Two-valve stroke synchronously-variable device

A valve lift, variable technology, used in valve devices, engine components, machines/engines, etc., can solve problems such as liquid leakage, delayed response to valve lift changes, and high sealing requirements, achieving fast response speed. , Simple structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

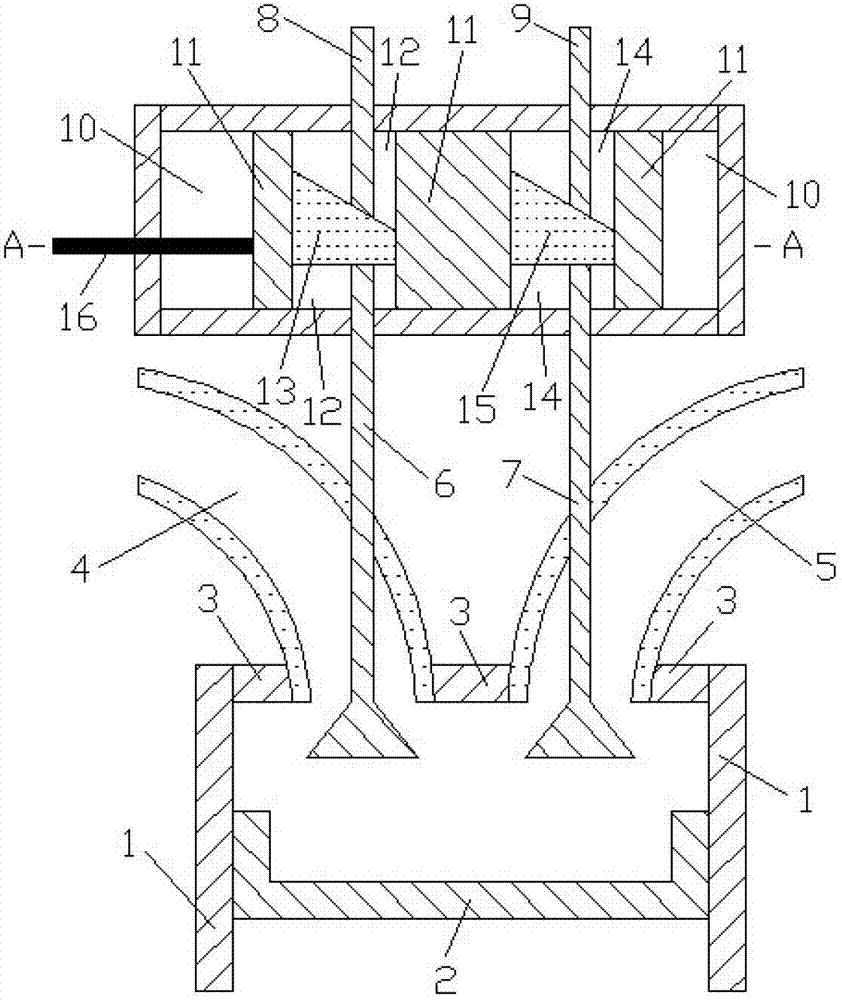

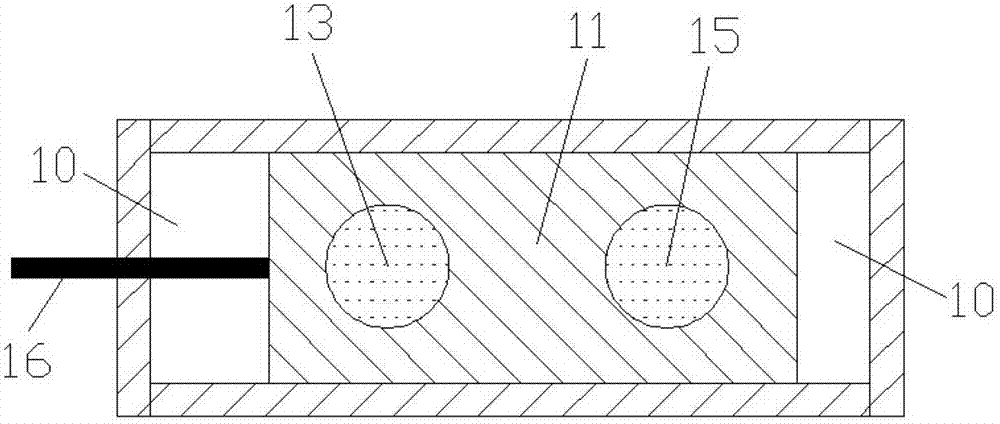

[0014] like figure 1 and figure 2 As shown, the present invention includes: comprising cylinder 1, piston 2, cylinder head 3, intake passage 4, exhaust passage 5, intake valve lower section 6, exhaust valve lower section 7, intake valve upper section 8, exhaust valve upper section 9. Volume cavity 10, moving body 11, first through pipe 12, first moving block 13, second through pipe 14, second moving block 15 and moving rod 16, piston 2 is installed in the space surrounded by cylinder 1 And in sealing contact with the inner wall of the cylinder 1, the intake port 4 and the exhaust port 5 are connected to the cylinder head, the moving body 11 is installed in the volume chamber 10 and is in sealing contact with the inner wall of the volume chamber 10, the first through pipe 12. The second through pipe 14 runs through the upper and lower walls of the moving body 11. The first moving block 13 is installed in the first through pipe 12 and is in sealing contact with the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com