Valve device and high pressure pump using the same

A technology of valve device and valve seat, which is applied in the direction of valve device, valve operation/release device, parts of pumping device for elastic fluid, etc., can solve the problem that it is difficult to fully suppress the automatic closing of valve components, and achieve Miniaturization and the effect of reducing the maximum output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

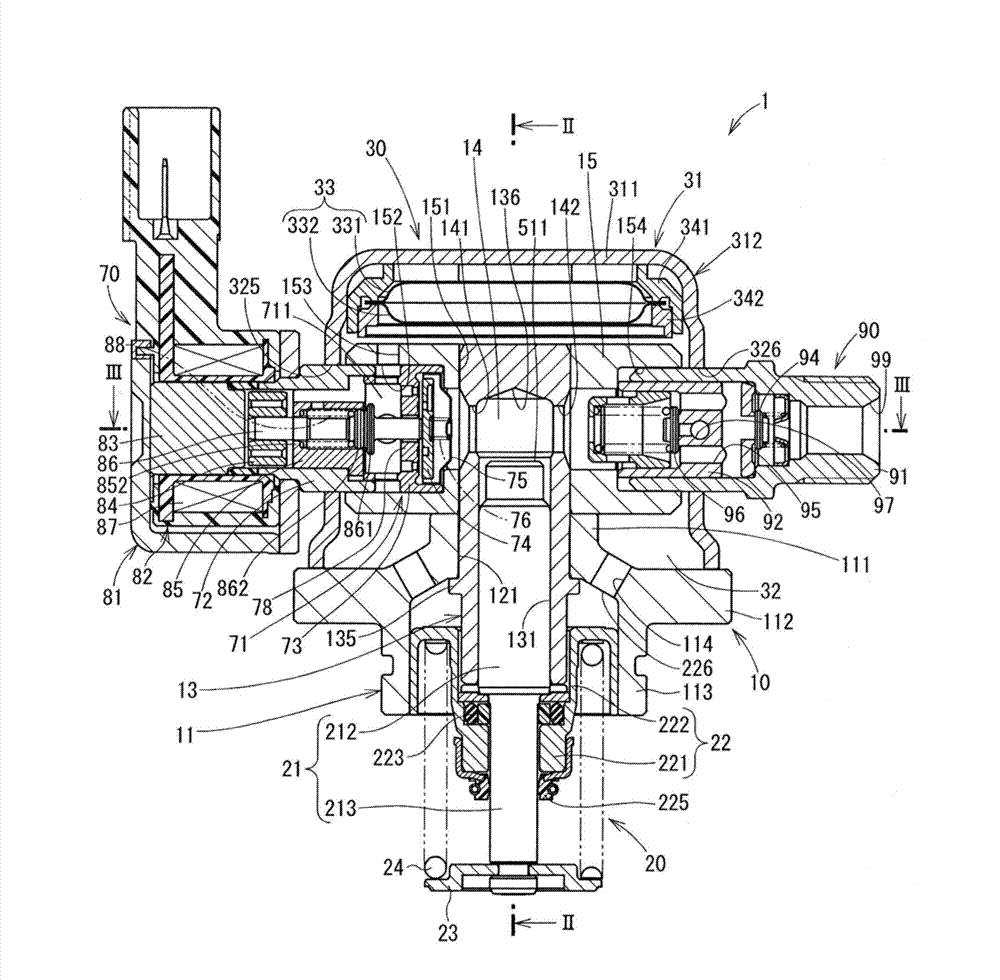

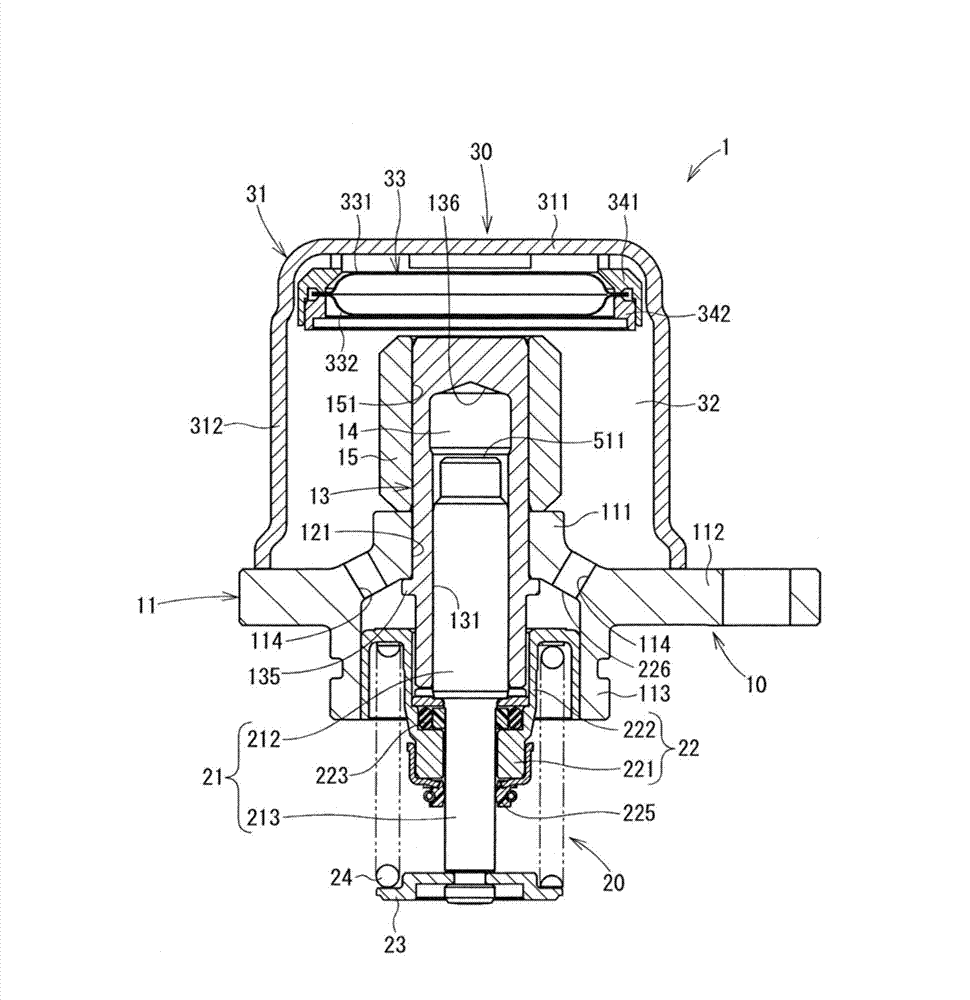

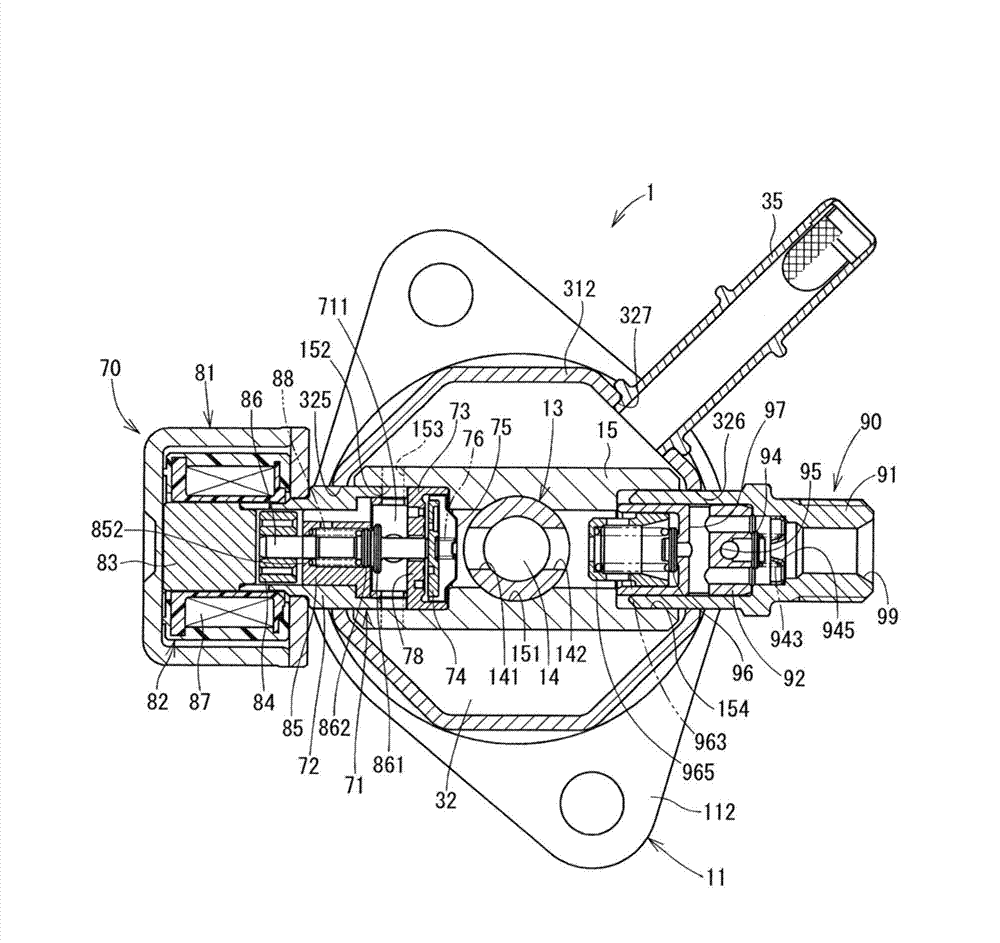

[0082] The high pressure pump of the first embodiment of the present invention is shown in Figures 1 to 3 middle. The high-pressure pump 1 is a fuel pump that compresses fuel supplied from a fuel tank not shown and discharges the pressurized fuel into a fuel rail. The high-pressure pump 1 is provided with a main body portion 10 , a fuel supply portion 30 , a plunger portion 20 , a fuel suction portion 70 and a fuel discharge release portion 90 . The fuel intake portion 70 corresponds to "valve device" in the following description, figure 1 The upper side of will be taken as "on", "up" or "above", and figure 1 The lower side of will be read as "below", "down" or "under".

[0083] The main body portion 10 includes a lower case 11 , a cylinder 13 and an upper case 15 . The lower housing 11 has a cylindrical cylinder holding portion 111 , an annular flange portion 112 protruding radially outward from a lower portion of the cylinder holding portion 111 , and a cylindrical engi...

no. 2 example

[0135] The following will refer to Figure 9 The suction valve portion of the second embodiment will be described. The first pressure equalization groove 421 and the second pressure equalization groove 422 of the suction valve portion 41 are formed to the suction valve member 42 . Therefore, since the weight of the suction valve member 42 becomes lighter, the attractive force of the electromagnetic drive unit can become smaller. Therefore, miniaturization of the electromagnetic drive unit is achieved. The processing cost of the second suction valve main body 43 can be reduced.

no. 3 example

[0137] The following will refer to Figure 10 The suction valve portion of the third embodiment of the present invention will be described. The radially inner wall of the first convex portion 451 of the suction valve member 45 of the suction valve portion 44 is closer to the first passage 743 toward the valve seat 78 . Therefore, fuel from the pressure chamber toward the first convex portion 451 is introduced radially inward along the radially inner wall of the first convex portion 451 . Therefore, at the time of metering, the fuel from the pressure chamber toward the suction valve member 45 can be smoothly guided to the first passage 743 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com