes in the rope system 19 are in a tensioned state, and the rope system 19 tightens the rocker shaft 10 and drives the high-speed rocker 7 to move to the left, so that the low-speed rocker 3 and the high-speed rocker 7 are combined. , the working cam is switched to the high-speed intake cam 5. When the rope system 19 was in a loose state, the return spring 1 made the rocker shaft 10 drive the high-speed rocker 7 to move to the right, the low-speed rocker 3 and the high-speed rocker 7 were separated, and the working cam was switched to the low-speed intake cam 4. This enables variable intake valve timing.

[0025] exist figure 1 Among them, the low-speed rocker arm 3 and the high-speed rocker arm 7 are connected together through their end face coupling teeth 8 and 9; the low-speed rocker arm and the high-speed rocker arm can also h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com